Professional Documents

Culture Documents

Of Mixing For: Derivation Chatelier's Rde Flammable

Uploaded by

Steve WanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Of Mixing For: Derivation Chatelier's Rde Flammable

Uploaded by

Steve WanCopyright:

Available Formats

Derivation of Le Chatelier’s Mixing

Rde for Flammable Limits

Chad V. Mashuga and DanielA. Crow1

Department of Chemical Engineering, Michigan Technological University, 1400 Townsend Drive, Houghton, MI 49931

In 1891 Le Chatelier [6]firstpro osed an empirical The narrower tube was graduated into thousandths of

mixing rulefor predicting theflamma tfle limit of leanfiel the total volume.

air mixtures - this method is still wide4 used today. This Le Chatelier mixed gases in this tube assembly by

first filling the tube with water and then holding the

paper presents a proof to Le Chatelierj mixing rule based tube upright under water and carefully bubbling the

on thermodynamics. A number of assumptions are required gases through the water into the open end of the

to produce theproof These assumptions are tube. The gas volume was measured using the narrow

Theproduct beat ca acittes are constant.

8

The number ofmo s ofgas is constant.

The combustion kinetics of the pure species are

tube and was done at atmospheric pressure by align-

ing the water levels inside and outside of the tube. L e

Chatelier then placed his finger over the open end of

inde endent and unchanged by the presence of other

f

com ustible species.

The adzabatic tem erature rise a t theflamma-

the tube and vigorously shook the tube for several

seconds to mix the gases.

To ignite the gases, the tube was quickly inverted

bilz limit is the samebr all s ecies. and the water within the tube was allowed to drain to

g e s e assumptions werehund to be reasonably the bottom. His thumb was then removed, and a small

valid a t the lower flammability limit and less so at match or flame was brought into the vicinity of the

the u perjlammability limit.

dis paper also considers experimental data that

support some of the assumptions made to arrive a t the

opening. A mixture was considered flammable if the

flame descended to the bottom of the test tube.

. Le Chatelier used methane and illuminating gas to

Le Chatelier mixing equation. prove Equation (11, although only 3 data points were

used.

INTRODUCTION This procedure has many drawbacks, although it

Le Chatelier [61 first proposed the following empiri- was undoubtedly innovative during Le Chatelier’s

cal mixing rule for predicting the flammable limit of time. First, the method determines only the downward

lean fuel air mixtures, propagating flammability limit, since the flame must

burn downward within the tube. The downward

1 lower limits are typically higher than limits obtained

LFL,,,, =

v A for combustion propagating upward. Second, the

gases are clearly saturated with water, which may

% LFL, have an effect on the flammability limits.

where yi is the mole fraction of the ifhcomponent Le Chatelier continued his combustion studies and in

considering only the combustible species, and LFL, is 1898 published a more detailed study (Le Chatelier and

the lower or lean flammable limit of the ith component Boudouard, [71) involving the flammability limits of 31

in volume percent. Algebraically, L e Chatelier’s species. These studies used a 21 liter flask and were

method states that the mixture flammability limit has a designed to study the flammability of species that are

value between the maximum and minimum of the normally liquid at room temperature. Le Chatelier con-

pure component flammability limits. cluded that, for most of the species tested, the heat pro-

Le Chatelier arrived at his mixture rule from his duced by the combustion of one molecular volume of

experiments with methane and other lower hydrocar- the mixture at the lower flammability limit is between 9

bons. He used a specially designed glass tube to mix and 13 cal, with most values between 12 and 13 cal. The

the gases. This tube was 30 mm in diameter and 300 lower flammability limit for most species is typically less

mm long with one open end narrowing to 20 mm so than lo%, so the mixture is composed mostly of air.

that it could be closed with one’s thumb. Connected Thus, Le Chatelier’s result implies that, assuming con-

to the other end of the main tube was a much narrow- stant heat capacity and constant moles, these species

combust at approximatelyequal flame temperatures.

er tube with a diameter of 10 mm and 250 mm 10%.

112 Summer 2000 Process Safety Progress (Vol. 19, N0.2)

Burgess and Wheeler [ll multiplied the lower flam- Consider a mixture of gas that is initially unburned.

mability limit (mole %) by the calorific value Assume that the gas combusts adiabatically at constant

(kcal/mole) to obtain a constant of about 1100 for pressure to its final burned state. From a total energy

most fuels. This also implies that the lean limits have balance with constant pressure the adiabatic process

the same final flame temperature. Egerton and Powl- is represented as,

ing [31 correlated the lower limit of combustion AH=O (4)

against the net molar heat of combustion, further rein-

forcing the concept of an approximate final flame where His the total enthalpy. Enthalpy is a state func-

temperature. tion. Thus, an adiabatic constant pressure reaction can

Recently Stull [131, Hansel et al. [51, Melhem [ill, be represented by two steps. First an isothermal, con-

Crow1 and Mashuga [lo1 used the constant final flame stant pressure reaction and second, a constant pres-

temperature approach to predict flammable limits. sure heating of the reaction products up to the final

This approach assumes a constant calculated adiabatic temperature of the adiabatic reaction. For the net

flame temperature (CAFT) threshold. Mixtures with process it follows that,

calculated adiabatic flame temperatures higher than

this value are considered flammable while those AH = AHc + AH, = ncAhc+ n,Ah, = 0 (5)

lower are considered non-flammable.

Other early contributors to experimental evidence where AH, is the total enthalpy change of the com-

include Eitner [41 and Coward et al. [21. With these bustion reaction at the initial temperature, AHp is the

data it was difficult to verify Le Chatelier’s mixing rule enthalpy change due to the heating of the products,

since experiments were unreliable and the criteria for n, is the total number of combustible moles, Ah, is

flammability had not yet been properly defined and the enthalpy change of the combustion per mole, n is

agreed upon. The upper flammable limits were even the number of product moles, and Ahp is the enthaby

more unreliable due to the small apparatus and type change due to the heating of the products per mole.

of ignition sources used. Coward et al. [21 was the first The energy required to heat the products to its final

to attempt an examination of the applicability of L e adiabatic temperature is found by,

Chatelier’s rule to both the lower and upper flamma- Tad

ble limits. Ah, = J C r d d T (6)

More recently Liekhus et al. [91, and others have

TI

compared experimental results to Le Chatelier’s pre-

diction with some success. where CpProd is the heat capacity of the product gas

Le Chatelier’s empirical mixing rule is still used mixture, TI is the initial temperature, and Tadis the

extensively today for predicting the lean fuel limits. final adiabatic flame temperature. If the heat capacity

This paper presents a proof of the validity of L e of equation [61 is considered constant then,

Chatelier’s mixing rule based on thermodynamics and

lists the assumptions and determines the applicability Ah, = C,AT (7)

of the method.

where C ’ is the constant heat capacity and ATis the

adiabatic temperature change. Combining equations

THEORY (5) and (7) results in the following ratio,

Lower FlammabilityLimit

Le Chatelier’s rule can be derived quite quickly

from the results of Le Chatelier and Boudouard [71 and

Burgess and Wheeler 111. If the fraction of the total Assume that the number of moles is constant dur-

heat release by species i is given by ing the combustion, i.e. the initial and final moles are

yi constant. This assumption is written,

(2)

LFL, np s nT (9)

where y, is the mole fraction of gas on a combustible where +is the total number of moles. Then by com-

basis only, and LFL, is the lower flammability limit. If bining equations (8) and (9) results in the following,

we assume that the heat release is the same for all

C, AT

limit mixtures, then the total heat release is given by, -nc_ - (10)

‘T (-Ahc)

1

(3) If an adiabatic temperature threshold, A P , is assumed,

$[&]=IFr_ then the left hand side of equation (10) is the mole

fraction of fuel at the flammability limit. In terms of

and L e Chatelier’s rule, Equation (11, is proved by the LFL,

solving for LFL,, This simplified approach is useful

for comprehension, but does not elucidate the (11)

detailed assumptions inherent in Equation (1). A more

rigorous approach is required.

Process Safety Progress (V01.19, No.2) Summer 2000 113

nitrogen heat capacity, the calculated adiabatic flame

Lower Flammability Limit and Heat of temperature at the lower limit and the heats of com-

Combustion bustion values shown. The results compare well to

10 , 1

experimental values.

LFL = 4332 [l/-Ah,] + 0.239

Development of a similar flammable limit equation

for a mixture with multiple fuels requires a modifica-

tion of equation (11). This modification results in,

Oxygencompounds

A Nilmgcn Compounds (12)

x Svlfvrcampoundr

-Lmm negreJsmn

0.0000 0.0005 0.0010 0.0015 0.0020 where (LFL/lOO),i, is the lean or lower flammable

limit of a multiple fuel mixture with an adiabatic tem-

l/(-Ahc) Ikl/mole]-’

perature change of AT*. The equation relating the

energy of a multi fuel combustion reaction and tem-

FIGURE 1. LFL and the standard enthalpy of combustion for 123 perature is,

compounds.

N

where LFL is the lean or lower flammable limit for a

single fuel (percent fuel in air). i=l

Egerton and Powling [31 in their studies on the limits

of flame propagation plotted and correlated the lower where n, is the total number of combustible moles,

flammable limit and the non-reciprocal heat of combus- (-Ah,),,, is the heat of combustion of the fuel mix-

tion. Equation (11) proposes that the LFL is proportional ture, niis the number of moles of the ith fuel species,

to the reciprocal of the heat of combustion. Suzuki [141 and (-Ahd, is the heat of combustion of the ifh fuel.

examined the trend of the LFL and the standard Equation (13) assumes that the net heat of combustiop

enthalpies of combustion for 123 compounds. These is determined from the heat of combustion of the pure

include 55 hydrocarbons, 48 oxygen-containing com- components. This assumes that the combustion kinet-

pounds, 16 nitrogen-containingcompounds, and 4 sulfur ics for the pure species are independent and

-containing compounds. Halogenated compounds are unchanged due to the presence of other combustible

not included because of inadequate knowledge of their gas species in the mixture. In actual combustion

stoichiometry. Figure 1 shows the linear relationship processes, the species share common elementary

between the LFL and the reciprocal of the standard reactions and the kinetics would b e expected to

enthalpy of combustion for this data which clearly sup- change due to the presence of the other combustible

ports the form of equation (11). species. Also, cool flames might arise in the mixture

For many lean mixtures the concentration of fuel is dramatically changing both the kinetics and the tem-

only a few percent, with the majority of the mixture perature increase at the limit.

nitrogen. The heat capacity of the gas mixture should Writing equation (13) for two species, and dividing

be close to the heat capacity for pure nitrogen (29.2 by n, results in,

J/mole-K). Table 1 shows flammability limit estimates

using Equation (11) for hydrocarbons and oxygen -

containing compounds. These calculations use the

TABLE 1. Properties of Selected Hydrocarbons and Oxygen-containing Compounds.

Experimental LFL 4 Ta,@LFL Calculated LFL from Equation (11)

Compound (vol.%) (kJ/mole) (K) ‘pN2 (ATad LFL) ’

-Ahc

Methane 5.3 -890.3 1481 4.9

Acetylene 2.5 -1299.6 1268 2.8

Ethylene 2.7 -1411.2 1370 2.8

Ethane 3.0 -1559.8 1534 2.9

Propyne 2.2 -1935.8 1431 2.2

1-Butene 1.6 -2716.8 1479 1.6

1-Hexene 1.2 -4032.5 1583 1.1

Ethanol 3.3 -1409.2 1492 3.1

Dimethyl ether 3.4 - 1460.5 1565 3.1

Acetone 2.6 -1821.4 1541 2.5

Heat of combustion and LFL data from Suzuki (1994).

Calculated flame temperatures at the LFL’s from Melhem (1997).

114 Summer 2000 Process Safety Progress (Vo1.19, No. 2)

Substituting equation (14) into equation (12) results EXAMPLE

in, A vapor is comprised of 63.5% ethyl acetate, 20.8%

C, AT * ethyl alcohol, and 15.6% toluene by volume on an air

(%)mix n C (-4

= nl 1

+ +Ah2

n C [ 1

(15) -free basis. The flammability limits for each are shown

in Table 2 below. Estimate the lower flammability

limit of the mixture.

Recognizing the molar ratios in the denominator of TABLE 2. Lower Flammability Limits for Example 1

equation (15) are equivalent to the mole fractions o n

a fuel only basis results in the following definitions, LFL (Lewis and

von Elbe, [81 LFL (NFPA [12]

y I = Jn and y2 = -nl Compound fuel in air) (vol. % fuel in air)

(16) (~01%

nc nc

Ethyl Acetate 2.5 2.0

Equations (16) are substituted into Equation (15) and

Ethyl Alcohol 4.3 3.3

the numerator and denominator are divided by C)P.

Toluene 1.4 1.2

This assumes a constant heat capacity and a constant

adiabatic temperature threshold, A P.The result is

SOLUTION

The lower flammability data are shown in Table 2.

T h e fuel composition is already o n a fuel only

basis, i.e. air excluded. Equation (19) is used to pre-

dict the LFL of the mixture. Using the limit data from

Lewis and von Elbe [81results in,

LFL,, =

-x

A*E

i=l

1

v.

Yi

-

- 0.635

~

2.5

1

0.208

+- 4.3

+-+- +

. 0.156

~

1.4

= 2.41%

An identical calculation using the l i t data from NFF'A

The terms in the brackets are the pure component [121 results in a mixture value of I.%%, a fairly si@icant

LFLs defined by equation (11). Thus, ddference from the previous value. This demonstrates the

sensitivity of the result to the initial limit values.

The experimentally determined value of the LFL is

2.04% (Lewis and Von Elbe, [8D.

Upper Flammability Limit

An equivalent form of Le Chatelier's equation for

the upper flammable limit (UFL) is commonly applied,

Final algebraic transformation of equation [181

results in t he simple mixing rule proposed b y L e (20)

Chatelier that estimates the lower o r lean limit of a

mixture of flammables in air.

1

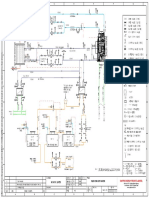

LFL,,,, = (19) Figure 2 shows the dependence of the UFL and the

IYL L Y2

LFL, LFL, Upper Flammability Limit and Heat of

Combustion

The result is readily applied to an y number of 100 - 1

.X= - A

species. The assumptions required to arrive at this 90

80 -

equation include,

the product heat capacities are constant

E

=

e

-0

\o

kq

7n

50

--

.

A

the number of moles of gas is constant A 40

the combustion kinetics of the pure species are f 30

4 20

independent and unchanged by the presence of other B 10

combustible species. 0

the adiabatic temperature rise at the flammability 0.000 0.001 0.001 0.002 0.002

limit is the same for all species. l/(-AhJ [kJ/mol]-'

An example calculation will illustrate the use of the FIGURE 2. UFL and the standard enthalpies of combustion for 123

L e Chatelier method of estimating the lower o r lean

compounds.

flammable limit from pure component data.

Process Safety Progress (Vol. 19, No.2) Summer 2000 115

standard enthalpy of combustion for the same 123 N Number of flammable species

compounds as Figure 1. The data are quite scattered

which makes it difficult to assess the functionality T Temperature

between the UFL and the enthalpy of combustion. How-

ever, a large number of the compounds on the lower left AT Temperature change

do appear to fit a straight line. Most of the species in Fig-

ure 2 are hydrocarbons. AT* Adiabatic temperature threshold or limit tem-

For the UFL, the fuel represents a large percentage of perature increase

the mixture. These mixtures can contain a complex mix-

ture of fuel, oxygen and nitrogen resulting in wide varia- UFL Upper flammable limit in volume percent fuel

tion from the initial to final heat capacities and molar in air

quantities. These conditions violate the assumptions

used to formulate equation (20). Decomposition kinetics, y Mole fraction on a combustible basis

soot formation, cool flames, and other complex effects

may also play an important role at the upper limit. superscripts

Prod Products

Additional Considerations

Proper usage of LaChatelier’s rule requires flamma- Subscripts

bility limit data at the same temperature and pressure. ad Adiabatic

Also, flammability data reported in the literature may

be from disparate sources, with wide variability in the i Species i

data. Combining data together from these disparate

sources may cause unsatisfactory results, which may mix Mixture

not be obvious to the user.

p Products

SUMMARY

This paper provides a proof of Le Chatelier’s empir- T Total

ical rule based on thermodynamics. The proof shows

the important assumptions inherent in the rule an d 1 Initial

the conditions under which L e Chatelier’s rule can be

applied. Furthermore, the result shows that Le Chate- UTERANRE CITED

lier’s rule is a special form of the cakulated adiabatic

1. Burgess, M. J., and Wheeler, R. V. J. Chem. SOC.,

flame temperature method, which is widely used

today to predict flammability limits. 99, 2013, (1911).

2. Coward, H. F., Carpenter, W. and Payman, W.,

Comparison with experimental data shows that Le

“The Dilution Limits of Inflammability of Gaseous

Chatelier’srule is moderately good at estimating the lower Mixtures. Part 111. T h e Lower Limits of Some

flammability limit, and poor to moderate at estimating the Mixed Inflammable Gases with Air. Part IV. The

upper flammability h i t , depending on the species. Upper Limits of Some Gases. Singly and Mixed, in

Air,”.!. Chem. SOC.,115, pp. 27-36, (1919).

ACKNOWLEDGEMENT 3. Edgerton, A., Powling, J., “The Limits of Flame

The authors wish to thank Larry Britton for his Propagation at Atmospheric Pressure. 11. The

commentary and assistance. Influences of Changes in the Physical Properties,”

Proc. Rqyal Socie[y,Volume 193A, (1948).

NOTATION 4. Eitner, Habilitationsschnyt,Munchen (1902).

Heat capacity at constant pressure 5. Hansel, J. G., Mitchell, J. W., Klotz, H. C., “Pre-

C,

dicting and Controlling Flammability of Multiple

Ah Enthalpy change d u e to the heating of the Fuel and Multiple Inert Mixtures,” Air Products

products per mole and Chemicals, Inc., Prepared for presentation at

the AIChE 25th Loss Prevention Symposium, 18-21

Ahc Enthalpy change of combustion per mole August, (1991).

6. Le Chatelier, H., “Estimation of Firedamp by

H Total enthalpy Flammability Limits,” Ann. Mines, Vol. 19, ser. 8,

pp. 388-395, (1891).

AH Total enthalpy change 7. Le Chatelier, H., and Boudouard, C., “On the

Limits of Inflammability of Combustible Mixtures,”

AHc Total enthalpy change due to combustion Comptes Rendus des Seances de L ’ Academie Sci-

ences, T. 126, page 1510, May 25th, (1898).

LFL Lower or lean flammable limit in volume per- 8. Lewis, Bernard, and von Elbe, Guenther, Com-

cent fuel in air bustion, Flames and Explosions of Gases, 3rd ed.,

Academic Press, Orlando, (1987).

n Number of moles 9. L i e k h u s , K., Z l o c h o w e r , I., D j o r d j e v i c S.,

Loehr, C., “Predicting Flammability of Gas Mix

116 Summer 2000 Process Safety Progress (Vol.19, N0.2)

tures Containing Volatile Organic Compounds,” tion Symposium, Houston, March, (1997).

International Symposium on Hazards, Prevention, 12. NFPA, Fire Protection Guide on Hazardous Mate-

and Mitigation of Industrial Explosions, Schaum- rials, 9th ed., National Fire Protection Association,

burg, IL, September 21-25, (1998). Quincy, MA., 1986.

10. Mashuga, Chad, V., and Crowl, Daniel, A., 13. Stull, D. R., “Fundamentals of Fire and Explo-

“Flammability Zone Prediction Using Calculated sion,’’ AIChE Monograph series 10, American

Adiabatic Flame Temperatures,” AIChE 33rd Loss Institute of Chemical Engineers, (1977).

Prevention Symposium, Houston, March, (1999). 14. Suzuki, T., “Empirical Relationship Between Lower

11. Melhem, G. A., “A Detailed Method For the Esti- Flammability Limits and Standard Enthalpies of Com-

mation of Mixture Flammability Limits Using bustion of Organic Compounds,” Fire and Materials,

Chemical Equilibrium,” AIChE 31st Loss Preven- 18,pp. 333-336, January, (194).

Process Safety Progress (Vo1.19, No.2) Summer 2000 117

You might also like

- HP Catalog 1976 PDFDocument580 pagesHP Catalog 1976 PDFrommelgasparNo ratings yet

- ThermodynamicsDocument98 pagesThermodynamicsHardeep Singh BaliNo ratings yet

- Poster 20090222aDocument1 pagePoster 20090222aKyle Martin BrunnerNo ratings yet

- Comsol - Models.heat - Tin Melting FrontDocument16 pagesComsol - Models.heat - Tin Melting Frontntr_mn4408No ratings yet

- CHME324-B-Lab Manual Fall 2016 (Ahmed Elkhatat)Document99 pagesCHME324-B-Lab Manual Fall 2016 (Ahmed Elkhatat)bebsybiswezNo ratings yet

- Efflux Time: TOGUN Iyanuoluwa JohnDocument24 pagesEfflux Time: TOGUN Iyanuoluwa JohnJohnNo ratings yet

- Cooling Towers Information PackageDocument25 pagesCooling Towers Information Packagemdawg467No ratings yet

- Study On Ethanol-Water Batch Distillation Tsf-1022Document11 pagesStudy On Ethanol-Water Batch Distillation Tsf-1022Robiel GashuNo ratings yet

- The Synergistic Effect of Temperature, H2S/CO2 Partial Pressure and Stress Toward Corrosion of X80 Pipeline SteelDocument11 pagesThe Synergistic Effect of Temperature, H2S/CO2 Partial Pressure and Stress Toward Corrosion of X80 Pipeline SteelRoberta VasquesNo ratings yet

- CHE 4433 - Petroleum and Petrochemical Processing - Lab ManualDocument38 pagesCHE 4433 - Petroleum and Petrochemical Processing - Lab ManualAhmad SaleemNo ratings yet

- Unit 4 Fluidization PDFDocument6 pagesUnit 4 Fluidization PDFMark FenixNo ratings yet

- Simulia SCN 1311Document24 pagesSimulia SCN 1311CelsoNo ratings yet

- Naca 2142Document12 pagesNaca 2142Viraj GandhiNo ratings yet

- Thermal Engineering - I Jntua Question PapersDocument15 pagesThermal Engineering - I Jntua Question PapersHimadhar SaduNo ratings yet

- Wong Sandler (1992)Document10 pagesWong Sandler (1992)Anonymous PO7VwbBnNo ratings yet

- Question 5Document4 pagesQuestion 5Muhammad AliffNo ratings yet

- 2009 S2 Exam SolutionsDocument14 pages2009 S2 Exam Solutions赵一伦No ratings yet

- CMP v4 PDFDocument576 pagesCMP v4 PDFKasia MazurNo ratings yet

- Equation of State PDFDocument84 pagesEquation of State PDFAnubhav SinghNo ratings yet

- CrackingDocument33 pagesCrackingEman El DsoukyNo ratings yet

- Bettering Operation of Robots by Learning, Arimoto Et AlDocument18 pagesBettering Operation of Robots by Learning, Arimoto Et AlPeps Peps PepsNo ratings yet

- Cet 2Document2 pagesCet 2Anonymous U4iBvF6No ratings yet

- Shock Tube Example ProblemDocument1 pageShock Tube Example ProblemThomas JohnsonNo ratings yet

- CAETraining (Fluid)Document129 pagesCAETraining (Fluid)andysarmientoNo ratings yet

- Skin Factor and Flow Efficiency in Wells Producing Under Solution Gas Drive T.E.W. NindDocument5 pagesSkin Factor and Flow Efficiency in Wells Producing Under Solution Gas Drive T.E.W. NindMiguel Angel GonzalesNo ratings yet

- 10.1038@s42254 019 0068 9 PDFDocument2 pages10.1038@s42254 019 0068 9 PDFLeonardo de AraujoNo ratings yet

- C A BT CT DT Et: Heat Capacity of Gas, Carbon Tetrachloride (Ccl4)Document3 pagesC A BT CT DT Et: Heat Capacity of Gas, Carbon Tetrachloride (Ccl4)Osmar Monja LopezNo ratings yet

- Sequential Modular and Simultaneous Modular StrategiesDocument13 pagesSequential Modular and Simultaneous Modular Strategieskim haksongNo ratings yet

- Review About MonoethanolamineDocument59 pagesReview About MonoethanolaminebexigaobrotherNo ratings yet

- Flares CFDDocument15 pagesFlares CFDRicardo BecNo ratings yet

- Pan, Hanratty - 2002 - Correlation of Entrainment For Annular Flow in Horizontal PipesDocument24 pagesPan, Hanratty - 2002 - Correlation of Entrainment For Annular Flow in Horizontal PipesJohn Doe100% (1)

- A New Empirical Model For Predicting Complex Modulus of Asphalt Concrete MaterialsDocument8 pagesA New Empirical Model For Predicting Complex Modulus of Asphalt Concrete MaterialsKHALID KRAMINo ratings yet

- 37 - 4 - Washington DC - 08-92 - 1855 PDFDocument9 pages37 - 4 - Washington DC - 08-92 - 1855 PDFMohamadMostafaviNo ratings yet

- Equivalent Hydraulic DiameterDocument3 pagesEquivalent Hydraulic DiameterSyeilendra PramudityaNo ratings yet

- IND 202 U2a Gas and Liquid Separation FCivan XXDocument61 pagesIND 202 U2a Gas and Liquid Separation FCivan XXrenatoNo ratings yet

- Redifined Approach For The Modeling of Sky DivingDocument14 pagesRedifined Approach For The Modeling of Sky Divingvarun varma100% (1)

- Review of Temperature MeasurementDocument20 pagesReview of Temperature MeasurementxeonixblueNo ratings yet

- My Bachelor Thesis Progress FIX PRINT! PDFDocument87 pagesMy Bachelor Thesis Progress FIX PRINT! PDFGsonic KrisnawanNo ratings yet

- Thermo 3 To PrintDocument13 pagesThermo 3 To Printnoodlelimbs100% (1)

- Poiseuille Flow: An Internet Book On Fluid DynamicsDocument4 pagesPoiseuille Flow: An Internet Book On Fluid DynamicsFelix EzomoNo ratings yet

- Saturation Nucleate Pool Boiling - A Simple CorrelationDocument9 pagesSaturation Nucleate Pool Boiling - A Simple CorrelationForcus on100% (1)

- High Energy Heat Shield Aero ThermodynamicsDocument10 pagesHigh Energy Heat Shield Aero ThermodynamicsRaman KrishNo ratings yet

- Sme 3033 Finite Element Method Steady STDocument37 pagesSme 3033 Finite Element Method Steady STSreedhar MNo ratings yet

- Ahmad, Linnhoff, Smith - Design of Multipass Heat Exchangers - An Alternative Approach (ASME) PDFDocument6 pagesAhmad, Linnhoff, Smith - Design of Multipass Heat Exchangers - An Alternative Approach (ASME) PDFjdgh1986No ratings yet

- Tenability W.pohDocument6 pagesTenability W.poh1jess6No ratings yet

- ChBE3210 Spring2007 Exam2Document6 pagesChBE3210 Spring2007 Exam2Abishek KasturiNo ratings yet

- Cycle Test 2 Rocket PropulsionDocument3 pagesCycle Test 2 Rocket Propulsionapi-271354682No ratings yet

- Chapter 07.00G Physical Problem For Integration Mechanical EngineeringDocument4 pagesChapter 07.00G Physical Problem For Integration Mechanical EngineeringMichael HaywardNo ratings yet

- Riemann Shock TubeDocument27 pagesRiemann Shock TubeSaravanan ShanmugamNo ratings yet

- Cinetica Rop PDFDocument14 pagesCinetica Rop PDFDiana Isabel Franco ZambranoNo ratings yet

- 2015 - 07094934Document9 pages2015 - 07094934mjimenezgNo ratings yet

- 10 CreepDocument6 pages10 CreepamokhtaNo ratings yet

- GMFIX Code DocumentsDocument63 pagesGMFIX Code Documentsclarklipman100% (1)

- LS Srinath Four Chapters CompleteDocument137 pagesLS Srinath Four Chapters CompleteSunil SharmaNo ratings yet

- AIGA 075 - 11 Cal Method For Prevention of Overpress - Cryogenic Tanks - Reformated Jan 12 PDFDocument57 pagesAIGA 075 - 11 Cal Method For Prevention of Overpress - Cryogenic Tanks - Reformated Jan 12 PDFdaimon_pNo ratings yet

- Practica5 TermoDocument6 pagesPractica5 TermoMclovin LopezNo ratings yet

- Resonance Energy of Naphthalene by Bomb Calorimetry: Monica Patel, Christy Crowly, Casey Theys and Kyle CraneDocument9 pagesResonance Energy of Naphthalene by Bomb Calorimetry: Monica Patel, Christy Crowly, Casey Theys and Kyle CraneMonica PatelNo ratings yet

- Lab 7Document12 pagesLab 7api-25252422380% (5)

- Ethlyene Solubility PDFDocument4 pagesEthlyene Solubility PDFJijia BaiNo ratings yet

- Selection PresentationDocument15 pagesSelection PresentationSteve WanNo ratings yet

- F 12102 Rules of CalculationDocument9 pagesF 12102 Rules of CalculationSteve WanNo ratings yet

- Plano Rizzi Sopladores B 6102 FCCDocument2 pagesPlano Rizzi Sopladores B 6102 FCCSteve WanNo ratings yet

- Pump Sizing Calculation SheetDocument10 pagesPump Sizing Calculation SheetSteve WanNo ratings yet

- Auxiliary BoilerDocument102 pagesAuxiliary BoilerSteve WanNo ratings yet

- Steam Boilers VeloaDocument96 pagesSteam Boilers VeloaSteve WanNo ratings yet

- Process Control BoilerDocument70 pagesProcess Control BoilerSteve WanNo ratings yet

- Air Damper Control System671 PDFDocument1 pageAir Damper Control System671 PDFSteve WanNo ratings yet

- Esp 100 TPD Precicon 3 Drawing PDFDocument1 pageEsp 100 TPD Precicon 3 Drawing PDFSteve WanNo ratings yet

- Combustion CalculationDocument2 pagesCombustion CalculationSteve WanNo ratings yet

- Boiler Safety Checklist &Document185 pagesBoiler Safety Checklist &Steve WanNo ratings yet

- Part 8 Exhaust FanDocument7 pagesPart 8 Exhaust FanSteve WanNo ratings yet

- Line List Ammonia Urea P1 RevisiDocument17 pagesLine List Ammonia Urea P1 RevisiSteve WanNo ratings yet

- Chimney CalculationsDocument3 pagesChimney CalculationsSteve WanNo ratings yet

- Furnace Typical Draft ProfileDocument1 pageFurnace Typical Draft ProfileSteve WanNo ratings yet

- Tank SizeDocument7 pagesTank SizeSteve WanNo ratings yet

- Heat Recovery P Id Raymond RV 06Document1 pageHeat Recovery P Id Raymond RV 06Steve WanNo ratings yet

- Hall Yarborough Z 1Document1 pageHall Yarborough Z 1Steve WanNo ratings yet

- Heat Loss Analysis 03Document3 pagesHeat Loss Analysis 03Steve WanNo ratings yet

- Compensation (Gas) eDocument1 pageCompensation (Gas) eSteve WanNo ratings yet

- Astm e 317-21Document13 pagesAstm e 317-21hashem Al-NasserNo ratings yet

- Wenner Method of Measuring Earth ResistivityDocument3 pagesWenner Method of Measuring Earth ResistivityErsi AgoNo ratings yet

- Electricity & Thermal PhysicsDocument59 pagesElectricity & Thermal Physicsapi-3743896No ratings yet

- Tutorial Work Power Efficiency AnswerDocument4 pagesTutorial Work Power Efficiency AnswerNicole Nicole100% (1)

- E Specific Oe SinglesDocument16 pagesE Specific Oe SinglesLLNo ratings yet

- Understanding The Basics of Quantum PhysicsDocument1 pageUnderstanding The Basics of Quantum Physicstiticelestin98No ratings yet

- SmartComm Design v2.1Document10 pagesSmartComm Design v2.1nagarajanNo ratings yet

- MecanicaClassica PG Aula13 MBGDDocument28 pagesMecanicaClassica PG Aula13 MBGDLeonardo Camargo RossatoNo ratings yet

- Els - G11Document36 pagesEls - G11Lem CastilloNo ratings yet

- Asme Section Ii A-2 Sa-724 Sa-724mDocument4 pagesAsme Section Ii A-2 Sa-724 Sa-724mdavid perezNo ratings yet

- RF and Microwave Cables and Connectors For Aviation PDF Catalogue PDFDocument28 pagesRF and Microwave Cables and Connectors For Aviation PDF Catalogue PDFStéphane SintesNo ratings yet

- Trip of A Zig Zag TransformerDocument22 pagesTrip of A Zig Zag TransformerPranesh PalNo ratings yet

- Flashcards - 2.2 Electric Circuits - Edexcel IAL Physics A-LevelDocument33 pagesFlashcards - 2.2 Electric Circuits - Edexcel IAL Physics A-LevelMelody NationNo ratings yet

- Far East 07Bn8-F: Power Cables EN 50525-2-21Document7 pagesFar East 07Bn8-F: Power Cables EN 50525-2-21dachinicuNo ratings yet

- DPP (30-32) 12th Physics - E - WADocument6 pagesDPP (30-32) 12th Physics - E - WAMeena ChakrabartyNo ratings yet

- Coaching Notes 1 PDFDocument22 pagesCoaching Notes 1 PDFKenny CaluzaNo ratings yet

- Chem Soc Rev: Tutorial ReviewDocument11 pagesChem Soc Rev: Tutorial ReviewpradeepNo ratings yet

- Material For Table LegsDocument5 pagesMaterial For Table Legskutaiba AlmarzokiNo ratings yet

- Ec Axial Fan - Axiblade: Nominal DataDocument1 pageEc Axial Fan - Axiblade: Nominal DataAykut BacakNo ratings yet

- Diagrama Electrico AsfaltadoraDocument25 pagesDiagrama Electrico AsfaltadoraSebastian SucerquiaNo ratings yet

- A19451811v01 PDFDocument2 pagesA19451811v01 PDFAnonymous OM5uU6No ratings yet

- Protection of Synchronous Generator: Thesis SupervisorDocument37 pagesProtection of Synchronous Generator: Thesis SupervisorIrfan Naqvi100% (1)

- Muscle TissueDocument1 pageMuscle TissueJennie WatanabeNo ratings yet

- Electrical Properties of Tissues and Cell Suspensions - Schwan2Document2 pagesElectrical Properties of Tissues and Cell Suspensions - Schwan2Douglas DutraNo ratings yet

- D9127 POPIT Modules Data Sheet enUS 2538276107Document3 pagesD9127 POPIT Modules Data Sheet enUS 2538276107José TacunanNo ratings yet

- JBL PS1400 Performance Series, Subwoofer SMDocument20 pagesJBL PS1400 Performance Series, Subwoofer SMalvhann_1No ratings yet

- Case Study: Object PhotosDocument8 pagesCase Study: Object PhotosDiwanNo ratings yet

- AE2428ZKSRDocument1 pageAE2428ZKSRphuongtn1991No ratings yet

- 5000 Indikator Calibration GuideDocument2 pages5000 Indikator Calibration GuideIrvan PradityaNo ratings yet

- Study Guide Ionic Compounds and Metals Student Editable PDFDocument8 pagesStudy Guide Ionic Compounds and Metals Student Editable PDFNicolyNo ratings yet