Professional Documents

Culture Documents

07 Hungary Interior VINNAPAS VAE Dispersions 2018e Kotschi

07 Hungary Interior VINNAPAS VAE Dispersions 2018e Kotschi

Uploaded by

Coco HüniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 Hungary Interior VINNAPAS VAE Dispersions 2018e Kotschi

07 Hungary Interior VINNAPAS VAE Dispersions 2018e Kotschi

Uploaded by

Coco HüniCopyright:

Available Formats

CREATING TOMORROW`S SOLUTIONS

VINNAPAS® VAE technology for environmentally-friendly

deco paints and coatings

Dr. Udo Kotschi, WACKER POLYMERS, March 2018

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 0 of 61

Raw materials and production process

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 1 of 61

Recipe components – overview

Water

(Main) monomers

(vinyl acetate, ethylene, vinyl chloride, acrylics, vinyl esters etc.)

Functional monomers

Stabilizers

Initiator system

pH adjust (buffer)

Defoamer

Biocide

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 2 of 61

Polymer structure of VAE

Vinyl acetate (VAM) Ethylene

Basic raw material Tg ~ - 100 °C (soft)

Hydrophobic

Polar, hydrophilic

Permanent flexibility

Tg ~ 28 °C (hard)

High hydrolysis resistance

Toughness

Ideal co-polymerization with VAM

Copolymer structure

O O O O

O O O O

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 3 of 61

The higher the ethylene contents, the lower the Tg

Tg of copolymers depends on polymer composition (Fox equation)

Tg, [C º]

30

1 x(monomer A) x(monomer B)

= +

20 Tg(copolymer) Tg( polymer A) Tg( polymer B)

1 0.88 0.12

10 Tg (copolymer) 301.15 K 173.15 K

-10

-20

0 5 10 15 20 25

Ethylene fraction [wt %]

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 4 of 61

Reactivity ratio comparison

r1 r2

Vinyl acetate – ethylene 1,03 0,88

Vinyl acetate – vinyl chloride 0,25 1,64

Vinyl acetate – butyl acrylate 0,018 3,48

Vinyl acetate – methyl methacrylate 0,03 26

Vinyl acetate – styrene 0,01 56

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 5 of 61

VAE dispersion technology –

comparing copolymers of VAc/E with VAc/BA

Besides the better plasticization with ethylene, VAE polymers provide in addition

a better consistency of the polymer

Ideal co-polymerization of vinyl acetate and ethylene

Vac/E polymers form a more random distribution in polymer chains and less

“blocks” of homopolymer chains like in VAc/BA polymers

Equal reactivity - VAc-E-VAc-E-VAc-E-VAc-E-VAc-E-VAc-E-VAc-

Unequal reactivity - VAc-VAc-VAc-VAc-VAc-BA-BA-BA-BA-BA

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 6 of 61

Functioning of surfactants / emulsifiers

- - - - --

- -

- -

-

-

- - - - - --

- - -

- -

- - Polymer particle

- -

- -

- - - - - -

-

-

-

-

- - - -

- - - - --

Surfactant

- -

- -

- -

- Hydrophobic Hydrophilic,

-

- chain anionic or

-

- cationic group

-

- - - -

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 7 of 61

Functioning of protective colloids

Polymer particle

Steric

hindrance

Protective colloid

Hydrophobic Hydrophilic

C-chains polar

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 8 of 61

Polymer stabilization and protection systems

Purpose of protection

Protect polymer particles during polymerisation

Protect polymer particles during transportation

Viscosity control

Control of properties (chemical compatibility, water resistance, etc.)

Type of protection systems

Protective colloids: Chemically graft to polymer particles

PVOH (PVA): most popular for adhesives

Cellulose

Surfactants: anchor to polymer particles

Protective colloids and surfactants: very popular for coatings VAE

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 9 of 61

Emulsion polymerization –

process overview

The process and apparatus used depend on the kind of monomers

Ethylene → gas

Open vessel does not work → Autoclave

Apparatus is under ethylene pressure

Vinyl acetate / ethylene dispersions (VAEs) are sometimes also called

“pressure polymers”

Result: dispersion of polymer VAE particles in water

Removal of the residual monomers and other volatile ingredients by

different chemical and/or physical measures

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 10 of 61

The production of vinyl acetate ethylene dispersions must be

done under pressure

Dispersions with ethylene; high demands on equipment

Ethylene Vinyl acetate, Silo

(max. 100 bar) water, initiator, additives

Reduction

of pressure

Ethylene

(10 - 20 bar)

Filter

Polymerization

Filter

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 11 of 61

VINNAPAS® VAE dispersion – preferred technology for

environmentally-friendly paints in Europe

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 12 of 61

Glass transition temperature (Tg)

SodaInfluence of vinylic co-monomers on glass transition temperature of

vinyl acetate copolymers

Ethylene is the ideal internal softener for vinyl acetate polymer dispersions!

°C

40

30

20

10

0 %-comonomer

0 10 20 30 40 50 60

-10

-20

-30

VAc/ E VAc/ VeoVa10 VAc/ VL VAc/ EHA Vac / BA

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 13 of 61

Minimum film forming temperature (MFFT)

The process of film formation only occurs over a defined temperature.

This temperature is called “minimum film forming temperature”

Above this temperature, the dispersion builds a homogeneous, crack-free film

The MFFT depends on

Tg of the polymer

Polymer type

Coalescing agents

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 14 of 61

MFFT ≠ Tg

A property of the dispersion A property of the dispersion

(liquid) film (dry)

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 15 of 61

Minimum film forming temperature (MFFT) –

VAE in comparison to SA

VAE forms film at low temperatures w/o coalescent:

SA

SA + 2% texanol

SA + 4% texanol

VAE

0 °C 12 °C 20 °C

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 16 of 61

Minimum film forming temperature (MFFT) –

paints based on VAE in comparison to SA

VAE forms film at low temperatures w/o coalescent:

A

SA

B SA + 2% texanol

C SA + 4% texanol

VAE

0 °C 12 °C 20 °C

A B C

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 17 of 61

VINNAPAS® VAE dispersions have outstanding coalescing

properties

Tg / MFFT correlation

30

MFFT [°C]

25

20

15

10

0

0 2 6 9 16 20 24 31

-5

Tg [°C]

SA VAE

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 18 of 61

VAE dispersions versus styrene acrylics –

conclusions

In VAE, water functions as a coalescing aid (hydroplastification!)

High scrub resistance

No additional coalescing agent

No migration (no fogging)

Film formation at low temperatures (< 5 °C)

VAE – the best option for modern low VOC paints

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 19 of 61

ECO labels or legislation in place and their impact on

coatings industry

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 20 of 61

The many shades of ‘Green’ in the European & US coatings

market

Europe

VdL

1978 1989 1991 1992 1996 1998 1999 2006 2007 2008 2010

USA

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 21 of 61

Why are solvents & VOC a concern?

A combination of

UV coming from sun activity

NOx produced by combustion

Solvents from various chemicals

… leads to formation of summer smog

UV (ozone building up in troposphere)

NOx VOC

Ozone very harmful to humans

E.g. allergy, asthma, heart attacks and

other cardio-pulmonary issues

There are programs to decrease amount

Photo- Ground of solvent in deco paints initiated long

Summer

chemical level

smog time ago across the world

activity ozone

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 22 of 61

Indoor air quality: not neutral for human health

Most important sources of organic

indoor pollutants

Outdoor environment

Human activities

Materials equipments (adhesives, caulks,

floor covering, sealants, furniture, paints,

wall covering, particle board, ….)

Indoor smoke containing many

dangerous pollutants produced by

heating / cooking / cleaning activities

High & efficient insulation system

prevents from good aeration / ventilation

leading to accumulation of these

pollutants in the house

Most heaviest pollutants accumulate on

surfaces due to migration of solvent &

plasticizer, creating “fogging” effect

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 23 of 61

VINNAPAS® VAE technology for low VOC emission paints

definition of VOC in water borne coatings

Emissions:

DIN EN ISO 16000 (chamber test)

ASTM D-5116

Volatile andCompounds

Organic ASTM D-6670

Liquid paint:

ISO 11890-2 (GC-Direct Injection)

ISO 17895 (In-Can VOC)

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 24 of 61

Concerns about in-can-VOC in Europe

EU deco paint directive:

< 30 g/l (approx. 21000 ppm)

ISO 11890-2:

“mandatory but not labeling”

< 1 g/l (approx. 700 ppm)

DIN EN ISO 17895

VdL

< 15 g/l (approx. 11000 ppm)

ISO 11890-2

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 25 of 61

VINNAPAS® VAE technology for indoor paints –

VOC after ISO 11890-2 (GC – direct injection)

VINNAPAS® EP 3360 SA Comp. 1 SA Comp. 2

VINNAPAS® EP 3360 shows less impurities.

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 26 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

definition of VOC in water-borne coatings

Definition after DIN EN ISO 16000-6 (for emissions):

SVOC – semi-volatile organic compound:

Organic compound whose boiling point is in the range from

(240 °C to 260 °C) to (380 °C to 400 °C)

VOC – volatile organic compound:

Organic compound whose boiling point is in the range from

(50 °C to 100 °C) to (240 °C to 260 °C)

VVOC – very volatile organic compound:

Organic compound whose boiling point is in the range from

< 0 °C to (50 °C to 100 °C)

TVOC – total volatile organic compound:

The sum of volatile organic compounds, which elute on TENAX TA between

and including n-hexane (C6H14; 69 °C) and n-hexadecane (C16H34; 287 °C)

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 27 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

concerns about VOC emissions in Europe

Optional labels:

Requirements for low emission

construction products:

CH2O < 50 µg/m3 (24 h)

123

TVOC < 300 µg/m3 (72 h)

1 3 7

TSVOC < 100 µg/m3 (72 h)

4

2 Worldwide 145 low emission

construction products in the market

(2014*)

Additionally: USA: 1 Jordan: 4

* Information courtesy of TÜV SÜD Industrie Service GmbH

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 28 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

concerns about VOC emissions in Europe

Mandatory label

Decree 2011-321

NOR: DEVL1104875A

Country: France

Applies to: construction, decoration

and furnishing products

Since 01.09.2013

Guideline

DIN EN ISO 16000

Similar to AgBB and DIBt

Evaluation after 28 days

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 29 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

concerns about VOC emissions in Europe

Mandatory label

Decree 2011-321, NOR: DEVL1104875A, classification criteria [µg/m3]

C B A A+

Formaldehyde > 120 < 120 < 60 < 10

Acetaldehyde > 400 < 400 < 300 < 200

Toluene > 600 < 600 < 450 < 300

Tetrachrloroethylene > 500 < 500 < 350 < 250

Xylene > 400 < 400 < 300 < 200

1,2,4-Trimethylbenzene > 2000 < 2000 < 1500 < 1000

1,4-Dichlorobenzene > 120 < 120 < 90 < 60

Ethylbenzene > 1500 < 1500 < 1000 < 750

2-Butoxyethanol > 2000 < 2000 < 1500 < 1000

Styrene > 500 < 500 < 350 < 250

TVOC > 2000 < 2000 < 1500 <1000

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 30 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

results of VOC emissions in paints

PVC 45% PVC 75%

Recipe: LA007MM

Water 264 320 Dispersions:

Tylose MH 30000 YP2 4 4

Standard VAE

Calgon N, (10%) 10 10 (MFFT = 2 °C; Tg = 10 °C)

Lopon 890 4 4

Agitan 295

Standard SA

1 1

Kronos 2310

(MFFT = 20 °C; Tg = 22 °C)

171 171

Durcal 2

Coalescent: Texanol

31 58

Omyacarb 15 GU 90 162

Dorkafill 600 59 103

Agitan 295 1 1

Dispersion (50%) 302 121

Coapur XS 71 4 3

Water 59 42

1000 1000

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 31 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

results of VOC emissions in paints

Verification of results with TÜV SÜD:

Satin paint LA007MM (basis standard SA)

Satin paint LA007MM (basis standard VAE)

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 32 of 61

VINNAPAS® VAE technology for low-VOC emission paints –

summary

Binders based on VAE technology are

an assertive option to

formulate low-VOC emission paints,

complying with strict requirements of

existing eco-label and legislations in

the European modern paint industry

without losing performance.

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 33 of 61

Today labels / regulations are not only focused on solvent

content …

()

APEOs

Formaldehyde Renewables

()

VOC TiO2

Fitness for use Heavy metals

Solvents criteria:

e.g. spreading

rate, abrasion,

water resistance, White pigments

Plasticizers adhesion,

weathering, …

Conalescing Dangerous substances

agents

Note*:

Anti-freeze additives Biocides VOC = volatile organic compound

VAH = volatile aromatic hydrocarbon

()

VAH APEO = alkyl phenol ethoxylate

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 34 of 61

Mega trend sustainable development –

topics for decorative coatings

Rising crude oil prices /

energy prices

Raw material availability

VOC reduction / co-solvents

Low formaldehyde

APEO absence

Low energy consumption

Low carbon footprint

Higher efficiency (less binder)

Longer lifetimes

Eco-friendly packaging

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 35 of 61

Niche, trends and megatrends ….?

… can be global

… can be local

Germany:

Paints based on renewable raw materials

Biocide-free paints

Hungary:

VOC- and plasticizer-free?

VOC-emission-free?

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 36 of 61

What’s renewable?

Renewable raw materials were recognized in the ECO label (Switzerland)

Paints of the category A have to contain more than 95% of renewable raw materials

respectively mineral raw materials (all inorganic raw materials of minerals or rocks,

which exists in the nature or which are produced by them) and water, which are

available unlimited. Hydrocarbons are not integrated to mineral raw materials.

Limitation of binder (not more than 10% of a 50% dispersion)

“FARBE, AUSBAU & FASSADE 2016” in Munich

Presentation of the CapaGeo-paint line

The binder is produced by 100% of renewable raw materials (mass balance

approach)

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 37 of 61

Mass balance approach

Bio acetic acid Conventional ethylene Bio VAE via certification

Conventional acetic acid VAM plant VAE plant Conventional VAE

Conventional

No separation

of acetic acid by origin possible!

Acetic Acid

Biomass input = renewable VAE output via certification

VAM Plant

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 38 of 61

Interior paints for allergy sufferers (CIT, MIT, BIT …)

„Biocide-free“ interior paints*

1. Dispersion paints with high pH (approx. < 11.5)

Emulsion paint + approx. 2% waterglas (Patent: EP 1 297 079)

Emulsion paint + approx. 2% potassium methyl siliconate (Patent: DE 10 2014 013 455

and DE 2016 002 221 respectively WO 2017144694

Biocide free (criteria of the Blue Angel): < 2 ppm BIT, < 2 ppm MIT, < 0.5 ppm CIT

2. Dispersion modified silicate paints

… some more solutions:

3. 2K-systems: normal interior paints + additive to destroy the biocide

4. Powder dispersion paints

* Due to that the dispersion itsself is not biocide-free, the dispersion modified silicate paint as well as the dispersion paint with high pH contains a small amount of biocide(s).

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 39 of 61

VINNAPAS® VAE dispersions for decorative paints

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 40 of 61

VINNAPAS® VAE technology for indoor paints and plasters –

overview

VINNAPAS® EP 3360 EF 3777 CEZ 3031 EZ 3019 EAF 380

Monomer base VAc/E VAc/E VAc/E/VC VAc/E/VeoVA VAc/E/A

Emulsifier

PVOH + ST ST CD + ST CD + ST ST

System

APEO-free Yes Yes Yes Yes Yes

MFFT +2 °C +1 °C +2 °C +2 °C 8 / 12

Preservation BIT/MIT BIT/MIT BIT/MIT BIT/MIT/CIT

Solids Content 60 ± 1 56 ± 1 50 ± 1 50 ± 1 51 ± 1

Viscosity 3000 - 6000 150 - 1850 6000 - 12000 2100 - 3900 600 - 1600

pH 4-6 3.5 - 5.5 4-5 4.5 - 5.5 7-9

Mat paints Mat paints

Application Universal Universal Latex paints

interior/exterior interior/exterior

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 41 of 61

Formulation latitude of VINNAPAS® VAE for interior coatings

Interior paint market

Undercritical CPVC Overcritical

High gloss Semi gloss Matt

PVC [%]

20 30 40 50 60 70 80

VINNAPAS® EP 3360

VINNAPAS® EF 3777

VINNAPAS® EZ 3019

VINNAPAS® CEZ 3031

VINNAPAS® EAF 380

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 42 of 61

VINNAPAS® EP 3360 – applications

All kinds of interior applications:

(with exception of silicate systems)

Solvent-free and plasticizer-free interior paints

Matt paints (wall and ceiling paints)

Glossy paints

Latex paints

Silicone paints

Matt and glossy full-shade paints

Multicolor paints (F&L March 2013)

Interior plasters

Scratched plasters

Plasters with a worm structure

Textured coatings

Primers

Fillers

Glue for glass, fabrics, and wallpapers

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 43 of 61

Formulation and film properties

Good compatibility with a wide range of raw materials

MFFT approx. 0 °C

Excellent film forming properties at low temperatures

Good film formation without the addition of coalescing agents

No solvents or plasticizers required

Very high binding power

High scrub resistance in matt paints (high PVC paints)

Good gloss / blocking behavior

Excellent thickener response

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 44 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

High scrub resistance Ingredient Parts

Tested in a matt paint according to Water x

RR 53 523 09 Dispex N 40 5

Natrosol plus 430 2

PVC = 45 - 85%

Rheolate 208 2

NaOH 10% 1

Addid 800 1

Kronos 2300 71

Mistron 754 G 71

Omyalite 90 142

Omyacarb 2 GU 261

Arbocel BE 600/30 PU 40

Parmetol DF 12 2

Dispersion x

Total 1,000

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 45 of 61

Equipment for the determination of scrub resistance

DIN 53 778 part 2 EN ISO 11 998

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 46 of 61

Equipment for the determination of scrub resistance

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 47 of 61

Equipment for the determination of scrub resistance OF SC

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 48 of 61

Equipment for the determination of scrub resistance

Source: Wacker Chemie AG

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 49 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

High scrub resistance

Scrub resistance of VINNAPAS® EP 3360, VINNAPAS® EF 3777 and

VINNAPAS® EZ 3010* as a function of the PVC (RR 53 523 09 test procedure)

250

Loss of Thickness [µm]

200

150

100

EZ 3010

50

EF 3777

0 EP 3360

30 40 50 60 70 80 90

PVC [%]

*New version available

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 50 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

Excellent film forming properties at low temperatures

Scrub resistance of VINNAPAS® EP 3360 as a function of the PVC and

temperature (RR 53 523 09 test procedure)

80

Loss of Thickness [µm]

70

60

50

40

30

20

23°C

10

0 +5°C

45 50 55 60 65 70 75 80 85

PVC [%]

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 51 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

VINNAPAS® EP 3360 Competitor SA

Emulsifier system: PVOH + ST Emulsifier system: ST

VINNAPAS® EP 3360 exhibits excellent hiding power.

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 52 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

Hiding power VINNAPAS® EP 3360 versus SA

99,7

Contrast ratio

99,6

99,5

99,4

99,3

99,2

99,1

99,0

98,9

6,0 6,5 7,0 7,5 8,0 8,5 9,0 9,5

Spreading rate [m2/liter]

Standard VAE Standard SA High performance SA EP 3888 ® EP 3360

VINNAPAS

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 53 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

High performance VAE dispersions like

VINNAPAS® EP 3360 have in high

PVC paints a much better hiding power

than styrene / acrylics at the same

scrub resistance!

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 54 of 61

Equipment for the determination of sheen respectively gloss

EN ISO 13 300

Mat < 10 units at 85°

Dead mat < 5 units at 85°

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 55 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

Low sheen in matt paints

Sheen (gloss 85) as a function of the PVC

Sheen (85)

4,5

4,0

3,5

3,0

2,5

2,0

1,5

30 40 50 60 70 80

PVC [%]

EP 3360

3888 EF 3777 EZ 3010*

Source: Wacker Chemie AG

* Newer version available

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 56 of 61

VINNAPAS® VAE dispersions –

key performance in paints / benchmarking

Excellent color strength

Excellent color stability, even in matt

interior paints After 6 weeks on the window

Competitor VINNAPAS®

binder EP 3360

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 57 of 61

VINNAPAS® EP 3360 shows advantage in wet adhesion on

glass plate substrate in comparison to styrene acrylic

Results after 1 day drying and water Results after 1 day drying and water

soak test soak test

60% PVC formulation 70% PVC formulation

7 days 30 min. 7 days 1 hour

VINNAPAS® Styrene VINNAPAS® Styrene

EP 3360 acrylic EP 3360 acrylic

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 58 of 61

VAEs offer advantage in touch-up

Touch-up refers to the ability of a paint VAE

to maintain uniform appearance and

sheen regardless of application Low

method or temperature at which a temp.

second coat of paint is applied over the

first coat

Ambient

temp.

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 59 of 61

VINNAPAS® EP 3360 – value in use

State of the art VAE regarding prize & performance

Performance features

High scrub resistance

Excellent thickener response

Excellent color stability

High hiding power

Low overall formulation costs

No coalescent agent demand

Environmentally friendliness

Low odor, low VOC, APEO-free

Complies with EU directives and ECO labels

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 60 of 61

Thank

THANKyou for your attention

YOU!!

Hungary, Dr. Udo Kotschi, March 2018

VINNAPAS® VAE technology for environmentally-friendly deco paints and coatings 61 of 61

You might also like

- List of Verbs, Nouns, Adjectives and Adverbs PDFDocument4 pagesList of Verbs, Nouns, Adjectives and Adverbs PDFKoteswaraRao Bandla74% (380)

- Where Is My Mind - Maxence CyrinDocument2 pagesWhere Is My Mind - Maxence Cyrinmasterhpotter89% (19)

- H.R. Ellis Davidson - Gods and Myths of Northern EuropeDocument251 pagesH.R. Ellis Davidson - Gods and Myths of Northern EuropeCarmen Currás100% (30)

- 07 ELEMENTIS Wood CoatingsDocument112 pages07 ELEMENTIS Wood CoatingsAmit MahajanNo ratings yet

- Oxazolidine Webinar 24th June 2015 DownloadDocument31 pagesOxazolidine Webinar 24th June 2015 DownloaddiablomatiNo ratings yet

- Finnfix 10000 CMC: Sodium Carboxymethyl CelluloseDocument2 pagesFinnfix 10000 CMC: Sodium Carboxymethyl CelluloseForeverNo ratings yet

- Primal™ SF-016 ErDocument8 pagesPrimal™ SF-016 ErAPEX SONNo ratings yet

- Increasing Sustainability of Industrial Coatings With Imerys Functional MineralsDocument28 pagesIncreasing Sustainability of Industrial Coatings With Imerys Functional Mineralss0n1907No ratings yet

- Talc in Polyester Putties - Mondo Minerals PDFDocument10 pagesTalc in Polyester Putties - Mondo Minerals PDFJuanan LopezNo ratings yet

- 07 Flooring - BS6920 (External)Document29 pages07 Flooring - BS6920 (External)Forever100% (1)

- Dirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.DDocument31 pagesDirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.Dichsan hakimNo ratings yet

- Dow Performance Solvents: - Your Choice of Coalescent in Waterborne CoatingsDocument4 pagesDow Performance Solvents: - Your Choice of Coalescent in Waterborne CoatingsAPEX SONNo ratings yet

- Dispersing Agents For Water-Based DTM CoatingsDocument36 pagesDispersing Agents For Water-Based DTM CoatingsRoman IsakNo ratings yet

- Evonik-Ancamide 221-X70 - EUDocument5 pagesEvonik-Ancamide 221-X70 - EUMOHAMED100% (1)

- Architectural EN-VINAVIL PDFDocument36 pagesArchitectural EN-VINAVIL PDFSeafar YachtingNo ratings yet

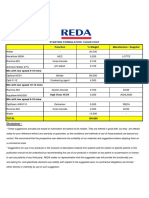

- Economic Paint RedaDocument1 pageEconomic Paint RedaForeverNo ratings yet

- LoVOCoat - For Low VOC High Performance Solvent Borne CoatingsDocument4 pagesLoVOCoat - For Low VOC High Performance Solvent Borne CoatingskarlaNo ratings yet

- AkzoNobel Paint Eng Tcm54-18194Document20 pagesAkzoNobel Paint Eng Tcm54-18194a2009sNo ratings yet

- Crayamid 115X - 70%Document2 pagesCrayamid 115X - 70%WALTER KLISSMANNo ratings yet

- Cong Thuc SonDocument23 pagesCong Thuc Sonvanhung68No ratings yet

- PaintsDocument14 pagesPaintsBarshat KhakurelNo ratings yet

- Byk 4510Document2 pagesByk 4510Juan Angel DechimaNo ratings yet

- Eastman Coatings: Formulating Solutions: Meeting VOC Regulations With CoalescentsDocument4 pagesEastman Coatings: Formulating Solutions: Meeting VOC Regulations With Coalescentsvijay662No ratings yet

- High-Pcv Water-Based Paint Ingredients % by Weight: Ginshicel MH 96-SdDocument3 pagesHigh-Pcv Water-Based Paint Ingredients % by Weight: Ginshicel MH 96-Sdfernando reyesNo ratings yet

- TDS 7212 XB 60Document3 pagesTDS 7212 XB 60Shafiq LatifNo ratings yet

- Eterac 7226-1-B-60Document2 pagesEterac 7226-1-B-60Imran Ahmad100% (1)

- Use of Soya Lecithin in Making PaintDocument1 pageUse of Soya Lecithin in Making PainttunlajiNo ratings yet

- How To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry PaintsDocument45 pagesHow To Achieve Better Than Acrylic Performance Without Acrylics For Architectural and Masonry Paintssriatul2006No ratings yet

- Croda How To LoVOCoatDocument6 pagesCroda How To LoVOCoatkarla100% (1)

- SC2889 PDFDocument15 pagesSC2889 PDFA MahmoodNo ratings yet

- FORM 07-1018A Semi Gloss Deeptone Paint Formula Af Xls 500 and Nhs 300 PDFDocument1 pageFORM 07-1018A Semi Gloss Deeptone Paint Formula Af Xls 500 and Nhs 300 PDFelgendawyNo ratings yet

- Multifunctional Additives: For Paints and CoatingsDocument2 pagesMultifunctional Additives: For Paints and Coatingspandep22No ratings yet

- Huber's Alumina Trihydrate (ATH) A Versatile Pigment For Coatings, Inks, Adhesives, Caulks and Sealants ApplicationsDocument5 pagesHuber's Alumina Trihydrate (ATH) A Versatile Pigment For Coatings, Inks, Adhesives, Caulks and Sealants ApplicationsdewanibipinNo ratings yet

- Economic PaintDocument1 pageEconomic PaintForeverNo ratings yet

- Latex Paint Formulations: University of Bristol School of Chemistry Cantock's Close Bristol BS8 iTSDocument13 pagesLatex Paint Formulations: University of Bristol School of Chemistry Cantock's Close Bristol BS8 iTSAriane MochéNo ratings yet

- Supreme: Premium Opacifying Mineral For Titanium Dioxide ExtensionDocument2 pagesSupreme: Premium Opacifying Mineral For Titanium Dioxide Extensionkensley oliveiraNo ratings yet

- Cril at 4830Document4 pagesCril at 4830ForeverNo ratings yet

- Acronal NX 3587: ConstructionDocument3 pagesAcronal NX 3587: ConstructionRajuNSanaboinaNo ratings yet

- Eastman Product For Ink and CoatingDocument28 pagesEastman Product For Ink and CoatingshikhajainNo ratings yet

- Long Durability Exterior CoatingDocument1 pageLong Durability Exterior CoatingAmit BholaNo ratings yet

- 01 - 2K PU SB Auto Refinish & Ind Systems 08-10Document67 pages01 - 2K PU SB Auto Refinish & Ind Systems 08-10محمد عزتNo ratings yet

- ExtendersDocument33 pagesExtenderssbttbsNo ratings yet

- Adekanol Uh-420: Thickener Rheology ModifiersDocument6 pagesAdekanol Uh-420: Thickener Rheology ModifierszxcvxcvxzcvNo ratings yet

- Primal Ac 369sDocument20 pagesPrimal Ac 369shongducxxx100% (1)

- Wanhua Interior Coating SolutionsDocument28 pagesWanhua Interior Coating SolutionsThanh Vu100% (1)

- Acronal 7079 PI EDADocument3 pagesAcronal 7079 PI EDAGokul Basker100% (2)

- Duroftal VPE 7186 Coil - e PDFDocument24 pagesDuroftal VPE 7186 Coil - e PDFPratik MehtaNo ratings yet

- EDAPLAN METOLAT GF For Inorg Pigments 2017Document18 pagesEDAPLAN METOLAT GF For Inorg Pigments 2017manuel h.ddc.No ratings yet

- 730AL 221 Allnex Crosslinkers Amino SpreadsDocument13 pages730AL 221 Allnex Crosslinkers Amino SpreadssidneidecarvalhoNo ratings yet

- Ucar Latex R-362 - Mielco PDFDocument3 pagesUcar Latex R-362 - Mielco PDFForever0% (1)

- Acronal MB 6476Document3 pagesAcronal MB 6476jose mondacaNo ratings yet

- UC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFDocument24 pagesUC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFchayanunNo ratings yet

- FP Pigments - Opacity Pigments, Cost Saving Opportunities in Architectural Coatings Paul DietzDocument22 pagesFP Pigments - Opacity Pigments, Cost Saving Opportunities in Architectural Coatings Paul DietzHiếu Mai ĐứcNo ratings yet

- MAINCOTE™ AEH-20 Acrylic-EpoxyDocument5 pagesMAINCOTE™ AEH-20 Acrylic-EpoxyAPEX SONNo ratings yet

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocument5 pagesSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNo ratings yet

- Soyol Polyol FormulationsDocument3 pagesSoyol Polyol FormulationsurethanNo ratings yet

- Altiris - Infrared Reflecting Macro Titania For CoatingsDocument23 pagesAltiris - Infrared Reflecting Macro Titania For CoatingsMuhammad AhsanNo ratings yet

- Jo GradeDocument40 pagesJo GradeEvonne TanNo ratings yet

- ROVACE™ 9900 Vinyl Acrylic Binder: Property Typical ValuesDocument7 pagesROVACE™ 9900 Vinyl Acrylic Binder: Property Typical ValuesNelNo ratings yet

- Industrial Coating Road Marking Paint, Yellow: Guide FormulationDocument1 pageIndustrial Coating Road Marking Paint, Yellow: Guide FormulationFabio Samir CuzinskyNo ratings yet

- EPODIL® 748 Reactive Diluent: DescriptionDocument2 pagesEPODIL® 748 Reactive Diluent: DescriptionArturo BarjauNo ratings yet

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3From EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3No ratings yet

- The Determination of Epoxide Groups: Monographs in Organic Functional Group AnalysisFrom EverandThe Determination of Epoxide Groups: Monographs in Organic Functional Group AnalysisNo ratings yet

- Hydrous and Calcined Kaolin Technical DetailsDocument2 pagesHydrous and Calcined Kaolin Technical DetailsForeverNo ratings yet

- Optifoam AW 6110 (TDS)Document1 pageOptifoam AW 6110 (TDS)ForeverNo ratings yet

- TDS OPT Optiperse A4650-Apr17Document1 pageTDS OPT Optiperse A4650-Apr17ForeverNo ratings yet

- Optiperse PF 7081 (TDS)Document1 pageOptiperse PF 7081 (TDS)ForeverNo ratings yet

- TDS Disperbyk-193 en PDFDocument2 pagesTDS Disperbyk-193 en PDFForeverNo ratings yet

- 124826carboset® CR-785Document17 pages124826carboset® CR-785ForeverNo ratings yet

- Ucar Latex R-362 - Mielco PDFDocument3 pagesUcar Latex R-362 - Mielco PDFForever0% (1)

- 5040 Plus PDFDocument3 pages5040 Plus PDFForeverNo ratings yet

- SDS BYK-037 US enDocument10 pagesSDS BYK-037 US enForeverNo ratings yet

- Dynasylan For Mineral Fillers and Pigments enDocument28 pagesDynasylan For Mineral Fillers and Pigments enForeverNo ratings yet

- Safety Data Sheet: 3M™ Easy Clean Coating ECC-1000Document10 pagesSafety Data Sheet: 3M™ Easy Clean Coating ECC-1000ForeverNo ratings yet

- Optiperse P 7075 (TDS) PDFDocument1 pageOptiperse P 7075 (TDS) PDFForeverNo ratings yet

- Product Offer de CON enDocument14 pagesProduct Offer de CON enForeverNo ratings yet

- CC301Document8 pagesCC301ForeverNo ratings yet

- TiO2 Physical Property ComparisonDocument2 pagesTiO2 Physical Property ComparisonForeverNo ratings yet

- Primal Ac337 Emulsione Acrilica 890029 TdsDocument18 pagesPrimal Ac337 Emulsione Acrilica 890029 TdsForeverNo ratings yet

- Optiboost WE 5080 (TDS)Document1 pageOptiboost WE 5080 (TDS)ForeverNo ratings yet

- Wacker PolymeDocument6 pagesWacker PolymeForeverNo ratings yet

- ZeolexDocument2 pagesZeolexForeverNo ratings yet

- Economic Paint RedaDocument1 pageEconomic Paint RedaForeverNo ratings yet

- Acrysol Viscosity LossDocument4 pagesAcrysol Viscosity LossForeverNo ratings yet

- Cril at 4830Document4 pagesCril at 4830ForeverNo ratings yet

- Mineral Fillers: DescriptionDocument1 pageMineral Fillers: DescriptionForeverNo ratings yet

- Economic PaintDocument1 pageEconomic PaintForeverNo ratings yet

- Guide Formulation Sealant of 6530Document1 pageGuide Formulation Sealant of 6530ForeverNo ratings yet

- Potentials of Nigerian Calcined Kaolin As Paint Pigment: ReviewDocument8 pagesPotentials of Nigerian Calcined Kaolin As Paint Pigment: ReviewForeverNo ratings yet

- Economic Paint RedaDocument1 pageEconomic Paint RedaForeverNo ratings yet

- Clear CoatDocument1 pageClear CoatForeverNo ratings yet

- Piano TrioDocument20 pagesPiano TrioChristopher H. MorrisonNo ratings yet

- Dungeon Nights - Scott MalthouseDocument7 pagesDungeon Nights - Scott MalthouseMrToadNo ratings yet

- YannaDocument392 pagesYannapishowi1No ratings yet

- Soal Paket Penilaian Tengah Semester Bahasa Inggris Kelas 7 8 9Document4 pagesSoal Paket Penilaian Tengah Semester Bahasa Inggris Kelas 7 8 9widiNo ratings yet

- Agatha CristieDocument1 pageAgatha CristieRaluca CiobanuNo ratings yet

- The Johann Sebastian Bach BiographyDocument61 pagesThe Johann Sebastian Bach BiographyernstpeterNo ratings yet

- Genealogia Darkover PassadoDocument1 pageGenealogia Darkover PassadoRubi AriadneNo ratings yet

- Soal Bhs Inggris Wajib Kls X Semester 1Document8 pagesSoal Bhs Inggris Wajib Kls X Semester 1Andriyani NaningNo ratings yet

- Jayapataka Swami Guru Maharaj, Mercy On Wheel, Sri Jagannath e Ratha Yatra Address, Sri Mayapur Dham, IndiaDocument3 pagesJayapataka Swami Guru Maharaj, Mercy On Wheel, Sri Jagannath e Ratha Yatra Address, Sri Mayapur Dham, Indianirav patelNo ratings yet

- Adelinas Whales Voc PDFDocument12 pagesAdelinas Whales Voc PDFezzeldin3khaterNo ratings yet

- Assignment 1 - Liliana Choque Condori - Profesorado de Inglés, PompeyaDocument4 pagesAssignment 1 - Liliana Choque Condori - Profesorado de Inglés, PompeyaLilyanaNo ratings yet

- The Following Are The Math Questions in 2017 Civil Service ExamDocument23 pagesThe Following Are The Math Questions in 2017 Civil Service ExamIan D ValdeztamonNo ratings yet

- Item Material Description Qty UnitDocument18 pagesItem Material Description Qty UnitFroilan EspinosaNo ratings yet

- Imagine - John LennonDocument1 pageImagine - John Lennonvicbenevides100% (1)

- 4 Freedoms Park Conservancy 2017-18Document28 pages4 Freedoms Park Conservancy 2017-18rooseveltislanderNo ratings yet

- English Essay 2Document3 pagesEnglish Essay 2Anonymous DshpFONo ratings yet

- Chord DictionaryDocument25 pagesChord DictionaryvandzNo ratings yet

- Asking and Giving SuggestionDocument4 pagesAsking and Giving SuggestionG BlekNo ratings yet

- 3Document1 page3Leanna Abdul WahabNo ratings yet

- Guitar QuickStart Guide - Eddie SlasherDocument46 pagesGuitar QuickStart Guide - Eddie SlasherJuann TorresNo ratings yet

- Jose Rizal and Philippine - PptfinalsDocument2 pagesJose Rizal and Philippine - PptfinalsVernadel ApolloNo ratings yet

- CH 01Document52 pagesCH 01Arjun K RNo ratings yet

- Slokas On GuruDocument27 pagesSlokas On GuruArun Sharma100% (3)

- Turkish CultureDocument39 pagesTurkish CultureArdelean DacianNo ratings yet

- Wedding Weekend Memo Template For WeddingbeeDocument15 pagesWedding Weekend Memo Template For WeddingbeeTanya Delgado AndersonNo ratings yet

- 4.1 Sigalovada S d31 PiyaDocument26 pages4.1 Sigalovada S d31 PiyasumangalaNo ratings yet

- The Bread of Salt - Literary Criticism Termplate (For Short Story)Document9 pagesThe Bread of Salt - Literary Criticism Termplate (For Short Story)John RainierNo ratings yet