Professional Documents

Culture Documents

Flange Sizes Tables

Uploaded by

Yasir ArafatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange Sizes Tables

Uploaded by

Yasir ArafatCopyright:

Available Formats

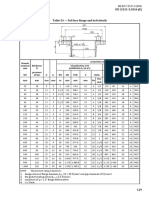

FLANGE TABLES FOR THE HEATING AND VENTILATING INDUSTRY - BS10 AND BS1560 (ANSI B16.

5)

BS1560 ANSI B16.5 BS1560 ANSI B16.5

BS10 Table D BS10 Table E BS10 Table F BS10 Table H Class 150 Class 300

Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. &

in Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length Dia. Thick PCD N o. of L ength Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length

in in in Holes of Bolts in in in Holes of Bolts in in in Holes of Bolts in in in Holes of Bolts in in in Holes of Bolts in in in Holes of Bolts

1/2 3.3/4 3/16 2.5/8 4 M12.25 3.3/4 1/4 2.5/8 4 M12.30 3.3/4 3/8 2.5/8 4 M12.40 4.1/2 1/2 3.1/4 4 M16.50 3.1/2 7/16 2.3/8 4 M12.45 3.3/4 9/16 2.5/8 4 M12.50

3/4 4 3/16 2.7/8 4 M12.25 4 1/4 2.7/8 4 M12.30 4 3/8 2.7/8 4 M12.40 4.1/2 1/2 3.1/4 4 M16.50 3.7/8 1/2 2.3/4 4 M12.50 4.5/8 5/8 3.1/4 4 M16.65

1 4.1/2 3/16 3.1/4 4 M12.25 4.1/2 9/32 3.1/4 4 M12.30 4.3/4 3/8 3.7/16 4 M16.45 4.3/4 9/16 3.7/16 4 M16.50 4.1/4 9/16 3.1/8 4 M12.50 4.7/8 11/16 3.1/2 4 M16.65

1.1/4 4.3/4 1/4 3.7/16 4 M12.30 4.3/4 5/16 3.7/16 4 M12.40 5.1/4 1/2 3.7/8 4 M16.45 5.1/4 11/16 3.7/8 4 M16.55 4.5/8 5/8 3.1/2 4 M12.55 5.1/4 3/4 3.7/8 4 M16.70

1.1/2 5.1/4 1/4 3.7/8 4 M12.30 5.1/4 11/32 3.7/8 4 M12.40 5.1/2 1/2 4.1/8 4 M16.50 5.1/2 11/16 4.1/8 4 M16.55 5 11/16 3.7/8 4 M12.55 6.1/8 13/16 4.1/2 4 M20.75

2 6 5/16 4.1/2 4 M16.40 6 3/8 4.1/2 4 M16.45 6.1/2 5/8 5 4 M16.55 6.1/2 3/4 5 4 M16.55 6 3/4 4.3/4 4 M16.70 6.1/2 7/8 5 8 M16.75

2.1/2 6.1/2 5/16 5 4 M16.40 6.1/2 13/32 5 4 M16.45 7.1/4 5/8 5.3/4 8 M16.55 7.1/4 3/4 5.3/4 8 M16.65 7 7/8 5.1/2 4 M16.75 7.1/2 1 5.7/8 8 M20.80

3 7.1/4 3/8 5.3/4 4 M16.45 7.1/4 7/16 5.3/4 4 M16.45 8 5/8 6.1/2 8 M16.55 8 7/8 6.1/2 8 M16.70 7.1/2 15/16 6 4 M16.75 8.1/4 1.1/8 6.5/8 8 M20.90

Nominal Bore

4 8.1/2 3/8 7 4 M16.45 8.1/2 1/2 7 8 M16.50 9 3/4 7.1/2 8 M16.65 9 1 7.1/2 8 M16.75 9 15/16 7.1/2 8 M16.75 10 1.1/4 7.7/8 8 M20.95

5 10 1/2 8.1/4 8 M16.50 10 9/16 8.1/4 8 M16.50 11 7/8 9.1/4 8 M20.70 11 1.1/8 9.1/4 8 M20.80 10 15/16 8.1/22 8 M20.80 11 1.3/8 9.1/4 8 M20.100

6 11 1/2 9.1/4 8 M16.50 11 11/16 9.1/4 8 M20.65 12 7/8 10.1/4 12 M20.70 12 1.1/8 10.1/4 12 M20.80 11 1 9.1/2 8 M20.80 12.1/2 1.7/16 10.5/8 12 M20.105

7 12 1/2 10.1/4 8 M16.50 12 3/4 10.1/4 8 M20.65 13.1/4 7/8 11.1/2 12 M20.70 13.1/4 1.1/4 11.1/2 12 M20.90 - - - - - - - - - -

8 13.1/4 1/2 11.1/2 8 M16.50 13.3/4 3/4 11.1/2 8 M20.65 14.1/2 1 12.3/4 12 M20.75 14.1/2 1.1/4 12.3/8 12 M20.90 13.1/2 1.1/8 11.3/4 8 M20.90 15 1.5/8 13 12 M22.105

9 14.1/2 5/8 12.3/4 8 M16.55 14.1/2 13/16 12.3/4 12 M20.70 16 1.1/8 14 12 M22.80 16 1.3/8 14 12 M22.100 - - - - - - - - - -

10 16 5/8 14 8 M20.55 16 7/8 14 12 M20.70 17 1.1/8 15 12 M22.80 17 1.3/8 15 12 M22.100 16 1.3/16 14.1/4 12 M22.95 17.1/2 1.7/8 15.1/4 16 M24.120

12 18 3/4 16 12 M20.65 18 1 16 12 M22.80 19.1/4 1.1/4 17.1/4 16 M22.90 19.1/4 1.5/8 17.1/4 16 M22.105 19 1.1/4 17 12 M22.100 20.1/2 2 17.3/4 16 M27.130

14 20.3/4 7/8 18.1/2 12 M22.70 20.3/4 1.1/8 18.1/2 12 M22.80 21.3/4 1.3/8 19.1/2 16 M24.100 21.3/4 1.7/8 19.1/2 16 M24.120 21 1.3/8 18.3/4 12 M24.105 23 2.1/8 20.1/4 20 M27.140

15 21.3/4 7/8 19.1/2 12 M22.70 21.3/4 1.1/4 19.1/2 12 M22.90 22.3/4 1.1/2 20.1/2 16 M24.105 22.3/4 2 20.1/2 16 M24.130 - - - - - - - - - -

16 22.3/4 7/8 20.1/2 12 M22.70 22.3/4 1.1/4 20.1/2 12 M22.90 24 1.5/8 21.3/4 20 M24.110 24 2.1/8 21.3/4 20 M24.140 23.1/2 1.7/16 21.1/4 16 M24.105 25.1/2 2.1/4 22.1/2 20 M30.150

18 25.1/4 1 23 12 M22.75 25.1/4 1.3/8 23 16 M22.100 26.1/2 1.3/4 24 20 M27.120 26.1/2 2.3/8 24 20 M27.150 25 1.9/16 22.3/4 16 M27.110 28 2.3/8 24.3/4 24 M30.150

20 27.3/4 1.1/8 25.1/4 16 M22.80 27.3/4 1.1/2 25.1/4 16 M22.105 29 2 26.1/2 24 M27.130 29 2.5/8 26.1/2 24 M27.170 27.1/2 1.11/16 25 20 M27.120 30.1/2 2.1/2 27 24 M30.160

24 32.1/2 1.1/4 29.3/4 16 M24.90 32.1/2 1.7/8 29.3/4 16 M27.120 33.1/2 2.1/4 30.3/4 24 M30.150 33.1/2 3 30.3/4 24 M30.200 32 1.7/8 29.1/2 20 M30.120 36 2.3/4 32 24 M36.180

Hex Round Hex (HRH) Bolts

STOKE-ON-TRENT

STOKE-ON-TRENT TRURO Temperature ( C) o To BS4190

Tel: 01782 744333 Tel: 01872 243500 Standard Bolt Sizes

Pressure Ratings

1/2” M12 1” M24

Fax: 01782 744577 Fax: 01872 222191 BS10 Imperial BS1560 ANSI B16.5

5/8” M16 1.1/4” M30

Temperature PSI PSI

LIVERPOOL TAMWORTH 3/4” M20

D E F H 150 300

-10 C to +100 C 100 200 300 500

o o

Tel: 0151 207 2588 Tel: 01827 54324 240 700 . Bolt lengths are approximate for flange - flange duty

o

Fax: 0151 298 1047 Fax: 01827 54325 200 C 100 200 300 500 180 655

assuming one 1/16” gasket and one bolt washer

250 oC 95 185 280 465 - -

THE SIN G L E SOURCE . Flange thicknesses shown are the greater

WREXHAM 300 oC 80 155 235 395 130 555

website: www.fwb.co.uk

www.fwb.co.uk 350 oC 65 130 195 320 - - thickness for that rating

Tel: 01978 720720 . BS10 are available as forged bossed or flat plate

email: enquiries@fwb.co.uk 400 oC 50 100 150 250 100 425

Fax: 01978 720721 flanges as standard

. BS1560 (ANSI B16.5) are normally forged flanges

FLANGE TABLES FOR THE WATER AND CONSTRUCTION INDUSTRIES

PN16 Flanged Joints

PN16 Flanges

Approx. Bolting Torques

O/D of Total Flange Flange Thickness Bolt Hole Details Bolt Size * Using 3mm Thick 80 IRHD Rubber Gaskets

DN Flange Thickness Exc. Raised Face PCD No. Dia. Dia. Length

mm mm mm mm mm mm Approx. Bolting Torque Nm

DN To Seal To Seal To Seal To Seal

80 200 19.0 16.0 160 8 19 M16 65

@ 10 Bar @ 16 Bar @ 20 Bar* @ 25 Bar*

100 220 19.0 16.0 180 8 19 M16 65 80 70 70 75 75

150 285 19.0 16.0 240 8 23 M20 70 100 75 80 80 80

200 340 20.0 17.0 295 12 23 M20 70 150 115 120 125 135

Nominal Size

250 400 22.0 19.0 355 12 28 M24 90 200 110 115 120 130

Nominal Size

300 455 24.5 20.5 410 12 28 M24 90 250 155 165 175 180

350 520 26.5 22.5 470 16 28 M24 90 300 165 180 190 210

400 580 28.0 24.0 525 16 31 M27 100 350 160 175 185 200

450 640 30.0 26.0 585 20 31 M27 100 400 200 220 235 270

500 715 31.5 27.5 650 20 34 M30 110 450 195 215 230 260

600 840 36.0 31.0 770 20 37 M33 120 500 240 270 295 345

* Mild Steel Grade 4.6 BS4190 600 305 365 425 505

* NOTE: The need to seal a flanged joint at pressures greater

than the flange PN rating is only for site hydrostatic test

purposes. Flanged joints should not be operated at these

FWB stocks pre-packed flange sets . Bolt lengths are approximate higher values.

comprising EPDM gaskets supplied . Table dimensions are designed Spanner Sizes for Bolts and Nuts

Used with Flanged Joints

with bolts and nuts in a variety of to connect ductile iron flange to Bolt Size

M16 M20 M24 M27 M30 M33

mm

coatings: Rilsan, Sheraplex, Zinc- ductile iron flange using Spanner Size

24 30 36 41 46 50

plated, Galvanised or Self-Colour 3mm gasket (mm across flats)

STOKE-ON-TRENT

STOKE-ON-TRENT TRURO

Tel: 01782 744333 Tel: 01872 243500 SECOND FIRST

QUADRANT QUADRANT

Fax: 01782 744577 Fax: 01872 222191

FIRST SECOND

LIVERPOOL TAMWORTH QUADRANT QUADRANT

Tel: 0151 207 2588 Tel: 01827 54324

Fax: 0151 298 1047 Fax: 01827 54325

THE SIN G L E SOURCE

WREXHAM website: www.fwb.co.uk

www.fwb.co.uk 4 Bolts 8 Bolts 12 Bolts or More

Tel: 01978 720720 email: enquiries@fwb.co.uk

Fax: 01978 720721

Bolt Tightening Sequence

FLANGE TABLES FOR THE HEATING AND VENTILATING INDUSTRY - BS4504

BS4504 Table 6 BS4504 Table 10 BS4504 Table 16 BS4504 Table 25 BS4504 Table 40 BS4504 Table 64

Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. & Flange Dimensions Dia. &

mm Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length Dia. Thick PCD No. of Length

mm mm mm Holes of Bolts mm mm mm Holes of Bolts mm mm mm Holes of Bolts mm mm mm Holes of Bolts mm mm mm Holes of Bolts mm mm mm Holes of Bolts

15 80 12 55 4 M10.45 95 14 65 4 M12.50 95 14 65 4 M12.50 95 16 65 4 M12.55 95 16 65 4 M12.55 105 20 75 4 M12.70

20 90 14 65 4 M10.50 105 16 75 4 M12.55 105 16 75 4 M12.55 105 18 75 4 M12.65 105 18 75 4 M12.65 130 22 90 4 M16.70

25 100 14 75 4 M10.50 115 16 85 4 M12.55 115 16 85 4 M12.55 115 18 85 4 M12.65 115 18 85 4 M12.65 140 24 100 4 M16.75

32 120 16 90 4 M12.55 140 16 100 4 M16.55 140 16 100 4 M16.55 140 18 100 4 M16.65 140 18 100 4 M16.65 155 24 110 4 M20.75

40 130 16 100 4 M12.55 150 16 110 4 M16.55 150 16 110 4 M16.55 150 20 110 4 M16.70 150 20 110 4 M16.70 170 26 125 4 M20.80

50 140 16 110 4 M12.55 165 18 125 4 M16.65 165 18 125 4 M16.65 165 20 125 4 M16.70 165 20 125 4 M16.70 180 26 135 4 M20.80

65 160 16 130 4 M12.55 185 18 145 4 M16.65 185 18 145 4 M16.65 185 22 145 8 M16.70 185 22 145 8 M16.70 205 26 160 8 M20.80

Nominal Bore

80 190 18 150 4 M16.65 200 20 160 8 M16.70 200 20 160 8 M16.70 200 24 160 8 M16.75 200 24 160 8 M16.75 215 30 170 8 M20.90

100 210 18 170 4 M16.65 220 20 180 8 M16.70 220 20 180 8 M16.70 235 26 190 8 M20.80 235 26 190 8 M20.80 250 32 200 8 M24.90

125 240 20 200 8 M16.70 250 22 210 8 M16.70 250 22 210 8 M16.70 270 28 220 8 M24.80 270 28 220 8 M24.80 295 34 240 8 M27.100

150 265 20 225 8 M16.70 285 22 240 8 M20.70 285 22 240 8 M20.70 300 30 250 8 M24.90 300 30 250 8 M24.90 345 36 280 8 M30.105

175 - - - - - 315 24 270 8 M20.75 315 24 270 8 M20.75 330 28 280 12 M24.80 350 32 295 12 M27.90 375 40 310 12 M30.120

200 320 22 280 8 M16.70 340 24 295 8 M20.75 340 24 295 12 M20.75 360 30 310 12 M24.90 375 34 320 12 M27.90 415 46 345 12 M33.130

250 375 24 335 12 M16.70 395 26 350 12 M20.80 405 26 355 12 M24.80 425 40 370 12 M27.90 450 42 385 12 M30.120 470 54 400 12 M33.150

300 440 24 395 12 M20.70 445 26 400 12 M20.80 460 28 410 12 M24.80 485 38 430 16 M27.110 515 50 450 16 M30.140 530 62 460 16 M33.160

350 490 26 445 12 M20.80 505 28 460 16 M20.80 520 32 470 16 M24.90 555 42 490 16 M30.125 580 55 510 16 M33.150 600 72 525 16 M39.180

400 540 28 495 16 M20.80 565 32 515 16 M24.90 580 36 525 16 M27.100 620 46 550 16 M33.140 660 64 585 16 M36.160 670 78 585 16 M39.200

450 595 30 550 16 M20.90 615 36 565 20 M24.105 640 40 585 20 M27.120 670 52 600 20 M33.140 685 68 610 20 M36.170 - - - - -

500 645 30 600 20 M20.90 670 38 620 20 M24.105 715 44 650 20 M30.125 730 58 660 20 M33.155 755 72 670 20 M39.180 - - - - -

600 755 32 705 20 M24.90 780 42 725 20 M27.120 840 52 770 20 M33.140 845 66 770 20 M36.165 - - - - - - - - -

Metric BS4504 Specification Temperature (oC)

Standard Flange Types . Bolt lengths are approximate for flange -

Pressure Ratings Hex Round Hex (HRH) Bolts

Old Spec. New Spec.

BS4504 Metric flange duty assuming one 1/16” gasket

Temperature

Bar to BS4190 and one bolt washer

Weld Neck 2 111 Standard Bolt Sizes . Flange thicknesses shown are the greater

-10oC to +100 oC 6 10 16 25 40 64

Slip-on-Plate 3 101 o 1/2” M12 1” M24

200 C 4.8 8 12.8 20 32 50 thickness for that rating

Screwed Bossed 4 113 250 oC 4.2 7 11.2 17.5 28 45 5/8” M16 1.1/4” M30

Slip-on-Bossed 5 112 300 oC 3.6 6 9.5 15 24 40 3/4” M20

. BS4504 (Metric) are available as forged,

Blank Plate 8 105 350 oC - - - - - - bossed or plate flanges as standard

o

400 C - - - - - -

Example: 100mm BS4504 Table 16/101

Although every care has been taken to ensure all the information presented in these tables is correct FWB Products Ltd. cannot accept any liability for errors and omissions of any sort.

You might also like

- BS Flange Tables EDocument3 pagesBS Flange Tables ERashedul HasanNo ratings yet

- Flange Drilling StandardDocument4 pagesFlange Drilling StandardNitin Aggarwal100% (1)

- Bolt Pocket ChartDocument2 pagesBolt Pocket ChartAlex LaraNo ratings yet

- Pocket Bolt Reference Chart: Sealing Global - Servicing LocalDocument2 pagesPocket Bolt Reference Chart: Sealing Global - Servicing Localgazwang478No ratings yet

- En 13121-3 Bridas Pn10Document1 pageEn 13121-3 Bridas Pn10Ricardo BustamanteNo ratings yet

- Flange DataDocument14 pagesFlange DataBrant AkkanNo ratings yet

- Enginnering DemandsDocument23 pagesEnginnering Demandswaqas_asad3081No ratings yet

- Fischer FBN AnchorsDocument23 pagesFischer FBN AnchorsIstván SzékelyNo ratings yet

- Tyco Flange Tech DetailsDocument0 pagesTyco Flange Tech DetailsRajesh KanalaNo ratings yet

- Glanding Schedule PeppersDocument6 pagesGlanding Schedule PeppersFreijNo ratings yet

- Spiral Wound Gasket CatalogDocument30 pagesSpiral Wound Gasket Catalogmayur_lanjewarNo ratings yet

- HDP-Victaulic Estilo 995Document4 pagesHDP-Victaulic Estilo 995hugorubenzNo ratings yet

- Flange DimensionsDocument7 pagesFlange DimensionsDave DonohueNo ratings yet

- ChumaceraDocument42 pagesChumaceraJoseth Revilla OchoaNo ratings yet

- Grease Fitting PDFDocument20 pagesGrease Fitting PDFleonardsiregarNo ratings yet

- UCP 213 Y UCP 215 - FYHcat3300 PDFDocument1 pageUCP 213 Y UCP 215 - FYHcat3300 PDFFranz Alex Fernandez CeronNo ratings yet

- Tico Pipe GripsDocument4 pagesTico Pipe GripsBilel MarkosNo ratings yet

- Goodwin BFRDocument2 pagesGoodwin BFRHamdzan As'atNo ratings yet

- SW 05Document5 pagesSW 05LLNo ratings yet

- Keystone: The Figure 320 Is An Economical Resilient Seated Butterfly Valve With Dimensions According ISO StandardsDocument4 pagesKeystone: The Figure 320 Is An Economical Resilient Seated Butterfly Valve With Dimensions According ISO StandardsteacgNo ratings yet

- ANSI B16.5 FlangesDocument24 pagesANSI B16.5 Flangesgateauxboy100% (2)

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- Forged Stainless AlloyDocument8 pagesForged Stainless AlloymsajanjNo ratings yet

- Metric Section BDocument26 pagesMetric Section BniladriprasadrNo ratings yet

- Electrical Cable PriceDocument9 pagesElectrical Cable PriceDayo DweezyNo ratings yet

- 11 05 2011 Tcid Ebara ItalyDocument5 pages11 05 2011 Tcid Ebara ItalyMinh NguyenNo ratings yet

- Katalog 2011Document68 pagesKatalog 2011Aziz ELNo ratings yet

- Galvanised Malleable Iron Pipe FittingDocument19 pagesGalvanised Malleable Iron Pipe FittingMichael SommerNo ratings yet

- MM Pipe O.DDocument11 pagesMM Pipe O.DVimin PrakashNo ratings yet

- Febolt: Hexagon Covernut Type "Febolt"Document1 pageFebolt: Hexagon Covernut Type "Febolt"Tuntun TatNo ratings yet

- Camperfiladas Asme 16 5Document8 pagesCamperfiladas Asme 16 5klara23No ratings yet

- Dimensions and TolerancesDocument18 pagesDimensions and TolerancesRubem Da Silva CerqueiraNo ratings yet

- Cooper Bearing - PartsDocument20 pagesCooper Bearing - PartsAndrei Krivda100% (1)

- Flange Dimensions (ANSI)Document3 pagesFlange Dimensions (ANSI)sergesxNo ratings yet

- Ansi B 16 2500 PDFDocument1 pageAnsi B 16 2500 PDFdzat_sudrazatNo ratings yet

- Swagwlok Lap Flange PDFDocument6 pagesSwagwlok Lap Flange PDFPraveen KumarNo ratings yet

- Assembly Drawing Example A0002Document1 pageAssembly Drawing Example A0002Dudeboy Nautic100% (1)

- SKF Bearing Fitting Tool TMFT 33Document2 pagesSKF Bearing Fitting Tool TMFT 33Nang Dapi100% (1)

- Rigid Pipe Covering (K450) : With Extr A Rig IDDocument6 pagesRigid Pipe Covering (K450) : With Extr A Rig IDraguhvacind4620No ratings yet

- 37° Tube Fittings: Instrumentation SolutionsDocument9 pages37° Tube Fittings: Instrumentation SolutionsNilesh MistryNo ratings yet

- Catalogo Industrial PDFDocument25 pagesCatalogo Industrial PDFJosé Luis Onofre CiriacoNo ratings yet

- ANSI 2500 Tech DataDocument1 pageANSI 2500 Tech DatajaisonvasNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- 5 Pipe FittingsDocument100 pages5 Pipe FittingsHaroon GhaniNo ratings yet

- Next Generation: Ultragrip Reducing CouplingsDocument1 pageNext Generation: Ultragrip Reducing CouplingsblindjaxxNo ratings yet

- Pipe Dimension Tables:: This Worksheet Has Data Ranges That Are Copied To Other Workbooks by MacrosDocument25 pagesPipe Dimension Tables:: This Worksheet Has Data Ranges That Are Copied To Other Workbooks by MacrosStory LoveNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- Steel Pipes - Pipe Schedule Chart: NPS Inches N.D. O.D. MMDocument2 pagesSteel Pipes - Pipe Schedule Chart: NPS Inches N.D. O.D. MMHanif MalekNo ratings yet

- Kennametal Feed Speed 3Document12 pagesKennametal Feed Speed 3absalon_jarvNo ratings yet

- PCBDocument26 pagesPCBdavideosto3560No ratings yet

- InoxDocument19 pagesInoxvalla_67No ratings yet

- SpectableBlinds Catalog SingleBlindsSpacersDocument10 pagesSpectableBlinds Catalog SingleBlindsSpacersMohd Hisyamuddin Mohd AminudinNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Idoc - Pub Medical Check Up FormDocument4 pagesIdoc - Pub Medical Check Up FormBobly SweaggerNo ratings yet

- Differential AnalysisDocument26 pagesDifferential AnalysisEdma Glory MacadaagNo ratings yet

- Chapter 1 Cell StructureDocument195 pagesChapter 1 Cell StructureVersha 2021100% (1)

- Howo SCR Tenneco. ManualDocument42 pagesHowo SCR Tenneco. Manualulyssescurimao1No ratings yet

- JLG Skytrak Telehandler 6042 Operation Service Parts ManualsDocument22 pagesJLG Skytrak Telehandler 6042 Operation Service Parts Manualschristyross211089ntz100% (133)

- What Is Research: Presented By: Anam Nawaz CheemaDocument13 pagesWhat Is Research: Presented By: Anam Nawaz CheemamahiftiNo ratings yet

- Introduction Manual: 30000mah Type-C Power BankDocument33 pagesIntroduction Manual: 30000mah Type-C Power BankIreneusz SzymanskiNo ratings yet

- UG190239 - Avaneesh NatarajaDocument21 pagesUG190239 - Avaneesh NatarajaAvaneesh NatarajaNo ratings yet

- Brosur HP Designjet Z5400 PDFDocument2 pagesBrosur HP Designjet Z5400 PDFMustamin TajuddinNo ratings yet

- CoveringlettersDocument45 pagesCoveringlettersbeautygirl3310No ratings yet

- Tutima Catalog 2020-1Document112 pagesTutima Catalog 2020-1lpstutterheimNo ratings yet

- ADAU1701Document12 pagesADAU1701onafetsNo ratings yet

- Simcnc Python Scripts Guide enDocument53 pagesSimcnc Python Scripts Guide enÁron SzárazNo ratings yet

- Form AK - Additional PageDocument3 pagesForm AK - Additional PagekatacumiNo ratings yet

- IPC Lab 9Document12 pagesIPC Lab 9abdullah1996No ratings yet

- 1975 - Shen - Science Literacy PDFDocument5 pages1975 - Shen - Science Literacy PDFRoberta Proença0% (1)

- Sergey Kojoian Graph Theory NotesDocument11 pagesSergey Kojoian Graph Theory NotesSergey KojoianNo ratings yet

- MEC Activities TimelineDocument13 pagesMEC Activities TimelineFranz Xavier GarciaNo ratings yet

- Saltwater Aquarium Guide: What's The Difference Between Saltwater and Freshwater? WhereasDocument10 pagesSaltwater Aquarium Guide: What's The Difference Between Saltwater and Freshwater? WhereasTimmy HendoNo ratings yet

- 9ER1 Question BookletDocument16 pages9ER1 Question BookletCSC TylerNo ratings yet

- Imagining The Other: Amazons and Ethnicity in Fifth-Century AthensDocument28 pagesImagining The Other: Amazons and Ethnicity in Fifth-Century Athensruja_popova1178100% (1)

- B 03 01 Operation Guide Parameters Material ManagementDocument12 pagesB 03 01 Operation Guide Parameters Material ManagementCdcArduino ArduinoNo ratings yet

- Theories of MotivationDocument8 pagesTheories of MotivationIrtaqa RazaNo ratings yet

- Ishida Checkweigher Scotraco PDFDocument6 pagesIshida Checkweigher Scotraco PDFchrissNo ratings yet

- Goulish, Matthew - 39 Microlectures in Proximity of PerformanceDocument225 pagesGoulish, Matthew - 39 Microlectures in Proximity of PerformanceBen Zucker100% (2)

- Imaginefx How To Draw and Paint Anatomy Volume 2Document116 pagesImaginefx How To Draw and Paint Anatomy Volume 2tofupastaNo ratings yet

- KATO Design Manual HighDocument98 pagesKATO Design Manual HighJai Bhandari100% (1)

- Acoustic Laster Final-1Document15 pagesAcoustic Laster Final-1Aisha SadiNo ratings yet

- Guidelines Adhd AdultDocument19 pagesGuidelines Adhd AdultJavier Cotobal100% (1)

- N384518, DW616 RouterDocument7 pagesN384518, DW616 RouterOswaldo Diaz NievesNo ratings yet