Professional Documents

Culture Documents

Pressure Ecualizer Device

Pressure Ecualizer Device

Uploaded by

andersonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Ecualizer Device

Pressure Ecualizer Device

Uploaded by

andersonCopyright:

Available Formats

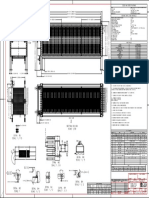

RIBE INGENIERIA.

PRESSURE ECUALIZER DEVICE

Prepared by: ING. ANDERSON RODRIGUEZ

Date: Saturday, April 10, 2021

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Report Contents

Summary _________________________________________________________________________________________________ 3

Software information ......................................................................................................................................................................... 3

Design 1___________________________________________________________________________________________________ 4

Scenario 1 ................................................................................................................................................................................................ 4

Materials ............................................................................................................................................................................................. 4

boundary conditions ..................................................................................................................................................................... 5

Initial Conditions ............................................................................................................................................................................ 5

mesh ..................................................................................................................................................................................................... 5

Physics ................................................................................................................................................................................................. 6

Solver Settings .................................................................................................................................................................................. 7

Convergence ...................................................................................................................................................................................... 7

Results ................................................................................................................................................................................................. 8

Scenario 2 .............................................................................................................................................................................................. 10

Materials ........................................................................................................................................................................................... 10

boundary conditions ................................................................................................................................................................... 11

Initial Conditions .......................................................................................................................................................................... 11

mesh ................................................................................................................................................................................................... 11

Physics ............................................................................................................................................................................................... 12

Solver Settings ................................................................................................................................................................................ 13

Convergence .................................................................................................................................................................................... 13

Results ............................................................................................................................................................................................... 14

Decision Center _________________________________________________________________________________________ 17

summary points .................................................................................................................................................................................. 17

1 in. NOZZLE (1) ............................................................................................................................................................................ 17

1 in. NOZZLE (2) ............................................................................................................................................................................ 18

1 in NOZZLE (3) ............................................................................................................................................................................. 18

1 in. NOZZLE (4) ............................................................................................................................................................................ 18

1 in. NOZZLE (5) ............................................................................................................................................................................ 19

1 in. NOZZLE (6) ............................................................................................................................................................................ 19

1 in. NOZZLE (7) ............................................................................................................................................................................ 20

Page 1 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

1 in. NOZZLE (8) ............................................................................................................................................................................ 20

1 in. NOZZLE (9) ............................................................................................................................................................................ 21

1 in. NOZZLE (10) ......................................................................................................................................................................... 21

1 in. NOZZLE (11) ......................................................................................................................................................................... 21

1 in. NOZZLE (12) ......................................................................................................................................................................... 22

1 in. NOZZLE (13) ......................................................................................................................................................................... 22

1/2 in. NOZZLE (1) ....................................................................................................................................................................... 23

1/2 in. NOZZLE (2) ....................................................................................................................................................................... 23

1/2 in. NOZZLE (3) ....................................................................................................................................................................... 24

1/2 in. NOZZLE (4) ....................................................................................................................................................................... 24

1/2 in. NOZZLE (5) ....................................................................................................................................................................... 24

1/2 in. NOZZLE (6) ....................................................................................................................................................................... 25

1/2 in. NOZZLE (7) ....................................................................................................................................................................... 25

1/2 in. NOZZLE (8) ....................................................................................................................................................................... 26

Page 2 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Summary

SOFTWARE INFORMATION

Simulation CFD version 19.2

Simulation CFD build code 20190802

Page 3 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Design 1

Length units cm

Coordinate system Cartesian 3D

SCENARIO 1

MATERIALS

NAME ASSIGNED TO PROPERTIES

Air CFDCreatedVolume Density Equation of State

Viscosity 1.817e-05 Pa-s

Conductivity 0.02563 W/m-K

Specific heat 1004.0 J/kg-K

Compressibility 1.4

Emissivity 1.0

Wall roughness 0.0 meter

Phase Vapor Pressure

Page 4 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

ABS (Molded) Part1.Body1 X-Direction 0.153 W/m-K

Part1.Body4 Y-Direction Same as X-dir.

Part1.Body3

Part1.Body2 Z-Direction Same as X-dir.

Density 1.05 g/cm3

Specific heat 2.05 J/g-K

Emissivity 0.469

Transmissivity 0.0

Electrical resistivity 1.65e+15 ohm-cm

Wall roughness 0.0 meter

BOUNDARY CONDITIONS

TYPE ASSIGNED TO

Pressure(1.25 Pa Gage) Surface:44

Temperature(-7 Celsius) Surface:44

Volume Flow Rate(45 ft3/min) Surface:45

INITIAL CONDITIONS

TYPE ASSIGNED TO

- -

MESH

Automatic Meshing Settings

Surface refinement 0

Gap refinement 0

Resolution factor 1.0

Edge growth rate 1.1

Minimum points on edge 2

Points on longest edge 10

Surface limiting aspect ratio 20

Mesh Enhancement Settings

Mesh enhancement 1

Page 5 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Enhancement blending 0

Number of layers 3

Layer factor 0.45

Layer gradation 1.05

Meshed Model

Number of Nodes 27022

Number of Elements 100580

PHYSICS

Flow On

Compressibility Compressible

Heat Transfer Off

Auto Forced Convection Off

Gravity Components 0.0, 0.0, 0.0

Radiation Off

Scalar No scalar

Turbulence On

Page 6 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

SOLVER SETTINGS

Solution mode Steady State

Solver computer MyComputer

Intelligent solution control On

Advection scheme ADV 5

Turbulence model k-epsilon

CONVERGENCE

Iterations run 250

Solve time 132 seconds

Solver version 19.2.20190802

Energy Balance

Mass Balance

IN OUT

Mass flow 25.5857 g/s -28.0525 g/s

Volume flow 21237.6 cm^3/s -23285.2 cm^3/s

Page 7 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

RESULTS

Inlets and Outlets

inlet 1 inlet bulk pressure 9328.75 dyne/cm^2

inlet bulk temperature -7.0 C

inlet mach number 0.00267363

mass flow in 25.5857 g/s

minimum x,y,z of 0.0

opening

node near minimum 46.0

x,y,z of opening

reynolds number 9239.68

Page 8 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

surface id 45.0

total mass flow in 25.5857 g/s

total vol. flow in 21237.6 cm^3/s

volume flow in 21237.6 cm^3/s

outlet 1 mass flow out -28.0525 g/s

minimum x,y,z of 0.0

opening

node near minimum 23.0

x,y,z ofbulk

outlet opening

pressure 12.5 dyne/cm^2

outlet bulk temperature -7.0 C

outlet mach number 0.00571468

reynolds number 10130.5

surface id 44.0

total mass flow out -28.0525 g/s

total vol. flow out -23285.2 cm^3/s

volume flow out -23285.2 cm^3/s

Field Variable Results

VARIABLE MAX MIN

cond 0.00153 W/cm-K 0.0002563 W/cm-K

dens 1.05 g/cm^3 0.00120473 g/cm^3

econd 0.408466 W/cm-K 0.0 W/cm-K

emiss 1.0 0.0

evisc 0.649936 g/cm-s 0.0 g/cm-s

gent 15960.9 1/s 0.0316228 1/s

press 9537.47 dyne/cm^2 -6341.89 dyne/cm^2

ptotl 9837.14 dyne/cm^2 -6341.89 dyne/cm^2

scal1 0.0 0.0

seebeck 0.0 V/K 0.0 V/K

shgc 0.0 0.0

spech 2.05 J/g-K 1.004 J/g-K

temp -7.0 C -7.0 C

transmiss 0.0 0.0

turbd 628257000.0 cm^2/s^3 0.677342 cm^2/s^3

turbk 1163720.0 cm^2/s^2 1.817e-07 cm^2/s^2

ufactor 0.0 0.0

visc 0.0001817 g/cm-s 0.0 g/cm-s

vx vel 984.16 cm/s -881.427 cm/s

vy vel 1122.9 cm/s -979.547 cm/s

vz vel 3398.67 cm/s -547.344 cm/s

wrough 0.0 cm 0.0 cm

Component Thermal Summary

PART MINIMUM MAXIMUM VOLUME AVERAGED

TEMPERATURE TEMPERATURE TEMPERATURE

Part1.Body1 -7 -7 -7

Page 9 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Part1.Body4 -7 -7 -7

Part1.Body3 -7 -7 -7

Part1.Body2 -7 -7 -7

CFDCreatedVolume -7 -7 -7

Fluid Forces on Walls

pressx 326.78 dynes

pressy 2696.7 dynes

pressz 2126100.0 dynes

shearx -5.4973 dynes

sheary 212.53 dynes

shearz 898.68 dynes

SCENARIO 2

MATERIALS

NAME ASSIGNED TO PROPERTIES

Air CFDCreatedVolume Density Equation of State

Viscosity 1.817e-05 Pa-s

Conductivity 0.02563 W/m-K

Specific heat 1004.0 J/kg-K

Compressibility 1.4

Emissivity 1.0

Wall roughness 0.0 meter

Phase Vapor Pressure

Page 10 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

ABS (Molded) Part1.Body1 X-Direction 0.153 W/m-K

Part1.Body4 Y-Direction Same as X-dir.

Part1.Body3

Part1.Body2 Z-Direction Same as X-dir.

Density 1.05 g/cm3

Specific heat 2.05 J/g-K

Emissivity 0.469

Transmissivity 0.0

Electrical resistivity 1.65e+15 ohm-cm

Wall roughness 0.0 meter

BOUNDARY CONDITIONS

TYPE ASSIGNED TO

Pressure(1.25 Pa Gage) Surface:44

Temperature(-7 Celsius) Surface:44

Volume Flow Rate(20 ft3/min) Surface:45

INITIAL CONDITIONS

TYPE ASSIGNED TO

MESH

Automatic Meshing Settings

Surface refinement 0

Gap refinement 0

Resolution factor 1.0

Edge growth rate 1.1

Minimum points on edge 2

Points on longest edge 10

Surface limiting aspect ratio 20

Mesh Enhancement Settings

Mesh enhancement 1

Page 11 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Enhancement blending 0

Number of layers 3

Layer factor 0.45

Layer gradation 1.05

Meshed Model

Number of Nodes 27022

Number of Elements 100580

PHYSICS

Flow On

Compressibility Compressible

Heat Transfer Off

Page 12 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Auto Forced Convection Off

Gravity Components 0.0, 0.0, 0.0

Radiation Off

Scalar No scalar

Turbulence On

SOLVER SETTINGS

Solution mode Steady State

Solver computer MyComputer

Intelligent solution control On

Advection scheme ADV 5

Turbulence model k-epsilon

CONVERGENCE

Iterations run 100

Solve time 98 seconds

Solver version 19.2.20190802

Energy Balance

Mass Balance

IN OUT

Mass flow 11.3714 g/s -12.6253 g/s

Volume flow 9438.95 cm^3/s -10479.7 cm^3/s

Page 13 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

RESULTS

Inlets and Outlets

inlet 1 inlet bulk pressure 1691.59 dyne/cm^2

Page 14 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

inlet bulk temperature -7.0 C

inlet mach number 0.00118828

mass flow in 11.3714 g/s

minimum x,y,z of 0.0

opening

node near minimum 46.0

x,y,z of opening

reynolds number 4106.53

surface id 45.0

total mass flow in 11.3714 g/s

total vol. flow in 9438.95 cm^3/s

volume flow in 9438.95 cm^3/s

outlet 1 mass flow out -12.6253 g/s

minimum x,y,z of 0.0

opening

node near minimum 23.0

x,y,z ofbulk

outlet opening

pressure 12.5 dyne/cm^2

outlet bulk temperature -7.0 C

outlet mach number 0.00248587

reynolds number 4559.33

surface id 44.0

total mass flow out -12.6253 g/s

total vol. flow out -10479.7 cm^3/s

volume flow out -10479.7 cm^3/s

Field Variable Results

VARIABLE MAX MIN

cond 0.00153 W/cm-K 0.0002563 W/cm-K

dens 1.05 g/cm^3 0.00120473 g/cm^3

econd 0.114774 W/cm-K 0.0 W/cm-K

emiss 1.0 0.0

evisc 0.0936659 g/cm-s 0.0 g/cm-s

gent 7933.96 1/s 0.0316228 1/s

press 1728.28 dyne/cm^2 -1131.83 dyne/cm^2

ptotl 1773.47 dyne/cm^2 -1131.83 dyne/cm^2

scal1 0.0 0.0

seebeck 0.0 V/K 0.0 V/K

shgc 0.0 0.0

spech 2.05 J/g-K 1.004 J/g-K

temp -7.0 C -7.0 C

transmiss 0.0 0.0

turbd 81391800.0 cm^2/s^3 0.0594652 cm^2/s^3

turbk 132025.0 cm^2/s^2 1.817e-07 cm^2/s^2

ufactor 0.0 0.0

visc 0.0001817 g/cm-s 0.0 g/cm-s

vx vel 436.264 cm/s -393.166 cm/s

vy vel 518.355 cm/s -416.049 cm/s

vz vel 1518.77 cm/s -253.051 cm/s

Page 15 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

wrough 0.0 cm 0.0 cm

Component Thermal Summary

PART MINIMUM MAXIMUM VOLUME AVERAGED

TEMPERATURE TEMPERATURE TEMPERATURE

Part1.Body1 -7 -7 -7

Part1.Body4 -7 -7 -7

Part1.Body3 -7 -7 -7

Part1.Body2 -7 -7 -7

CFDCreatedVolume -7 -7 -7

Fluid Forces on Walls

pressx 5.7229 dynes

pressy 176.16 dynes

pressz 380990.0 dynes

shearx -0.90485 dynes

sheary 33.793 dynes

shearz 191.98 dynes

Page 16 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Decision Center

SUMMARY POINTS

1 IN. NOZZLE (1)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0516617 0.0278794 cm/s

Velocity Magnitude 1689.56 911.777 cm/s

Vx-Velocity -19.8837 -0.426408 cm/s

Vy-Velocity -80.4486 3.6511 cm/s

Vz-Velocity 1685.36 910.74 cm/s

Static Pressure -35.7972 4.57907 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0173505 0.000681234 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0209942 0.00178624 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00930595 -0.00303021 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0774679 0.0399695 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

Page 17 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

1 IN. NOZZLE (2)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0541761 0.0285324 cm/s

Velocity Magnitude 1771.8 933.133 cm/s

Vx-Velocity -28.7597 -2.94362 cm/s

Vy-Velocity -80.0754 5.38484 cm/s

Vz-Velocity 1765.57 931.888 cm/s

Static Pressure -102.643 -6.26667 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0169148 0.00186651 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0254584 -0.00231128 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00359537 -1.17794e-05 dyne/cm^2

Shear Stress (Tau) Magnitude 0.081949 0.0478697 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN NOZZLE (3)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0590472 0.0299719 cm/s

Velocity Magnitude 1931.1 980.212 cm/s

Vx-Velocity -24.3702 -1.10567 cm/s

Vy-Velocity -89.0484 -2.19936 cm/s

Vz-Velocity 1927.78 979.984 cm/s

Static Pressure -362.361 -61.9008 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0173419 0.000963768 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0191493 0.000718176 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00451302 -0.000932228 dyne/cm^2

Shear Stress (Tau) Magnitude 0.045621 0.0182855 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (4)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0652178 0.0318227 cm/s

Velocity Magnitude 2132.91 1040.74 cm/s

Vx-Velocity -21.3484 -1.76397 cm/s

Page 18 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Vy-Velocity -80.349 -4.48405 cm/s

Vz-Velocity 2130.15 1040.55 cm/s

Static Pressure -812.262 -142.513 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0163889 0.000317104 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0262977 -0.000382781 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00735926 -0.00538065 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0487336 0.0170627 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (5)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0736047 0.0346253 cm/s

Velocity Magnitude 2407.2 1132.4 cm/s

Vx-Velocity -12.8669 -1.14719 cm/s

Vy-Velocity -61.9635 -7.05142 cm/s

Vz-Velocity 2405.17 1132.05 cm/s

Static Pressure -1509.37 -272.951 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.012063 0.000520891 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.034629 -0.00248749 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00741319 -0.00508658 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0514402 0.0197819 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (6)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0828356 0.0378549 cm/s

Velocity Magnitude 2709.09 1238.02 cm/s

Vx-Velocity -2.82553 -0.282716 cm/s

Vy-Velocity -29.6811 -5.47367 cm/s

Vz-Velocity 2708.01 1237.66 cm/s

Static Pressure -2265.61 -419.531 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0074234 0.000610136 dyne/cm^2

Page 19 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Shear Stress YZ (Tau-YZ) -0.0419403 -0.00791055 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00610425 -0.00396612 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0446464 0.0144383 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (7)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0905328 0.0407715 cm/s

Velocity Magnitude 2960.82 1333.41 cm/s

Vx-Velocity 3.88358 0.726307 cm/s

Vy-Velocity -23.2813 -8.02946 cm/s

Vz-Velocity 2958.74 1332.69 cm/s

Static Pressure -2811.6 -527.014 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.00459561 -0.000364732 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0363721 -0.00515125 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00356487 -0.00306176 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0375948 0.0126481 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (8)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0983378 0.044184 cm/s

Velocity Magnitude 3216.08 1445.01 cm/s

Vx-Velocity 11.6062 2.76958 cm/s

Vy-Velocity -24.2212 -13.1488 cm/s

Vz-Velocity 3215.71 1444.85 cm/s

Static Pressure -2883.01 -548.545 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.00320614 -0.000712691 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0236555 -0.00436475 dyne/cm^2

Shear Stress ZX (Tau-ZX) 0.00388191 -0.000535555 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0265589 0.00636742 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

Page 20 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

1 IN. NOZZLE (9)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.103197 0.0460801 cm/s

Velocity Magnitude 3375.0 1507.02 cm/s

Vx-Velocity 2.11344 -2.8279 cm/s

Vy-Velocity -60.9258 -24.6462 cm/s

Vz-Velocity 3374.35 1506.73 cm/s

Static Pressure -2703.92 -515.592 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.00426486 0.0028153 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.000784953 -0.00118779 dyne/cm^2

Shear Stress ZX (Tau-ZX) 0.00428635 -0.000803608 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0084081 0.00464602 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (10)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.100737 0.0445053 cm/s

Velocity Magnitude 3294.53 1455.52 cm/s

Vx-Velocity -11.6351 -14.6732 cm/s

Vy-Velocity -166.135 -54.1964 cm/s

Vz-Velocity 3288.27 1453.44 cm/s

Static Pressure -1264.56 -234.658 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.0102021 0.00528048 dyne/cm^2

Shear Stress YZ (Tau-YZ) 0.0257511 0.00693172 dyne/cm^2

Shear Stress ZX (Tau-ZX) 0.00125127 -0.00188563 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0317357 0.0111594 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (11)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0906858 0.0397515 cm/s

Velocity Magnitude 2965.82 1300.05 cm/s

Vx-Velocity 2.52704 -14.2987 cm/s

Page 21 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Vy-Velocity -209.061 -63.5156 cm/s

Vz-Velocity 2952.51 1296.46 cm/s

Static Pressure 2021.63 410.719 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.00429385 0.00301028 dyne/cm^2

Shear Stress YZ (Tau-YZ) 0.000328338 -0.00289528 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00591929 -0.00279502 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0199445 0.0118647 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (12)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0708224 0.0315042 cm/s

Velocity Magnitude 2316.2 1030.33 cm/s

Vx-Velocity 21.6583 -7.60712 cm/s

Vy-Velocity -232.511 -68.8584 cm/s

Vz-Velocity 2297.76 1025.81 cm/s

Static Pressure 4367.35 827.92 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.00129214 0.00197972 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0122627 -0.0071578 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.00370353 -0.00402028 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0571457 0.0279803 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1 IN. NOZZLE (13)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0550277 0.0251161 cm/s

Velocity Magnitude 1799.65 821.405 cm/s

Vx-Velocity 28.2225 -6.08401 cm/s

Vy-Velocity -251.971 -75.8868 cm/s

Vz-Velocity 1779.06 816.925 cm/s

Static Pressure 5587.03 1032.06 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.000615878 0.00153698 dyne/cm^2

Page 22 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Shear Stress YZ (Tau-YZ) -0.038424 -0.0178816 dyne/cm^2

Shear Stress ZX (Tau-ZX) 0.00205398 -0.00212089 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0604536 0.0290066 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/Cm2

1/2 IN. NOZZLE (1)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0418197 0.0218952 cm/s

Velocity Magnitude 1367.69 716.069 cm/s

Vx-Velocity -74.1314 -18.1863 cm/s

Vy-Velocity -45.197 9.44153 cm/s

Vz-Velocity 1364.11 715.408 cm/s

Static Pressure 3.18803 13.5572 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0158424 -0.000795831 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0108264 0.0050867 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.0349315 -0.0135073 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0755218 0.0430305 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

1/2 IN. NOZZLE (2)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0476738 0.024404 cm/s

Velocity Magnitude 1559.14 798.118 cm/s

Vx-Velocity -76.4043 -20.0307 cm/s

Vy-Velocity -46.1296 9.41226 cm/s

Vz-Velocity 1555.32 797.417 cm/s

Static Pressure -45.4268 5.10635 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0193647 -0.000799292 dyne/cm^2

Shear Stress YZ (Tau-YZ) 0.00769967 0.0125335 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.0318913 -0.0154392 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0796347 0.0400318 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

Page 23 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

1/2 IN. NOZZLE (3)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0556409 0.0272834 cm/s

Velocity Magnitude 1819.7 892.286 cm/s

Vx-Velocity -71.8224 -21.7418 cm/s

Vy-Velocity -42.9667 9.47619 cm/s

Vz-Velocity 1816.26 891.371 cm/s

Static Pressure -396.478 -57.501 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0221272 -0.00100572 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.00719251 0.00379585 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.0318303 -0.0139226 dyne/cm^2

Shear Stress (Tau) Magnitude 0.106936 0.0489553 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

1/2 IN. NOZZLE (4)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.0716297 0.0329682 cm/s

Velocity Magnitude 2342.61 1078.2 cm/s

Vx-Velocity -32.405 -10.7822 cm/s

Vy-Velocity -24.2492 8.11183 cm/s

Vz-Velocity 2340.67 1077.64 cm/s

Static Pressure -1554.45 -265.86 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.0171921 -0.00358505 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.00773834 0.00674541 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.0340944 -0.0155958 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0585657 0.0255985 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

1/2 IN. NOZZLE (5)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.090022 0.0404916 cm/s

Velocity Magnitude 2944.12 1324.25 cm/s

Vx-Velocity -11.9555 -7.3766 cm/s

Page 24 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Vy-Velocity -10.882 3.28759 cm/s

Vz-Velocity 2942.38 1323.57 cm/s

Static Pressure -3054.23 -553.52 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.00429037 -0.000315419 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.00377464 0.00675775 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.0127943 -0.00581289 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0236524 0.0147713 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

1/2 IN. NOZZLE (6)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.100551 0.044878 cm/s

Velocity Magnitude 3288.46 1467.71 cm/s

Vx-Velocity -34.9498 -18.6959 cm/s

Vy-Velocity -6.2551 1.41025 cm/s

Vz-Velocity 3288.23 1467.57 cm/s

Static Pressure -2889.72 -480.244 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) -0.00460723 -2.6107e-05 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.00510485 0.00071873 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.000510305 -0.00185059 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0115251 0.00566094 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

1/2 IN. NOZZLE (7)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.087764 0.0383012 cm/s

Velocity Magnitude 2870.27 1252.62 cm/s

Vx-Velocity -22.3617 -9.90953 cm/s

Vy-Velocity 0.0934329 5.88972 cm/s

Vz-Velocity 2856.78 1247.07 cm/s

Static Pressure 1791.42 445.193 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.00461699 0.00376517 dyne/cm^2

Page 25 Generated with Autodesk CFD 2019

PRESSURE ECUALIZER DEVICE.cfdst Prepared by: ING. ANDERSON RODRIGUEZ

Shear Stress YZ (Tau-YZ) -0.00973902 -0.00357404 dyne/cm^2

Shear Stress ZX (Tau-ZX) 0.000267771 -0.000279519 dyne/cm^2

Shear Stress (Tau) Magnitude 0.0612791 0.0285636 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

1/2 IN. NOZZLE (8)

RESULT QUANTITY DESIGN: DESIGN: UNIT

SCENARIO 1 SCENARIO 2

Unknown 0.051107 0.0223894 cm/s

Velocity Magnitude 1671.42 732.231 cm/s

Vx-Velocity -30.0455 -4.81636 cm/s

Vy-Velocity -4.9506 -7.43519 cm/s

Vz-Velocity 1657.63 727.427 cm/s

Static Pressure 5547.08 1041.69 dyne/cm^2

Temperature -7.0 -7.0 °C

Density 0.00120473 0.00120473 g/cm3

Viscosity 0.0001817 0.0001817 Pa-s

Shear Stress XY (Tau-XY) 0.0114567 0.00596184 dyne/cm^2

Shear Stress YZ (Tau-YZ) -0.0136834 -0.00764489 dyne/cm^2

Shear Stress ZX (Tau-ZX) -0.000272061 -0.00133194 dyne/cm^2

Shear Stress (Tau) Magnitude 0.144229 0.0606682 dyne/cm^2

Wall Film Coefficients 0.0 0.0 W/cm2/K

Wall Heat Flux 0.0 0.0 W/cm2

Page 26 Generated with Autodesk CFD 2019

You might also like

- Technical Guide With NOxMixer PDFDocument88 pagesTechnical Guide With NOxMixer PDFMehaboob RahmanNo ratings yet

- The Basics of Cloud Computing: Understanding the Fundamentals of Cloud Computing in Theory and PracticeFrom EverandThe Basics of Cloud Computing: Understanding the Fundamentals of Cloud Computing in Theory and PracticeNo ratings yet

- CompTIA Linux+ Certification Study Guide (2009 Exam): Exam XK0-003From EverandCompTIA Linux+ Certification Study Guide (2009 Exam): Exam XK0-003No ratings yet

- FloEFD TutorialDocument340 pagesFloEFD Tutorial차봉재No ratings yet

- Operating Instructions I10 Lock en Im0073380Document32 pagesOperating Instructions I10 Lock en Im0073380于洋No ratings yet

- 10045D-000-PI-SP-202 - Rev 0 - 20sep11Document26 pages10045D-000-PI-SP-202 - Rev 0 - 20sep11RVELEZNo ratings yet

- Century CD & Dynamic Data Storage Installation & Operation ManualDocument44 pagesCentury CD & Dynamic Data Storage Installation & Operation Manualmannyvill0% (1)

- Abb Tzid 200Document18 pagesAbb Tzid 200Kalyan GrandhiNo ratings yet

- November 23rd: Interactive Dashboard For A Greener Built EnvironmentDocument35 pagesNovember 23rd: Interactive Dashboard For A Greener Built Environmentapi-16652449No ratings yet

- Lexium 17D Series Servo Drive User Guide: ModiconDocument182 pagesLexium 17D Series Servo Drive User Guide: ModiconRodrigo DuarteNo ratings yet

- FK Show Led - 20141219testDocument215 pagesFK Show Led - 20141219testEdo AntonioNo ratings yet

- 2D Eddy Current GuideDocument151 pages2D Eddy Current GuideEduardo SalgadoNo ratings yet

- Vostro 3400: Setup and Specifications GuideDocument39 pagesVostro 3400: Setup and Specifications GuideN-jay ErnietaNo ratings yet

- Operating Instructions To Amplifier Module SD7Document98 pagesOperating Instructions To Amplifier Module SD7kanbouchNo ratings yet

- Master Plate Roll 2nd Ediz 6rev ENGDocument87 pagesMaster Plate Roll 2nd Ediz 6rev ENGPratik RaiNo ratings yet

- Instructions Inspectorp61Document70 pagesInstructions Inspectorp61vs.mansonrjbr1991No ratings yet

- AIS700 Class B Transceiver: Installation InstructionsDocument52 pagesAIS700 Class B Transceiver: Installation InstructionsManuelNo ratings yet

- The Prepar3d v4 Guide by Rdpresets v1.1Document38 pagesThe Prepar3d v4 Guide by Rdpresets v1.1azerty971No ratings yet

- FDS 5000 en From HW 200Document106 pagesFDS 5000 en From HW 200Krittaphak Hacheyram0% (1)

- Course1 Candy BasicsDocument106 pagesCourse1 Candy BasicsAmin ZaatrehNo ratings yet

- Incyte-Arc-Sensor - EN - LR - ManualDocument81 pagesIncyte-Arc-Sensor - EN - LR - ManualDispositivos PerinaNo ratings yet

- gpdk045 PDK ReferencemanualDocument128 pagesgpdk045 PDK ReferencemanualMasud SarkerNo ratings yet

- DynamixelSDK Manual EN 160408Document79 pagesDynamixelSDK Manual EN 160408furqon maulanaNo ratings yet

- En DM00073742Document26 pagesEn DM00073742CristianNo ratings yet

- CUDA-GDB Debugger - User Manual - DU-05227-042 - v7.0 (March 2015)Document64 pagesCUDA-GDB Debugger - User Manual - DU-05227-042 - v7.0 (March 2015)Alex DedalusNo ratings yet

- Central Water Heater SpecificationDocument42 pagesCentral Water Heater Specificationsibin.everest.1No ratings yet

- Manual SerDia2010 EN PDFDocument225 pagesManual SerDia2010 EN PDFЛюбовь БазуеваNo ratings yet

- Orchestra User Manual and Help User Manual: © 2019 HED, Inc. HED, IncDocument70 pagesOrchestra User Manual and Help User Manual: © 2019 HED, Inc. HED, IncLorenzoNo ratings yet

- Applications Manual 302 - PCPDocument210 pagesApplications Manual 302 - PCPmansel manselNo ratings yet

- TG0042en - Ed04 - Session Initiation Protcol (SIP) - 1 - de - 2Document68 pagesTG0042en - Ed04 - Session Initiation Protcol (SIP) - 1 - de - 2Eduardo SilvaNo ratings yet

- Manual SerDia2010 enDocument235 pagesManual SerDia2010 eneduargon.94No ratings yet

- Manual de Operación Densimetro Mettler Toledo DE40Document96 pagesManual de Operación Densimetro Mettler Toledo DE40Laura GuarguatiNo ratings yet

- Operating Instructions Rms3xx Radar Sensors en Im0075504Document30 pagesOperating Instructions Rms3xx Radar Sensors en Im0075504Олег ЕфимовNo ratings yet

- Rly3 Ossd200 Ins enDocument36 pagesRly3 Ossd200 Ins enobed Salazar MartinezNo ratings yet

- Inclinalysis ManualDocument67 pagesInclinalysis ManualbetongleeNo ratings yet

- Operating Instructions gls6 en Im0085585Document58 pagesOperating Instructions gls6 en Im0085585Trần ChiếnNo ratings yet

- 9125 TC Inst ManualDocument64 pages9125 TC Inst ManualAniq AhmedNo ratings yet

- X2 Series User Manual ENDocument147 pagesX2 Series User Manual ENwaelNo ratings yet

- Stober FDS5000 Frequentieregelaar Handleiding enDocument164 pagesStober FDS5000 Frequentieregelaar Handleiding endafal6No ratings yet

- TETRA System Release 7.0: CDD Server, Commissioning ManualDocument133 pagesTETRA System Release 7.0: CDD Server, Commissioning ManualRafaelNo ratings yet

- Glazing in Buildings: Part 3: Human Impact Safety RequirementsDocument12 pagesGlazing in Buildings: Part 3: Human Impact Safety Requirementsavik6294846No ratings yet

- 1MRK514026-UUS - en - N - Installation Manual, 670 Series Version 2.2 ANSIDocument102 pages1MRK514026-UUS - en - N - Installation Manual, 670 Series Version 2.2 ANSIJADSON SOUZANo ratings yet

- IP 930D Plan and Install GuideDocument102 pagesIP 930D Plan and Install GuideRoger JeríNo ratings yet

- BIM StandardDocument109 pagesBIM Standarddennis tomas leonNo ratings yet

- VDK - R2020x - Piping Parts Creation - V1.0Document83 pagesVDK - R2020x - Piping Parts Creation - V1.0fibriladoNo ratings yet

- Manual GDS RomiDocument79 pagesManual GDS RomiErickNo ratings yet

- 542935b Atys P M Nmo ENDocument76 pages542935b Atys P M Nmo ENb400013No ratings yet

- Manual SerDia2010 EN PDFDocument217 pagesManual SerDia2010 EN PDFAttila EngiNo ratings yet

- Kodak C140 - CD14 EasyShare Digital Camera SMDocument82 pagesKodak C140 - CD14 EasyShare Digital Camera SMRoger Martínez BermúdezNo ratings yet

- Vol 1 ITTDocument84 pagesVol 1 ITTRamesh BabuNo ratings yet

- Mtg18a PDFDocument85 pagesMtg18a PDFFIRMANSYAHNo ratings yet

- Renewable and Sustainable Energy Reviews: Sunanda Sinha, S.S. ChandelDocument14 pagesRenewable and Sustainable Energy Reviews: Sunanda Sinha, S.S. ChandelAzizul MohamadNo ratings yet

- Visual OPC Server NET Developer GuideDocument94 pagesVisual OPC Server NET Developer GuidePavan Pradeep PeelaNo ratings yet

- Ansys CAD Integration PDFDocument86 pagesAnsys CAD Integration PDFSamuel PintoNo ratings yet

- Ie-Epss-Dcf and Power LLD v1.0Document43 pagesIe-Epss-Dcf and Power LLD v1.0Ethio DotNetDeveloperNo ratings yet

- FACE - SDK - Manual Fid 90 - Fid86 - Fid87 PDFDocument86 pagesFACE - SDK - Manual Fid 90 - Fid86 - Fid87 PDFRizq WardhanaNo ratings yet

- Epcos Magnetic Design Tool: SER AnualDocument32 pagesEpcos Magnetic Design Tool: SER AnualYonny ColqueNo ratings yet

- Occupational Health and Safety PlanDocument69 pagesOccupational Health and Safety PlanGiorgi KenkebashviliNo ratings yet

- 1313combined Manual enDocument114 pages1313combined Manual enAdrian FerreyraNo ratings yet

- Team13 BlueMarketDocument28 pagesTeam13 BlueMarketMitul PatelNo ratings yet

- One Touch For Windows SDK C-C++ Developer GuideDocument111 pagesOne Touch For Windows SDK C-C++ Developer GuideIsaac Sosa0% (1)

- BHCN 2700 TS 20249C 1020 EnglishDocument40 pagesBHCN 2700 TS 20249C 1020 EnglishandersonNo ratings yet

- Ambient Heat Loss From A VesselDocument2 pagesAmbient Heat Loss From A VesselandersonNo ratings yet

- Ambient Heat Loss From A VesselDocument2 pagesAmbient Heat Loss From A VesselandersonNo ratings yet

- Design Calculation S: Item: Tag No.: Serial No.: Project Name: Customer: Job No: DesignerDocument23 pagesDesign Calculation S: Item: Tag No.: Serial No.: Project Name: Customer: Job No: DesignerandersonNo ratings yet

- Carbon Filter HeadDocument1 pageCarbon Filter HeadandersonNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- Shallow Water Effect On Ship ResistanceDocument30 pagesShallow Water Effect On Ship ResistanceGoutam Kumar Saha100% (5)

- CHE F498 Colloids Interfaces HandoutDocument3 pagesCHE F498 Colloids Interfaces HandoutShubham JainNo ratings yet

- Steady Flow, Otherwise It Is Called As Unsteady Flow.: Prof. Dr. Atıl BULUDocument59 pagesSteady Flow, Otherwise It Is Called As Unsteady Flow.: Prof. Dr. Atıl BULUMigori Art DataNo ratings yet

- 00 - IWCF - Equipment B&W PDFDocument19 pages00 - IWCF - Equipment B&W PDFCerón Niño SantiagoNo ratings yet

- Sitara Internship ReportDocument19 pagesSitara Internship ReportEngr Hafiz Husnain BasraNo ratings yet

- Experiment 2 Procedure - v2Document5 pagesExperiment 2 Procedure - v2John Nicholson LanderoNo ratings yet

- High Efficiency and Robustness: Spiral Tube Heat Exchangers: CombiningDocument3 pagesHigh Efficiency and Robustness: Spiral Tube Heat Exchangers: CombiningSaid FerdjallahNo ratings yet

- 01 Applied MechanicsDocument115 pages01 Applied MechanicsFavour EdetNo ratings yet

- Sl. No. Short Description: 1 Central AC Material Rate 2 Installation Rate Total AmountDocument23 pagesSl. No. Short Description: 1 Central AC Material Rate 2 Installation Rate Total AmountSofiqNo ratings yet

- GATE CHEMICAL 2018 Solution PDFDocument28 pagesGATE CHEMICAL 2018 Solution PDFAneeta RaniNo ratings yet

- Barablend - 665 LCM Standard Field Application Procedure: BaroidDocument16 pagesBarablend - 665 LCM Standard Field Application Procedure: Baroidrushikesh pandyaNo ratings yet

- Job Advertisement PDFDocument1 pageJob Advertisement PDFAfif ZenaNo ratings yet

- 01 Handline Nozzles-Adjustable Gallonage - MA-MBDocument1 page01 Handline Nozzles-Adjustable Gallonage - MA-MBjoana ramirezNo ratings yet

- TDZ Repair GuideDocument7 pagesTDZ Repair Guideclaudio mezaNo ratings yet

- Plant Room Riser - R8-TRF Hvac Piping Layout PDFDocument1 pagePlant Room Riser - R8-TRF Hvac Piping Layout PDFVudatha sai harishNo ratings yet

- BOSS Supastor Stainless Steel Unvented CylindersDocument10 pagesBOSS Supastor Stainless Steel Unvented Cylinderstrabant424No ratings yet

- Coatings: Porosity and Its Significance in Plasma-Sprayed CoatingsDocument19 pagesCoatings: Porosity and Its Significance in Plasma-Sprayed CoatingsAbdul Ahad ShamsNo ratings yet

- CHEN3005 Process Instrumentation and ControlDocument4 pagesCHEN3005 Process Instrumentation and ControlVincent Ys TanNo ratings yet

- Jointing of Pipes FinalDocument34 pagesJointing of Pipes FinalSusantaPaulNo ratings yet

- API RP 07G Errata 1 Drill String Design N Oper Limits May2000Document12 pagesAPI RP 07G Errata 1 Drill String Design N Oper Limits May2000Budi KurniawanNo ratings yet

- Hossam Sholkamy - MSCDocument2 pagesHossam Sholkamy - MSChossam sholkamyNo ratings yet

- Orifice Plate CalculationDocument10 pagesOrifice Plate CalculationkswaghmareNo ratings yet

- CO Storage: 20 ASCO ISO Tank ContainersDocument5 pagesCO Storage: 20 ASCO ISO Tank ContainersMB ManyauNo ratings yet

- Ssr-125 Ssr-150 Ssr-200 Ssr-250 Ssr-300 Ssr-E300 Ssr-E350 Ssr-E400 Ssr-E450 Operators Manual Installation Maintenance Includes Nema 4-12 125-200 Ops D '89Document44 pagesSsr-125 Ssr-150 Ssr-200 Ssr-250 Ssr-300 Ssr-E300 Ssr-E350 Ssr-E400 Ssr-E450 Operators Manual Installation Maintenance Includes Nema 4-12 125-200 Ops D '89user0% (1)

- 001 CT Tools - PulsonixDocument11 pages001 CT Tools - PulsonixRuben VillegasNo ratings yet

- TestDocument3 pagesTestNSS GBPECNo ratings yet

- Anika Et Al. - 2020 - Roughness Effect in An Initially Laminar Channel FDocument26 pagesAnika Et Al. - 2020 - Roughness Effect in An Initially Laminar Channel FOliver HouNo ratings yet

- Chapter 05Document5 pagesChapter 05Mougaliz Gales33% (3)

- FR21 083 2 1Document1 pageFR21 083 2 1Huber Pucuhuayla RojasNo ratings yet