Professional Documents

Culture Documents

Micro-Project (Automotive Elctrical and Electronic Systems) Part A

Uploaded by

cpt.ghost0 ratings0% found this document useful (0 votes)

35 views4 pagesAEE Part A

Original Title

AEE Part A

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAEE Part A

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views4 pagesMicro-Project (Automotive Elctrical and Electronic Systems) Part A

Uploaded by

cpt.ghostAEE Part A

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

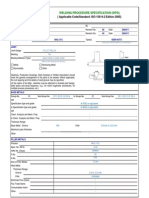

Pimpri-Chinchwad Education Trust’s

Pimpri-Chinchwad Polytechnic

Automobile Department

(ISO 9001:2008 Certified Department)

Academic Year: 2020-2021

Micro-Project

[AUTOMOTIVE ELCTRICAL AND ELECTRONIC SYSTEMS]

Part A

Name of Program: Diploma in Automobile Egg.

Semester: 6thsemester

Name Of Course and Code: AUTOMOTIVE ELCTRICAL AND ELECTRONIC

SYSTEMS (AEE)[22651]

Title of the Micro-Project: Prepare charts on relevant to diagnosis of sensors/actuators

(Oxygen sensor)

Name of Team Members: Name Enrollment no.

1. Het J. Patel. 1800560003

2. Chaitanya S. Kale. 1800560004

3. Rushikesh S. Kale. 1800560023

4. Rajkumar K. Landage. 1800560026

Name and Sign of the Prof. S.G. Gandhi.

project Guide: Sign:

Micro-Project Proposal

Part A

[AUTOMOTIVE ELCTRICAL AND ELECTRONIC SYSTEMS]

6thSemester

Prepare charts on relevant to diagnosis of sensors/actuators

(Oxygen sensor)

1.0 Brief Introduction:

An oxygen sensor (or lambda sensor, where lambda refers to air–fuel equivalence ratio, usually denoted

by λ) is an electronic device that measures the proportion of oxygen (O2) in the gas or liquid being

analyzed. It was developed by Robert Bosch GmbH during the late 1960s under the supervision of Dr.

Günter Bauman. The original sensing element is made with a thimble-shaped zirconia ceramic coated on

both the exhaust and reference sides with a thin layer of platinum and comes in both heated and unheated

forms. The planar-style sensor entered the market in 1990 and significantly reduced the mass of the

ceramic sensing element, as well as incorporating the heater within the ceramic structure. [1] This resulted in

a sensor that started sooner and responded faster. The most common application is to measure the exhaust-

gas concentration of oxygen for internal combustion engines in automobiles and other vehicles in order to

calculate and, if required, dynamically adjust the air-fuel ratio so that catalytic converters can work

optimally, and also determine whether the converter is performing properly or not. Divers also use a

similar device to measure the partial pressure of oxygen in their breathing gas. An oxygen sensor will

typically generate up to about 0.9 volt when the fuel mixture is rich and there is little unburned oxygen in

the exhaust.

2.0 Aim of The Micro-Project:

This micro-project aims at:

To study how the oxygen sensor works

To study how to the oxygen sensor applications

3.0 Course Outcomes:

Maintain the automobile electrical and electronic

Test battery and charging systems.

Troubleshoot starting and ignition systems.

4.0 Literature review:

The requirement for the detection of oxygen in industrial safety applications has historically

been met by electrochemical technologies based on the consumption of metal anodes.

Products using this approach have been technically and commercially successful for more

than three decades. However, a combination of new requirements is driving the development

of alternative approaches offering fresh opportunities and challenges. This paper reviews

some key aspects in the evolution of consumable anode products and highlights recent

developments in alternative technologies aimed at meeting current and anticipated future

needs in this important application.

5.0 Proposed Methodology:

1. Group discussion for the micro project assigned.

2. Collecting information through websites and books.

3. Distributing the work equally in our group and planning to execute it.

4. Timely submission of Micro-project Report.

6.0 Resources Required:

Sr. Name of Resource Specification

No

1.

7.0 Action Plan:

Name of program: Automobile Engineering. Sem: 6thsemester.

Course: AUTOMOTIVE ELCTRICAL AND ELECTRONIC SYSTEMS (AEE) Code: [22651]

Title of micro-project: Prepare charts on relevant to diagnosis of sensors/actuators

(Oxygen sensor)

Name of Subject Teacher: Prof S.G. Gandhi. Sign:

You might also like

- Hydrogen Economy: Processes, Supply Chain, Life Cycle Analysis and Energy Transition for SustainabilityFrom EverandHydrogen Economy: Processes, Supply Chain, Life Cycle Analysis and Energy Transition for SustainabilityAntonio ScipioniNo ratings yet

- Solar InteligentDocument37 pagesSolar InteligentPrekshitha NNo ratings yet

- Gas Leakage SensorDocument45 pagesGas Leakage SensorVarnika sharmaNo ratings yet

- Thermal Engineering SyllabusDocument144 pagesThermal Engineering SyllabusVpr NaturalsNo ratings yet

- A Minor Project Report Traffic Light Controller Using 555 TimerDocument15 pagesA Minor Project Report Traffic Light Controller Using 555 TimerSarvesh Vk100% (1)

- Humidity and Temperature DetectorDocument29 pagesHumidity and Temperature Detectorram poisonNo ratings yet

- Comparative Experimental Investigation of Oxyhydrogen (HHO) Production Rate Using Dry and Wet CellsDocument8 pagesComparative Experimental Investigation of Oxyhydrogen (HHO) Production Rate Using Dry and Wet CellsNam stareNo ratings yet

- D.T Project KartikDocument44 pagesD.T Project KartikKartik mondalNo ratings yet

- BoAE IE1Document4 pagesBoAE IE1Shruti DabhadeNo ratings yet

- Ns - Seminar ReportDocument45 pagesNs - Seminar ReportEldho Samuel0% (1)

- Experimental Investigation of Vapour Absorption Refrigeration Cycle For Automobile Cabin CoolingDocument8 pagesExperimental Investigation of Vapour Absorption Refrigeration Cycle For Automobile Cabin CoolingShahzaib Anwar OffNo ratings yet

- The Design of Air Contamination DetectionDocument16 pagesThe Design of Air Contamination DetectionAli NikfarjamNo ratings yet

- Internal CombustionDocument26 pagesInternal CombustionakbsrajNo ratings yet

- Ee3271 Ec Lab SpcetDocument85 pagesEe3271 Ec Lab SpcetvijayakumarNo ratings yet

- AGR OptimizationDocument43 pagesAGR Optimizationinara amatullahNo ratings yet

- Ane Iii-I Sem PDFDocument150 pagesAne Iii-I Sem PDFMuthu RamNo ratings yet

- Setiawan 2018 IOP Conf. Ser. Mater. Sci. Eng. 384 012008Document10 pagesSetiawan 2018 IOP Conf. Ser. Mater. Sci. Eng. 384 012008NiTiN MiSHRANo ratings yet

- Gobiewski 2018 IOP Conf. Ser.3A Mater. Sci. Eng. 421 022010Document12 pagesGobiewski 2018 IOP Conf. Ser.3A Mater. Sci. Eng. 421 022010balasubramani krishnamurthiNo ratings yet

- Spice Modeling of Taguchi Sensors: September 2007Document7 pagesSpice Modeling of Taguchi Sensors: September 2007Srijeet TripathyNo ratings yet

- Mech 2022Document476 pagesMech 2022Rahul HansdahNo ratings yet

- New SME Lab ManualDocument64 pagesNew SME Lab ManualSahil GupteNo ratings yet

- Air Quality Monitoring SystemDocument7 pagesAir Quality Monitoring SystemWafaaNo ratings yet

- Monitorizacion Del Aire Usando Micro y Red de SensoresDocument5 pagesMonitorizacion Del Aire Usando Micro y Red de SensoresDanny AlejandroNo ratings yet

- Sciencedirect: Simplified Life Cycle Assessment of A Hybrid Car Body PartDocument6 pagesSciencedirect: Simplified Life Cycle Assessment of A Hybrid Car Body PartTarun Krishna PrabhakarNo ratings yet

- Rohan ToteDocument4 pagesRohan ToteBhavesh TandelNo ratings yet

- Design Modification of Automated Power Window Circuit System For Automobiles Air - ConditionDocument10 pagesDesign Modification of Automated Power Window Circuit System For Automobiles Air - ConditionMuhammad ZamanNo ratings yet

- Catalaytic ConverterDocument14 pagesCatalaytic Convertermithunl60411No ratings yet

- Project Proposal FormatDocument15 pagesProject Proposal FormatMelkamu Desta100% (1)

- ElectiveDocument37 pagesElectiveMayur RaoNo ratings yet

- Project Format PDFDocument5 pagesProject Format PDFmdaakhilNo ratings yet

- Project Formats and Contents: Dr.R.Elumalai & Dr. Sujitha SDocument5 pagesProject Formats and Contents: Dr.R.Elumalai & Dr. Sujitha SmdaakhilNo ratings yet

- Project Format PDFDocument5 pagesProject Format PDFmdaakhilNo ratings yet

- Liquid Level Sensor in Automotive Design PDFDocument6 pagesLiquid Level Sensor in Automotive Design PDFzokandza4092No ratings yet

- Automobile Engineering Revised Syllabus 2008Document38 pagesAutomobile Engineering Revised Syllabus 2008Alicia CarterNo ratings yet

- EEE3010 - ES and C - CPDocument10 pagesEEE3010 - ES and C - CPdatojo9257No ratings yet

- AT Manual Back To Back Print PDFDocument97 pagesAT Manual Back To Back Print PDFAvinash UgaleNo ratings yet

- 06 Application Form 6 WithCMDocument23 pages06 Application Form 6 WithCMFilip JurićNo ratings yet

- Government Polytechnic Ambawadi, Ahmedabad-15: Design and Fabrication of Heat Powered RefrigeratorDocument41 pagesGovernment Polytechnic Ambawadi, Ahmedabad-15: Design and Fabrication of Heat Powered RefrigeratorNigNo ratings yet

- TNSCST Proposal Format SampleDocument7 pagesTNSCST Proposal Format SampleSathish KumarNo ratings yet

- Final ProjectDocument16 pagesFinal ProjectRitesh NandurkarNo ratings yet

- IOT Based Air Quality Monitoring System Using MQ13Document9 pagesIOT Based Air Quality Monitoring System Using MQ13AlphaNo ratings yet

- BE8261 - BEEIE Lab Manual For II Sem Mech/ AeroDocument123 pagesBE8261 - BEEIE Lab Manual For II Sem Mech/ AeroRAJARAJAN RNo ratings yet

- Annexures IceDocument3 pagesAnnexures IcekgmaheswaranNo ratings yet

- Epl Lab Manual Sxcce PDFDocument110 pagesEpl Lab Manual Sxcce PDFBijumonNo ratings yet

- B.E EEE - R2022CBCS - Curriculum Syllabi I IV 1Document82 pagesB.E EEE - R2022CBCS - Curriculum Syllabi I IV 1Hari DharanNo ratings yet

- Venkat EshDocument44 pagesVenkat EshAjayNo ratings yet

- Gas Leakage DetectionDocument7 pagesGas Leakage DetectionEngr Wahab MarwatNo ratings yet

- Eco Car Black BookDocument26 pagesEco Car Black BookharshalNo ratings yet

- Gbs Artical OxygenDocument14 pagesGbs Artical OxygenDr Gajanan ShirkeNo ratings yet

- Pic 1 ProjDocument19 pagesPic 1 ProjJibril hassen kedirNo ratings yet

- Hvac For AuditoriumDocument15 pagesHvac For AuditoriumkomalNo ratings yet

- Gas Leakage Monitoring and SMS Alert System.Document36 pagesGas Leakage Monitoring and SMS Alert System.34jashanjotsidhuNo ratings yet

- Electrical Machines Lab 4rd Sem-1Document33 pagesElectrical Machines Lab 4rd Sem-1Shubham kumarNo ratings yet

- M.SC - in Mechanical EngineeringDocument41 pagesM.SC - in Mechanical EngineeringIslam FattouhNo ratings yet

- EEE SylbDocument108 pagesEEE SylbBala KumarNo ratings yet

- V6i4 0130Document8 pagesV6i4 0130Willy WankaNo ratings yet

- Hardware in Loop Testing For Aftertreatment Solutions: Sundar Ganesh C SDocument13 pagesHardware in Loop Testing For Aftertreatment Solutions: Sundar Ganesh C SDonald Charles FernoughtyNo ratings yet

- B.Tech 8th Sem PEI FinalDocument11 pagesB.Tech 8th Sem PEI FinalStu HelpNo ratings yet

- Titles and CoursesDocument22 pagesTitles and Coursesmagsuarez1No ratings yet

- MFS Unit No 4 Numerical FinalDocument2 pagesMFS Unit No 4 Numerical Finalcpt.ghostNo ratings yet

- Form 20 To, The Registering Authority Pune ...........................Document3 pagesForm 20 To, The Registering Authority Pune ...........................cpt.ghostNo ratings yet

- ES2102 Batch1 QuespaperDocument4 pagesES2102 Batch1 Quespapercpt.ghostNo ratings yet

- PRN No. Total No. of Questions: 07: (An Autonomous Institute Affiliated To Savitribai Phule Pune University)Document3 pagesPRN No. Total No. of Questions: 07: (An Autonomous Institute Affiliated To Savitribai Phule Pune University)cpt.ghostNo ratings yet

- An Autonomous Institute Affiliated To Savitribai Phule Pune UniversityDocument3 pagesAn Autonomous Institute Affiliated To Savitribai Phule Pune Universitycpt.ghostNo ratings yet

- ASSEMBLYDocument1 pageASSEMBLYrohit mohanNo ratings yet

- MFS Unit No 4 Numerical FinalDocument2 pagesMFS Unit No 4 Numerical Finalcpt.ghostNo ratings yet

- An Autonomous Institute Affiliated To Savitribaiphule Pune UniversityDocument3 pagesAn Autonomous Institute Affiliated To Savitribaiphule Pune Universitycpt.ghostNo ratings yet

- Ch.2 Case and Duct SystemDocument11 pagesCh.2 Case and Duct Systemcpt.ghostNo ratings yet

- CH.4 A.C. System Control DevicesDocument10 pagesCH.4 A.C. System Control Devicescpt.ghostNo ratings yet

- An Autonomous Institute Affiliated To Savitribai Phule Pune UniversityDocument6 pagesAn Autonomous Institute Affiliated To Savitribai Phule Pune Universitycpt.ghostNo ratings yet

- Ch.3 Air Conditioning SystemDocument15 pagesCh.3 Air Conditioning Systemcpt.ghostNo ratings yet

- CH.4 A.C. System Control DevicesDocument10 pagesCH.4 A.C. System Control Devicescpt.ghostNo ratings yet

- Ch.1 Heating, Ventilation & Ac SystemsDocument8 pagesCh.1 Heating, Ventilation & Ac Systemscpt.ghostNo ratings yet

- Title: Identify Parts of Ducts System Used in LMV/ HMV/ MMV. Function of Duct SystemDocument3 pagesTitle: Identify Parts of Ducts System Used in LMV/ HMV/ MMV. Function of Duct Systemcpt.ghostNo ratings yet

- CH.6 Comfort Heating SystemDocument2 pagesCH.6 Comfort Heating Systemcpt.ghostNo ratings yet

- IndexDocument2 pagesIndexcpt.ghostNo ratings yet

- TestDocument7 pagesTestcpt.ghostNo ratings yet

- CH.6 Comfort Heating SystemDocument2 pagesCH.6 Comfort Heating Systemcpt.ghostNo ratings yet

- Maharashtra EV PolicywwwDocument20 pagesMaharashtra EV Policywwwcpt.ghostNo ratings yet

- Expt 14Document2 pagesExpt 14cpt.ghostNo ratings yet

- Ch.3 Air Conditioning SystemDocument15 pagesCh.3 Air Conditioning Systemcpt.ghostNo ratings yet

- Title:Perform Charging of Refrigerant in Air Conditioning SystemDocument3 pagesTitle:Perform Charging of Refrigerant in Air Conditioning Systemcpt.ghostNo ratings yet

- CH.4 A.C. System Control DevicesDocument10 pagesCH.4 A.C. System Control Devicescpt.ghostNo ratings yet

- CH.4 A.C. System Control DevicesDocument10 pagesCH.4 A.C. System Control Devicescpt.ghostNo ratings yet

- Ch.3 Air Conditioning SystemDocument15 pagesCh.3 Air Conditioning Systemcpt.ghostNo ratings yet

- Ch.2 Case and Duct SystemDocument11 pagesCh.2 Case and Duct Systemcpt.ghostNo ratings yet

- Ch.1 Heating, Ventilation & Ac SystemsDocument8 pagesCh.1 Heating, Ventilation & Ac Systemscpt.ghostNo ratings yet

- Maharashtra State Board of Technical Education: CertificateDocument1 pageMaharashtra State Board of Technical Education: Certificatecpt.ghostNo ratings yet

- Ch.3 Air Conditioning SystemDocument15 pagesCh.3 Air Conditioning Systemcpt.ghostNo ratings yet

- Mil STD 278FDocument128 pagesMil STD 278Fexwhiskeyhouse100% (1)

- Geotechnical GEO5 Fem enDocument2 pagesGeotechnical GEO5 Fem encesmanroe231No ratings yet

- IOM Manual C132355.SflbDocument14 pagesIOM Manual C132355.SflbVenkat SubramanianNo ratings yet

- Quick Guide To ISO-14692Document12 pagesQuick Guide To ISO-14692maninventor100% (5)

- Stick Hydraulic SystemDocument9 pagesStick Hydraulic SystemWaridi RidiNo ratings yet

- Peru Herramientas Weldy Extrusora Booster Ex2-Ex3 MDocument6 pagesPeru Herramientas Weldy Extrusora Booster Ex2-Ex3 MandersNo ratings yet

- Che 416 Lecture Notes For Part-B 2018-19 SessionDocument67 pagesChe 416 Lecture Notes For Part-B 2018-19 Sessioneze josephNo ratings yet

- Design and Development of Pneumatic Cotton Picker: Durgesh Gupta, Jayesh Teli, Paras Badhe, Suraj BanhattiDocument3 pagesDesign and Development of Pneumatic Cotton Picker: Durgesh Gupta, Jayesh Teli, Paras Badhe, Suraj Banhattidurgesh3guptaNo ratings yet

- Tolerances For Frame Side Members (RLT) : Accuracy of ShapeDocument8 pagesTolerances For Frame Side Members (RLT) : Accuracy of ShapeAkmal NizametdinovNo ratings yet

- Hubbel ATS PDFDocument16 pagesHubbel ATS PDFalexiuteodorNo ratings yet

- Compressor Design PDFDocument7 pagesCompressor Design PDFwaheedNo ratings yet

- Manual Pump Down On An Air ConditioningDocument7 pagesManual Pump Down On An Air ConditioningRay Ravel100% (1)

- 4D Seismic Analysis: Robertson Research International LTDDocument35 pages4D Seismic Analysis: Robertson Research International LTDHanan KakiNo ratings yet

- CFM 56 - 5C Basic-EngineDocument365 pagesCFM 56 - 5C Basic-Enginebugerkng94% (18)

- Kerax 380 P6X4Document6 pagesKerax 380 P6X4sulimanNo ratings yet

- GB Twin Shafts Paddle MixerDocument2 pagesGB Twin Shafts Paddle MixerBanzragch JamsranNo ratings yet

- Aashto T283 PDFDocument7 pagesAashto T283 PDFguru nathNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Automated Drilling MachineDocument14 pagesAutomated Drilling MachineVardhan ChipperNo ratings yet

- S04 FIP FIPD En-BDocument16 pagesS04 FIP FIPD En-BzuccoloNo ratings yet

- Product Catalog PDFDocument38 pagesProduct Catalog PDFMbaye DiagneNo ratings yet

- Discharge CoefficientDocument2 pagesDischarge Coefficientموسى جعفر احمد محمدNo ratings yet

- World Class Visual Lubrication Reliability ProgramDocument53 pagesWorld Class Visual Lubrication Reliability ProgramJuan Jiménez GamezNo ratings yet

- BS en 13001-3-6-2018Document60 pagesBS en 13001-3-6-2018Ash TurnerNo ratings yet

- Review: Modeling Damping in Mechanical Engineering StructuresDocument10 pagesReview: Modeling Damping in Mechanical Engineering Structuresuamiranda3518No ratings yet

- Isuzu REDTech 4J Lit SheetDocument2 pagesIsuzu REDTech 4J Lit SheetVăn Tuấn NguyễnNo ratings yet

- Mechanical ReliabilityDocument3 pagesMechanical ReliabilityAndre MarsNo ratings yet

- Ammonia Ref CycleDocument11 pagesAmmonia Ref CycleJom BonhayagNo ratings yet

- Manual Source1 S1-TheC11NS Rev 4Document25 pagesManual Source1 S1-TheC11NS Rev 4nichokolNo ratings yet

- Standards For Nuts Bolts and Washers Rev EDocument326 pagesStandards For Nuts Bolts and Washers Rev EValentinNo ratings yet