Professional Documents

Culture Documents

Koomey Unit 53 Items A3

Koomey Unit 53 Items A3

Uploaded by

أحمد إبراهيم شواربOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Koomey Unit 53 Items A3

Koomey Unit 53 Items A3

Uploaded by

أحمد إبراهيم شواربCopyright:

Available Formats

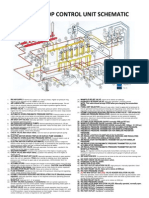

TYPICAL BOP CONTROL UNIT SCHEMATIC

1. RIG AIR SUPPLY: Normal air supply is at 125 psi (9 bar). Higher air pressure may 24. MANIFOLD RELIEF VALVE: Valve set to relieve at 5,500 psi.

require an air regulator for No. 88660 air pumps. 25. HYDRAULIC BLEEDER VALVE: Manually operated – normally closed.

2. AIR LUBRICATOR: Located on the air inlet line to the air operated pumps. The oil- NOTE. This valve should be kept OPEN when pre-charging the accumulator

mist in the air ensures internal lubrication and helps to protects against internal bottles.

corrosion. Use SAE 10 lubricating oil. 26. PANEL-UNIT SELECTOR: Manual 3-way valve. Used to apply pilot air pressure to

3. BYPASS VALVE: To automatic hydro-pneumatic pressure switch. When pressures the air operated Koomey pressure reducing and regulating valve, either from the air

higher than the normal 3,000 psi (207 bar) are required, open this valve. Keep closed regulator on the unit or from the air regulator on the remote control panel.

at all other times. 27. KOOMEY PRESSURE REDUCING AND REGULATING VALVE – AIR OPERATED

4. AUTOMATIC HYDRO-PNEUMATIC PRESSURE SWITCH: Pressure switch is set at (ANNULAR PRESSURE REGULATOR): Reduces the accumulator pressure to the

2,900 (200 bar) psi cut-out when air and electric pumps are used. Otherwise set at required annular BOP operating pressure. Pressure ran be varied for stripping

3,000 psi (207 bar) for air pumps alone. Adjustable spring tension control. operations. Maximum recommended operating pressure of the annular preventer

5. AIR SHUT-OFF VALVES: Manually operated – to open or close the air supply to the should not be exceeded.

air operated hydraulic pumps. 28. ACCUMULATQR PRESSURE GAUGE (normally 3000 psi/207 bar)

6. AIR OPERATED HYDRAULIC PUMPS: Normal operating air pressure is 125 psi. 29. MANIFOLD PRESSURE GAUGE (normally 1500 psi/103 bar)

7. SUCTION SHUT-OFF VALVE: Manually operated. Keep normally open. One for each 30. ANNULAR PREVENTER PRESSURE GAUGE (normally 600–1500psi / 41-103 bar)

air operated hydraulic pump suction line. 31. PNEUMATIC PRESSURE TRANSMITTER FOR ACCUMULATOR PRESSURE.

8. SUCTION STRAINER: One for each air operated hydraulic pump suction line. Has 32. PNEUMATIC PRESSURE TRANSMITTER FOR MANIFOLD PRESSURE.

removable screens. Clean every 30 days. 33. PNEUMATIC PRESSURE TRANSMITTER FOR ANNULAR PREVENTER

9. CHECK VALVE (Non-return valve) : One for each air operated hydraulic pump PRESSURE

delivery line. 34. AIR FILTER : Located on the supply line to the air regulators.

10. ELECTRIC MOTOR DRIVEN TRIPLEX OR DUPLEX PUMP ASSEMBLY. 35. AIR REGULATOR FOR KOOMEY PRESSURE REDUCING AND REGULATING

11. AUTOMATIC HYDRO-ELECTRIC PRESSURE SWITCH: Pressure switch is set at VALVE – AIR OPERATED (ANNULAR REGULATOR)

3,000 psi cut-out and 250 psi (18 bar) cut in differential. Adjustable. 36. AIR REGULATOR FOR PNEUMATIC TRANSMITTER (33) FOR ANNULAR

12. ELECTRIC MOTOR STARTER (AUTOMATIC): Automatically starts or stops the PRESSURE.

electric motor driving the triplex or duplex pump. Is controlled by the automatic hydro- 37. AIR REGULATOR FOR PNEUMATIC PRESSURE TRANSMlTTER (31) FOR

electric pressure switch and has a manual overriding on-off switch. ACCUMULATOR PRESSURE.

13. SUCTION SHUT-OFF VALVE: Manually operated, normally open. Located in the 38. AIR REGULATOR FOR PNEUMATIC PRESSURE TRANSMlTTER (32) FOR

suction line of the triplex or duplex pump. MANIFOLD PRESSURE.

14. SUCTION STRAINER: Located in the suction line of the triplex or duplex pump. NOTE. Air regulator controls for pneumatic transmitters normally set at 15 psi.

15. CHECK VALVE (Non-return valve): Located in the delivery line of the triplex or Increase or decrease air pressure to calibrate panel gauge to hydraulic pressure

duplex pump. gauge on unit.

16. ACCUMULATOR SHUT-OFF VALVE: Manually operated. Normally in open position 39. AIR JUNCTION BOX: To connect the air lines on the unit to the air lines coming from

when the unit is in operation. Close when testing or skidding rig or when applying the remote control panels through air cable.

pressure over 3,000 psi to open side of ram preventers. OPEN WHEN TEST IS 40. RIG TEST CHECK VALVE (non-return valve).

COMPLETED. 41. HYDRAUUC FLUID FILL PORT.

17. ACCUMULATORS: Check nitrogen pre-charge in accumulator system every 30 days. 42. INSPECTION PLUG PORT.

Nitrogen pre-charge should be 1000 psi ± 10 % (69 bar). CAUTION. Use NITROGEN 43. RIG TEST OUTLET ISOLATION VALVE: High pressure, manually operated. Close

when adding to pre-charge. Other gasses and air may cause fire and/or explosion. when rig testing – open when test is complete.

18. ACCUMULATOR RELIEF VALVE: Valve set to relieve at 3,500 psi. 44. RIG TEST RELIEF VALVE: Valve set to relieve at 6500 psi.

19. FLUID STRAINER: Located on the inlet side of the pressure reducing and regulating 45. RIG TEST PRESSURE GAUGE

valves. Clean strainer every 30 days. 46. [A] RIG SKID OUTLET and [46B]. VALVE HEADER ISOLATION VALVES:

20. KOOMEY PRESSURE REDUCING AND REGULATING VALVE (Manifold pressure Manually operated. Close valve header isolator valve and open rig skid isolator valve

regulator): Manually operated. Adjust to the required continuous operating pressure when rig skidding. Open value header isolator valve and close rig skid isolator valve

of ram type BOP's. during normal drilling operations.

21. MANIFOLD: 5000 psi W.P., 2" all welded. 47. RIG SKID RELIEF VALVE : Valve set to relieve at 2500 psi.

22. 3/4-WAY VALVES (3 positions, 4 connections): With air cylinder operators for 48. RIG SKID PRESSURE GAUGE.

remote operation from the control panels. Keep in standard operating mode (open or 49. ACCUMULATOR BANK ISOLATION VALVES: Manually operated, normally open.

close), NEVER IN CENTER (block) POSITION. 50. RIG SKID RETURN: Customer's connection.

23. BYPASS VALVE: With air cylinder operator for remote operation from the control 51. RIG SKID OUTLET: Customer's connection.

panels. In CLOSE position. it puts regulated pressure on main value header (21), and 52. ELECTRIC POWER: Customer's connection.

in OPEN position, it puts full pump pressure on that header. Keep in CLOSE position 53. RIG TEST OUTLET: Customer’s connection.

unless 3,000 psi (or more) is required on ram type BOP's.

You might also like

- BOP TL Operation and Maintenance ManualDocument22 pagesBOP TL Operation and Maintenance Manualadvantage02580% (5)

- Baker CAC 1984-1985 CatalogDocument452 pagesBaker CAC 1984-1985 CatalogBruce87% (15)

- Koomey Unit ManuelDocument108 pagesKoomey Unit ManuelLakshmi Kishore100% (2)

- Wind Tunnel Lab ReportDocument5 pagesWind Tunnel Lab Reportmuaz_ds100% (3)

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīNo ratings yet

- Koomey Unit-53 Items - A3Document1 pageKoomey Unit-53 Items - A3Jayaprakash Gopala Kamath83% (6)

- Drilling Data Handbook 9th EditionDocument4 pagesDrilling Data Handbook 9th Editiondedete50% (2)

- Bop Anular T-90Document2 pagesBop Anular T-90EDUARROCHANo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Of Mixing For: Derivation Chatelier's Rde FlammableDocument6 pagesOf Mixing For: Derivation Chatelier's Rde FlammableSteve WanNo ratings yet

- BOP 2006 E-CatalogDocument32 pagesBOP 2006 E-Catalogwoodiehed903950% (2)

- Bop Drawing TemplateDocument65 pagesBop Drawing TemplateMohd AmaniNo ratings yet

- API Spec 4E App B PDFDocument3 pagesAPI Spec 4E App B PDFeochiufpic100% (1)

- HydrilDocument46 pagesHydrilAdolfo AnguloNo ratings yet

- Manual Spider Varco 750Document38 pagesManual Spider Varco 750JAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Burn BodyDocument32 pagesBurn BodyMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Twin Pumping Unit 600 HP Press PDFDocument2 pagesTwin Pumping Unit 600 HP Press PDFDidin Delgado100% (1)

- 13-5m Annular Bop Operation ManualDocument20 pages13-5m Annular Bop Operation ManualJaime Yovany Rodriguez100% (1)

- BOP and AccumulatorDocument8 pagesBOP and AccumulatorFani Purnama HasanNo ratings yet

- Mud Gas Separator CalculationDocument16 pagesMud Gas Separator CalculationErwin Gomop-as100% (2)

- Manual F 1300 1600Document71 pagesManual F 1300 1600Camilo Sanchez VanegasNo ratings yet

- Cameron Catalog 2006 020819 PDFDocument162 pagesCameron Catalog 2006 020819 PDFTitanBOP100% (1)

- Type U & Um Bop Replacement Parts CatalogDocument64 pagesType U & Um Bop Replacement Parts Catalogjuan morales100% (2)

- Part 5 HeatDocument25 pagesPart 5 Heatأحمد إبراهيم شواربNo ratings yet

- Process Engineering StandardsDocument8 pagesProcess Engineering Standardssal143100% (1)

- Degasser Manual DM 002 Rev3 VAKDocument21 pagesDegasser Manual DM 002 Rev3 VAKcorsini999100% (1)

- 2016.06.20 GNZYQ Poor Boy Degasser ManualDocument14 pages2016.06.20 GNZYQ Poor Boy Degasser ManualGeorge100% (2)

- Choke Manifold ManualDocument34 pagesChoke Manifold ManualAlex RamirezNo ratings yet

- Flow Head: Drill Stem Testing Christmas TreeDocument22 pagesFlow Head: Drill Stem Testing Christmas TreeMahmoud Ahmed Ali AbdelrazikNo ratings yet

- API Rp53 RecommendationsDocument2 pagesAPI Rp53 Recommendationseight minutes100% (1)

- Sprint CTU ContigencyPlanDocument32 pagesSprint CTU ContigencyPlanJawad Khan100% (1)

- Well Control EquipmentDocument8 pagesWell Control Equipmentyamid muñozNo ratings yet

- Access - Air Kelly Spinner Manual PDFDocument9 pagesAccess - Air Kelly Spinner Manual PDFadjoudj100% (1)

- Super Choke BasicsDocument10 pagesSuper Choke Basicsel_guariquenoNo ratings yet

- Manual - Remote Control Console PDFDocument34 pagesManual - Remote Control Console PDFMehdi Hajd Kacem0% (1)

- MANNUL of Double Ram BOP Cameron Type UDocument44 pagesMANNUL of Double Ram BOP Cameron Type URaouf Rasmy ShalabyNo ratings yet

- Preventive Maintenance Program For Spherical Blowout PreventerDocument19 pagesPreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts List Southwest 8490-25alew Fluid End For Lewco Wh-2214Document12 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts List Southwest 8490-25alew Fluid End For Lewco Wh-2214Alejandro AlejandreNo ratings yet

- Jereh Wellhead EquipmentDocument25 pagesJereh Wellhead EquipmentYaroslav RuizNo ratings yet

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 pagesTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanNo ratings yet

- API 16C Choke and KillDocument26 pagesAPI 16C Choke and Killrps197750% (2)

- Information From The Api RP 53Document1 pageInformation From The Api RP 53فؤاد ابوزيدNo ratings yet

- 1604 FZ35-35U FZ35-70U闸板防喷器 用户手册A1 英文Document40 pages1604 FZ35-35U FZ35-70U闸板防喷器 用户手册A1 英文Jaya Manggala SaktiNo ratings yet

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro100% (3)

- Ram BOP Manual BookDocument28 pagesRam BOP Manual BookIgor Ungur100% (2)

- Rong Sheng PDFDocument45 pagesRong Sheng PDFHendri YantoNo ratings yet

- BOP Catalog vFEB20152 PDFDocument36 pagesBOP Catalog vFEB20152 PDFMadirley Pimenta100% (1)

- CAD Product Brouchure 2010Document11 pagesCAD Product Brouchure 2010jlmunozvNo ratings yet

- Managed Pressure Drilling (MPD) Choke Manifold: Field Installation and Operation ManualDocument40 pagesManaged Pressure Drilling (MPD) Choke Manifold: Field Installation and Operation ManualЕТМ100% (3)

- Gardener Denver PZ8 SpecsDocument2 pagesGardener Denver PZ8 SpecsExpertum99No ratings yet

- (Equip (Accumulator)Document34 pages(Equip (Accumulator)Nagendra Singh Ranawat100% (4)

- Accumulator Draw Down TestDocument8 pagesAccumulator Draw Down Testadeelsn100% (4)

- Crown Mounted Compensator - CMC 2500-1000-25 PDFDocument1 pageCrown Mounted Compensator - CMC 2500-1000-25 PDFMarcos SobreiroNo ratings yet

- Sucker Rod InspectionDocument1 pageSucker Rod InspectionkhalilNo ratings yet

- Manual Hydrill K20-5000Document16 pagesManual Hydrill K20-5000IgorCencič100% (3)

- API RP 16E Control Systems For Drilling Well Control EquipmentDocument31 pagesAPI RP 16E Control Systems For Drilling Well Control EquipmentRashid GhaniNo ratings yet

- Araña BJ 350 Ton 13 3-8Document60 pagesAraña BJ 350 Ton 13 3-8ceciliachableNo ratings yet

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalheNo ratings yet

- KoomeyDocument13 pagesKoomeyDennyVAnggaraNo ratings yet

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Document9 pagesFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannNo ratings yet

- Accumulator and BOP Control Unit5 - Aly2Document65 pagesAccumulator and BOP Control Unit5 - Aly2Khaled Yazid100% (1)

- Part 10 HeatDocument16 pagesPart 10 Heatأحمد إبراهيم شواربNo ratings yet

- Part 9 HeatDocument27 pagesPart 9 Heatأحمد إبراهيم شواربNo ratings yet

- Sheet Ch2 طاقةDocument3 pagesSheet Ch2 طاقةأحمد إبراهيم شواربNo ratings yet

- Principles of Energy ConversionDocument12 pagesPrinciples of Energy Conversionأحمد إبراهيم شواربNo ratings yet

- Methods of Analysis: NPTEL, IIT Kharagpur, Prof. Gargi Das, Department of Chemical EngineeringDocument3 pagesMethods of Analysis: NPTEL, IIT Kharagpur, Prof. Gargi Das, Department of Chemical Engineeringأحمد إبراهيم شواربNo ratings yet

- Homogeneous Flow ModelDocument4 pagesHomogeneous Flow Modelأحمد إبراهيم شواربNo ratings yet

- Homogeneous Flow Model: NPTEL, IIT Kharagpur, Prof. Gargi Das, Department of Chemical EngineeringDocument5 pagesHomogeneous Flow Model: NPTEL, IIT Kharagpur, Prof. Gargi Das, Department of Chemical Engineeringأحمد إبراهيم شواربNo ratings yet

- Steam Type Questions PDFDocument21 pagesSteam Type Questions PDFأحمد إبراهيم شواربNo ratings yet

- Pick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct AnswersDocument4 pagesPick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct Answersأحمد إبراهيم شواربNo ratings yet

- gg250 Lab 10 PPTDocument15 pagesgg250 Lab 10 PPTأحمد إبراهيم شواربNo ratings yet

- Pick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct AnswersDocument6 pagesPick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct Answersأحمد إبراهيم شواربNo ratings yet

- Pick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct AnswersDocument9 pagesPick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct Answersأحمد إبراهيم شواربNo ratings yet

- DR17 HDPE Friction Loss Table PDFDocument1 pageDR17 HDPE Friction Loss Table PDFBinar KusumahNo ratings yet

- 7th Sem - Seminar ListlDocument2 pages7th Sem - Seminar ListlParth PatelNo ratings yet

- Clean Coal Initiatives of Bhel: Conference On Clean Coal and Carbon Capture and Storage TechnologiesDocument51 pagesClean Coal Initiatives of Bhel: Conference On Clean Coal and Carbon Capture and Storage TechnologiessvvsnrajuNo ratings yet

- Social ScinnceDocument3 pagesSocial ScinnceRajkaran brarNo ratings yet

- KompresibilitasDocument16 pagesKompresibilitasDebbie NovalinaNo ratings yet

- Pump TypesDocument5 pagesPump TypesJayanth VarmaNo ratings yet

- Chapter 2Document33 pagesChapter 2mtas97No ratings yet

- Hydrogen Safety Aspects Related To High Pressure PDocument9 pagesHydrogen Safety Aspects Related To High Pressure PSannidi ShettyNo ratings yet

- MRF-140CG Magneto-Rheological Fluid: Lord Technical Data Lord Technical DataDocument2 pagesMRF-140CG Magneto-Rheological Fluid: Lord Technical Data Lord Technical Dataalexander fetisovNo ratings yet

- 4.0 Floor Standing Mount Hydronic TGF-W R32 18,000-36,000BTUH 5.3-10.6kW 1.5-3TRDocument4 pages4.0 Floor Standing Mount Hydronic TGF-W R32 18,000-36,000BTUH 5.3-10.6kW 1.5-3TRMoeenulHaqueNo ratings yet

- Crest (2005) 35 515-569Document56 pagesCrest (2005) 35 515-569montblankiNo ratings yet

- Sedimentation CE4305Document117 pagesSedimentation CE4305Jeezan AzikNo ratings yet

- Control ValvesDocument23 pagesControl ValvesAndriy IshchenkoNo ratings yet

- Heat Pipe DemonstratorDocument1 pageHeat Pipe DemonstratorBalRam DhimanNo ratings yet

- Application Engineering BulletinDocument15 pagesApplication Engineering BulletinJose VidalNo ratings yet

- Wind Load2Document1 pageWind Load2Waqar FaziNo ratings yet

- Shallow Well Jet Pumps: PrimingDocument2 pagesShallow Well Jet Pumps: PrimingShahjad AlamNo ratings yet

- MLVSS / MLSS Ratio's Standard Value Obtained From Different Aeration Tank Samples of Different Capacity Sewage Treatment Plant - A Case StudyDocument5 pagesMLVSS / MLSS Ratio's Standard Value Obtained From Different Aeration Tank Samples of Different Capacity Sewage Treatment Plant - A Case StudyRanadive AnanthNo ratings yet

- HT1600 Heat Treatment Presentation - Trueline Vostok PDFDocument19 pagesHT1600 Heat Treatment Presentation - Trueline Vostok PDFdocumentation5070No ratings yet

- AMRUT PH - II PROGRESS 18-06-2019Document96 pagesAMRUT PH - II PROGRESS 18-06-2019Deekshit ReddyNo ratings yet

- TVL Smaw11 Q1 M 3Document10 pagesTVL Smaw11 Q1 M 3Earl Christian BonaobraNo ratings yet

- Boundary Layer ThicknessDocument23 pagesBoundary Layer ThicknessPridhar ThiagarajanNo ratings yet

- Steam BoilerDocument148 pagesSteam BoilerDinesh MechNo ratings yet

- WORKSHEET 3 (June 2019)Document5 pagesWORKSHEET 3 (June 2019)imranNo ratings yet

- TDS Total Dacnis-Se-46 1KV 202008 enDocument1 pageTDS Total Dacnis-Se-46 1KV 202008 enHendra KosasihNo ratings yet

- Mad Dog HIPO Preliminary Lessons Learned PDFDocument4 pagesMad Dog HIPO Preliminary Lessons Learned PDFbehnazrzNo ratings yet

- Ejemplo 51 Calculo FEM Con AdinaDocument20 pagesEjemplo 51 Calculo FEM Con AdinaJorge Gustavo HilgenbergNo ratings yet