Professional Documents

Culture Documents

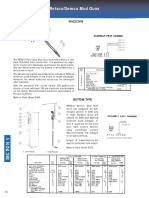

Butterfly Valve 2

Uploaded by

luisedonossaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butterfly Valve 2

Uploaded by

luisedonossaCopyright:

Available Formats

FMC’s Weco

Butterfly Valve

Maintenance Procedures 2. When replacing the seat, new O-rings using a right angle alignment

should be installed. fixture to align the stems.

Disassembly Insert the seat enough to

3. It is recommended that all rubber get started and then

1. Close valve and remove from the parts (seats, O-rings) be lightly but remove the stems from the

line. Turn the valve to the open thoroughly lubricated with a grease body and the seat/disc

position. Handle may be left on the such as Dow Corning® #111 silicone, assembly. Complete

upper stem or taken off by removing to facilitate assembly. Spread inserting the seat/ disc

cap screw and washer. lubricant on the inside diameter of the assembly into the body

seat. with uniform pressure.

2. Remove both the upper and lower

spirol pins with a drift pin or pin Assembly (Ref: FMC Specification 6. Lubricate the upper and

3253718) lower stems and place the

punch and hammer. (Use any strong

piece of steel rod which fits the third O-ring on the upper

1. Place well lubricated O-rings into the stem. The type of lubricant

spirol pin hole I.D.) top and bottom holes of the seat. used on the stems should be

3. Pull both the upper and lower stems Climax 422 CM or equivalent

2. Place the seat in a vise with the stem (Ref: FMC Specification 3259721).

from the body. If the stems cannot holes parallel to the vise jaws. Use

be removed readily, grasp the stem in Installation with Flanges

smooth jaws or otherwise protect the 7. Install the lower stem into the body.

a vise and gently tap the body with a seat O.D. from damage. Carefully

hammer. A twisting motion between The lower stem is in correct position Valves for installation between

apply pressure to distort the seat and when the roll pin hole in the body is flanges should be closed to prevent

the body and stems will allow the only enough pressure to insert the

stems to be removed easily. A groove aligned with the groove in the stem. damage to the disc. Caution should

disc. Excessive pressure can damage be taken to prevent the flange from

on the lower stem permits prying the seat. Slide the disc into the seat and

lower stem from the body by using a 8. Before installing the upper stem, striking the disc and causing possible

center the disc by inserting the upper align the indicator groove on top of leak paths. When flanges are pulled

screwdriver. and lower stems. Remove the seat/ the upper stem so that it is parallel tight, the valve may be opened. The

disc subassembly from the vise. with the disc. Install the upper stem O.D. of the valve will locate the valve

4. Remove the disc from the seat.

into the body by pushing the stem between the flanges. Disc position is

3. Using the upper stem, rotate the disc while slightly turning back and forth. determined by a slot in the top of the

5. Remove the seat from the body. The to the partially closed position.

seat may have to be tapped lightly This will allow the stem to align with square shafts or by the square shafts

and evenly around the edge from one the disc hex. The upper stem is in the or by the keyway in the keyed shafts.

4. Remove the upper stem (leaving the correct position when the roll pin is

end since the seat fits snugly in the lower stem in place).

body I.D. Take care not to damage aligned with the groove in the stem.

the inside of the body. 5. Lubricate the body I.D. (silicone 9. Install the handle on the valve so that

spray recommended). Using the Locking Key

Maintenance and Repair it aligns with the disc.

lower stem in the seat/disc assembly O-Ring

Upper Stem

1. Inspect the disc and stems. If worn and a lower stem in the body, lay the 10. Install the cap screw and washer to Upper Stem Seal

or pitted, substitute new ones. seat/disc assembly on top of the body retain the handle.

Locking key Retainer pin

0-ring

Upper stem seal Retainer pin

0-ring

Body

Upper

Upper stem O-ring

stem Seat

Retainer pin Disc

Retainer pin Body

Retainer pin

0-ring

Body

Seat Retainer

Lower stem snap ring

Disc

Retainer pin

O-ring O-ring

Retainer snap Upper stem

Retainer pin ring FMC Corporation

Retainer pin Lower

Fluid Control Division

0-ring

Lower stem

stem 2825 West Washington

Retainer pin P.O. Box 1377

Stephenville, Texas 76401, U.S.A.

Body Phone: 254/968-2181

O-ring Fax: 254/968-5709

Seat Toll Free: 1-800-772-8582

Disc Email: fluid_control@fmc.com

www.fmcenergysystems.com

Lower stem

O-ring Retainer pin

©Copyright 1999, FMC Corporation

Printed in U.S.A., SW 0.5M, 1-99

BV-01-99

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mtto Manual ChicksanDocument21 pagesMtto Manual ChicksanluisedonossaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- MudgunDocument1 pageMudgunluisedonossaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Lubricated Rotary Screw Air Compressors: 25 To 40 HP Sullair LS-10 Series Air Compressors. They're BulletproofDocument12 pagesLubricated Rotary Screw Air Compressors: 25 To 40 HP Sullair LS-10 Series Air Compressors. They're BulletproofluisedonossaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- QR-25 QR-25 QR-25 QR-25 QR-25 Series Series Series Series SeriesDocument44 pagesQR-25 QR-25 QR-25 QR-25 QR-25 Series Series Series Series SeriesluisedonossaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Rotary Screw Air Compressor Es-11Document98 pagesRotary Screw Air Compressor Es-11luisedonossa100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Chiksan Swivel LubricantsDocument1 pageChiksan Swivel Lubricantsluisedonossa100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Baylor 1Document66 pagesBaylor 1Cesar GamboaNo ratings yet

- CertexDocument376 pagesCertexRuben Gamarra RodriguezNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Lovejoy CouplingsDocument20 pagesLovejoy CouplingsrigengNo ratings yet

- Ficha Tecnica Rig Pic 24Document2 pagesFicha Tecnica Rig Pic 24luisedonossaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- General Purpose Solenoid Valves Series 8262 & 8263 Applications FeaturesDocument1 pageGeneral Purpose Solenoid Valves Series 8262 & 8263 Applications FeaturesluisedonossaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Pump Output Oilfield and Metric UnitDocument4 pagesPump Output Oilfield and Metric UnitluisedonossaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Catalogo Lovejoy Serie JawDocument26 pagesCatalogo Lovejoy Serie JawJuan Pablo CirizaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Ficha Tecnica Rig Pic 18 PDFDocument2 pagesFicha Tecnica Rig Pic 18 PDFluisedonossaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Ficha Tecnica Rig Pic 20Document2 pagesFicha Tecnica Rig Pic 20luisedonossaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Ficha Tecnica Rig Pic 18 PDFDocument2 pagesFicha Tecnica Rig Pic 18 PDFluisedonossaNo ratings yet

- TIME PumpsDocument13 pagesTIME PumpsAndres RedondoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Accumulator IncDocument58 pagesAccumulator IncEduardo Cramer100% (1)

- Governor D-2 & D-2A Parts List PDFDocument2 pagesGovernor D-2 & D-2A Parts List PDFluisedonossaNo ratings yet

- Nitrogen Gas Charging Kits Brochure PDFDocument12 pagesNitrogen Gas Charging Kits Brochure PDFluisedonossaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Ficha Tecnica Rig Pic 18 PDFDocument2 pagesFicha Tecnica Rig Pic 18 PDFluisedonossaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tubular Frame Power Unit D & 10 SeriesDocument4 pagesTubular Frame Power Unit D & 10 SeriesluisedonossaNo ratings yet

- 2019 Product CatalogDocument58 pages2019 Product CatalogluisedonossaNo ratings yet

- Despiece Butterfly ValvesDocument1 pageDespiece Butterfly ValvesMauricio GarciaNo ratings yet

- Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake Model 7040Document54 pagesInstallation, Operation and Maintenance Instructions For Baylor Eddy Current Brake Model 7040luisedonossaNo ratings yet

- Lovejoy CouplingsDocument20 pagesLovejoy CouplingsrigengNo ratings yet

- QR-N Valve Service PDFDocument4 pagesQR-N Valve Service PDFluisedonossaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Tuflo 1000 Parts List PDFDocument12 pagesTuflo 1000 Parts List PDFluisedonossaNo ratings yet

- 166-31590-AT ManualDocument66 pages166-31590-AT ManualRafael Charry AndradeNo ratings yet

- What Are The Different Types of PollutionDocument9 pagesWhat Are The Different Types of PollutionPatricia DurandNo ratings yet

- OL Lect 9 Seismic Acquisition NewDocument106 pagesOL Lect 9 Seismic Acquisition NewMohammad BilalNo ratings yet

- Material Cost - EOQDocument16 pagesMaterial Cost - EOQSimranNo ratings yet

- Men FootwearDocument442 pagesMen FootwearAbhishekNo ratings yet

- ANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODDocument9 pagesANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODmuhammad yaminNo ratings yet

- Amulets Talismans and CharmsDocument3 pagesAmulets Talismans and CharmsreikiladyNo ratings yet

- Company & Project Information for Electrical, Instrumentation ServicesDocument28 pagesCompany & Project Information for Electrical, Instrumentation ServicesMrudul PatilNo ratings yet

- Prof. Vijaya Lakshmi Nag CVDocument24 pagesProf. Vijaya Lakshmi Nag CVanislinek15No ratings yet

- 5 Successful Open Innovation ExamplesDocument44 pages5 Successful Open Innovation ExamplesSambhav MehtaNo ratings yet

- Datasheet GenDocument2 pagesDatasheet GenEdgar Bonilla MuñozNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chords ListDocument5 pagesChords ListakshayNo ratings yet

- Overview of Metal Forming ProcessesDocument19 pagesOverview of Metal Forming ProcessesAnonymous 7yN43wjlNo ratings yet

- Meng 2nd Year Death Anniversary MassDocument6 pagesMeng 2nd Year Death Anniversary Massjoy in the spirit of the lordNo ratings yet

- Jazz Band LiteratureDocument4 pagesJazz Band LiteratureJohnny LaounNo ratings yet

- Astm C1396 C1396M-17Document8 pagesAstm C1396 C1396M-17Stefano CamillucciNo ratings yet

- 2021 SC Hurricane GuideDocument16 pages2021 SC Hurricane GuideWMBF News100% (1)

- Decline of Controversy and the Catholic ChurchDocument3 pagesDecline of Controversy and the Catholic ChurchEugenio PalandriNo ratings yet

- GY HM 100 Service ManualDocument36 pagesGY HM 100 Service Manualvideoengr100% (1)

- ZQL1688 - Function Testing SOP - ADocument22 pagesZQL1688 - Function Testing SOP - AAlexandre PatrocinioNo ratings yet

- Max Out On Squats Every Day PDFDocument7 pagesMax Out On Squats Every Day PDFsamsung684No ratings yet

- Budget-of-Work-General Biology 1Document2 pagesBudget-of-Work-General Biology 1joei ArqueroNo ratings yet

- BrinjalDocument2 pagesBrinjalGajananNo ratings yet

- Mater BiDocument10 pagesMater BihanjunyieeNo ratings yet

- Honeywell TH6210U2001 Install InstructionsDocument44 pagesHoneywell TH6210U2001 Install Instructionsdarwin jose palacioNo ratings yet

- SR-21 SniperDocument6 pagesSR-21 SniperBaba HeadquaterNo ratings yet

- SynonymsDocument14 pagesSynonymsMursal IbrahimiNo ratings yet

- Your Msa Scba System: Cleaning/DisinfectingDocument1 pageYour Msa Scba System: Cleaning/Disinfectingjohn rajNo ratings yet

- Ch.2 Case and Duct SystemDocument11 pagesCh.2 Case and Duct Systemcpt.ghostNo ratings yet

- Hunter'S Bump: YsteryDocument3 pagesHunter'S Bump: YsteryMar De EchevarriaNo ratings yet

- Al KynesDocument12 pagesAl KynesjolanpascualNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsFrom EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo ratings yet

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)