Professional Documents

Culture Documents

Mahindra 475 DI Tractor BUDNI TEST REPORT

Uploaded by

Shyam KatareOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mahindra 475 DI Tractor BUDNI TEST REPORT

Uploaded by

Shyam KatareCopyright:

Available Formats

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

Manufacturer : M/s. Mahindra & Mahindra Limited

(Farm Equipment Sector)

Akurli Road, Kandivli (East)

MUMBAI – 400 101

Month : August Test Report No. T-731/1238/ 2010 Year : 2010

GOVERNMENT OF INDIA

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE

TRACTOR NAGAR, BUDNI (MADHYA PRADESH) 466445, INDIA

Email: fmti-mp@nic.in

Web site: dacnet.nic.in/cfmtti

Telephone: 07564-234729 FAX: 07564-234743

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 1 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

Type of Test : COMMERCIAL (INITIAL)

Test code/Procedure : IS: 5994-1998 (Reaffirmed in 2009),

IS: 9253-2001 (Reaffirmed in 2007),

and IS: 12207-2008

Period of Test : November, 2009 to March, 2010

Test Report No. : T- 731/1238/ 2010

Month/Year : August, 2010

i) The results reported in this report are observed values and no corrections have been

applied for atmospheric and site conditions.

ii) The data given in this report pertain to the particular machine submitted by the

applicant for test.

iii) The results presented in this report do not in any way attribute to the durability of the

machine.

iv) This report should not be reproduced in part or full without prior permission of the

Director, Central Farm Machinery Training and Testing Institute, Budni (M.P.).

v) This test report supersedes the following test reports on this tractor.

S. No. Make & Model of the tractor Nature of test Test report No.

1. Mahindra 475 DI Tractor Commercial (Initial) T-310/681,1995

2. Mahindra 475 DI Tractor Commercial (Batch) T-517/1003,

March 2005

3. Mahindra 475 DI MKM Commercial T-606/1111,

New Boomiputra Tractor (Variant) January, 2008

SELECTED CONVERSIONS

S. No Units Conversion Factor

1 Force:

1 kgf 9.80665 N

2.20462 lbf

2 Power:

1 hp 1.01387 metric hp (Ps)

745.7 W

1 Ps 735.5 W

1 kW 1.35962 Ps

3 Pressure:

1 psi 6.895 kPa

2

1 kgf/cm 98.067 kPa = 735.56 mm of Hg

2

1 bar 100 kPa = 10 N/cm

1 mm of Hg 1.3332 m-bar

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 2 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

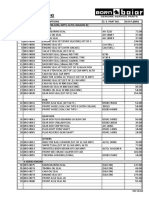

17. SUMMARY OF OBSERVATIONS, COMMENTS & RECOMMENDATIONS

17.1 Evaluative (mandatory) / Non-evaluation (Non-mandatory) parameter applicable for

qualifying Minimum Performance criteria as per Clause-4 (Table-1) of IS: 12207-2008 for

acceptance of the tractor for the purpose of subsidies/NABARD financing are

summarized as under:

Values

Category Requirements declared Whether

S. No. Characteristic (Evaluative / as per IS: 12207-2008 by the As meets the

Non applicant observed require-

Evaluative) (D)/ ments

Require- (Yes/No.)

ment (R)

1 2 3 4 5 6 7

17.1.1 PTO Performance :

a) -Maximum power Declared value to be

under 2 h test, achieved with a

(kW ) tolerance of: - 5/ +10

Evaluative

(Natural ambient % for PTO power >35 27.9 (D) 28.3 Yes

condition) hp, –7.5/+10% for

PTO power 35 hp

b) Power at rated Non

engine speed, (kW) Evaluative

-do- 27.9 (D) 28.3 Yes

c) Specific fuel

consumption

Non

corresponding to Yes

Evaluative 5% 235 (D) 237

maximum power,

(g/kWh)

d) Maximum

equivalent Non 8% 177 (D) 159.8 No

crankshaft torque, Evaluative

(Nm)

e) Back-up torque, Non

percent Evaluative

7 percent, min. 13 (D) 12.5 Yes

1 2 3 4 5 6 7

O

f) Maximum operating temperature ( C)

1) Engine oil Non The declared value

Evaluative should not exceed the

max. value specified by

the oil company and the

observed value under 130 (D) 109 Yes

high ambient condition

should not exceed the

declaration.

2) Coolant Evaluative The declared value

(water) should not exceed the

boiling temperature of

coolant under the

pressurized or otherwise

and the observed value 112 (D) 91 Yes

under high ambient

condition should not

exceed the declaration.

g) Engine oil Not exceeding 1% of

consumption, Evaluative SFC at max. power

(g/kWh) under High ambient 2.39 (R) 0.58 Yes

conditions

h) Smoke level Maximum light

Evaluative absorption coefficient of

3.25 per meter or

equivalent BOSCH No.

3.25 per

meter (R) 0.44 Yes

5.2 or 75 Hatridge value

(As per CMVR)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 3 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

17.1.2 Drawbar performance :

a) Max. drawbar pull Minimum 65% of 18.65 (D)

with ballast Non static mass with

corresponding to Evaluative ballast 17.50 Yes

15 percent wheel Minimum (R) 20.47

slip, (kN)

b) Max. drawbar pull 12.25 (D)

with standard Evaluative Minimum 65% of

ballast static mass of tractor 11.12

Yes

corresponding to with standard ballast Minimum (R) 12.98

15 percent wheel

slip, (kN)

c) Maximum drawbar Min. 80% of PTO 22.1 (D)

power without Evaluative power as referred in

ballast/with 17.1.1(a) of PTO 22.6 Yes

standard ballast, performance 23.9

Minimum (R)

(kW).

d) Maximum The declared value

transmission oil Non should not exceed the

o maximum value 110 77 Yes

temperature ( C) Evaluative

specified by oil company

17.1.3 Power lift and hydraulic pump performance :

a) Maximum lifting capacity throughout the range of lift, (kN):

1) At hitch Non [Tolerance of minus 11.7 (D)

points Evaluative 10%]

13.59 Yes

2) With the The lift capacity should 7.80 (D)

standard Evaluative at least be 18 kg/PTO

frame hp. and it should be 16

kg/engine hp where the 6.70 9.55 Yes

tractor is not provided Minimum(R)

with a PTO shaft

1 2 3 4 5 6 7

b) Maximum drop in the

height of the point of

application of the force Non [Tolerance of

after each 5 minutes 50 (R) 125 No

Evaluative plus

interval for a total

5 mm]

duration of 30 minute,

(mm)

17.1.4 Brake performance at 25 kmph:

a) Maximum stopping distance at a force, equal to or less than 600 N on brake pedal with

road ballast, (m):

1) Yes

Cold brake Evaluative 10 10 (R) 7.00

2) Yes

Hot brake Evaluative 10 10 (R) 8.10

b) Maximum force

exerted on the brake

pedal to achieve a

deceleration of 2.5 Evaluative 600 600 (R) 385 to 405 Yes

2

m/s (N)

c) Whether parking

brake is effective at a

force of 600 N at foot

pedal(s) or 400 N at Evaluative Yes / No Yes (R) Yes Yes

hand lever

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 4 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

17.1.5 Noise measurement :

a) Maximum ambient

noise emitted by the Evaluative As per CMVR 88 (R) 84 Yes

tractor dB(A)

b) Maximum noise at

operator‟s ear level Evaluative As per CMVR 98 (R) 94 Yes

dB(A)

17.1.6 Amplitude of mechanical vibrations at :

1) Left foot rest 100 (R) 460 No

2) Right foot rest 100 (R) 520 No

Non

3) Seat (with driver 100 microns 100 (R) 130 No

Evaluative

seated) (max)

4) Steering wheel 100 (R) 190 No

17.1.7 Haulage requirements :

a) Gross mass of the trailers, (tones):

1) Two wheel Non -- 4.0 (D) 4.0 Yes

2) Four wheel Evaluative -- 5.5 (D) 5.5 Yes

b) Distance travelled / litre of fuel consumption, (km/l):

1) Two wheel Non -- 6 to 7 (D) 7.12 to 7.27 Yes

2) Four wheel Evaluative -- 6 to 7(D) 6.68 to 6.75 Yes

c) Fuel consumption (ml/km/tonne):

1) Two wheel Non -- 35 to 45 (D) 34.4 to 35.1 Yes

2) Four wheel Evaluative -- 25 to 35 (D) 26.9 to 27.2 Yes

1 2 3 4 5 6 7

17.1.8 Wetland cultivation :

Sealing for the Evaluative The identified

following assemblies: assemblies should

1) Clutch -do- essentially meet There should No ingress

the requirement of be no of mud and

assembly Yes

IS: 11082. No

2) Brake housings -do- ingress of / or water

water ingress in

the identified water and/or was

assembly given in mud observed

3) Front axle hubs -do- (R)

column-2.

If tractor does not

meet the require-

ments of wetland

cultivation, it may

be recommended

for dry land

operation only.

17.1.9 Safety features :

a) At present

Guards against

moving and hot parts

Evaluative As per CMVR no require- Provided Yes

ments

b) Lighting arrangement Evaluative As per CMVR Provided Yes

17.1.10 Labelling of tractors (Provision of labelling plate):

1) Make Evaluative -- Mahindra Yes

2) Model Evaluative -- 475 DI Yes

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 5 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

3) Year of Should conform -- 2009 (F9)

manufacture

Evaluative

to the require-

Yes

4) Engine number ments of CMVR -- RENW

Evaluative along-with Yes

7013

5) Chassis number declared value of -- RENW

Evaluative PTO HP Yes

7013

6) Declaration of --

PTO power, Evaluative 27.9

(kW) Yes

17.1.11 Discard limit for:

(a) Cylinder bore 88.91 to

diameter, (mm) Evaluative To be specified 89.13 88.93 Yes

by the manu-

(b) Clearance between 0.125 to

facturer

piston & cylinder liner Evaluative 0.20 0.156 Yes

at skirt, (mm)

(c) Ring end gap (mm):

- Top comp. ring. To be specified by 2.50 0.30 to 0.35 Yes

nd the manufacturer

- 2 comp. ring. Evaluative 2.50 0.60 to 0.65 Yes

- Oil ring. 2.00 0.35 to 0.45 Yes

(d) Ring groove clearance (mm):

- Top comp. ring. -do- -Tapered ring -

nd

- 2 comp. ring. -do- 0.30 0.063 to Yes

Evaluative 0.083

- Oil ring. -do- 0.20 0.036 to Yes

0.048

1 2 3 4 5 6 7

(e) Clearance of main bearings (mm):

- Diametrical 0.20 0.054 to Yes

clearance Evaluative -do-

0.076

- Crankshaft end 0.60 0.12 Yes

Evaluative --do--

float

(f) Clearance of big end bearings, (mm):

- Diametrical 0.20 0.075 to Yes

Evaluative -do-

0.115

- Axial Evaluative -do- 0.75 0.20 to 0.25 Yes

(g) Clearance between 0.30 0.07 to 0.15 Yes

Non

king pin and bush, -do-

Evaluative

(mm)

(h) Clearance between 0.30 0.05 to 0.14 Yes

Non

center pin and bush, -do-

Evaluative

(mm)

17.1.12 CATEGORY OF BREAKDOWNS / DEFECTS :

Category Whether

S. Characteristic (Evaluative / Requirements As meets the

No. Non as per IS: 12207-2008 observed require-

Evaluative) ments

(Yes/No.)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 6 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

1. Critical Evaluative No critical breakdown None Yes

Not more than two and neither of None Yes

2. Major Evaluative

them should be repetitive in nature

Not more than five and frequency Mn7 Yes

3. Minor Evaluative of each should not be more than (Two)

two.

4. Total In no case, the total number of Mn7 Yes

breakdowns breakdowns should exceed five, (Two)

Evaluative

that is, (2 major + 3 minor) or 5

minor breakdowns.

17.2 Optional requirements as per Clause-4 (Table-2) of IS:122107-2008:

S. Characteristic Requirements AS observed Remarks

No. as per IS: 12207-2008

1 2 3 4 5

1 Air cleaner oil pull 0.25% (max.) 0.15 Yes

over, max. oil pull

over (%)

2. Seating requirements Should meet the requirements Does not meet No

of IS: 12343-1998 the requirement

3. Fitment of ROPS With a provision for fitment of Not provided No

ROPS.

If ROPS fitted it should meet the ROPS not --

requirement of IS: 11821-1992 provided

4. Technical Should meet the requirements Does not meet No

requirements for PTO of IS: 4931 -1995 the

shaft requirement

1 2 3 4 5

5. Dimensions of three Should meet the requirements Meets the Yes

point linkage of IS: 4468 (Part-I)-1997 requirement

6. Specifications of Should meet the requirements Meets the Yes

linkage drawbar of IS: 12953-1990 requirement

Specifications of Should meet the requirements Not provided --

swinging drawbar of IS:12362 Part 3-1994.

7. Accessories Trailer hitch, front tow hook, Front tow No

linkage drawbar may be hook is not

provided. provided

17.3 Conformity with following IS:

i) Guidelines for declaration of power and specific fuel : Conforms

consumption and labeling of agricultural tractors

(First revision) [IS 10273:1987 (Reaffirmed in March,

2009)]

ii) Agricultural tractors – Rear mounted power take-off - : Does not conforms

Types 1, 2 and 3(third revision)[IS: 4931-1995

(Reaffirmed in March, 2009)]

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 7 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

iii) Agricultural wheeled tractors - Rear mounted three- : Conforms

point linkage: Part 1 Categories 1, 2, 3 & 4 (fourth

revision) [IS 4468(Part-I):1997 (Reaffirmed in March,

2007)]

iv) Drawbar for agricultural tractors – Link type [IS : Conforms

12953:1990 (Reaffirmed in March, 2007)]

v) Agricultural tractors - Operator‟s seat technical : Does not conform

requirement (First revision) [IS 12343:1998

(Reaffirmed in March, 2009)]

vi) Guide for safety & comfort of operator of agricultural : Does not conform

tractors: Part 1 General requirements (first revision)

: [IS 12239(PT-1)-1996 (Reaffirmed in March,

2007)]/ISO 4254-1:1989]

vii) Tractors and machinery for agriculture and forestry – : Does not conform

Technical means for ensuring safety Part 2: Tractors

(first revision) [(IS : 12239 (PT-2)-1999 (Reaffirmed in

March, 2009)]

viii) Tractors and machinery for agriculture and forestry, : Does not conform

powered lawn and garden equipment – Symbols for

operator controls and other displays [IS: 6283 (Part-

1)-2006 (Reaffirmed in March, 2009) and IS:6283

(Part-2)-2007 (Reaffirmed in March, 2009)]

ix) Guide lines for location and operation of operator : Does not conform

controls on agricultural tractors and machinery (first

revision) (IS: 8133 – 1983 (Reaffirmed in March,

2009)]

x) Agricultural Tractor & Machinery Lighting device for : Conforms

travel on public roads [(IS: 14683-1999 (Reaffirmed

in March, 2009)]

17.4 Salient Observations:

17.4.1 Laboratory tests:

17.4.1.1 PTO Performance:

i) The backup torque is 12.5%.

ii) The specific fuel consumption corresponding to maximum power was

measured as 237g/kWh against the declaration of 235 g/kWh, which is within

the tolerance limit as specified in the IS: 12207-2008.

iii) The maximum equivalent crankshaft torque was recorded as 159.8 kN against

the declaration of 177 kN, which is 9.7% less and does not meet the

requirement of IS:12207-2008 in respect of tolerance. This should be looked

into.

17.4.1.2 Drawbar performance

During drawbar performance test, rear tyre creeping was observed as 58 & 80

mm for LHS and RHS tyres respectively which is on higher side and calls for

necessary corrective action.

17.4.1.3 Hydraulic Performance:

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 8 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

i) The lifting capacity at standard frame was recorded as 9.55 kN and the moment

about the rear axle was computed as14.56 kN-m. The moment about rear axle

is on higher side when compared to the moment about front axle i.e. 12.36 kN.

It is therefore, recommended that the lifting capacity of the hydraulic system

may be reduced suitably or additional standard ballast mass at front axle may

be provided to avoid front lifting of the tractor.

ii) Total drop in height of lift during lift load maintenance test was recorded as 125

mm against the preferably maximum requirement of 50 mm, and calls for

necessary corrective action.

17.4.1.4 Mechanical Vibration:

The amplitude of mechanical vibration on various assemblies marked as (*) in

Chapter-9 of this test report is on higher side, especially at the steering control wheel,

foot rest and operator‟s seat. This calls for dampening down of vibrations to improve

the operational comfort and service life of components.

17.4.1.5 Three point linkage:

Some of the parameters of three point linkage conforms to Cat.I and some of them

conforms to Cat.II. Keeping in view the sprit of standardization, necessary

improvement may be incorporated.

17.4.1.6 Specifications of PTO Shaft:

Dimension “DΦ” and “dΦ” (Refer Fig. 2) of PTO shaft does not meet the requirement

of IS:4931:1995, this should be looked into for compliance.

17.4.1.7 Operator’s Seat:

i) Width of Operator‟s seat does not meet the requirements of IS: 12343:1998 and

calls for necessary corrective action.

ii) Instead of longitudinal adjustment on operator‟s seat, two positions at a distance

of 30 mm has been provided for the seat. This does not meet the minimum and

optimum requirements of ± 25 mm and ± 100 mm respectively. In view of the

enhancing comfort level of operator, this may be looked into for increasing.

17.4.1.8 Symbols of operator's control and other displays:

The power take-off shaft engaged position, starting switch, oil lubricant type &

frequency, are not identifiable with the symbols as per IS: 6283 (Part-1&2)-1998. This

needs to be looked into.

17.4.1.9 Location and operation of operator's control:

Operations of some of the operator‟s control does not meet the requirements of IS:

8133-1983. This may be looked into.

17.4.2 Field performance:

17.4.2.1 Dry land operation:

The average area covered in M .B. ploughing operation with recommended size of

plough was recorded in the range of 0.138 to 0.155 ha/h. Keeping in view the PTO

power of the tractor, the area coverage is considered less, hence the recommended

size of the plough may be reviewed.

17.4.2.2 Wetland operation (Puddling operation):

No ingress of mud/or water was noticed during puddling operation of the tractor.

Hence, It meets the requirements of IS:11082-1984 (Technical requirements of

agricultural tractors for wetland operation). The tractor is suitable for wetland

operation (Puddling).

17.4.2.3 Haulage performance:

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 9 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

During haulage performance test, drops of water were found in engine oil. The

cylinder liner „O‟ ring (water) and cylinder liner „O‟ ring (oil) of second cylinder were

found in damaged condition. The following parts were replaced with new one for all

the four cylinder liners.

i) Liner „O‟ ring water (Part No. 005553024R2) – 4 Nos.

ii) Liner „O‟ ring oil (Part No. 005554163R1) – 4 Nos.

The above replacements are considered as pre-mature nature of breakdown and

calls for introduction of suitable remedial measures at production/assembly line.

17.5 Maintenance / Service Problems:

No noticeable maintenance or service problem was observed during the test. However,

suitable provision for draining of sediments/water may be provided at the fuel tank.

17.6 Recommendation with regard to safety on tractor:

The following requirements, inter alia, may be considered for incorporation on the

tractor:

i) Provision of safety against accidental start of engine.

ii) Provision of Power take –off shaft master shield.

iii) Provision for spark arresting device in exhaust system.

iv) The working clearance around the draft control lever may be provided as per IS:

12239 (Part-2) – 1999.

v) “Minimum cautionary notice” may be provided.

17.7 Adequacy of Literature supplied with machine:

17.7.1 The following modified literature has been supplied by the manufacturer.

a) Operator‟s manual for DI Tractors

b) Part‟s catalogue Mahindra tractors

c) Supplementary part‟s catalogue for Bhoomiputra MKM & New Bhoomiputra DLX

models [265 DI, 275 DI, 275 DI TU, 475 DI & 575 DI] Tractors.

d) Service manual for Mahindra tractors

17.7.2 The revised literature submitted by the firm was found adequate. However, the

following points may be re-examined and suitably incorporated in the operator‟s

manual:

a) All variants model of tractor along with their features may be provided at a glance.

b) The engine lubricating oil change period has been specified as after every 250

hours of operation in the application. Whereas the same has been specified as

first change after 250 hours and thereafter, every 300 hours of operation in the

printed literature.

c) The transmission lubricating oil change period has been specified as after every

1000 hours of operation in the application. Whereas the same has been specified

as after every 1200 hours of operation in the printed literature.

17.7.3 These literatures may also be brought out in national as well as other regional

languages.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 10 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

TESTING AUTHORITY:

R.K. NEMA

AGRICULTURAL ENGINEER

J.J.R. NARWARE

SENIOR AGRICULTURAL ENGINEER

V.N. KALE

DIRECTOR

Hari/dongre/Final reports/August-2010//Mahndra 475DI

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 11 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

18. APPLICANT’S COMMENTS

Para No. Our Reference Applicant’s comments

18.1 Remark on 17.3 We are giving serious attention to your feed back

which will ultimately help to improve the quality. The

observations pertaining to para 17.3 of the test report

would be studied and necessary actions would be

incorporated in the production as a part of continuous

journey in quality improvement.

18.2 17.4.1.1 (iii) & (iv), The observations are under study and appropriate

17.4.1.3 (i) & (ii) action will be planned.

18.3 17.4.1.6 Observations will be studied and necessary action will

17.4.1.7(i) & (ii), 17.4.1.8, be incorporated.

17.4.1.9, & 17.6

18.4 17.4.1.2, 17.4.1.4, Observations will be studied and the corrective

17.4.2.1 actions will be implemented.

18.5 17.4.2.3 Necessary quality checks will be implemented in

production system.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 12 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

ANNEXURE – I

COMPARATIVE MAJOR MODIFICATION IN THE SPECIFICATIONS OF THE TRACTOR

S. Previous model Present model

No. Parameters (As per Test Report No. (As declared)

T-517/1003)

1. Tractor Brand name Sarpanch Bhoomiputra

2. Engine model MDI 2385 MDI 23853A

3. Max. high idling speed, (rpm) 2500 ± 50 2125 ± 50

4. Rated Engine speed, (rpm) 2300 1900

5. Stroke, (mm) 96.0 110.0

6. Cubic capacity, (cc) 2384 2730

7. Bare radiator capacity, (l) 1.8 2.9

8.. Capacity of expansion flask, (l) Not provided 1.4

9. Total coolant capacity,(l) 6.3 8.5

10. Number of fan blades and outer 07 and 399.42 mm 06 and 396 mm

diameter of fan

11. Nominal speed, (kmph): %, Variation

L1 2.68 2.79 +4.1%

L2 4.57 4.76 +4.2%

L3 6.50 6.87 +5.7%

L4 9.71 9.72 +0.1%

H1 7.80 8.09 +3.7%

H2 13.33 13.81 +3.6%

H3 18.96 19.93 +5.1%

H4 28.33 28.20 -0.5%

LR 4.06 4.23 +4.2%

HR 11.83 12.27 +3.7%

12. Speed reduction through crown 4.888 4.182

wheel and bevel pinion

13. Speed reduction through rear final 3.69 : 1 3.58 : 1

drive

14. Speed of hydraulic pump 2875 2394

corresponding to rated engine

speed, (rpm)

15. Discharge of hydraulic pump at 31.6 26.0

rated engine speed, (lpm)

16. Crack-off pressure of relief valve, 16.0 12.0

(MPa)

17. Engine to PTO speed ratio Low-3.667:1 Low-3.500:1

High-1.28:1 High-1.200:1

19. Maximum equivalent crankshaft 133 177

torque, (Nm)

20. Equivalent crankshaft torque at 122.5 155

maximum power, (Nm)

21. Maximum lifting capacity at hitch 9.81 12.0

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 13 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

points, (kN)

ANNEXURE –II

BRIEF SPECIFICATION OF IMPLEMENTS USED DURING FIELD TEST

S. Mould Board

Item Rotavator Puddler

No. Plough

Anil

1. Make Industries, Shaktimaan Not available

Bina

2. Type Mounted Mounted Mounted

12 (6 in each

3. No. of bottoms/blades Two 30

gang)

4. General

Type of bottoms/blades Hatchet Notched

purpose

5. Size of bottoms/blades, (mm) 340 170 x 140 x 5 460

6. Spacing of bottoms/flanges, (mm) 300 230 164

7. Lower hitch point span, (mm) 785 870 680

8. Mast height, (mm) 580 560 680

9. Overall dimensions, (mm):

- Length 1535 1000 1190

- Width 1220 1420 1810

- Height 1150 1070 1330

10. Gross mass, (kg) 230 420 240

ANNEXURE - III

BRIEF SPECIFICATION OF HALF CAGE WHEEL

S. No. Items Specification

1. Type Half cage wheel

2. Dia, (mm) 1085

3. Width, (mm) 340

4. No. and types of lugs 12, straight lugs of MS section

5. Size of angle section, (mm) 50 x 50 x 5

6. Length of lugs, (mm) 340

7. Spacing of lugs, (mm) 240

8. Weight of each cage wheel (kg) 60

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 14 of 15

MAHINDRA, 475 DI TRACTOR

T-731/1238/2010

(Brand Name: Bhoomiputra) - Commercial (Initial)

ANNEXURE - IV

TRACTOR RUN HOURS DURING TEST

A. LABORATORY AND TRACK TESTS: HOURS

1. Running-in --

2. PTO performance test 10.9

3. Power lift and hydraulic pump performance test 1.6

4. Drawbar performance test 14.1

5. Turning ability 0.2

6. Location of centre of gravity 0.2

7. Operator‟s field of vision 0.1

8. Brake test 3.0

9. Noise measurement 1.5

10. Air cleaner oil pull over test 4.0

11. Mechanical vibration test 1.0

12. Theoretical speed test 1.0

B. FIELD TEST:

1. Mould board ploughing 10.3

2. Rotavation 11.1

3. Puddling (including five hours water proof test) 15.0

C. HAULAGE TEST: 8.8

D. Miscellaneous test and other run hours including idle run, 9.7

transportation, trials and preparation for test

TOTAL: 92.5

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 15 of 15

You might also like

- JD 425 445 Operators ManualDocument141 pagesJD 425 445 Operators Manualtheoneman167% (6)

- Caja MaxitorqueDocument268 pagesCaja MaxitorqueMiguel Angel Santos Pintado98% (58)

- Manual Reparatie Massey Ferguson-8400Document1,194 pagesManual Reparatie Massey Ferguson-8400Florina Iordan96% (26)

- Allison 4700 Oilfield Series OFSDocument6 pagesAllison 4700 Oilfield Series OFSNaman Shah100% (4)

- Belarus 900-952-EngDocument269 pagesBelarus 900-952-Engpaky1111100% (1)

- Statement of Account for Indus Way Emerging Market FundDocument2 pagesStatement of Account for Indus Way Emerging Market FundAadeesh JainNo ratings yet

- Field Engineering Bulletin: Improved Tapered Land Thrust BearingDocument2 pagesField Engineering Bulletin: Improved Tapered Land Thrust BearingMichel FloresNo ratings yet

- Sample of Commission BillDocument1 pageSample of Commission BillmanojNo ratings yet

- Product Catalogue.27214653 PDFDocument28 pagesProduct Catalogue.27214653 PDFJohny GharialNo ratings yet

- JCB Hammer Master 36XHDDocument4 pagesJCB Hammer Master 36XHDMadesh kumar100% (1)

- Bjelorus 1025.5Document159 pagesBjelorus 1025.5paky1111100% (1)

- Versatile Tractor Service Manual Ve S 835 855Document21 pagesVersatile Tractor Service Manual Ve S 835 855jperez_mseNo ratings yet

- Kioti Daedong DK901 Tractor Operator Manual PDFDocument15 pagesKioti Daedong DK901 Tractor Operator Manual PDFfjjsekfkskemeNo ratings yet

- Massey Furguson Mf4707, Mf4708, Mf5709, Mf5710, Mf6710, Mf6711, Mf6712, Mf6713 - Manual de Partes - Pag-86Document86 pagesMassey Furguson Mf4707, Mf4708, Mf5709, Mf5710, Mf6710, Mf6711, Mf6712, Mf6713 - Manual de Partes - Pag-86Manuales De Maquinaria Jersoncat100% (3)

- Swaraj 735 Fe Tractor - T - 768-1276-2011Document13 pagesSwaraj 735 Fe Tractor - T - 768-1276-2011Amit Chopra Amit0% (1)

- Mahindra Arjun 555 DIDocument9 pagesMahindra Arjun 555 DIPrashant Patil0% (1)

- MKC Infrastructure Ltd Quotation for Apollo ANP-2000 Plant Spare PartsDocument1 pageMKC Infrastructure Ltd Quotation for Apollo ANP-2000 Plant Spare Partsmkcil purchaseNo ratings yet

- Report On HMT Tractor Division, Summer Training, PinjoreDocument26 pagesReport On HMT Tractor Division, Summer Training, PinjorePradeep RanaNo ratings yet

- Pump RateslDocument12 pagesPump RateslsureshpahariaNo ratings yet

- 2017 GST - Sant Retail Price List Dated 27.07.17 PDFDocument60 pages2017 GST - Sant Retail Price List Dated 27.07.17 PDFkoto group100% (1)

- Annexure - I List of Bse - 500 Companies: S.No Scrip Code Scrip ID Company Name/ IndustryDocument16 pagesAnnexure - I List of Bse - 500 Companies: S.No Scrip Code Scrip ID Company Name/ IndustrySushant KumarNo ratings yet

- Quotation For Hiring of JCB 3DX - New - Aginfra Metro - 1Document1 pageQuotation For Hiring of JCB 3DX - New - Aginfra Metro - 1STORMNo ratings yet

- EV Product Catalogue PDFDocument174 pagesEV Product Catalogue PDFAkNo ratings yet

- AIP Abilities India Piston & Rings LTDDocument21 pagesAIP Abilities India Piston & Rings LTDSushant_Sagar_9240100% (1)

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument98 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedCwsNo ratings yet

- Dealer Kit Book 31-5-19 Final PDFDocument51 pagesDealer Kit Book 31-5-19 Final PDFSamsher AliNo ratings yet

- Broad Status Report: Thermal Power ProjectsDocument120 pagesBroad Status Report: Thermal Power Projectslaloo01No ratings yet

- Mandev Tubes Pvt Ltd copper tube specification chartDocument1 pageMandev Tubes Pvt Ltd copper tube specification chartAdil Amin100% (1)

- Rotoflex Geared Motors GuideDocument67 pagesRotoflex Geared Motors GuideHanamantappa dhanojiNo ratings yet

- VD2019 01.07.2019 Rev.6Document223 pagesVD2019 01.07.2019 Rev.6qc deNo ratings yet

- Top quality value added services from Tata MotorsDocument2 pagesTop quality value added services from Tata Motorsgopikishana100% (1)

- IFB AutomotiveDocument13 pagesIFB Automotiveprudhvikrishna123No ratings yet

- Dumper Spec FinalDocument1 pageDumper Spec FinalJackson PhinniNo ratings yet

- Luk Price List Nepal 2080 Bageshwari Tractor 9848024782Document30 pagesLuk Price List Nepal 2080 Bageshwari Tractor 9848024782Sandeep SinghalNo ratings yet

- Karnataka Mining LessesDocument52 pagesKarnataka Mining Lessessunil_kanthNo ratings yet

- E catalogue20Clutches202620Flywheel20Market202019 20Document16 pagesE catalogue20Clutches202620Flywheel20Market202019 20Shubham GoelNo ratings yet

- TAX INVOICE FOR HOTEL BOOKINGDocument1 pageTAX INVOICE FOR HOTEL BOOKINGShúbhâm ÇháúdhâryNo ratings yet

- Sterling Agro PresentationDocument25 pagesSterling Agro PresentationViteysatya SengNo ratings yet

- Swaraj Engines LTD PPT 2014 by Satnam SinghDocument80 pagesSwaraj Engines LTD PPT 2014 by Satnam SinghSatnam Singh67% (3)

- SQ Irr El Cage MotorsDocument87 pagesSQ Irr El Cage Motorsnsprasad88No ratings yet

- Rolling & Extrusion Case StudyDocument20 pagesRolling & Extrusion Case StudyMahmoud KassabNo ratings yet

- LuK Tractor Price List 2020Document6 pagesLuK Tractor Price List 2020Amit Chopra AmitNo ratings yet

- Equivalent Grades and their Chemical CompositionDocument1 pageEquivalent Grades and their Chemical Compositionmini p shendeNo ratings yet

- QR Codes - Print & ShipDocument1,081 pagesQR Codes - Print & Shipramansharma1769No ratings yet

- Date. India Certificate of Conformance DIN EN 10204-3.1 Test Certificate No. B03940807000335712 30.03.2019 Deepak Fasteners Limited Quality Control Test CertificateDocument1 pageDate. India Certificate of Conformance DIN EN 10204-3.1 Test Certificate No. B03940807000335712 30.03.2019 Deepak Fasteners Limited Quality Control Test CertificateNaresh SainiNo ratings yet

- RDSO Vendor1Document169 pagesRDSO Vendor1adarshietk100% (1)

- (New) Cummins Power Generation 28kVA Silent Diesel Generator - C28D5 3 Phase - Ebay PDFDocument4 pages(New) Cummins Power Generation 28kVA Silent Diesel Generator - C28D5 3 Phase - Ebay PDFNovancyNo ratings yet

- FGD InstallationsDocument6 pagesFGD InstallationsdsoNo ratings yet

- Gear Technology India 2013 # 4 PDFDocument68 pagesGear Technology India 2013 # 4 PDFUday Sankar Sarma YerramilliNo ratings yet

- Schunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFDocument2 pagesSchunk Carbon Technology Sealring Bearing SiSiC SSiC EN PDFMUHAMMAD ASYRAAF BIN ANUARNo ratings yet

- Test Report: Brakes: Enquiries@vca - Gov.ukDocument103 pagesTest Report: Brakes: Enquiries@vca - Gov.ukMarsellusProbstNo ratings yet

- Maruti Oil Seals 2016Document3 pagesMaruti Oil Seals 2016Gurjot Singh100% (1)

- 2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilDocument2 pages2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilSaugata HalderNo ratings yet

- Coal Blocks - 29.08.2018Document6 pagesCoal Blocks - 29.08.2018SekhNo ratings yet

- Motor Flange-Universal InputDocument4 pagesMotor Flange-Universal InputAgus Yulfizar100% (1)

- Project Report For UNOKEM - Unokem Resins Pvt. Ltd.Document31 pagesProject Report For UNOKEM - Unokem Resins Pvt. Ltd.Rahul PancholiNo ratings yet

- Jfe Special SteelDocument18 pagesJfe Special Steelkhwanta-btaNo ratings yet

- Maximum Retail Price List: Moving The Wheels of IndustryDocument22 pagesMaximum Retail Price List: Moving The Wheels of IndustryAlexander David Pino SalazarNo ratings yet

- Price List Cum Equivalent ChartDocument2 pagesPrice List Cum Equivalent ChartGaurav GargNo ratings yet

- 01 - 07 - 2017 List of Approved Vendors PDFDocument132 pages01 - 07 - 2017 List of Approved Vendors PDFPratik GuptaNo ratings yet

- Chota ChilliDocument1 pageChota ChilliRishu ranaNo ratings yet

- Gear Testing Machines of Companies in Western IndiaDocument31 pagesGear Testing Machines of Companies in Western IndiaPramod PatilNo ratings yet

- MahindraDocument13 pagesMahindraCvsiva Krishna ReddyNo ratings yet

- Swaraj 855 Fe Xtra Tractor - T - 852-1362-2012Document12 pagesSwaraj 855 Fe Xtra Tractor - T - 852-1362-2012Surajit SarkarNo ratings yet

- Powertrac 4455 DX Tractor-T - 688-1194-2009Document13 pagesPowertrac 4455 DX Tractor-T - 688-1194-2009Suliman ZekriNo ratings yet

- Agrolux 50E Tractor - T-676-1182-2009 PDFDocument10 pagesAgrolux 50E Tractor - T-676-1182-2009 PDFPreet SinghNo ratings yet

- Kubota B 2420 Tractor - T-674-1180-2009Document11 pagesKubota B 2420 Tractor - T-674-1180-2009Sooraj Kannan, P.V.No ratings yet

- Mahindra 605 Di PS Tractor-T-954-1472-2015Document12 pagesMahindra 605 Di PS Tractor-T-954-1472-2015Prashant PatilNo ratings yet

- Deutz-Fahr Agrolux-55 e tractor test reportDocument12 pagesDeutz-Fahr Agrolux-55 e tractor test reportMamta RaybageNo ratings yet

- John Deere Tractor Parts Manual JD P Pc1539Document33 pagesJohn Deere Tractor Parts Manual JD P Pc1539jose marfullNo ratings yet

- Installmanual Cotta ArregladoDocument20 pagesInstallmanual Cotta ArregladoguillermoNo ratings yet

- HD9-sheet-chassis-euro3-8x4-GB Camión PDFDocument4 pagesHD9-sheet-chassis-euro3-8x4-GB Camión PDFAlonso Fernando Magallanes PalominoNo ratings yet

- CubCadet RZT S Series 2012 2014 Spec SheetDocument17 pagesCubCadet RZT S Series 2012 2014 Spec SheetRobby RenzNo ratings yet

- Case International 7110 7120 7130 7140 Shop ManualDocument10 pagesCase International 7110 7120 7130 7140 Shop Manualconnie100% (46)

- Fast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWDocument6 pagesFast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWĐại DươngNo ratings yet

- Operation Manual for F-1000 Mud Pump SkidDocument68 pagesOperation Manual for F-1000 Mud Pump SkidDarshan Makwana100% (1)

- C15 PDFDocument5 pagesC15 PDFZamir Andres Sencio100% (1)

- Product Catalog Linde Hydraulics enDocument36 pagesProduct Catalog Linde Hydraulics enАнатолій Павлюк100% (1)

- New Holland CR9090, CX8080 Elevation, CX8090 Elevation Tier 4A Combine Service Repair ManualDocument31 pagesNew Holland CR9090, CX8080 Elevation, CX8090 Elevation Tier 4A Combine Service Repair ManualggjjjjotonesNo ratings yet

- Rex 4 VDocument4 pagesRex 4 VsergioNo ratings yet

- FE826 6x2 Platform 26 Tonne - Rear Air Suspension FE 62TR ADocument4 pagesFE826 6x2 Platform 26 Tonne - Rear Air Suspension FE 62TR AAbdulmaola AlmamariNo ratings yet

- AirDocument188 pagesAirDapi Dapi100% (2)

- Parts Catalog: 0CS10-M57800ENDocument233 pagesParts Catalog: 0CS10-M57800ENsasaNo ratings yet

- Caterpillar Programming Cat Electronic Truck Engine May 2005Document10 pagesCaterpillar Programming Cat Electronic Truck Engine May 2005linda100% (33)

- LS-DDNC: B600 - Mistral - Typhon IiDocument16 pagesLS-DDNC: B600 - Mistral - Typhon IiYoussef AdnaneNo ratings yet

- Greaves Cotton Non-Automotive Engines for Agriculture, Construction, Marine and Industrial ApplicationsDocument6 pagesGreaves Cotton Non-Automotive Engines for Agriculture, Construction, Marine and Industrial ApplicationsRicardo TurlaNo ratings yet

- Chelsea HY25-2859-Part List PTODocument20 pagesChelsea HY25-2859-Part List PTOPrajna SatyaNo ratings yet

- Installation Manual: D 909 / 910 B/FL 1011 / F / 2011 B/FM 1011 F / 2011 B/FL 912/913/914/C B/FL 413 F / 513 /C / CPDocument290 pagesInstallation Manual: D 909 / 910 B/FL 1011 / F / 2011 B/FM 1011 F / 2011 B/FL 912/913/914/C B/FL 413 F / 513 /C / CPnenadNo ratings yet

- Ocean Engineering: Martyn Hann, Deborah Greaves, Alison RabyDocument14 pagesOcean Engineering: Martyn Hann, Deborah Greaves, Alison RabyAfif Fahza NurmalikNo ratings yet

- Marine Engine Programme bbb4Document260 pagesMarine Engine Programme bbb4Sea Man MktNo ratings yet