Professional Documents

Culture Documents

Technical Information: Determining Heat Energy Requirements

Uploaded by

Yosmar GuzmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information: Determining Heat Energy Requirements

Uploaded by

Yosmar GuzmanCopyright:

Available Formats

Thermal Devices, Inc. Mount Airy, Maryland USA 410-795-6100 www.thermaldevices.

com

Heat Tracing Sales Mount Airy, Maryland USA 410-795-2223 sales@heattracingsales.com

Technical

Technical Information

Determining Heat Energy Requirements

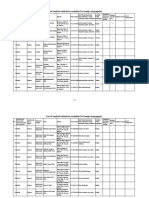

Pipe & Tank Tracing Table 1 — Heat Losses from Insulated Metal Pipes

(Watts per foot of pipe per °F temperature differential 1)

The following tables can be used to determine

the heat losses from insulated pipes and tanks Insulation Thickness (In.)

Pipe Size Insul. I.D.

for heat tracing applications. To use these (IPS) (In.) 1/2 3/4 1 1-1/2 2 2-1/2 3 4

tables, determine the following design factors: 1/2 0.840 0.054 0.041 0.035 0.028 0.024 0.022 0.020 0.018

3/4 1.050 0.063 0.048 0.040 0.031 0.027 0.024 0.022 0.020

• Temperature differential ΔT = TM - TA 1 1.315 0.075 0.055 0.046 0.036 0.030 0.027 0.025 0.022

Where: 1-1/4 1.660 0.090 0.066 0.053 0.041 0.034 0.030 0.028 0.024

TM = Desired maintenance temperature °F 1-1/2 1.990 0.104 0.075 0.061 0.046 0.038 0.034 0.030 0.026

TA = Minimum expected ambient 2 2.375 0.120 0.086 0.069 0.052 0.043 0.037 0.033 0.029

temperature °F 2-1/2 2.875 0.141 0.101 0.080 0.059 0.048 0.042 0.037 0.032

3 3.500 0.168 0.118 0.093 0.068 0.055 0.048 0.042 0.035

• Type and thickness of insulation 3-1/2 4.000 0.189 0.133 0.104 0.075 0.061 0.052 0.046 0.038

4 4.500 0.210 0.147 0.115 0.083 0.066 0.056 0.050 0.041

• Diameter of pipe or surface area of tank — 5.000 0.231 0.161 0.125 0.090 0.072 0.061 0.054 0.044

5 5.563 0.255 0.177 0.137 0.098 0.078 0.066 0.058 0.047

• Outdoor or indoor application 6 6.625 0.300 0.207 0.160 0.113 0.089 0.075 0.065 0.053

— 7.625 0.342 0.235 0.181 0.127 0.100 0.084 0.073 0.059

• Maximum expected wind velocity (if 8 8.625 0.385 0.263 0.202 0.141 0.111 0.092 0.080 0.064

outdoors). — 9.625 0.427 0.291 0.224 0.156 0.121 0.101 0.087 0.070

10 10.75 0.474 0.323 0.247 0.171 0.133 0.110 0.095 0.076

Pipe Tracing Example — Maintain a 1-1/2 12 12.75 0.559 0.379 0.290 0.200 0.155 0.128 0.109 0.087

inch IPS pipe at 100°F to keep a process fluid 14 14.00 0.612 0.415 0.316 0.217 0.168 0.138 0.118 0.093

16 16.00 0.696 0.471 0.358 0.246 0.189 0.155 0.133 0.104

flowing. The pipe is located outdoors and is in-

18 18.00 0.781 0.527 0.401 0.274 0.210 0.172 0.147 0.115

sulated with 2 inch thick Fiberglas® insulation. 20 20.00 0.865 0.584 0.443 0.302 0.231 0.189 0.161 0.125

The minimum expected ambient temperature is 24 24.00 1.034 0.696 0.527 0.358 0.274 0.223 0.189 0.147

0°F and the maximum expected wind velocity is 1. Values in Table 1 are based on a pipe temperature of 50°F, an ambient of 0°F, a wind

®

35 mph. Determine heat losses per foot of pipe. velocity of 20 mph and a “k” factor of 0.25 (Fiberglas ). Values are calculated using the

following formula plus a 10% safety margin:

1. Heat Loss Rate — Using Table 1, Watts/ft of pipe = 2 ϖ k (ΔT) ÷ (Z) In (D0/D1)

Where: k = Thermal conductivity (Btu/in./hr/ft2/°F) D1 = Inside dia. of insulation (in.)

determine the heat loss rate in W/ft of pipe ΔT = Temperature differential (°F) Z = 40.944 Btu/in/W/hr/ft

per °F temperature differential. Enter table D0 = Outside diameter of insulation (in.) In = Natural Log of D0/D1 Quotient

with insulation ID or IPS pipe size (1-1/2

in.) and insulation thickness (2 in.). Table 2 — Thermal Conductivity (k) Factor of Typical Pipe Insulation

Rate = 0.038 Watts/ft/°F. Materials (Btu/in./hr/ft2/°F)

2. Heat Loss per Foot — Calculated heat Pipe Maintenance Temperature (°F)

loss per foot of pipe equals the maximum Insulation Type 0 50 100 150 200 300 400 500

temperature differential (ΔT) times heat Fiberglas® or k value 0.23 0.25 0.27 0.30 0.32 0.37 0.41 0.45

loss rate in Watts/ft/°F. Mineral Fiber Based Adjustment factor (0.92) (1.00) (1.08) (1.20) (1.28) (1.48) (1.64) (1.80)

on ASTM C-547

ΔT = 100°F - 0°F = 100°F Calcium Silicate2 k value 0.35 0.37 0.40 0.43 0.45 0.50 0.55 0.60

Q = (ΔT)(heat loss rate per °F) Based on ASTMC-533 Adjustment factor (1.52) (1.48) (1.60) (1.72) (1.80) (2.00)

(2.20) (2.40)

Foamed Glass 2

k value 0.38 0.40 0.43 0.47 0.51 0.60 0.70 0.81

Q = (100°F) (0.038 W/ft) = 3.80 W/ft Based on ASTMC-552 Adjustment factor (1.52) (1.60) (1.72) (1.88) (2.04) (2.40)(2.8) (3.24)

3. Insulation Factor — Table 1 is based on Foamed Urethane k value 0.18 0.17 0.18 0.21 0.25 Not

Based on ASTMC-591 Adjustment factor (0.72) (0.68) (0.72) (0.84) (1.00) Recommended

Fiberglas® insulation and a 50°F ΔT.

Adjust Q for thermal conductivity 2. When using rigid insulation, select an inside diameter one size larger than the

(k factor) and temperature as necessary, pipe on pipe sizes through 9 in. IPS. Over 9 in. IPS, use same size insulation.

using adjustment factors from Table 2.

Table 3 — Heat Losses from Insulated Metal Tanks (W/ft2/°F)3

Adjusted Q = (Q)(1.08) = 3.80 W/ft x 1.08

Q = 4.10 W/ft Insulation Thickness (In.)

1/2 3/4 1 1-1/2 2 2-1/2 3 3-1/2 4 5 6

4. Wind Factor — Table 1 is based on 20

mph wind velocity. Adjust Q for wind 0.161 0.107 0.081 0.054 0.040 0.032 0.027 0.023 0.020 0.016 0.013

velocity as necessary by adding 5% for 3. Values in Table 3 are based on a tank temperature of 50°F, an ambient of 0°F, a wind

each 5 mph over 20 mph. Do not add velocity of 20 mph and a “k” factor of 0.25 (Fiberglas®). Values are calculated using the

following formula plus a 10% safety margin:

more than 15% regardless of wind speed. Watts/ft2 = Y k(ΔT ) ÷ X k = Thermal conductivity

INFORMATION

TECHNICAL

Where: Y = 0.293W/hr/btu X = Thickness of insulation (in.)

Adjusted Q = (Q)(1.15) = 4.10 W/ft x 1.15 Δ = Temperature differential (°F)

Design heat loss per linear foot

Q = 4.72 W/ft Note — The above information is presented as a guide for solving typical heat tracing applica-

tions. Contact your Local Chromalox Sales office for assistance in heater selection and for pipes

Note — For indoor installations, multiply Q by 0.9. made of materials other than metal.

I-11

Heat Tracing Sales Mount Airy, Maryland USA 410-795-2223 sales@heattracingsales.com

Thermal Devices, Inc. Mount Airy, Maryland USA 410-795-6100 www.thermaldevices.com

Thermal Devices, Inc. Mount Airy, Maryland USA 410-795-6100 www.thermaldevices.com

Heat Tracing Sales Mount Airy, Maryland USA 410-795-2223 sales@heattracingsales.com

Technical

Technical Information

Determining Heat Energy Requirements 4. Insulation Factor — Table 3 is based on

Fiberglas® insulation and a 50°F ΔT.

Adjust Q for thermal conductivity (k factor)

Pipe & Tank Tracing (cont’d.) Tank Tracing Example — Maintain a metal and temperature as necessary, using

tank with 2 inch thick Fiberglas® insulation at factors from Table 2.

Tank tracing requires an additional calculation 50°F. The tank is located outdoors, is 4 feet in

of the total exposed surface area. To calculate diameter, 12 feet long and is exposed at both 5. Wind Factor — Table 3 is based on 20

the surface area: ends. The minimum ambient temperature is mph wind velocity. Adjust Q for wind

0°F and the maximum expected wind speed is velocity as necessary, by adding 5% for

Cylindrical Tanks — r each 5 mph over 20 mph. Do not add

15 mph.

Area = 2 ϖ r2 + ϖ DH more than 15% regardless of wind speed.

A = ϖ D (r + H) H 1. Surface Area — Calculate the surface area Note — For indoor installations, multiply

of the tank. Q by 0.9.

A = ϖ D (r + H)

A = ϖ 4 (2 + 12) 6. Calculate Total Heat Loss for Tank —

Horizontal Tanks — D

A = 175.9 ft2 Multiply the adjusted heat loss per square

Area = 2[(W x L) + (L x H) + (H x W)] foot per °F figure by the temperature

2. Temperature Differential (ΔT) differential. Multiply the loss per square

foot by the area.

ΔT = TM - TA = 50°F - 0°F = 50°F

Q = 0.04 W/ft2/°F x 50°F ΔT = 2 W/ft2

3. Heat Loss Per Foot2 — Obtain the heat

H Q = Adjusted W/ft2 x tank surface area

loss per square foot per degree from

L Q = 2 W/ft2 x 175.9 ft2

Table 3.

W Heat Loss from Tank = 351.8 Watts

Heat loss/ft2/°F = 0.04 W/ft2/°F

Comfort Heating Comfort Heating Chart

For complete building and space heating ap-

5600

plications, it is recommended that a detailed

.

analysis of the building construction heat

. ft

5200

t.

ft.

.f

Cu

losses (walls, ceilings, floors, windows, etc.)

u.

/C

W/

/C

4800

W

W

1.5

.5

be performed using ASHRAE guidelines.

-2

-2

A-

4400

C

B

This is the most accurate and cost effec-

Volume of Room or Space (Cubic Feet)

. ft.

tive estimating procedure. However, a quick /Cu

4000 4W

estimate of the kW requirements for room and D-

3600

supplemental heating or freeze protection can

be obtained using the chart to the right. 3200

Problem — A warehouse extension measures 2800

20 ft long x 13 ft wide x 9 ft high. The building 2400

is not insulated. Construction is bare concrete

block walls and an open ceiling with a plywood 2000

deck and built-up roof. Determine the kW 1600

required to maintain the warehouse at 70°F

1200

when the outside temperature is 0°F.

800

Solution —

400 Estimating kilowatts required to maintain

1. Calculate the volume of the room. 70°F with an outside temperature of 0°F

0

20 ft x 13 ft x 9 ft = 2,340 ft3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Kilowatts Required

2. Refer to the chart, use Curve D which Curve A — Rooms with little or no outside exposure. No roof or floor with outside exposure; only 1 wall exposed with not

corresponds to the building construction. over 15% door and window area.

Curve B — Rooms with average exposure. Roof and 2 or 3 walls exposed, up to 30% door and window area. But with roof,

3. Find the intersection of 2,340 ft3 with walls and floor insulated if exposed to outside temperatures.

curve D. The kilowatts required are 9.3 kW.

Curve C — Rooms with roof, walls and floor uninsulated but with inside facing on walls and ceiling.

Suggest using a 10 kW unit blower heater.

Curve D — Exposed guard houses, pump houses, cabins and poorly constructed rooms with reasonably tight joints but no

Note — If the volume of the room is larger insulation. Typical construction of corrugated metal or plywood siding, single layer roofs.

than the chart values, divide by 2, 3, 4, etc. until the trial volume fits the curve. Then select heater

from this volume. Multiply heaters selected by the number used to select the trial volume.

I-12

Heat Tracing Sales Mount Airy, Maryland USA 410-795-2223 sales@heattracingsales.com

Thermal Devices, Inc. Mount Airy, Maryland USA 410-795-6100 www.thermaldevices.com

You might also like

- IEEEDocument66 pagesIEEEyogkrishnaNo ratings yet

- 2 - Civil Liberties Union Vs Executive SecretaryDocument3 pages2 - Civil Liberties Union Vs Executive SecretaryTew BaquialNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- Gas Generator Set G3516: Standby PowerDocument4 pagesGas Generator Set G3516: Standby PowerGeneral-Turbos Machinery100% (4)

- CF34-10E LM June 09 Print PDFDocument301 pagesCF34-10E LM June 09 Print PDFPiipe780% (5)

- Gaseous Fuels - Application & Installation Guide - Lebw4977Document48 pagesGaseous Fuels - Application & Installation Guide - Lebw4977Yosmar Guzman100% (1)

- MOZLEY Wellhead DesanderDocument2 pagesMOZLEY Wellhead DesanderYosmar GuzmanNo ratings yet

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Corrosion - M-506r2 - IFE - 06-2005Document59 pagesCorrosion - M-506r2 - IFE - 06-2005Yosmar GuzmanNo ratings yet

- API Standard 521 - Guide For Pressure-Relieving and Depressuring Systems PDFDocument9 pagesAPI Standard 521 - Guide For Pressure-Relieving and Depressuring Systems PDFYosmar Guzman100% (3)

- 4 5827923419810760428Document250 pages4 5827923419810760428T M Santhosh KumarNo ratings yet

- Separator Design MethodologyDocument19 pagesSeparator Design Methodologyromdhan88100% (1)

- Guidelines For Hydraulic Desig of Multiple Pipe Slug CatchersDocument34 pagesGuidelines For Hydraulic Desig of Multiple Pipe Slug CatchersYosmar Guzman75% (4)

- AIFI Association of Indian Forgin IndustryDocument7 pagesAIFI Association of Indian Forgin IndustryDnyanesh ThorathNo ratings yet

- Advanced Heat TransferDocument17 pagesAdvanced Heat TransferDiego Serrate100% (1)

- NYY 1 X (1.5-500) MM 0.6/1 KVDocument5 pagesNYY 1 X (1.5-500) MM 0.6/1 KVFebi HerdianaNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- ASTM D6560 AsfaltenosDocument5 pagesASTM D6560 AsfaltenosCarlos Garcia CerqueraNo ratings yet

- ISO PLUS Cijevi (Pipes)Document39 pagesISO PLUS Cijevi (Pipes)Gradska toplana - ServisNo ratings yet

- Spherical PerformanceDocument6 pagesSpherical PerformancelizarazojavierNo ratings yet

- InsulationDocument23 pagesInsulationFabio TemporiniNo ratings yet

- HT Xlpe PDFDocument3 pagesHT Xlpe PDFrengaramanujanNo ratings yet

- 303 Spec SheetDocument2 pages303 Spec SheetYankMulya MusaNo ratings yet

- Prunte Kettenwerk GMBH Co. KGDocument6 pagesPrunte Kettenwerk GMBH Co. KGAhmed SadekNo ratings yet

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportDocument7 pagesACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoNo ratings yet

- Labfacility LimitedDocument2 pagesLabfacility LimitedliusfelipebNo ratings yet

- Deflection in BimetalDocument4 pagesDeflection in BimetalRoisin ClearNo ratings yet

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- Product Data: Immersion Sensor W/ Weatherproof EnclosureDocument2 pagesProduct Data: Immersion Sensor W/ Weatherproof EnclosureRobert UrquiaNo ratings yet

- Afico Duct LinerDocument3 pagesAfico Duct LinerChris SolonNo ratings yet

- Sarthak Dadkar PIIAL-Practical-6 PDFDocument7 pagesSarthak Dadkar PIIAL-Practical-6 PDFAjuba AbujaNo ratings yet

- Chapter 07.00G Physical Problem For Integration Mechanical EngineeringDocument4 pagesChapter 07.00G Physical Problem For Integration Mechanical EngineeringMichael HaywardNo ratings yet

- Area of Steel Calculation: (Limit State)Document16 pagesArea of Steel Calculation: (Limit State)RAVI PRAKASH SAININo ratings yet

- DS - IN0023 - GB - 51412 TermoparesDocument12 pagesDS - IN0023 - GB - 51412 TermoparesRicardo DurànNo ratings yet

- KEI Cables-1Document72 pagesKEI Cables-1chandu1821No ratings yet

- June 19, 2012Document9 pagesJune 19, 2012ahmed.abdelmegeed78No ratings yet

- TOTAL - Heat Transfer FluidDocument2 pagesTOTAL - Heat Transfer Fluidahmet100% (1)

- Brosur TRUST COPPERDocument6 pagesBrosur TRUST COPPERWidhi NugrohoNo ratings yet

- Reboiler 1Document12 pagesReboiler 1kishna009No ratings yet

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document26 pagesAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98No ratings yet

- NAYADocument1 pageNAYAhenry_gtNo ratings yet

- NTE303A Silicone Thermal Compound 1 Oz. Plunger Tube: DescriptionDocument2 pagesNTE303A Silicone Thermal Compound 1 Oz. Plunger Tube: DescriptionDavid Antonio Bonilla ChaónNo ratings yet

- Vacuum Oven: DZF ModelDocument15 pagesVacuum Oven: DZF ModelFernanda ContursiNo ratings yet

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 pagesasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNo ratings yet

- DS IN0023 en Co 51542 PDFDocument13 pagesDS IN0023 en Co 51542 PDFIrfan SyukranNo ratings yet

- J 46 en 5 SBTRDDocument3 pagesJ 46 en 5 SBTRDMohamed SelimNo ratings yet

- 210 SuperlonFR Insulation BrochureDocument8 pages210 SuperlonFR Insulation BrochurealexNo ratings yet

- Heatpipe Spec CCI FarnellDocument3 pagesHeatpipe Spec CCI FarnellcivicbladeNo ratings yet

- Seriola-1510 TDS v180724Document2 pagesSeriola-1510 TDS v180724Thiago MolverstetNo ratings yet

- Building Roll (KBR) : Light Weight, No Sagging Nor SettlingDocument8 pagesBuilding Roll (KBR) : Light Weight, No Sagging Nor SettlingPhan LongNo ratings yet

- PNS 260 2002 - Annealed Copper Wires Specification - Solid - THHN - THW - TWDocument8 pagesPNS 260 2002 - Annealed Copper Wires Specification - Solid - THHN - THW - TWshivam dwivediNo ratings yet

- Katalog Vendor KabelDocument4 pagesKatalog Vendor KabellampujogjaNo ratings yet

- DIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42H - Prehardened CrMnMo-alloyed Steel in Holderblock Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- J 3 H 5 WtegkDocument3 pagesJ 3 H 5 WtegkMohamed SelimNo ratings yet

- 1 3207hs104310Document1 page1 3207hs104310marko9292No ratings yet

- Part Number: Acw-107: Electrical SpecificationsDocument2 pagesPart Number: Acw-107: Electrical SpecificationsgfshhdNo ratings yet

- Manual de Herreria Una Guia Paso A Paso Lesur Luis Libro en Papel 9786071701251 Libreria El SotanoDocument3 pagesManual de Herreria Una Guia Paso A Paso Lesur Luis Libro en Papel 9786071701251 Libreria El Sotanodiego rotpeNo ratings yet

- NyaDocument1 pageNyaahmat kharisNo ratings yet

- Voltage Drop - ARD - TameplateDocument6 pagesVoltage Drop - ARD - TameplateJian RoganNo ratings yet

- 1 3343hs652c24 PDFDocument1 page1 3343hs652c24 PDFmarko9292No ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- DatasheetDocument12 pagesDatasheetGunda VenkateshNo ratings yet

- 1.3505 100cr6 PDFDocument1 page1.3505 100cr6 PDFmcNo ratings yet

- Standard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Document7 pagesStandard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Bhagoo HatheyNo ratings yet

- Model: T210: Remote Reading ThermometerDocument4 pagesModel: T210: Remote Reading ThermometerajithNo ratings yet

- Unitherm Cat 2210 Pre Insulated TubingDocument2 pagesUnitherm Cat 2210 Pre Insulated TubingSebas FaustoNo ratings yet

- Technical Information: The Stelrad You Know and So Much MoreDocument2 pagesTechnical Information: The Stelrad You Know and So Much MoreSunnyNo ratings yet

- 6 Je 5 RHTSGDDocument3 pages6 Je 5 RHTSGDMohamed SelimNo ratings yet

- Stackup - CN TDS 1911 03 S1000H S1000HBDocument2 pagesStackup - CN TDS 1911 03 S1000H S1000HBMuhamad Sayid Akil MhsAkilNo ratings yet

- New Copper Cylinder 02Document7 pagesNew Copper Cylinder 02Khalid SaeedNo ratings yet

- SIFS Product Submision PDFDocument72 pagesSIFS Product Submision PDFmahmoud IbrahemNo ratings yet

- CIBSE Propane R290 CPDDocument4 pagesCIBSE Propane R290 CPDYosmar GuzmanNo ratings yet

- 3758 HPD Evap Crystal 9 17 LRDocument6 pages3758 HPD Evap Crystal 9 17 LRYosmar GuzmanNo ratings yet

- User Instructions For Flange Immersion Heaters With Field Installed Controls Used in Hazardous LocationsDocument5 pagesUser Instructions For Flange Immersion Heaters With Field Installed Controls Used in Hazardous LocationsYosmar GuzmanNo ratings yet

- Air Cooled Screw Chiller Performance DatasheetDocument2 pagesAir Cooled Screw Chiller Performance DatasheetYosmar GuzmanNo ratings yet

- 3758 HPD Evap Crystal 9 17 LRDocument6 pages3758 HPD Evap Crystal 9 17 LRYosmar GuzmanNo ratings yet

- Technical Data Sheet: Air Cooled Chiller With Scroll or Reciprocating Compressors and Axial Fans For Outdoor InstallationDocument19 pagesTechnical Data Sheet: Air Cooled Chiller With Scroll or Reciprocating Compressors and Axial Fans For Outdoor InstallationYosmar GuzmanNo ratings yet

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementDocument25 pagesAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your Advertisementsachyn7No ratings yet

- Nozzles MonitorDocument8 pagesNozzles MonitorYosmar GuzmanNo ratings yet

- Water and Wastewater Calculation Manual by Shun - 2nd EdDocument8 pagesWater and Wastewater Calculation Manual by Shun - 2nd EdYosmar GuzmanNo ratings yet

- Astm d86 2007Document30 pagesAstm d86 2007ricoo90eNo ratings yet

- Instrument AirDocument6 pagesInstrument Airasarobin1989No ratings yet

- Urban Housing Standards PDFDocument38 pagesUrban Housing Standards PDFJoanFitriaRachmadani75% (4)

- Methods of TrainingDocument26 pagesMethods of TrainingDevanshuNo ratings yet

- Bc-6800plus Series Auto Hematology Analyzer Operator's ManualDocument322 pagesBc-6800plus Series Auto Hematology Analyzer Operator's ManualHenock MelesseNo ratings yet

- Communication Systems Engineering Solutions Manual PDFDocument2 pagesCommunication Systems Engineering Solutions Manual PDFKristin0% (2)

- Safety Data Sheet: Armohib Ci-28Document21 pagesSafety Data Sheet: Armohib Ci-28SJHEIK AbdullahNo ratings yet

- Milling of Legume PulsesDocument7 pagesMilling of Legume Pulsessuresh100% (1)

- SL 70953 Liebert Gxt5 Lithium Ion 1 3kva I 230v Ups User GuideDocument70 pagesSL 70953 Liebert Gxt5 Lithium Ion 1 3kva I 230v Ups User Guidepetermaroko69No ratings yet

- Laser Pointing StabilityDocument5 pagesLaser Pointing Stabilitymehdi810No ratings yet

- BF PP 2017Document4 pagesBF PP 2017Revatee HurilNo ratings yet

- Carreño Araujo Cesar - Capturas Calculadora Sesion 02Document17 pagesCarreño Araujo Cesar - Capturas Calculadora Sesion 02CESAR JHORCHS EDUARDO CARREÑO ARAUJONo ratings yet

- In-N-Out vs. DoorDashDocument16 pagesIn-N-Out vs. DoorDashEaterNo ratings yet

- PMP Cheat SheetDocument9 pagesPMP Cheat SheetzepededudaNo ratings yet

- RidleyBoxManual1 17Document63 pagesRidleyBoxManual1 17Sergio Omar OrlandoNo ratings yet

- S.No Company Name Location: Executive Packers and MoversDocument3 pagesS.No Company Name Location: Executive Packers and MoversAli KhanNo ratings yet

- American Bar Association American Bar Association JournalDocument6 pagesAmerican Bar Association American Bar Association JournalKarishma RajputNo ratings yet

- Beer Benefits From Aerator TreatmentDocument2 pagesBeer Benefits From Aerator TreatmentSam MurrayNo ratings yet

- Human Behavior in OrganizationDocument85 pagesHuman Behavior in OrganizationNeric Ico Magleo100% (1)

- EE 4702 Take-Home Pre-Final Questions: SolutionDocument11 pagesEE 4702 Take-Home Pre-Final Questions: SolutionmoienNo ratings yet

- Technical Sheet Azud Watertech WW EngDocument2 pagesTechnical Sheet Azud Watertech WW EngMiguel Torres ObrequeNo ratings yet

- List of Medical Institutions Available For Foreign Language(s)Document24 pagesList of Medical Institutions Available For Foreign Language(s)leithNo ratings yet

- Invoice: Buyer Information Delivery Information Transaction DetailsDocument1 pageInvoice: Buyer Information Delivery Information Transaction DetailsZarida SahdanNo ratings yet

- Transmission Line4 PDFDocument46 pagesTransmission Line4 PDFRevathi PrasadNo ratings yet

- Jurnal Chapter 1 Diesel Bhs - InggrisDocument4 pagesJurnal Chapter 1 Diesel Bhs - Inggrisandino yogaNo ratings yet

- JavaDocument14 pagesJavaGANESH REDDYNo ratings yet