Professional Documents

Culture Documents

iCAP 7000 Familiarisation v1-01

Uploaded by

Tùng Hồ ThanhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

iCAP 7000 Familiarisation v1-01

Uploaded by

Tùng Hồ ThanhCopyright:

Available Formats

iCAP 7000 Series ICP-OES Spectrometer

Customer Familiarisation and Maintenance Manual

© March 2013 Thermo Fisher Scientific Inc.

www.thermoscientific.com

http://www.thermofisher.com

iCAP Customer Familiarisation Manual

1 Contents

iCAP 7000 Series ICP-OES Spectrometer ................................................................................... 1

Customer Familiarisation and Maintenance Manual ..................................................................... 1

1 Contents .............................................................................................................................. 2

2 Instrument Overview ............................................................................................................ 4

2.1 General ........................................................................................................................ 4

2.2 Optical system and light path ....................................................................................... 4

3 Further information .............................................................................................................. 6

3.1 Qtegra ISDS Help ........................................................................................................ 6

3.2 Quick Start Guide......................................................................................................... 6

3.3 User Manual ................................................................................................................ 6

3.4 Online Assistance ........................................................................................................ 6

4 Instrument Hardware ........................................................................................................... 7

4.1 LED indicators ............................................................................................................. 7

4.2 Preparing the System for Use ...................................................................................... 7

4.3 Instrument Shut-down .................................................................................................. 8

5 Standard Sample Introduction Glassware Assembly ............................................................ 9

5.1 Duo and Radial Torch Assembly .................................................................................. 9

5.2 Center Tube Options .................................................................................................. 10

5.3 Centre tube holder ..................................................................................................... 10

5.4 Centre tube insertion into torch holder ........................................................................ 11

5.5 Torch holder insertion into the torch box ..................................................................... 11

5.6 Positioning of the spray chamber drain ....................................................................... 11

5.7 Position of the nebulizer in the spray chamber............................................................ 12

5.8 Connection of spray chamber adaptor to torch assembly ............................................ 13

5.9 Connection of pump tubing ........................................................................................ 14

5.10 Radial view window on a Duo instrument. .................................................................. 16

5.11 iCAP Sprint Valve installation guide (iCAP 7600 only) ................................................ 17

6 Autosampler Use ............................................................................................................... 21

6.1 Introduction ................................................................................................................ 21

6.2 Autosampler Installation ............................................................................................. 21

6.3 Autosampler Set-up ................................................................................................... 21

7 Instrument Optimization ..................................................................................................... 22

7.1 Instrumental method optimization ............................................................................... 22

7.2 Example Standard Operating Procedures .................................................................. 23

7.3 Preparing the System................................................................................................. 23

7.4 Striking the Plasma .................................................................................................... 23

7.5 Setting up Analyses ................................................................................................... 25

7.6 Running the Analysis ................................................................................................. 35

7.7 Auto Peak Adjust ....................................................................................................... 37

7.8 Setting the pump tension. ........................................................................................... 38

7.9 Torch Alignment ......................................................................................................... 39

7.10 Reporting results ........................................................................................................ 39

7.11 Exporting Labbooks. .................................................................................................. 46

7.12 Shutting Down the System ......................................................................................... 47

8 Maintenance ...................................................................................................................... 49

8.1 Instrument Cleaning ................................................................................................... 49

8.2 Preventive Maintenance ............................................................................................. 50

9 Analytical Problems Hints and Tips .................................................................................... 60

9.1 Poor Precision ........................................................................................................... 60

9.2 Poor accuracy/feedback ............................................................................................. 63

9.3 Poor detection limits ................................................................................................... 63

Page 2 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

10 Suggested maintenance in the case of poor precision and detection limits ..................... 64

10.1 Introduction ................................................................................................................ 64

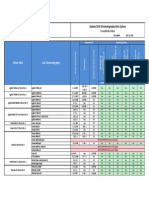

10.2 Typical Maintenance Schedule ................................................................................... 64

10.3 Replacing pump windings .......................................................................................... 64

10.4 Preventing blocking of the nebuliser ........................................................................... 65

10.5 Removing solids from the nebuliser ............................................................................ 66

10.6 Cleaning the glass mixing chamber ............................................................................ 68

11 Sample Introduction Spares & Consumables ................................................................. 69

Page 3 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

2 Instrument Overview

2.1 General

The iCAP 7000 Series is a range of Inductively Coupled Argon Plasma Optical Emission

Spectrometers (ICP-OES) which use an Echelle optical design and a Charge Injection Device

(CID) solid-state detector to measure trace elemental concentrations in a wide range of samples.

Liquid samples are pumped through a nebuliser to produce a fine spray. Large droplets are

removed by a spray chamber, small droplets then pass through the center tube in the torch to the

plasma. Solvent is evaporated and the residual sample decomposes to atoms and ions that are

excited by the electrical Radio Frequency (RF) generated Plasma to 9000K that will emit a unique

set of wavelengths of light for each element as they decay to a lower energy state. The intensity

of this light is measured and this corresponds to the concentration of element type in the original

sample.

The iCAP 7000 spectrometer consists of several major components:

• Plasma torch and sample introduction parts

• Radio frequency power generator

• Echelle polychromator optical system

• CID detector

• Data station

2.2 Optical system and light path

Page 4 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

The dispersive elements in the optic system are the Echelle grating and the prism. The

orientation of the prism is such that the light is dispersed at right angles to the direction of light

dispersal by the grating. This combined dispersal generates a two dimensional spectrum

(“echellogram”) consisting of a wavelength and order separation.

The CID detector is cooled to -45ºC to increase sensitivity and dynamic range.

Warning: Before operating your iCAP ensure you read and understand all the safety

information in the iCAP 7000 reference guide.

Page 5 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

3 Further information

3.1 Qtegra ISDS Help

Help with running your instrument, including comprehensive software user guides can be found in

the Qtegra Help page.

3.2 Quick Start Guide

The Quick Start Guide includes basic information required to get you started with operating your

iCAP 7000 Series ICP-OES.

OES.

3.3 User Manual

The User Manual details the operation and maintenance of your instrument hardware. It also

includes full information about

ut the safety hazards involved in working with the spectrometer and

its accessories, and the means by which such hazards can be minimised. This manual is supplied

in Adobe PDF format on the DVD supplied with your instrument.

3.4 Online Assistance

For information

tion about Thermo Scientific and your iCAP 7000 Series ICP

ICP-OES

OES Spectrometer,

including application notes and other material visit the Thermo Scientific website and search for

iCAP 7000:

www.thermoscientific.com

Page 6 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

4 Instrument Hardware

The iCAP 7000 is designed to be constantly powered up and

the optical system continuously purged.

The instrument is powered via an on/off switch at the rear of the

left side.

4.1 LED indicators

On the rear right hand side of instrument there are row of LED’s which

indicate the status of the instrument.

Once the chiller has been turned on and has reached its set temperature

LED’s 2-7 should be on and led 1 and 8 should be flashing.

LED 9 indicates engineer fast purge has been selected and should be

turned off when analysing samples.

4.2 Preparing the System for Use

If the gas supplies have been switched off, the optical components should be purged and

for at least one hour before powering on the instrument. This is to stop ice damage to the

camera which is cooled to -45ºC. It will take at least 4-8 hours of normal purge for the iCAP

7400, or iCAP 7600 instruments, to measure aluminium at 167nm with the specified

stability and sensitivity.

Ideally the system should be purged constantly, under trickle purge this is a very small

gas flow.

If the instrument is switched off, allow at least two hours after restoring power to thermally

stabilise the instrument before the chiller is turned on.

With the plasma aspirated a blank sample for 15 minutes to allow the instrument to fully stabilise

before analysis. Warm up time can be set up in the get ready page of Qtegra.

Page 7 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

4.3 Instrument Shut-down

After an analysis is finished a blank sample should be aspirated for five minutes to insure the

sample introduction part have been rinsed of sample. To remove the blank sample deionised or

distilled water should be aspirated for a further minute.

When organic solvent based samples are being analysed the final rinse should be the pure

solvent. Air should be aspirated for two minutes to remove organic vapours.

After completing the above the plasma should be turned off. The optical components will move to

a parked position after about thirty seconds.

After plasma has been turned off for at least 30 seconds turn off the chiller, following the

manufacturer’s instructions (turning off the chiller by removing the power can often cause

breakages!)

Allow five minutes after switching off the plasma before disconnecting the electrical power or

other supplies to the instrument, or accessories.

The tension on the pump platens should be released to preserve the life of the pump tubing.

NOTE: For the iCAP 7600 the valve and tubing should be rinsed and then purged of solutions. To

purge the 7600 Sprint Valve - open the Sprint Valve Configurator. Verify both Sample and Rinse

probes are in air, confirm (or set) Load, turn On the Vacuum Pump Control for several seconds.

When the Sample Loop and Valve are emptied turn Off. See the Qtegra section below.

Page 8 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5 Standard Sample Introduction Glassware Assembly

Warning: Appropriate care and safety procedures should be followed to

avoid breaking any glassware and causing injury to the operator. Broken

glassware should be handled with appropriate care. ▲

Gloves must be worn when handling glass or ceramic torches as handprints will reduce the life of

the torch and may cause the torch not to light.

5.1 Duo and Radial Torch Assembly

The O-rings in the metal torch mount (3 internal & 2 external) should be inspected and replaced if

any wear, or damage, is visible.

Gloves must be warn when handling a torch as contamination from hands will make the torch

harder to light and reduce its life.

The quartz body of the torch should be pushed into the metal torch mount. Ensure the torch body

is pushed fully into the metal torch mount. The marked circle on the quartz torch should be

aligned with the notch on the torch holder assembly and the associated line marking on the torch

should be aligned with the edge of the torch holder assembly.

The alignment of the torch markings in accordance with the torch holder assembly are essential

in order to ensure that the optical radial view hole on a duo torch and gas holes are correctly

aligned.

Page 9 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5.2 Center Tube Options

5.2.1 1mm with 2 RED bands centre tube

Used for organic solvents. Used for both radial and duo instruments.

This is to reduce the amount of sample reaching the plasma as larger center tubes result in too

much sample reaches the plasma and the plasma may go out.

5.2.2 1.5mm RED band centre tube

Best compromise for a radial instrument,

5.2.3 2mm Blue band centre tube

Best Compromise for a duo instrument.

5.2.4 2mm Ceramic centre tube

Used for specific sample types (for example hydrofluoric acid digests)

5.3 Centre tube holder

Check the 4 o-rings in the Center tube holder are not damaged. Insure the centre tube is inserted

fully into the plastic centre tube holder.

Note: the tip of the centre tube holder will discolor with use. This discoloration is normal and will

not affect the performance of the torch holder assembly. ▲

Page 10 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5.4 Centre tube insertion into torch holder

Insert the centre tube assembly into the metal torch holder.

Screw the centre tube holder assembly in a clockwise direction into the metal torch holder until

the o-ring is compressed. Do not over tighten as this will reduce the lifetime of the O-ring seal.

When fitted the center tube should be 1-3mm lower than the intermediate tube as shown above.

5.5 Torch holder insertion into the torch box

Insert the torch holder into the

torch box and turn the metal torch holder clockwise until the red orientation lock self locates in the

torch box casting.

5.6 Positioning of the spray chamber drain

Insert the white plastic tubing connector and wide bore tubing (0.79mm inner diameter) into the

spray chamber drain tube. The drain and spray chamber should be positioned so that no pulsing

Page 11 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

occurs during the liquid removal.

5.7 Position of the nebulizer in the spray chamber

Liquid should be delivered to the nebulizer using an identical plastic tubing connector but with

narrow bore tubing (0.50mm inner diameter). Push the white plastic tubing connector with the

attached narrow bore sample tubing into the rear of the nebulizer as far as possible without

exerting undue pressure.

The O-rings in the spray chamber should be inspected and replaced if any wear, or damage, is

visible. Using a twisting motion, insert the nebulizer into the spray chamber so that the collar is a

tight fit. The collar will set the insertion depth and aid reproducibility of results.

Attach the quartz glass spray chamber adaptor to the spray chamber with the fitting clamp

provided.

Warning: The adaptor provided with the instrument is specially designed to prevent UV radiation

escaping from the torch box. ▲

Page 12 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5.8 Connection of spray chamber adaptor to torch assembly

Insert spray chamber adaptor fitting into torch assembly holder as far as it will go, and connect up

the Nebulizer gas supply to the push-fit fitting.

After assembly of the sample introduction system and prior to ignition of the plasma checks

should be made for correct assembly:

• Make sure the torch is fully rotated and locked in place.

• Make sure the centre tube holder is fully rotated and locked into the torch.

• Make sure the spray chamber adaptor is fully pushed into the torch body.

• Make sure the spray chamber is tightly clamped to the spray chamber adaptor.

Problems in any of these areas may cause air leaks or disruption of the gas flows making the

plasma difficult to ignite and may cause damage to the torch.

WARNING: It is extremely important that the correct Thermo Scientific parts are used for the

sample introduction system. In addition interlocks on the torch holder and other parts of the

instrumentation are there for safety and must not be bypassed. Operators could be exposed to

dangerous UV and radio frequency radiation if alternate parts are used for the spray chamber

adaptor. ▲

Page 13 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5.9 Connection of pump tubing

The following figure shows the peristaltic pump and 2-stop windings are typical of the iCAP 7200.

iCAP 7200 sample pump tubing has white and orange stops and the drain tubing has white and

white stops.

The iCAP 7400 and 7600 instrumentation has a Mini Pump and 3-stop windings (providing two

sections for reduced running costs.

The sample pump tubing has yellow, white and yellow stops. The drain pump tubing has white,

blue and white stops.

For all instrumentation the assembly procedure is similar:

• Feed the sample capillary tubing from the rear of the nebulizer through the upper holder

in the cover and towards the pump.

• Ensure there are no twists or bends in the nebulizer and drain PTFE tubing that may

prevent flow of the sample.

• Pass the drain capillary tubing through the lower holder in the cover and towards the

pump. The lower holder contains a drain sensor detecting bubbles produced when the

spray chamber is draining normally. The plasma and the pump will be switched off after 2

minutes if no bubbles are detected.

• Insert the sample and drain PTFE tubing into their respective peristaltic pump tubes.

Page 14 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Note: the drain tubing should be connected correctly to the peristaltic pump to account for the

anticlockwise flow.

• Release the pump tubing clamps and locate the sample and drain pump tubing over the

pump rollers, locking the lugs on the pump tubing into the left and right clamps.

• Connect the sample pump tubing to the sample capillary tubing and the drain pump

tubing to the drain capillary tubing; remember to allow for the direction of flow.

• Pump tubing should be inspected before each analysis and should be replaced if there

are indications of wear.

• Additional lengths of capillary tubing should be used to allow connection to the input of

the sample pump tubing to the sample and the output of the drain pump tubing to a waste

container.

• For a freely aspirating nebulizer. The pump tension can be adjusted with the plasma

running and the pump stopped. Lock the sample pump tubing and clamp into position.

Release the tension adjustment and allow the nebulizer to free aspirate. Tighten the

tension adjustment until the flow just stops then tighten by one turn. Turn on the pump

and, if necessary, tighten the tension until a smooth flow is produced.

• Do not over-tighten the pump clamps as it will result in excessive wear and tear of the

pump tubing and require replacement tubing at more frequent intervals.

Page 15 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5.10 Radial view window on a Duo instrument.

For a Duo instrument check that the radial view bucket shaped window is in place and clean. It is

possible to rotate the window holder to gain access (take the torch out before inspection). When

assembling the torch and radial view window insure the window is located against the torch as

shown below:

Page 16 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

5.11 iCAP Sprint Valve installation guide (iCAP 7600 only)

5.11.1 Connecting the tubing

Fit the drain fitting to the spray chamber

(black ringed), insert the fittings capillary

tube into the yellow/blue peristaltic pump

tubing and attach it to the pump so that the

waste runs counter clockwise across the

pump: Cut a length of the supplied drain

tubing so it can reach between the pump

tubing and the waste container.

Page 17 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Inset the tubing with the green valve fitting

and the carrier uptake tube (bubbler) into

the white/white peristaltic pump tubing:

Attach the pump tubing onto the peristaltic

pump so that the bubbler runs counter

clockwise across the pump:

Screw the green valve fitting into port 5 on

the valve head:

Next take the white valve fitting tube and

attach one end to port 3 on the valve head:

Page 18 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Screw the other end of the fitting tube into

the vacuum valve connector on the iCAP:

Attach the vacuum pump waste tubing to

the waste out connector on the iCAP, and

insert the other end into the waste

container:

Screw the autosampler probe valve fitting

into port 2 on the valve head:

Attach the sample loop into ports 1 and 4

on the valve head (this is the same as the

loop provided in the Field Service Test Kit):

Page 19 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Screw the fitted nebulizer tube into port 6:

Attach the other end on the nebulizer line

and the nebulizer gas fitting onto the

nebulizer:

5.11.2 Manual sampling using the Sprint Valve

Manual sampling uses the Inject position (5) with a standard or non-aerating sample probe.

Page 20 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

6 Autosampler Use

6.1 Introduction

The autosampler can be configured to suit an application, or several applications.

The volume, number and type of sample will all influence the set-up of the autosampler and

instrument.

6.2 Autosampler Installation

To comply with safety and warranty requirements the iCAP 7000, accessories and associated

equipment must be installed by a Thermo Fisher trained and certified engineer.

Refer to the Autosamplers Operators Manual for assembly and maintenance.

6.3 Autosampler Set-up

For analysis with an autosampler the capillary tubing attached to the end of the autosampler

probe should be attached to the end of the sample pump tubing on the iCAP 7000. To minimise

the sample volume required the length of the capillary tubing should be minimised, but should

allow free movement over the whole sample area of the autosampler.

Page 21 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

7 Instrument Optimization

The iCAP 7000 will require optimization that is dependent on the sample being analyzed and the

method requirements.

It is important that the method development verifies the data produced by the method.

It is also important that a suitable quality control regime is established that verifies the continuing

validity of data.

Training courses are available through a local Thermo Scientific Sales Office; contact details are

available at www.Thermoscientific.com.

7.1 Instrumental method optimization

The following parameters can all affect the data obtained and should be optimized. Usually a

default setting will give data that is satisfactory, (Apart from a Duo iCAP where radial / axial views

have to be selected manually) may not be optimal for the analysis requirements:

7.1.1 Nebulizer Gas flow

Changes the nebulisation performance and Viewing Height on a radial instrument.

7.1.2 Radial instrument Plasma viewing height

Used to select optimum height view height.

7.1.3 Radial Axial View

On a Duo instrument you have a choice of Axial and Radial views you will have to select the view

you want to use manually. General rule all low Wavelengths Axial View, all High Wavelengths

Radial view.

7.1.4 RF Power

1150 works with most samples you may want to select higher power for organics, High TDS

samples

7.1.5 Pump speed

45-50 RPM for most samples as low as 20 RPM for organics to reduce the plasma loading.

7.1.6 Auxiliary gas flow

0.5l/min works on most samples 1l/min may be required for high TDS and 1.5- 2l/min for organic

samples.

7.1.7 Coolant gas

12l/min works with most samples 14L/min for organics if (7600 only)

7.1.8 Additional gas supply

For organics samples to burn off the excess Carbon normally set to about 25ml/min

7.1.9 Organics Check box

To enable Autopeak to be performed with organic standards.

7.1.10 Sample chemistry

All instrument parameters are separate to the development of the chemical requirements of the

method, for example variation in sample ionization solvent volatility and viscosity effects.

Page 22 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

7.2 Example Standard Operating Procedures

This method setup procedure, which by no means covers all the possible parameters used in

Qtegra, should be enough for setting up a basic analysis. It is recommended that the user reads

the iCAP software manual for more advanced use of the system.

7.3 Preparing the System

Turn Argon Gas on at Cylinder and set for 0.55 MPa (5.5 BAR) pressure on gauge near

instrument

Turn on the purge gas if separate

Note: for normal use gas should be left purging constantly ▲

Turn on the air supply for the Additional gas supply (7600 only) if used.

Switch on power to iCAP Spectrometer.

Note: for normal use power should be left on constantly. ▲

Switch on Water Chiller

Push Platen on to rollers of pump by way of the 4 (3) pressure screws

Make sure the drain tube is placed in an open neck vessel

Place sample tube in a blank solution

Switch on computer

Click on the Qtegra Icon on the computer desktop.

7.4 Striking the Plasma

Click on Qtegra to open the program.

7.4.1 Interlocks

Check the interlocks are all green and take appropriate action if any are RED

Page 23 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Torch Compartment Interlock:- If red this indicates the torch door is open or the torch holder is

not inserted correctly. The plasma will not light.

Plasma gas pressure:- should be green if the plasma gas input pressure is 5.5 Bar, if it turns red

during the ignition sequence it indicates problems with the external gas supply to the iCAP If red

the plasma will not light.

Purge gas pressure:- should be green if the input pressure for the plasma gas is 5.5 Bar, if it

turns red during the ignition sequence it indicates problems with the external gas supply to the

iCAP. If red the plasma will not light.

Detector water flow:- should be green if the correct water flow is flowing for the camera to cool

down and the RF to light the plasma. If red the plasma will not light. (If the LED flickers even

slightly the plasma will go out and this indicates there is a problem with the chiller.

Drain Flow sensor:- if this is red this indicates that the iCAP has not seen an air bubble in the

drain sensor for two minutes, it will turn the plasma off. To reset the drain sensor turn the pump

on to 45RPM.

Exhaust flow;- This interlock checks that the exhaust is of sufficient flow to ensure the safe

removal of heat and combustion gases. (In a 20 second period the extraction needs to be low for

5 seconds for the interlock to occur.

Detector Temperature:- This interlock indicates that the camera has cooled down to -45ºC and

is ready to measure samples. (Notes: RED = too hot, Green = -45ºC Blue = Too cold.) When the

chiller is turned on the camera will take 5 minutes to cool down to -45ºC.

Optics temperature:- This indicates that the optical tank has reached the operating temperature.

From cold it could take 2 hours to reach 38ºC and an additional 1 hour to fully stabilize.

When ready, click on the “red ringed” Get ready icon on the Dashboard Page:

Page 24 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

This will bring a page up with several options.

1. The ‘Warm Up’ time is normally set to 15 minutes to enable the system to stabilize prior to

spectrometer optimization.

2. ‘Spectrometer Optimization’ is normally turned on to make an automatic minor adjustment to

the spectrometer optics.

3. ‘Run Performance Checks’ will run the factory recommended performance test using defined

sample introduction and Standards. (On installation the Torch Alignment and Autopeak must

be completed first).

4. Use Manual Sampling. If an autosampler is configured this will enable the use of manual

sampling.

Clicking OK will turn the plasma on and spectrometer optimization will be performed. During

these procedures the remaining warm-up time is shown in the Dashboard page.

▲Note: To allow the plasma to stabilize leave Plasma on with blank solution running for about 10

minutes before carrying out an analysis.

7.5 Setting up Analyses

7.5.1 LabBooks

On the Homepage, click LabBooks. The LabBooks page of Qtegra opens.

When creating a new LabBook select eQUANT, enter a name and select a location.

Page 25 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

LabBooks can be created from blank Templates, existing Templates, imported Templates of

appropriate configuration, or from existing LabBooks.

From Analytes use the Periodic Table to begin selecting your elements of choice by pausing

cursor over the element symbol to see a preferred wavelength list as shown below.

Page 26 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

From Analytes use the Periodic Table and a left click on the element of choice to auto pick from

the top of the preferred wavelength list.

Where the first element wavelength is not desired, a right click will bring up a window and allow

optional selections. This also will show interfering elements graphically (assuming they are the

same concentration as the analyte).

Page 27 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

From Measure Modes, source parameters such as RF Power, Nebulizer and Additional Gas flows

(if used) and Exposure Time(s) may be adjusted.

The Acquisition Parameters window shows (among other things) default slit positions, measure

mode view used and left and right background settings.

Here Analysis Modes Speed, Normal, Sprint, and sample pump RPM’s can be set.

Page 28 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Note:- Blanks (all zero concentration) are selected in the sample list view and not in the standards

list.

From the Standards window select “New” to add a standard where “Elemental Standard” should

be selected.

The default concentration can be set prior to creating the standard by clicking the button to

minimize typing. Otherwise double click each Concentration field and type in values.

Repeat this for each standard and QC check required for the Method/LabBook.

Page 29 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

As above, double click each Concentration field and type in appropriate values.

As above, double click each Concentration field and type in appropriate values.

Page 30 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Select the Quality Control checkbox to bring up the Quality control menu.

When an autosampler is being used, define Wash Time and Uptake Times by selecting the

appropriate autosampler. Rack type selection changes may also be made here.

NOTE: For the iCAP 7600 Sprint Valve the Wash Time may be set to ZERO as this function is

multi-tasked with the Uptake Time, which can also be reduced to about 20 seconds as using the

Valve provides quicker sampling.

Page 31 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Use Manual Sample Control to disable the autosampler and define the Uptake and wash

times.

Use the Sample list to build a sequence and define the samples to be analyzed. Add lines

individually for BLANK and each of the calibration standards and QC checks. Use the label

identifier and sample type drop down list as required.

If using an autosampler identify the rack and vial for each sample at the far right on this table.

Click the down arrow next to the Add lines button for multiple rows additions.

Page 32 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Enter the number of Unknown samples you wish to run and click OK.

Under the Label column you can type individual identifiers’ or type one followed by a number

such as sample 1, then highlight the column, right click in the highlighted column and select

Increment fill to fill down with numbering.

This same Increment fill technique can be used for sample type and rack and vial at the end of

this table for sample tube locations.

Page 33 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

>>>

For incremental QC Checks, highlight the QC Check standard row, click the “Copy” tool bar

button, click the location where you would a check performed then click the “Insert” tool bar

button, repeat for each location desired. Every 10 samples is common, for this example 5 was

used. For a final check at the end of the sample list the “Append” tool bar button can be clicked.

Page 34 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

In the toolbar of your LabBook click Save.

7.6 Running the Analysis

In the toolbar of your LabBook click Run to schedule the LabBook for execution (will not be active

unless properly saved). The LabBook is added to the scheduler. If the check box Automatic has

been selected for Start Queue in the options settings of the scheduler the measurement is started

immediately.

Page 35 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Page 36 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

The LabBook sample sequence run will wait in the queue until the Scheduler “Run” button is

clicked ... unless the “Automatic” Start Queue has been selected in the Scheduler Options, in

which case the analysis is started immediately.

7.7 Auto Peak Adjust

For optimum performance it is important that the analyte wavelengths are correctly aligned in the

centre of the sub array measurement window. The iCAP 7000 Series Spectrometer will

automatically check a reference line each time the plasma is ignited to maintain wavelength

accuracy.

Auto Peak only needs to be run whenever a new wavelength is used for analysis. The

autopeak may also need to be run if the instrument has been switched off for an extended period

of time.

To carry out an Auto Peak, allow the plasma to stabilize for 10 minutes and in the Acquisition

Parameters of the Methods Parameters of your LabBook Qtegra select Perform Auto Peak.

Page 37 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Introduce the sample “Method development standard” (high standard concentration solution of

the selected element(s)). Ensure you leave enough time for the sample to enter the plasma and

then click OK. This procedure will set the default position for this line until the next auto peak

adjustment takes place. If all elements are not in the same solution then multiple standards may

be used.

The result of the test is displayed in the bottom (right side) of the page. If the test is unsuccessful

or partially successfully there is a message in the log view tab stating the reason of the failure.

This is normally due to the solution not being aspirated for long enough before the test began, or

a problem with the solution.

7.8 Setting the pump tension.

To ensure long life of the pump tubing and correct operation the pump tensioning has to be

performed.

The pump tension can be adjusted with the plasma running and the pump stopped. Lock the

sample pump tubing and clamp into position. Release the tension adjustment and allow the

Page 38 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

nebulizer to free aspirate. Tighten the tension adjustment until the flow just stops then tighten by

one turn. Turn on the pump and, if necessary, increase the tension until a smooth flow is

produced. Do not over-tighten the pump clamps as it will result in excessive wear and tear of the

pump tubing and require replacement tubing at more frequent intervals.

7.9 Torch Alignment

For maximum sensitivity and optimum results it is advisable to check the alignment of the torch

whenever it has been removed and replaced in the instrument or if the torch body or centre tube

has been replaced.

Click on Qtegra to open the program. In the Dashboard Page, click Torch Alignment to start

the procedure. Introduce a “loaded Blank” sample (2 ppm Zn solution). And ensure you leave

enough time for the sample to enter the plasma before clicking ok. Aspirate until the process is

finished. The result of the test is displayed in the bottom (right side) of the page.

7.10 Reporting results

Reporting can be found in the Query tab of acquired LabBooks. Reports are global and not

saved per LabBook. The latest report style will be available for any LabBooks that are opened

subsequently (where they can also be modified).

To change general settings, click on the Report Options button and change the required

parameters:

Page settings – Paper format, Portrait or Landscape, Font size...

Report Image – For example a company logo can be used.

Page 39 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

The report structure works by group with two types of groups: Result Group and Method

Parameter Group.

7.10.1 Result Group.

The general structure of reports is shown here with Result groups divided into Headers, Rows

and Columns:

Page 40 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

The general structure of reports is shown here with one group and several results (samples):

Having selected the Result group option different groups can be created and selected for the

report. The order of the groups can be changed as well using the arrows next to Create report.

Page 41 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

A name for the Result Group can be added and ticking boxes selects groups to add to data

reporting.

Press Create Report.

Selecting Show Calibration Graphs will display the graph before any results.

Page 42 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

The Header section allows selection of the information for each sample. This is displayed before

the results table.

The Rows section allows the selection of data appearing for each sample (Concentration

average, RSD...).

Page 43 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

The Columns selection allows the individual Analytes to be reported. This can be done

individually or transfer “Analytes” to the right to select all.

Save Groups saves changes to the group settings. Any groups saved can then be used or

modified for other LabBooks. The latest saved version is the “live” version.

Create Report applies settings to the current LabBook. The report can be printed or saved.

Going back to the group settings allows changes which can be and applied by selecting Create

Report.

Page 44 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

7.10.2 Method parameter group

As for the Result group, name the group.

Select the source of the data to be included in the report (create different groups to include

different sources) and within one source select the required fields to be included:

Table Options are used to set the formatting and the arrows next to Create Report are used to set

the positioning.

Page 45 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

7.11 Exporting Labbooks.

This can be used to obtain help by e-mail (Problem reporting).

From the home page go to File Manager, Right hand click a LabBook and select Export from the

menu:

Select the location to save the data and press OK:

Other data (such as instrument logs) can also be exported as a .csv file. This is particularly useful

when requesting Service Engineer help:

Page 46 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

7.12 Shutting Down the System

Follow the procedure detail earlier.

On the Dashboard Page, click on the “green ringed” Qtegra Driven icon.

Figure 5-9. System shut down

For the 7600 Sprint Valve open the Sprint Valve Configurator software from the desktop icon.

When the software starts most of the options will be grayed out, click “Connect to Sprint Valve”.

Expand the screen using the arrow button on the right side of the window to open manual

controls.

Verify both Sample and Rinse probes are in air, verify or set to Load, turn On the Vacuum Pump

Control for several seconds to evacuate the Sample Loop and Valve then turn Off.

Page 47 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Page 48 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

8 Maintenance

The iCAP 7000 has been designed for minimum maintenance. However, it is critical that the

sample introduction components be checked regularly for contamination and wear. Failure to do

so could result in loss of instrument performance.

Therefore, routine user maintenance of the iCAP 7000 is mainly concerned with keeping the

instrument clean.

Before using any cleaning or decontamination methods except those specified by the

manufacturer, the user should check with the manufacturer that the proposed method will not

damage the equipment.

8.1 Instrument Cleaning

Any spillage on the external covers or within the sample introduction areas should be cleaned up

immediately using appropriate safety precautions, prolonged contact with solvents and acids

could result in permanent damage.

Stains and marks on the covers should be removed with a soft cloth moistened with a mild

detergent solution. Do not use any solvent based cleaners.

8.1.1 Sample Introduction System Cleaning and Decontamination

Failure to maintain the sample introduction system can result in erroneous results, poor precision,

poor detection limits and blockages.

After use, the instrument shut down procedures from earlier in this manual should be followed.

Components contaminated with sample residues should be cleaned.

It is recommended that several spares for each part are available in case blockages, sample

contamination and breakages happen during analysis.

Suitable protective clothing, glasses and gloves should be worn.

8.1.2 Torch Cleaning

The O-rings in the metal torch mount (3 internal & 2 external) should be inspected and replaced if

any wear or damage is visible.

Warning: Allow at least 10 minutes for any hot components to cool before

removing them from the torch compartment. Care should be taken to remove any

broken glass from the Duo radial POP window if a breakage occurs in the torch

box. ▲

To remove salt deposits soak the torch in a dilute analytical-grade surfactant for five minutes.

To remove metallic deposits from the tip, separate the torch quartz section, immerse the tip of

the torch in a 10 % acid solution for several hours or until clean (a mixture of nitric and

hydrochloric acid is normally suitable).

After cleaning, rinse the torch with de-ionized water and place in a drying oven at 95°C until it is

dry. Rinsing with a volatile, zero residue, organic solvent (propanol is suitable) will aid drying.

To clean the torch of carbon deposits, place the torch in a muffle furnace and heat to 450°C.

Open the door for a few seconds to allow air to enter, close and allow the oven to reach 450°C

again. Repeat this several times to remove all the carbon. Allow the furnace to cool over several

hours, as this will prevent stress building up in the quartz.

Page 49 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

8.1.3 Spray Chamber Cleaning

If the spray chamber becomes greasy and droplets form on the inside soak the spray chamber in

a dilute analytical-grade surfactant for five minutes.

If the spray chamber becomes dirty or deposits form inside it, soak the spray chamber in a 10 %

acid solution for two hours (a mixture of nitric and hydrochloric acid is normally suitable). After

cleaning rinse the spray chamber in deionized water.

8.1.4 Nebulizer Cleaning

Rinse with deionized water, dilute acid or organic solvent at the end of each day, or aspirate a

cleaning solution through it.

Warning: Do not put the concentric nebulizer in an ultrasonic bath or heat it in an

oven. ▲

8.1.5 Purged Optical Path Window Cleaning

Before attempting to clean the Purged Optical Path (POP) window (note: there is also one below

the torch on a Duo configuration instrument) turn off the plasma and allow thirty minutes for any

hot areas to cool down.

Open the small access door next to the sample compartment door and withdraw the POP window

assembly. Clean the POP window using a lint free cloth and clean water. Repeat the cleaning

process using methanol then, when dry, re-insert the POP window into the fore optic assembly.

Warning: Do not open this access door when the plasma is running, there is a

potential UV radiation hazard. All mirrors in the optical system are coated so be

sure not to touch the mirror below the radial view POP window in the Duo

configuration. ▲

If further cleaning is necessary, remove the quartz window from the POP window holder and soak

in a 10 % acid solution for two hours (a mixture of nitric and hydrochloric acid is normally

suitable). After acid soaking rinse in de-ionized water, then with a volatile, zero residue, organic

solvent (propanol is suitable) to aid drying.

The radial view window below the torch on a Duo instrument can be treated in the same way.

8.2 Preventive Maintenance

Although minimum user maintenance is required, periodic checking of performance is required by

many laboratories. This is particularly important for customers subject to external standards and

regulations (for example ISO9000, EPA or UKAS). Details of these options are available from a

local Thermo Fisher Office.

All electrical supplies, gas supplies and extraction must be checked to ensure local health and

safety guidelines and regulations are complied with. The gas and cooling water should be

checked for leaks at regular intervals.

8.2.1 Water Chiller

It is important that the cooling fluid used is made up correctly as specified in the Site Guide (Pre-

installation Guide).

Page 50 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Warning: Failure to maintain your chiller with the appropriate cooling fluid may

cause internal damage to your instrument.

An effective maintenance plan would include replacing the cooling fluid with new fluid at least

once every six months depending on the usage of your instrument, and also to ensure that any

air filters and water filters a kept clean. Refer to chiller manufacturers documentation for

more information.

8.2.2 Water Filter

The water filter fitted between the chiller and the iCAP inlet must be checked for cleanliness to

prevent loss of instrument performance. If the filter appears dirty, flush out your chiller and clean

the filter.

8.2.3 Gas Filters

Gas filters fitted to your purge and plasma gas inlets must be checked for cleanliness to prevent

loss of instrument performance. If the filters appear dirty, replace them and check the quality of

your gas supplies.

8.2.4 Sprint Valve (optional hardware)

Routine maintenance of the Sprint Valve rapid sample introduction system consists of daily and

weekly cleaning of specific components. Routine maintenance also includes checking sprint valve

components for leaks or other damage. Additional periodic maintenance tasks may be required,

including replacement of the following components: peristaltic pump tubing, rinse tubing, and

sample probe.

8.2.4.1 Regular Inspection of Components

The procedure for cleaning the sprint valve, inspection for leaks and replacing damaged

components is detailed below.

It is important to verify that all system components are in good working order and are undamaged

prior to operation.

Visually inspect these components:

Valve/pump module:

6-port valve

Vacuum pump ports

Peristaltic pump on the autosampler

Tubing— pay special attention to all tubing to ensure that no kinks exist, as this condition will

impair proper performance of the Sprint Valve system by reducing flow rates. Check that

tubing is not rubbing against moving parts.

Cables

If you detect a leak or other damage to any Sprint Valve Rapid Sample Introduction System

component, you must replace it.

8.2.4.2 Cleaning the System

Cleaning the Sprint Valve Rapid Sample Introduction System is a primary maintenance task.

Failure to do so regularly causes increased wear and reduces the system’s life.

The Sprint Valve must be cleaned daily to protect the instrument, prevent damage and extend its

life. Follow appropriate Health and Safety procedures dependent on the chemicals and samples

used.

Page 51 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

8.2.4.3 Daily External Cleaning

The Sprint Valve is often operated in environments where spills and exposure to vapors is

common. Good maintenance requires that you clean the system daily.

8.2.4.4 Cleaning the 6-Port Valve

It will be necessary to periodically disassemble the 6-port valve and clean the inside to prolong

the life of the valve. Cleaning must be done in a clean area to prevent contamination of the valve.

NOTE

It is recommended to clean the 6-port valve every 20,000 cycles, or approximately every 1-2

weeks. However, the frequency of cleaning interval will vary depending on application.

The valve head should be cleaned regularly as part of the routine maintenance of the sample

introduction components; spray chamber, nebulizer etc. To clean the valve, complete the

following steps:

To clean the valve head start by removing all of the tubing connectors from the 6 port valve:

Use the 7/64 hexagonal key provided to remove the three screws in the front of the valve:

NOTE

Do not remove the valve body from the instrument as it will lose its position and will need

retraining using the home valve function in the sprint valve Configurator software.

Page 52 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Remove the Stator and the separator, noting their orientation:

Carefully remove the rotor, from the valve:

Using a clean cloth, gently clean the channels, ports and surfaces of the stator and rotor. If

necessary use low-pressure, canned air to blow the channels and ports free of any remaining

debris.

Page 53 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Carefully replace the rotor into the valve, the rotor will only fit in the correct orientation, forcing it

will cause damage.

Page 54 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Place one of the screws through the stator and separator and reattach it to the valve, in the

orientation noted during removal:

Using the hexagonal key, tighten all three screws, to firmly set the parts in place:

NOTE

The screws should be finger tight with the separator unable to move independently, over

tightening can cause damage to the rotor.

Page 55 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Reattach the tubing connectors and use the ‘manual cycle’ function in the sprint valve

Configurator software to check for leaks:

8.2.4.5 Checking for Leaks

The tubing has a finite lifespan, and will wear out under normal use. Standard maintenance

procedures require that you periodically check for leaks. To do so, complete the following steps:

• Visually inspect all tubing and valves for leaks or signs of deterioration.

• Visually inspect the surfaces below all tubing for signs of liquid.

If you detect a leak or other damage to any component, you must replace it. For more

information, see the appropriate section in this chapter.

8.2.4.6 Replacing the Tubing

To replace the tubing, complete the following steps:

• Remove and replace all tubing as necessary, using care to remove/replace tubing at barb

fittings and at compression type fittings without damaging those fittings to which they

connect.

For more information on how to install the rinse tubing refer to the installation section earlier.

8.2.4.7 Replacing or Reorienting the 6-Port Valve

The 6-Port valve assembly has a finite lifespan that is dependent upon the conditions and sample

media to which it is exposed. Exposure to higher sample solids levels reduces the valve lifespan.

To determine whether the 6-port valve requires replacement, inspect the unit for these conditions:

• Valve dripping or leaking from the overflow hole behind port #4 at bottom of the valve body.

• With no other apparent problems, air is present in the lines (indicating a leak or poor seal).

The valve can also be reoriented so that the nebulizer port is as close as possible to the

nebulizer.

Note that any time the 6-port valve body is removed from its actuator; the valve will require

retraining (re-initialization).

To replace or re-orientate the 6-port valve:

Page 56 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Remove all of the tube connectors to the 6 port valve:

Using the provided hex key (9/64), loosen the hex screw on the locking collar which secures the

base of the valve to the instrument:

Firmly but carefully remove the valve head:

Insert the new valve, or reinsert the existing valve, at the desired angle. Rotate it so that the

nebulizer port will be as close as possible to the nebulizer.

Page 57 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Push in the valve to make sure that it is completely seated, there should be no gap between the

valve and the collar:

Use the hex key to tighten the locking collar:

Open the sprint valve Configurator software:

Expand the software using the arrow button on the right side of the window and click

‘home valve’:

Page 58 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

Reconnect the tubing:

Check for any leaks using the manual cycle function:

Page 59 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

9 Analytical Problems Hints and Tips

9.1 Poor Precision

A quick test should be run to determine if the poor analytical results are matrix

related.

A 10 ppm solution of a few common elements such as Cu, Mn, Ba, Cd, Zn and

Fe should be put together and a metho

methodd made using the primary lines and

default conditions.

After standardisation, the standard should read back, on the iCAP for example,

with a precision of typically 0.2 to 0.5 percent (with a 10 second integration

time). If the precision obtained is substantially greater than this try Torch

alignment then go o on to trouble-shoot

shoot further if the problem remains.

If the instrument meets these specifications then the sample matrix itself is

suspect.

Possibly modifying plasma parameters such as power will help the situation.

Poor precision generally relates to

problems

lems in the sample introduction

system.

First check to ensure that the

nebuliser pressure or flow is set

correctly by aspirating a 1000 ppm

Yttrium solution (Sodium will also

work if no Yttrium is available).

Check to ensure that the centre

orange "bullet" is even with or slightly

above the top of the Radial torch. If

not, adjust the nebuliser pressure up

or down until the "bullet" looks correct.

At this point the nebuliser pressure

should be approximately 0.15 mPa

(150kPa/25psi) for aqueous solutions.

If the pressure is substantially higher,

the nebuliser orifice is generally to

blame and should be cleaned.

Pooling and dripping in the spray

chamber can also cause many

precision

ecision problems. You may be able

to see this visually using the Y test

described above.

If the Yttrium "bullet" is bouncing up

and down inside the plasma, it is

Page 60 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

usually indicative of dripping. In a

glass or Teflon chamber the chamber

should be wetted properly;

operly; that is

there should be no water droplets

building up on the walls of the spray

chamber.

This is usually caused by an oily film

and can be easily cured by aspirating

a 0.1% HF acid solution for about 20

seconds.

HF however, will cause a problem

with Si analysis for a short time

afterwards. If Si is being analysed try

using a 0.01%Triton

Triton X-100

X solution. Dirty Spray Chamber

This solution is also good for the

polypropylene spray chamber.

Clean Spray Chamber

Other causes of poor precision can be

in the expendable parts such as

nebuliser and torch/centre tube.

Spares should always be available

and these should be substituted one

by one to observe the result. If the

nebuliser is the culprit, check the

inside of the orifice, by removing the

gas fitting, then with a magnifying

glass look for any small obstruction.

Also check the capillary for

obstructions.

Page 61 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

9.1.1 Teflon capillary tubing:

Should be free of kinks and scissor or

pinch cut ends. For best results, razor cut

at 45° for the drain. Also check the

sample peristaltic pump winding condition

and platen pressure for proper adjustment.

Replace the winding if it is used or

collapsed. Pump

ump windings typically last

only a couple of days. Introduce an air

bubble into the sample uptake tube and

watch its migration through the tubing, it

should be smooth and consistent.

Worn rollers, bent pump head shaft or bad

roller bearings can cause inconsistent

inc

pump action and any such damaged

pumps should be replaced.

The peristaltic pump may also be

used for the pumped drain spray

chamber systems and the internal

standards mixing kits.

9.1.2 Peristaltic Sample Pump

Note: When using a concentric or crossflow free aspirating type nebuliser, the pump

platen pressure should be adjusted with the plasma torch ignited and the pump stopped.

To adjust the Platen Pressure

Dip the uptake capillary (which is

normally connected to a sipper probe)

into deionised water.

Withh the nebuliser gas switched on

gradually reduce the platen pressure

by pushing in the tension adjustment

lever until the water freely aspirates

through the pump tubing. You can

briefly remove the capillary or sipper

probe from the rinse for a short period

to introduce a small air bubble.

Tighten the tension adjustment until

the flow stops then tighten by one

more turn. Turn on pump and, if

necessary, tighten the tension until a

smooth flow is produced

With pump turned on adjust the drain

pressure to allow small bubbles to

flow in the drain tube

Finally, argon/air leaks can cause many problems including poor precision.

Check the gas fittings on the lines coming from the bulkhead to the torch and

nebuliser with a suitable soapy liquid su

such

ch as Snoop. Leaks at these joints are

usually caused by rough tubing and can be stopped by cutting off about 1/2 inch of

tubing and reinserting. Replace the tubing with ¼ inch Teflon if the tubing becomes

too short

Page 62 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

9.2 Poor accuracy/feedback

First we should define accuracy as reproducing the standard value once standardised

Proceed by making a standard as in the previous section (10 ppm Cu, Mn, Cd, Zn, Fe)

and using this as the test solution. Remember we are not defining accuracy for this test

tes

as the ability to read a 1 or 100 ppm standard after standardising on the 10 ppm. Most of

the time that problem is operator

operator-related.

related. As far as we are concerned at this point we

have only one standard to test with. If this simple standard will not repeat back for all

elements, check the pump winding first. Replace it if it is used or collapsed.

Note: Pump windings typically last only a couple of days.

Check the method to see if a fast pump rate is used for the flush period. If it is, then

make the flushh pump rate the same as the analysis rate and try it again. Inaccuracy

can sometimes be traced to the inability of the pump tubing to recover its shape

after being stretched.

Check the flush time for adequate rinse time. A 30-second

30 second rinse time is adequate in

most cases but not if a slow pump rate is being used or if a very long piece of tubing

is used (as with the autosampler probe).

9.3 Poor detection limits

This problem can be also related to

the poor precision problem discussed

earlier and is usually solved

solv by

approaching it as such. However, if

the loss of intensities is especially

pronounced at lower wavelengths it

may be due to a dirty window

mounted in the Purged Optical Path.

UV burn or a dirty mirror is

characterised by a long term decline

(six monthss or longer) of intensities.

Page 63 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

10 Suggested maintenance in the case of poor precision

and detection limits

10.1 Introduction

Maintenance refers to a series of periodic activities that should be performed on a

periodic basis to optimise the short term and long term performance of the system. In

this chapter we describe activities that should be performed by the typical user of the

instrument.

10.2 Typical Maintenance Schedule

Replace Pump Tubing Weekly

Clean the Nebuliser Weekly

Clean the Plasma Torch Weekly

Switching valve weekly

10.3 Replacing pump windings

Type Solvent Types

Tygon Aqueous solutions, strong acids and highly

polar organic solvents (e.g. methanol and

ethanol)

Viton Solvents of low polarity (e.g. alkanes,

aromatics and halogenated hydrocarbons

such as gasoline, kerosene, Toluene,

xylene, chloroform and carbon

tetrachloride).

SOLVAFLEX Solvents of low polarity (e.g. alkanes,

aromatics and halogenated hydrocarbons

such as gasoline, kerosene, Toluene,

xylene, chloroform and carbon

tetrachloride).

A pump tubing in poor condition is characterised by either being flattened hard or

discoloured. Squashed tubing is usually caused by leaving the platen pressure on

the tubing when it is not being used

To minimise squashing of the tubing, release platen pressure when the pump is not

being used, even for short periods. Hardened and discoloured tubing is caused by

chemical reactions with the sample. While these phenomena cannot be avoided,

they can be minimised by frequently flushing it with deionised water.

Page 64 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

10.4 Preventing blocking of

the nebuliser

The most common problem with the

nebuliser is the blockage of the tip by

the deposition of particulate matter. In

this section we provide a series of

suggestions to minimise blockage.

In most instances blockage in the

nebuliser is caused by either

particulate matter (from the sample)

or chemical deposits. It normally

occurs in the nozzle where the flow

passages are extremely small and

constriction is greatest in the annular

gas channel between the tip of the

capillary and the taper of the nozzle.

o Tip: Filter the sample. The sample capillary is more tolerant of particulate

matter than the gas annulus. For high sample uptake nebulisers, the capillary

will frequently transport visibly turbid suspensions. We suggest that you filter or

centrifuge the sample if the solids are not of analytical importance. Particulates

and colloids of a polar nature such as silica, peptides, polyvalent metal

hydroxides and others tend to build up on the (polar) glass and impede the fluid

flow. In some instances you can prevent deposition by adjusting the pH of the

suspension away from its isoelectric point.

o Tip: Rinse the nebuliser. It is very important to rinse the nebuliser before

turning the gas off. It is advisable to rinse the nebuliser periodically throughout

the sequence (depending on the chemistry of your samples).

o Solids may be deposited in the nozzle as sample solvent evaporates, further

constricting the flow passages and reducing the signal. Rinsing will minimise or

eliminate these deposits.

o Gas flow through most nebuliser models creates a venturi suction at the capillary

tip which can be used to draw rinse liquid through the capillary.

o After the testing of any salt solution, promptly rinse the system with a chemically

compatible rinse consisting only of volatiles (this is especially necessary in flow

injection analysis systems).

o A low-pH (acidic) sample should be followed by a low-pH rinse, a high-pH

sample by a high-pH rinse and an organic sample by an appropriate solvent.

The final rinse should use deionised water and/or isopropyl alcohol.

Note: Allow the nebuliser to dry before turning off the gas and make

sure that the liquid feed is disconnected or arranged so that siphoning into

the nebuliser while the gas is off cannot occur.

DO NOT use ultrasonic cleaning to remove particulate matter as

sympathetic vibrations may be set up in the capillary causing it to

bounce against the inside of the nozzle and chip, also do not use

any wire to clean capillary of the nebuliser. performance of the

nebuliser can decline as a result.

Page 65 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

10.5 Removing solids from the nebuliser

If solids inside the nebuliser are interfering with performance of the system, the

steps described below will generally remove them and provide normal operation.

10.5.1 To rinse the nebuliser

Introduce a rinsing agent into the shell, either from the gas input or the nozzle (a

squeeze bottle works well in both cases). Fill all areas previously exposed to

corrosive solutions.

Attach pressurised gas to the side-arm to expel the liquid.

Inject more rinse solution into the liquid input while the gas is flowing and allow

venture suction to draw it through the capillary.

The final rinse should use isopropyl alcohol to speed the drying process.

Repeat the treatment if you think it is necessary.

After the rinse is complete, dry the nebuliser completely.

10.5.2 Particles

These operations are ranked in order of increasing aggressiveness. We recommend that

you start with the gentlest procedure and continue with more aggressive procedures as

required.

Tap the liquid input line of the nebuliser gently against a wooden surface (or a

surface of comparable hardness) to shake the particle loose. This helps the particle

to move in the direction of increasing inner diameter. Repeat the tapping as

necessary to work the particle toward the appropriate exit orifice. Avoid extremely

harsh tapping.

Apply compressed gas (15-30 psi) to the nozzle, forcing the gas backwards through

the annulus and the capillary (back flushing).

Note: Make sure the nebuliser is held securely during this operation.

Gently tap or flick the shell soundly with your fingernail a few times. If this fails to

dislodge the particle, close off the liquid and gas input tubes with your fingertips.

When the pressure builds up, move your fingertip quickly off the appropriate orifice

(if something is wedged in the gas annulus, "pop" your finger off the gas input; if in

the capillary). The sudden expansion of gas should help jar the particle loose in the

direction of increasing inner diameter. Try to orient the nebuliser so that gravity

assists you.

Force isopropyl alcohol backwards through the nozzle in an attempt to float the

particle out through the larger gas and liquid input tubes. Use a squeeze bottle or

plastic dropper with a tip that will form a good seal over the nebuliser nozzle. After

the particle has been removed, remove the alcohol through the input tubes using

compressed gas, or drain onto lint-free tissue. A variation of this procedure involves

the use of a solvent that is known to dissolve the particle (this variation works best if

you know which passage the particle is in and your nebuliser is a type C or K with a

recessed capillary. In this procedure, inject a slug of 1/4" to 1/2" of solvent into the

shell through the nozzle or the gas input tube and close off the nozzle with a

fingertip. Apply pressurised gas to the passage that does not contain the particle.

Pressurised solvent will force its way out the other channel in the direction of

increasing diameter, hopefully carrying the particle along with it).

Page 66 of 71 This document is part numbered 849940090071 Version 1.01

iCAP Customer Familiarisation Manual

10.5.3 Solid deposit in sample capillary

Note: This step assumes that a passage still exists through the

contaminating material (i.e. the tip is not entirely clogged).

Try to deduce the chemical nature of the deposit from the type of samples that are