Professional Documents

Culture Documents

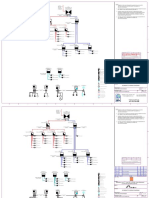

Map View: General Layout Drawings

Uploaded by

BadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Map View: General Layout Drawings

Uploaded by

BadiCopyright:

Available Formats

1. Please refer to the Coordinates Table for the Tag numbers and Coordinates of each component of CP Equipment.

2. The ICCP continuous anode will be buried in the pipe trench at a distance of 0.5 m from the pipe at the 3 or 9 o'clock

position (i.e. halfway between bottom and top of pipe depth). Anode splicing shall be done using splice kits and shall

be done as per approved procedure and drawings. Anode tail cables shall be terminated at designated AJB. Sufficient

watering shall be carried out after anode laid in the trench and before backfilling. In any case anodes shall not be in

touch/in electrical contact with the pipe.

3. Where there are branching pipes, the sock anode will run all around the branching pipe if the branch length is lower

than five meters, while the sock anode will be spliced to a branching sock anode if the pipe branch length is above five

metres.

N = 2510.250 DRAWING LIMIT

4. Bonding cables shall be installed to maintain electrical continuity at locations such as nonwelded joints, mechanical

E = 1789.500

BD-EY-W400 BD-EY-W400 joints, flanges, couplings, concrete pits and locations where there is no electrical continuity within the piping system

W400 ELECTRICAL BURIED EXISTING W400 ELECTRICAL BURIED EXISTING

TRENCH

to be cathodically protected. Bonding/Jumper among the pipes shall be provided outside the pits.

TRENCH

5. The piping shall be isolated with neoprene rubber from any reinforced concrete support / wall to minimize current

2003.350FGL

N= 2505.350

E= 1827.763 BD-EY-W600 drains from rebars in reinforced concrete structures.

EXISTING FENCE 4- 6. Soil access shall be installed next to the test posts and junction boxes at paved areas.

BD-EY-W400 7. The number of Permanent Magnesium Anodes at TP Type 3 locations shall be as per "DETAILED DESIGN CALCULATION

REPORT " document no. 4058-VW-CX-00OO000013 (Ref. No. 19).

8. CP cable shall not be laid in instrument / ELECT Trench. A separate cable tray shall be used for CP at least 300mm away

from ELECT cable in order to avoid the interference. All cables shall be laid without coils or kinks, buried in sand at a

CJ

CJ

CJ

CJ

CJ

CJ

2003.350FGL IJ

depth of at least 0.75 m, provided with cable protection tiles and warning tape installed 250 mm above the cable. The

N= 2501.850

820-FX-43-01 E= 1886.850

trench shall be 300 mm wide.

VALLEY LINE

A430-DOV-4"-A01BU-001 A430-DO-CB-001 9. Distance from piping to junction boxes and test posts shall be approx 1.5 m.

(TYP.) 820-VD-43-05

N= 2496.332

E= 1897.658

CJ 2003.350FGL 10. For the Cable Schedule, please refer to the relevant Document (Ref. No. 27).

FUN-072-6"x4"

N= 2495.286

E= 1887.695 11. For the basic requirement/guidelines to be followed by construction personnel during installation, and for brief

BD-EY-W600

A430-DO-10"-A01BU-002 IJ guidelines/precautions, please refer to the Intallation Specification document (Ref. No. 23) and to the Installation

746-XA-71-01

HOLD-2

A FUN-077-6"x4"

N= 2494.032

2003.350FGL Drawings (Ref. No. 24).

820-PG-43-05A E= 1897.658

CJ 12. For the Schematic Drawing, please refer to the relevant Document (Ref. No. 25).

TP13

FOR CONTINUATION REFER SHEET 2

N= 2492.861

820-PG-43-05B

TP12

E= 1887.695

HOLD-1 (FV-011-02)

13. All installation works associated with the Cathodic Protection system shall be conducted in accordance with this

A430-DO-4"-A01BU-001

WF-VP-004 drawing and the complete CP design package (see documents Ref No. 16 to 29 for full list). Any conflict between this

14" EXISTING WF LINE EXISTING

A430-DO-10"-A01BU-003 drawing and other CP drawings and / or other project specifications and drawings shall be brought to the attention of

EXISTING NATURAL A IJ the CP Engineer in writing for clarification as soon as it is discovered.

CJ

CJ

CJ

CJ

CJ

CJ

SOIL 14" EXISTING WF LINE

(R-011-3) 14. The final location of the TR Units, Junction Boxes and Test Posts shall be checked by the CP Engineer in consultation

(EXISTING) N= 2486.318

E= 1836.900

24" EXISTING DO

6"-WF-71-4821-A01BU-N BD-IY-W300 24" EXISTING DO with the installation Sub-contractor and client. The TR Units, Junction Boxes and Test Posts shall, where practicable, be

LINE

DRAWING LIMIT

LINE

(R-011-1)

installed in such a fashion that safe and convenient access to them is maintained.

(RCF-011-4)

TIE-IN N= 2486.318

E= 1885.298 A430-DO-SM-030

(EXISTING)

N= 2486.661

E= 1929.295

Under no circumstances shall the TR Units, Junction Boxes and Test Posts be installed in a location where they could

TP-328

be damaged and / or cause an obstruction or interference to the regular activities of the operator.

15. Wherever there is a pit, Electrical continuity among the pipes like DO, DOV shall be provided at all the locations using

(R-011-2)

bonding Jumper cable (1c 25 mm2) and thermite welding.

EXTRA WIDTH

INSTALL PE / PVC SHEET TO 16. Packaged Sacrificial anodes shall be installed 1.5 m away from the pipes and shall be installed at the bottom level of

EXTRA WIDTH

MITIGATE INTERFERENCE

W400 ELECTRICAL BURIED EXISTING

14" EXISTING WF LINE

BD-EY-W600 pipe.

17. Sacrificial anodes shall be laid horizontally. Anodes shall be soaked in water 24 hours prior to installation.

2003.350FGL

18. Test station shall be installed 1.5 m away from the pipe.

19. AJB/PDB/BB/NDB/NJB shall be installed 1.5 m away from the pipe. Cables inside the TP/JB shall be terminated with

proper tagging for easy identifications.

20. Polarisation coupon and permanent reference cells shall be installed 100 mm away from the pipe and shall be 1/3rd of

pipe depth from pipe bottom level.

C OF 6.0M. WIDE

TRENCH

PLEASE SEE SHEET 7 FOR ADDITIONAL NOTES

24" EXISTING DO

ROAD

W400 INSTRUMENTAL BURIED EXISTING

MAP VIEW

L

TRENCH

LINE

LP1

LP1

1789.500

1832.150

E= 2040.000

E= 2044.000

E=

E=

N=

2510.250

N= 2507.000

E= 2063.775

DRAWING LIMIT DRAWING LIMIT N= 2497.801

E = 1789.500

W400 ELECTRICAL BURIED EXISTING

TRENCH

DRAWING LIMIT

EXISTING LIGHT EXISTING LIGHT EXISTING LIGHT N=

2459.000

E= 1936.700

POLE POLE POLE

N= 2446.300

N= 2445.000

14" EXISTING WF LINE

EXISTING EXTRA

A340-DO-6"-A01BU-044

WIDTH

DRAWING LIMIT

E= 1937.010

DRAWING

N= 2383.100

LIMIT

N= 2378.700

N = 2459.000 DRAWING LIMIT

DRAWING LIMIT

THIS PAGE

DRAWING

LIMIT

MATCH

LINE-A

LEGEND

TRANSFORMER RECTIFIER UNIT (TRU)

DRAWING LIMIT

DRAWING LIMIT

NEGATIVE DISTRIBUTION BOX (NDB) - OR

NEGATIVE JUNCTION BOX (NJB) - OR

DRAWING LIMIT

BOND BOX (BB)

N= 2168.300

N= 2149.446

DRAWING LIMIT

POSITIVE DISTRIBUTION BOX (PDB) DRAWING LIMIT DRAWING LIMIT

ANODE JUNCTION BOX (AJB) DRAWING LIMIT

Acceptance status Eng. Dept. Date

TEST BOX (TB) - TYPE 1 (PSP AND TCP) code

TEST BOX (TB) - TYPE 2 (PSP AND TCP) A B.LENKA PROCS 30-03-3021

TEST BOX (TB) - TYPE 3 (PCP) Comment status code:

A - Accepted CR - Commented. Resubmit for Acceptance

TEST BOX (TB) - TYPE 4 (INTERFERENCE MITIGATION)

AC - Accepted with Comment, NA

Resubmit

- Not accepted, Resubmit

TEST BOX (TB) - TYPE 5 (PVC CASING)

IMPORTANT: CONTRACTOR acceptance of this Document does not relieve the

STRUCTURE CONNECTION VENDOR from full compliance with contractual obligation

NEGATIVE WELD PAD/CLEAT CONNECTION

SPLICE KIT 5 25MAR21 25MAR21 REVISED PER CLIENT COMMENTS N.SIPPEL A.BONETTI S.FILMORE

PERMANENT CSE REFERENCE ELECTRODE

4 10FEB21 23FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

C COUPON

3 10FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

AND THERMOWELD CONNECTIONS)

7.7kg MAGNESIUM ANODE 2 15DEC20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

A

(TEMPORARY CP)

1 23SEP20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

14.5kg MAGNESIUM ANODE

A

(PERMANENT CP) 0 15JUL20 ISSUED FOR APPROVAL L.HULL N.SIPPEL A.BONETTI

PIPE LEGEND

A 2x ZINC RIBBON ANODES

WS: WATER SOURCE (PERMANENT CP)

FD: FUEL DIESEL

WF: FIRE WATER

OWS: OILY WATER SYSTEM

DOV: VENT PIPE Realisation du 4eme Train GPL a ZCINA, Hassi Messaoud

DO: OPEN DRAIN (NON-HAZ) CT-EPC/001/SH/EPM-G/EP/18

DC: CLOSED DRAIN

DP: PROCESS DRAIN BOND CABLE

HM: HEATING MEDIUM ANODE SOCK

GENERAL LAYOUT DRAWINGS

29 PRE-COMMISSIONING AND COMMISSIONING CHECK SHEETS 4058-VW-RC-00OO000026

14 LAYOUT OF HAZARDOUS AREA CLASSIFICATION PROCESS TRAIN 4 4058-SN-DH-00OO000003-IS0 28 PRE-COMMISSIONING AND COMMISSIONING PROCEDURE 4058-VW-PC-00OO000025

13 LAYOUT OF HAZARDOUS AREA CLASSIFICATION OVERALL LPG TRAIN 4 4058-SN-DH-00OO000001-IS0 27 CABLE SCHEDULE 4058-VW-LK-00OO000023

12 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A800 4058-AQ-DA-A800000009 26 FOUNDATION AND BASE FRAME DETAIL DRAWINGS 4058-VW-DW-00OO000022

4058-VW-DG-00OO000020 1/7

11 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A630, A710 & A720 4058-AQ-DA-A630000008 25 SCHEMATIC WIRING DRAWINGS 4058-VW-DN-00OO000021

10 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A430 4058-AQ-DA-A430000011 24 INSTALLATION DRAWINGS 4058-VW-DW-00OO000018 EPC001-00-DD-EU-CPC-00020-M 1:250 5

9 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A340 & A350 4058-AQ-DA-A340000003 23 INSTALLATION SPECIFICATION 4058-VW-SG-00OO000017

8 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A330, A360 & A380 4058-AQ-DA-A330000005 22 BILL OF MATERIAL LIST 4058-VW-LM-00OO000016

7 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A310, A320 & A370 4058-AQ-DA-A310000004 21 MATERIALS SPECIFICATION 4058-VW-SG-00OO000015 Grantham, Lincs, UK, NG31 7XS Tel. +44(0)1476 590666

6 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A210 & A220 4058-AQ-DA-A220000002 20 POWER SUPPLY REQUIREMENTS 4058-VW-LN-00OO000014 E-mail cpc@cathodic.co.uk Web www.cathodic.co.uk

5 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A100, A101 & A102 4058-AQ-DA-A100000001 19 DETAILED DESIGN CALCULATION REPORT 4058-VW-CX-00OO000013

4 UNDERGROUND GENERAL DRAWINGS - KEY PLAN 4058-AQ-DX-A100000001 18 DESIGN PHILOSOPHY & SPECIFICATION 4058-VW-SG-00OO000012

3 COATING SPECIFICATION FOR BURIED SURFACES 4058-VW-SG-0000000005 17 PRE-DESIGN SITE SURVEY REPORT 4058-VW-RT-00OO000011

2 MATERIAL SPECIFICATION AND DATASHEET 4058-VW-SG-00OO000007-IS0 16 PRE-DESIGN SITE SURVEY SPECIFICATION 4058-VW-SG-00OO000010 VENDOR DOCUMENT NO.

1 CATHODIC PROTECTION SPECIFICATION 4058-VW-SG-00OO000006-ISA 15 LAYOUT OF HAZARDOUS AREA CLASSIFICATION COMPRESSOR 4058-SN-DH-00OO000004-IS0

42119-CLO-029

REF NO. DOCUMENT TITLE DOCUMENT NUMBER REF NO. DOCUMENT TITLE DOCUMENT NUMBER

DRAWING LIMIT N = 2497.801

1. Please refer to the Coordinates Table for the Tag numbers and Coordinates of each component of CP Equipment.

2. The ICCP continuous anode will be buried in the pipe trench at a distance of 0.5 m from the pipe at the 3 or 9 o'clock

E = 1789.500

E = 2063.775

(FV-0120-04) position (i.e. halfway between bottom and top of pipe depth). Anode splicing shall be done using splice kits and shall

24" EXISTING DO

TIE-IN TIE-IN TIE-IN

WF-VP-EXISTING

EXISTING TP-325 EXISTING ROAD TP-324 TP-323

(FV-0120-03) be done as per approved procedure and drawings. Anode tail cables shall be terminated at designated AJB. Sufficient

POLE (TYP)

LIGHT WF-VP-EXISTING watering shall be carried out after anode laid in the trench and before backfilling. In any case anodes shall not be in

TIE-IN INSTALL PE / PVC SHEET touch/in electrical contact with the pipe.

LINE

TP-323 TO MITIGATE 3. Where there are branching pipes, the sock anode will run all around the branching pipe if the branch length is lower

W400 ELECTRICAL BURIED EXISTING TRENCH

(FV-011-02) INTERFERENCE than five meters, while the sock anode will be spliced to a branching sock anode if the pipe branch length is above five

WF-VP-004 (R-012-13) W400 INSTRUMENTAL BURIED EXISTING TRENCH metres.

EXISTING A310-DO-MH-020

8"-WF-71-0815-A01BU-N 6"-WF-71-0832-A01BU-N 14" EXISTING WF LINE 4. Bonding cables shall be installed to maintain electrical continuity at locations such as nonwelded joints, mechanical

14" EXISTING WF LINE

joints, flanges, couplings, concrete pits and locations where there is no electrical continuity within the piping system

DO-TIE-IN-001 BD-IY-W300 A A to be cathodically protected. Bonding/Jumper among the pipes shall be provided outside the pits.

BD-IY-W300

24" EXISTING DO 6"-WF-71-0831-A01BU-N TIE-IN TP-301 5. The piping shall be isolated with neoprene rubber from any reinforced concrete support / wall to minimize current

LINE

N= 2486.619

TP14 TP15 BB2-1 drains from rebars in reinforced concrete structures.

BD-IY-W300 E= 1965.000 741-XW-71-10

741-XM-71-03 14" EXISTING WF LINE 6. Soil access shall be installed next to the test posts and junction boxes at paved areas.

N= 2486.619

E= 1958.624

A310-DO-16"-A01BU-007

(FV-012-4)

A310-WF-VP-001

(FV-012-5)

A310-WF-VP-002

TP16 7. The number of Permanent Magnesium Anodes at TP Type 3 locations shall be as per "DETAILED DESIGN CALCULATION

4"-WF-71-4809-A01BU-N

741-XM-71-02

R-012-1

4"-WF-71-4810-A01BU-N

(FV-012-7) REPORT " document no. 4058-VW-CX-00OO000013 (Ref. No. 19).

(EXISTING) A A320-WF-VP-001

8. CP cable shall not be laid in instrument / ELECT Trench. A separate cable tray shall be used for CP at least 300mm away

from ELECT cable in order to avoid the interference. All cables shall be laid without coils or kinks, buried in sand at a

BD-EY-W600

depth of at least 0.75 m, provided with cable protection tiles and warning tape installed 250 mm above the cable. The

A310-DO-16"-A01BU-001

A320-DO-16"-A01BU-002

N= 2482.275 N= 2482.275 TIE-IN

E= 2000.400 E= 2002.300

TP-302 trench shall be 300 mm wide.

BD-EY-W600

150THK.CURB 484-KF-41-01

9. Distance from piping to junction boxes and test posts shall be approx 1.5 m.

W400 ELECTRICAL BURIED EXISTING TRENCH

FUEL GAS SKID

FUEL GAS SKID

WALL (TYP)

G14-KF-24-01 10. For the Cable Schedule, please refer to the relevant Document (Ref. No. 27).

11. For the basic requirement/guidelines to be followed by construction personnel during installation, and for brief

FOR CONTINUATION REFER SHEET 1

W400 INSTRUMENTAL BURIED EXISTING TRENCH

(TYP)

guidelines/precautions, please refer to the Intallation Specification document (Ref. No. 23) and to the Installation

2-

Drawings (Ref. No. 24).

12. For the Schematic Drawing, please refer to the relevant Document (Ref. No. 25).

A320-DO-DT-006-W400

14" EXISTING WF LINE

13. All installation works associated with the Cathodic Protection system shall be conducted in accordance with this

N= 2469.500

E= 1989.000 drawing and the complete CP design package (see documents Ref No. 16 to 29 for full list). Any conflict between this

C

L OF G14-UF-24-01 C

L OF 484-UF-41-01 drawing and other CP drawings and / or other project specifications and drawings shall be brought to the attention of

DRAWING LIMIT

N= 2469.500

(RCF-012-3) E= 2025.000

TP29 the CP Engineer in writing for clarification as soon as it is discovered.

A310-DO-SM-007 6 THK. CHQUERED

N= 2464.900 PLATE

A320-DO-SM-015 14. The final location of the TR Units, Junction Boxes and Test Posts shall be checked by the CP Engineer in consultation

E= 1965.000

6 THK. CHQUERED A320-DO-MH-019 N= 2465.350

E= 2059.300

with the installation Sub-contractor and client. The TR Units, Junction Boxes and Test Posts shall, where practicable, be

PLATE A320-DO-TD-001-W400 installed in such a fashion that safe and convenient access to them is maintained.

W400 ELECTRICAL BURIED EXISTING TRENCH

A320-DOV-4"-A01BU-001

EXISTING ROAD

EXTRA WIDTH

A310-DO-16"-A01BU-002

C Under no circumstances shall the TR Units, Junction Boxes and Test Posts be installed in a location where they could

TR-EY-W600 A320-DO-16"-A01BU-001 N= 2464.550

E= 2049.000

be damaged and / or cause an obstruction or interference to the regular activities of the operator.

14" EXISTING WF LINE N= 2464.550

E= 2042.501

A320-DO-16"-A01BU-004 15. Wherever there is a pit, Electrical continuity among the pipes like DO, DOV shall be provided at all the locations using

A310-DOV-4"-A01BU-001

200W X 250H

INSTALL PE / PVC bonding Jumper cable (1c 25 mm2) and thermite welding.

BD-EY-W600

BD-EY-W800

SHEET TO MITIGATE

EXISTING ROAD

CUTOUT 200W X 250H 16. Packaged Sacrificial anodes shall be installed 1.5 m away from the pipes and shall be installed at the bottom level of

EXISTING EXTRA

150 CURB WALL CUTOUT INTERFERENCE pipe.

(TYP) 705-XM-71-11

N = 2459.000 (TYP) EXISTING 17. Sacrificial anodes shall be laid horizontally. Anodes shall be soaked in water 24 hours prior to installation.

2000.000HPP

18. Test station shall be installed 1.5 m away from the pipe.

WIDTH

6" EXISTING WF LINE

19. AJB/PDB/BB/NDB/NJB shall be installed 1.5 m away from the pipe. Cables inside the TP/JB shall be terminated with

proper tagging for easy identifications.

MAINTENANCE AREA

300mm COMPACTED

N= 2456.120

E= 1959.575

TP21 20. Polarisation coupon and permanent reference cells shall be installed 100 mm away from the pipe and shall be 1/3rd of

884-FX-43-01

14" EXISTING WF LINE

EXISTING EXTRA

TUFF 2000.000

TIE-IN pipe depth from pipe bottom level.

TP-303

TP17 6"-WF-71-4801-A01BU-N

A

PLEASE SEE SHEET 7 FOR ADDITIONAL NOTES

WIDTH

A320-DO-16"-A01BU-003

A A 6" EXISTING WF LINE

741-XA-71-04

MAP VIEW

A310-DO-16"-A01BU-003

6"-WF-71-4804-A01BU-N 741-XA-71-03 INSTALL PE / PVC

INSTALL PE / PVC SHEET TO SHEET TO MITIGATE

MITIGATE INTERFERENCE INTERFERENCE DRAWING LIMIT DRAWING LIMIT

BD-IY-W300

A310-DO-SM-026

DRAWING LIMIT

N= 2441.504

A370-DO-4"-A01BU-001 E= 2004.946

AJB2-2

NJB2-3

DRAWING LIMIT

N= 2439.000 N= 2439.857

E= 1990.000 E= 2003.300

DRAWING

LIMIT

N= 2439.000

E= 2004.800 BD-IY-W300

A310-DO-MH-018

C A

DRAWING LIMIT

N= 2439.000 A310-DO-12"-A01BU-005 A310-DO-6"-A01BU-006 THIS PAGE

E= 1965.000

3"-HM-57-4403-A03-N

A310-DO-16"-A01BU-004

TP11

DRAWING

LIMIT

MATCH

LINE-A

A310-DOV-4"-A01BU-002

N= 2435.500 FOR CONTINUATION REFER SHEET 3

LEGEND

DRAWING LIMIT

TRANSFORMER RECTIFIER UNIT (TRU)

DRAWING LIMIT

NEGATIVE DISTRIBUTION BOX (NDB) - OR

DRAWING LIMIT

NEGATIVE JUNCTION BOX (NJB) - OR

BOND BOX (BB) DRAWING LIMIT

POSITIVE DISTRIBUTION BOX (PDB)

DRAWING LIMIT DRAWING LIMIT

DRAWING LIMIT

ANODE JUNCTION BOX (AJB)

Acceptance status Eng. Dept. Date

TEST BOX (TB) - TYPE 1 (PSP AND TCP) code

TEST BOX (TB) - TYPE 2 (PSP AND TCP)

TEST BOX (TB) - TYPE 3 (PCP) Comment status code:

A - Accepted CR - Commented. Resubmit for Acceptance

TEST BOX (TB) - TYPE 4 (INTERFERENCE MITIGATION)

AC - Accepted with Comment, NA

Resubmit

- Not accepted, Resubmit

TEST BOX (TB) - TYPE 5 (PVC CASING)

IMPORTANT: CONTRACTOR acceptance of this Document does not relieve the

STRUCTURE CONNECTION VENDOR from full compliance with contractual obligation

NEGATIVE WELD PAD/CLEAT CONNECTION

SPLICE KIT 5 25MAR21 25MAR21 REVISED PER CLIENT COMMENTS N.SIPPEL A.BONETTI S.FILMORE

PERMANENT CSE REFERENCE ELECTRODE

4 10FEB21 23FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

C COUPON

3 10FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

AND THERMOWELD CONNECTIONS)

7.7kg MAGNESIUM ANODE 2 15DEC20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

A

(TEMPORARY CP)

1 23SEP20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

14.5kg MAGNESIUM ANODE

A

(PERMANENT CP) 0 15JUL20 ISSUED FOR APPROVAL L.HULL N.SIPPEL A.BONETTI

PIPE LEGEND

A 2x ZINC RIBBON ANODES

WS: WATER SOURCE (PERMANENT CP)

FD: FUEL DIESEL

WF: FIRE WATER

OWS: OILY WATER SYSTEM

DOV: VENT PIPE Realisation du 4eme Train GPL a ZCINA, Hassi Messaoud

DO: OPEN DRAIN (NON-HAZ) CT-EPC/001/SH/EPM-G/EP/18

DC: CLOSED DRAIN

DP: PROCESS DRAIN BOND CABLE

HM: HEATING MEDIUM ANODE SOCK

GENERAL LAYOUT DRAWINGS

29 PRE-COMMISSIONING AND COMMISSIONING CHECK SHEETS 4058-VW-RC-00OO000026

14 LAYOUT OF HAZARDOUS AREA CLASSIFICATION PROCESS TRAIN 4 4058-SN-DH-00OO000003-IS0 28 PRE-COMMISSIONING AND COMMISSIONING PROCEDURE 4058-VW-PC-00OO000025

13 LAYOUT OF HAZARDOUS AREA CLASSIFICATION OVERALL LPG TRAIN 4 4058-SN-DH-00OO000001-IS0 27 CABLE SCHEDULE 4058-VW-LK-00OO000023

12 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A800 4058-AQ-DA-A800000009 26 FOUNDATION AND BASE FRAME DETAIL DRAWINGS 4058-VW-DW-00OO000022

4058-VW-DG-00OO000020 2/7

11 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A630, A710 & A720 4058-AQ-DA-A630000008 25 SCHEMATIC WIRING DRAWINGS 4058-VW-DN-00OO000021

10 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A430 4058-AQ-DA-A430000011 24 INSTALLATION DRAWINGS 4058-VW-DW-00OO000018 EPC001-00-DD-EU-CPC-00020-M 1:250 5

9 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A340 & A350 4058-AQ-DA-A340000003 23 INSTALLATION SPECIFICATION 4058-VW-SG-00OO000017

8 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A330, A360 & A380 4058-AQ-DA-A330000005 22 BILL OF MATERIAL LIST 4058-VW-LM-00OO000016

7 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A310, A320 & A370 4058-AQ-DA-A310000004 21 MATERIALS SPECIFICATION 4058-VW-SG-00OO000015 Grantham, Lincs, UK, NG31 7XS Tel. +44(0)1476 590666

6 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A210 & A220 4058-AQ-DA-A220000002 20 POWER SUPPLY REQUIREMENTS 4058-VW-LN-00OO000014 E-mail cpc@cathodic.co.uk Web www.cathodic.co.uk

5 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A100, A101 & A102 4058-AQ-DA-A100000001 19 DETAILED DESIGN CALCULATION REPORT 4058-VW-CX-00OO000013

4 UNDERGROUND GENERAL DRAWINGS - KEY PLAN 4058-AQ-DX-A100000001 18 DESIGN PHILOSOPHY & SPECIFICATION 4058-VW-SG-00OO000012

3 COATING SPECIFICATION FOR BURIED SURFACES 4058-VW-SG-0000000005 17 PRE-DESIGN SITE SURVEY REPORT 4058-VW-RT-00OO000011

2 MATERIAL SPECIFICATION AND DATASHEET 4058-VW-SG-00OO000007-IS0 16 PRE-DESIGN SITE SURVEY SPECIFICATION 4058-VW-SG-00OO000010 VENDOR DOCUMENT NO.

1 CATHODIC PROTECTION SPECIFICATION 4058-VW-SG-00OO000006-ISA 15 LAYOUT OF HAZARDOUS AREA CLASSIFICATION COMPRESSOR 4058-SN-DH-00OO000004-IS0

42119-CLO-029

REF NO. DOCUMENT TITLE DOCUMENT NUMBER REF NO. DOCUMENT TITLE DOCUMENT NUMBER

A310-DO-16"-A01BU-00

FOR CONTINUATION REFER SHEET 2 1. Please refer to the Coordinates Table for the Tag numbers and Coordinates of each component of CP Equipment.

A320-DO-16"-A01BU-003

N = 2439.000 2. The ICCP continuous anode will be buried in the pipe trench at a distance of 0.5 m from the pipe at the 3 or 9 o'clock

E = 1789.500

A310-DOV-4"-A01BU-002

2000.000

PIPE LEGEND

E = 2063.775

BD-IY-W300

position (i.e. halfway between bottom and top of pipe depth). Anode splicing shall be done using splice kits and shall

mm COMPACTED

3"-HM-41-4403-A03-N

WS: WATER SOURCE be done as per approved procedure and drawings. Anode tail cables shall be terminated at designated AJB. Sufficient

MAINTENANCE

watering shall be carried out after anode laid in the trench and before backfilling. In any case anodes shall not be in

A340-DO-6"-A01BU-044

N= 2432.145

OC1-VL-57-09

AJB2-1

E= 1959.650

EXISTING LIGHT POLE

FD: FUEL DIESEL touch/in electrical contact with the pipe.

N= 2428.290 TP30 3. Where there are branching pipes, the sock anode will run all around the branching pipe if the branch length is lower

AREA

W400 INSTRUMENTAL BURIED EXISTING TRENCH

N= 2428.140

TUFF

N= 2428.100 E= 2034.940

E= 1982.510 E= 2027.050

WF: FIRE WATER

300

A360-DO-MH-001

N= 2428.500

E= 1965.000 than five meters, while the sock anode will be spliced to a branching sock anode if the pipe branch length is above five

8"-DP-57-4349-M01-N N= 2428.141

metres.

N= 2428.100

A350-DO-6"-A01BU-006 A350-DOV-4"-A01BU-001 OWS: OILY WATER SYSTEM 4. Bonding cables shall be installed to maintain electrical continuity at locations such as nonwelded joints, mechanical

(TYP.)

E= 2034.940

OC1-VL-57-12 E= 1985.510 N= 2426.300

E= 2059.300

8"-DC-57-4343-A01BUCD-N 8"-DC-57-4343-A01BUCD-N C

8"-DP-57-4301-M01-N N= 2426.000

E= 2034.940 N= 2425.500

E= 2036.625

DOV: VENT PIPE joints, flanges, couplings, concrete pits and locations where there is no electrical continuity within the piping system

A350-DO-4"-A01BU-005

(RCF-012-18)

N= 2425.383

E= 1985.510

(RD-012-3)

A350-DO-SM-027

to be cathodically protected. Bonding/Jumper among the pipes shall be provided outside the pits.

A350-DO-CO-009

DO: OPEN DRAIN (NON-HAZ) 5. The piping shall be isolated with neoprene rubber from any reinforced concrete support / wall to minimize current

INSTALL PE /

6" EXISTING WF LINE

drains from rebars in reinforced concrete structures.

6" EXISTING WF LINE

N= 2420.900

3"-HM-41-4301-A03-N

E= 2035.800

N= 2418.501

PVC SHEET TO DC: CLOSED DRAIN 6. Soil access shall be installed next to the test posts and junction boxes at paved areas.

3"-DC-57-4368-A01BUCD-N E= 2035.800 2000.000 FGL

N= 2418.353

E= 2035.800

MITIGATE 7. The number of Permanent Magnesium Anodes at TP Type 3 locations shall be as per "DETAILED DESIGN CALCULATION

INTERFERENCE DP: PROCESS DRAIN REPORT " document no. 4058-VW-CX-00OO000013 (Ref. No. 19).

A360-DO-16"-A01BU-001

MAINTENANCE AREA

8. CP cable shall not be laid in instrument / ELECT Trench. A separate cable tray shall be used for CP at least 300mm away

300mm COMPACTED

FUN-070-6"x4" HM: HEATING MEDIUM from ELECT cable in order to avoid the interference. All cables shall be laid without coils or kinks, buried in sand at a

14" EXISTING WF LINE

E= 2018.366

E= 2018.693

484-VL-41-02

N= 2415.177

E= 2014.477

N= 2415.179

E= 2019.375

FUN-006-6"x4" depth of at least 0.75 m, provided with cable protection tiles and warning tape installed 250 mm above the cable. The

N= 2416.000

trench shall be 300 mm wide.

8"-DC-57-4300-A01BUCD-N

E= 2039.358

C

L OF 884-VD-43-01 N= 2413.500

W400 ELECTRICAL BURIED EXISTING TRENCH

9. Distance from piping to junction boxes and test posts shall be approx 1.5 m.

TUFF

E= 2026.970

150 THK. CURB WALL

2"-HM-41-4405-A03-N

N= 2412.084 N= 2413.540

A370-DO-6"-A01BU-003

(TYP) E= 2016.600

10. For the Cable Schedule, please refer to the relevant Document (Ref. No. 27).

(TYP) 11. For the basic requirement/guidelines to be followed by construction personnel during installation, and for brief

8"-DP-57-4301-M01-N

2"-HM-41-4397-A03-N

E= 2018.791

N= 2409.569

E= 2013.453

guidelines/precautions, please refer to the Intallation Specification document (Ref. No. 23) and to the Installation

A330-DOV-4"-A01BU-003

N= 2408.505

N= 2408.505

E= 1995.700

MAINTENANCE

Drawings (Ref. No. 24).

N= 2409.650

50 THK. N= 2407.633

E= 1990.595

E= 1994.982

300

AREAmm COMPACTED TP 305 12. For the Schematic Drawing, please refer to the relevant Document (Ref. No. 25).

E= 1968.375

COVER

GRATING TUFF

13. All installation works associated with the Cathodic Protection system shall be conducted in accordance with this

EXISTING ROAD

EXISTING EXTRA

2000.000

A330-DO-4"-A01BU-007

N= 2405.000

2"-HM-41-4408-A03-N drawing and the complete CP design package (see documents Ref No. 16 to 29 for full list). Any conflict between this

A350-DO-6"-A01BU-003

E= 1997.000

drawing and other CP drawings and / or other project specifications and drawings shall be brought to the attention of

6" EXISTING WF LINE

6"-WF-71-4802-A01BU-N

A330-DO-SM-006

A330-DO-6"-A01BU-005 BB2-2 N= 2405.639

CRD-6"x4" E= 2013.455

the CP Engineer in writing for clarification as soon as it is discovered.

A330-DO-DT-002-W400

N= 2405.000

A340-DO-6"-A01BU-012

WIDTH

E= 1979.150

N= 2402.800

E= 1994.982

N= 2402.800

E= 1999.200 741-XA-71-05 14. The final location of the TR Units, Junction Boxes and Test Posts shall be checked by the CP Engineer in consultation

with the installation Sub-contractor and client. The TR Units, Junction Boxes and Test Posts shall, where practicable, be

3"-DP-57-4424-M01-N

A330-DO-4"-A01BU-009 2"-HM-41-4396-A03-N N= 2400.700

TP18 N= 2402.436

E= 2013.900

E= 2027.700

A installed in such a fashion that safe and convenient access to them is maintained.

A350-DO-16"-A01BU-001

HOLD-1

N= 2399.640

E= 2012.000 A340-DO-CO-008 TP22 Under no circumstances shall the TR Units, Junction Boxes and Test Posts be installed in a location where they could

A 6"-WF-71-4805-A01BU-N 741-XA-71-02

N= 2398.755

E= 2033.603 be damaged and / or cause an obstruction or interference to the regular activities of the operator.

A330-DO-6"-A01BU-001 3"-DC-57-4370-A01BUCD-N

(FV-012-8)

A340-WF-VP-001

15. Wherever there is a pit, Electrical continuity among the pipes like DO, DOV shall be provided at all the locations using

A330-DO-16"-A01BU-003 (RD-012-012) 2"-HM-41-4400-A03-N CURB WALL bonding Jumper cable (1c 25 mm2) and thermite welding.

A340-DO-CO-019 N= 2396.150

N= 2396.739

E= 2025.131

150 THK., 100 HT. 16. Packaged Sacrificial anodes shall be installed 1.5 m away from the pipes and shall be installed at the bottom level of

EXISTING LIGHT

C

L OF G14-CE-32-01

E= 2024.574

pipe.

484-PA-41-01A TP 308

NDB2 A330-DO-SM-005 17. Sacrificial anodes shall be laid horizontally. Anodes shall be soaked in water 24 hours prior to installation.

N= 2391.300

E= 1979.150 N= 2390.650

E= 1984.150

N= 2394.033

E= 2021.856

N= 2392.325

18. Test station shall be installed 1.5 m away from the pipe.

N= 2391.800

E= 1965.000 3"-DP-57-4429-M01-N N= 2390.739

E= 2030.725

19. AJB/PDB/BB/NDB/NJB shall be installed 1.5 m away from the pipe. Cables inside the TP/JB shall be terminated with

TR-2

N= 2390.600

PDB2

E= 2025.131

proper tagging for easy identifications.

E= 1992.094

A330-DO-16"-A01BU-002 2"-DP-57-4382-M01-N

N= 2390.150

G14-PA-32-02B E= 2024.574

484-PA-41-01B

484-VL-41-01

N= 2391.033

E= 2036.765 20. Polarisation coupon and permanent reference cells shall be installed 100 mm away from the pipe and shall be 1/3rd of

N= 2389.000

A330-DOV-4"-A01BU-001 A330-DOV-4"-A01BU-002 E= 1992.642

2000.000 FGL pipe depth from pipe bottom level.

N= 2389.000 A330-DO-6"-A01BU-011 3"-DP-57-4301-M01-N 3"-DP-57-4385-M01-N N= 2387.100

N= 2389.050 E= 2043.600

E= 1985.800

E= 1965.800

G14-PA-32-02A TP34 PLEASE SEE SHEET 7 FOR ADDITIONAL NOTES

A330-DO-4"-A01BU-010

N= 2388.026

E= 2021.864

A N= 2386.900

E= 2043.600

4"-DP-57-4301-M01-N

3"-DP-57-4803-M01-N A340-DO-16"-A01BU-005

MAP VIEW

N= 2387.500 N= 2383.700 N= 2383.700

E= 1992.094 E= 2027.870 E= 2053.750

A340-DO-16"-A01BU-004

A330-DO-16"-A01BU-004

N= 2381.996

TP09 E= 2022.493

A340-DO-16"-A01BU-006

CL OF G14-VL-32-06 CL OF G14-VL-32-02

A340-DO-MH-003

N= 2383.700

(RCF-012-12)

N= 2383.700

E= 2033.250 E= 2049.000 A340-DO-MH-002 DRAWING LIMIT DRAWING LIMIT

DRAWING LIMIT

DRAWING LIMIT

A A340-DO-SM-013

A340-DO-SM-014

8"-DP-57-4301-M01-N

N= 2380.580

A340-DO-6"-A01BU-028

E= 2028.370

A340-DO-VP-001

6"-WF-71-0818-A01BU-N

TP31

(FDF-012-1)

DRAWING LIMIT

A340-DO-16"-A01BU-003

A

3"-DP-57-4383-M01-N N= 2379.004

TP19 TP35 A

E= 2022.493

A340-DOV-4"-A01BU-003

DRAWING LIMIT

3"-DP-57-4386-M01-N N= 2377.952

A 4"-WF-71-4815-A01BU-N E= 2030.203

N= 2375.650

E= 2059.300

A340-DO-16"-A01BU-007

DRAWING

N= 2374.000

LIMIT

E= 1958.250

DRAWING LIMIT

705-XM-71-10

INSTALL PE / PVC SHEET TO G14-PA-32-03A

N= 2374.600

E= 2032.444 N= 2374.850

14" EXISTING WF LINE

EXISTING

E= 2053.750

A340-DO-TD-001-W400 A340-DO-SM-012

MITIGATE INTERFERENCE N= 2373.335 THIS PAGE

DRAWING

E= 2024.944

LIMIT

MATCH

LINE-A

C

L OF

G14-VL-32-03

A340-DO-10"-A01BU-008

A380-DO-16"-A01BU-001

A340-DO-4"-A01BU-027

A380-DO-SM-002

3"-DP-57-4804-M01-N G14-PA-32-03B

2000.000 N= 2369.280

6" EXISTING WF LINE LEGEND

DRAWING LIMIT

E= 2024.944

A340-DO-CO-007

MAINTENANCE AREA TRANSFORMER RECTIFIER UNIT (TRU)

DRAWING LIMIT

300mm COMPACTED 3"-DP-57-4387-M01-N N= 2368.376

DRAWING LIMIT

E= 2033.251

6"-DP-57-4301-M01-N

TUFF N= 2367.600

3"-DP-57-4387-M01-N E= 2037.810

NEGATIVE DISTRIBUTION BOX (NDB) - OR

TP 309

DRAWING LIMIT

N= 2364.675

E= 1998.000

6"-DP-57-4301-M01-N 4"-DC-57-4371-A01BUCD-N

N= 2365.595

E= 2040.692

(FV-012-9) NEGATIVE JUNCTION BOX (NJB) - OR

A340-WF-VP-002

N= 2362.250

E= 1971.800 A TP45 N= 2362.910

E= 2025.050

N= 2364.541

E= 2038.050 BOND BOX (BB) DRAWING LIMIT

3-

A380-DO-SM-003

TP38 TP23 NJB2-2 POSITIVE DISTRIBUTION BOX (PDB) DRAWING LIMIT

DRAWING LIMIT DRAWING LIMIT

G14-PA-32-01B G14-CB-32-01

AJB2-3 N= 2362.250

G14-PA-32-01A

A N= 2360.100

A ANODE JUNCTION BOX (AJB)

14" EXISTING WF LINE

A380-DO-16"-A01BU-002

E= 1965.000 E= 2047.250

10"-WF-71-0824-A01BU-N

A380-DO-DT-001-W400

Acceptance status Eng. Dept. Date

N= 2359.200

A

TP36

A380-DO-16"-A01BU-003

N= 2359.025 N= 2360.400

E= 1957.475

E= 1957.475

2"-DP-57-4389-M01-N E= 2024.294

TEST BOX (TB) - TYPE 1 (PSP AND TCP) code

6" EXISTING WF LINE

N= 2359.079

E= 1989.025 G14-PA-32-04A 8"-WF-71-4818-A01BU-N

A380-DOV-4"-A01BU-003 A380-DOV-4"-A01BU-002 N= 2358.734

TP 310

A

N= 2359.079 E= 2037.419

N= 2357.050

TEST BOX (TB) - TYPE 2 (PSP AND TCP)

8"-DC-57-4300-A01BUCD-N

E= 1994.345 E= 2032.865 N= 2357.050

A380-DOV-4"-A01BU-001 N= 2357.050

E= 2033.262

8"-DP-57-4301-M01-N

A E= 2029.859

A380-DO-6"-A01BU-008 TEST BOX (TB) - TYPE 3 (PCP) Comment status code:

PVC PIPE SLEEVE

N= 2358.850

E= 1957.475

PIPE DIA + 100mm TP39 A380-DO-4"-A01BU-009 N= 2356.300

E= 2024.294

G14-PA-32-04B TEST BOX (TB) - TYPE 4 (INTERFERENCE MITIGATION)

A - Accepted CR - Commented. Resubmit for Acceptance

2"-DP-57-4301-M01-N

N= 2356.350

WITH ENCASING AC - Accepted with Comment, NA

Resubmit

(RCF-012-9)

E= 2030.870

N= 2356.350 - Not accepted, Resubmit

A

A380-DO-SM-001 TP37 E= 2031.763

TEST BOX (TB) - TYPE 5 (PVC CASING)

A

IMPORTANT: CONTRACTOR acceptance of this Document does not relieve the

A340-DO-6"-A01BU-033

TP20 3"-DP-57-4395-M01-N N= 2353.000

E= 2029.400

N= 2353.650

E= 2036.285

STRUCTURE CONNECTION VENDOR from full compliance with contractual obligation

A380-DO-6"-A01BU-007

N= 2351.080 A380-DO-4"-A01BU-011 NEGATIVE WELD PAD/CLEAT CONNECTION

E= 1989.269

N= 2352.260

E= 1991.250

CURB WALL

TIE-IN MAINTENANCE 5 25MAR21 25MAR21 REVISED PER CLIENT COMMENTS N.SIPPEL A.BONETTI S.FILMORE

TP-335

A N= 2351.400 3"-DP-57-4392-M01-N

150 THK., 100 HT.

300 mm COMPACTED

AREA (RCF-012-14) SPLICE KIT

E= 1971.300 4"-DP-57-4391-M01-N 8"-DP-57-4301-M01-N TUFF

(RCF-012-16) A340-DO-SM-009

6"-WF-71-4806-A01BU-N

A340-DO-SM-010

2000.000 PERMANENT CSE REFERENCE ELECTRODE

N= 2346.080

E= 2024.750

N= 2345.655

E= 2031.100

N= 2346.080

E= 2033.263 N= 2346.080

E= 2053.750

4 10FEB21 23FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

C COUPON

mm COMPACTED

G14-KA-32-01

A340-DO-8"-A01BU-010 A

W400 ELECTRICAL BURIED EXISTING TRENCH

G14-KH-32-01 BD-EY-W600

(RCF-012-15) TP24 3 10FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

MAINTENANCE

741-XA-71-01

A380-DO-16"-A01BU-004

A340-DO-SM-011

6"-DP-57-4301-M01-N 741-XA-71-06 AND THERMOWELD CONNECTIONS)

2000.000

A340-DO-6"-A01BU-009 2 15DEC20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

DROP

A TP41

N= 2342.351

7.7kg MAGNESIUM ANODE

AREA

E= 2022.000

A

TUFF

AREA

(TEMPORARY CP)

300

4"-DP-57-4391-M01-N A340-DOV-4"-A01BU-006 6"-WF-71-4803-A01BU-N

G14-VD-24-01 N= 2339.850

1 23SEP20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

3"-DP-57-4398-M01-N E= 2051.450

14.5kg MAGNESIUM ANODE

3"-DC-57-4376-A01BUCD-N

N= 2340.500

N= 2340.500

E= 2031.100 A

A

BD-IY-W300 E= 2030.900

2000.000 FGL (PERMANENT CP)

N= 2338.316

E= 2021.350

N= 2337.000

0 15JUL20 ISSUED FOR APPROVAL L.HULL N.SIPPEL A.BONETTI

N= 2340.413 E= 2047.450

A340-DO-6"-A01BU-037

TP40 E= 2022.585 N= 2337.000

E= 2028.997

N= 2337.000

E= 2034.997

N= 2337.000

E= 2040.997 G14-MB-24-01A

A

A340-DO-8"-A01BU-011

BD-IY-W300

4"-DP-57-4400-M01-N

(RD-012-7) N= 2335.800

A 2x ZINC RIBBON ANODES

E= 2050.384

1- A340-DO-CO-004 G14-MB-24-02 (PERMANENT CP)

2000.000

N= 2335.800

E= 2022.000

N= 2334.450

E= 2046.200

(RD-012-10)

6" EXISTING WF LINE

N= 2333.900

A340-DO-CO-017 E= 2050.382

FUN-021-6"x4"

C

L OF

BD-IY-W300

G14-GA-32-02A N= 2330.950 G14-VK-24-01B G14-VK-24-01C G14-MB-24-01B

E= 2023.000 G14-VK-24-01A

MAINTENANCE AREA

300mm COMPACTED

A340-DO-4"-A01BU-042

N= 2329.200

E= 2053.250

Realisation du 4eme Train GPL a ZCINA, Hassi Messaoud

N= 2327.590 N= 2329.200

E= 2046.850

C

L OF

E= 2016.554

2000.000

N= 2327.600

W400 NEW ROUTING OF G14-GA-32-02B E= 2023.450

1-

INSTRUMENT BURIED TRENCH MAINTENANCE A340-DOV-4"-A01BU-007

CT-EPC/001/SH/EPM-G/EP/18

TUFF

(WITHOUT EXTRA 300

AREAmm COMPACTED

LENGTH) C TUFF

N= 2323.500 A340-DO-6"-A01BU-041 N= 2323.500

E= 1971.300 E= 2053.675

A340-DO-6"-A01BU-043

A NJB2-1 (RD-012-9)

N = 2318.280 TP10 AJB2-4 A340-DO-CO-003 BOND CABLE

A380-DO-12"-A01BU-006

N= 2323.499

(RCF-012-17)

BD-IY-W300

E= 2021.000 2000.000 FGL A340-DO-SM-008

FOR CONTINUATION REFER SHEET 4 ANODE SOCK

GENERAL LAYOUT DRAWINGS

29 PRE-COMMISSIONING AND COMMISSIONING CHECK SHEETS 4058-VW-RC-00OO000026

14 LAYOUT OF HAZARDOUS AREA CLASSIFICATION PROCESS TRAIN 4 4058-SN-DH-00OO000003-IS0 28 PRE-COMMISSIONING AND COMMISSIONING PROCEDURE 4058-VW-PC-00OO000025

13 LAYOUT OF HAZARDOUS AREA CLASSIFICATION OVERALL LPG TRAIN 4 4058-SN-DH-00OO000001-IS0 27 CABLE SCHEDULE 4058-VW-LK-00OO000023

12 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A800 4058-AQ-DA-A800000009 26 FOUNDATION AND BASE FRAME DETAIL DRAWINGS 4058-VW-DW-00OO000022

4058-VW-DG-00OO000020 3/7

11 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A630, A710 & A720 4058-AQ-DA-A630000008 25 SCHEMATIC WIRING DRAWINGS 4058-VW-DN-00OO000021

10 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A430 4058-AQ-DA-A430000011 24 INSTALLATION DRAWINGS 4058-VW-DW-00OO000018 EPC001-00-DD-EU-CPC-00020-M 1:250 5

9 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A340 & A350 4058-AQ-DA-A340000003 23 INSTALLATION SPECIFICATION 4058-VW-SG-00OO000017

8 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A330, A360 & A380 4058-AQ-DA-A330000005 22 BILL OF MATERIAL LIST 4058-VW-LM-00OO000016

7 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A310, A320 & A370 4058-AQ-DA-A310000004 21 MATERIALS SPECIFICATION 4058-VW-SG-00OO000015 Grantham, Lincs, UK, NG31 7XS Tel. +44(0)1476 590666

6 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A210 & A220 4058-AQ-DA-A220000002 20 POWER SUPPLY REQUIREMENTS 4058-VW-LN-00OO000014 E-mail cpc@cathodic.co.uk Web www.cathodic.co.uk

5 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A100, A101 & A102 4058-AQ-DA-A100000001 19 DETAILED DESIGN CALCULATION REPORT 4058-VW-CX-00OO000013

4 UNDERGROUND GENERAL DRAWINGS - KEY PLAN 4058-AQ-DX-A100000001 18 DESIGN PHILOSOPHY & SPECIFICATION 4058-VW-SG-00OO000012

3 COATING SPECIFICATION FOR BURIED SURFACES 4058-VW-SG-0000000005 17 PRE-DESIGN SITE SURVEY REPORT 4058-VW-RT-00OO000011

2 MATERIAL SPECIFICATION AND DATASHEET 4058-VW-SG-00OO000007-IS0 16 PRE-DESIGN SITE SURVEY SPECIFICATION 4058-VW-SG-00OO000010 VENDOR DOCUMENT NO.

1 CATHODIC PROTECTION SPECIFICATION 4058-VW-SG-00OO000006-ISA 15 LAYOUT OF HAZARDOUS AREA CLASSIFICATION COMPRESSOR 4058-SN-DH-00OO000004-IS0

42119-CLO-029

REF NO. DOCUMENT TITLE DOCUMENT NUMBER REF NO. DOCUMENT TITLE DOCUMENT NUMBER

A380-DO-12"-

1. Please refer to the Coordinates Table for the Tag numbers and Coordinates of each component of CP Equipment.

N = 2318.280 FOR CONTINUATION REFER SHEET 3 2. The ICCP continuous anode will be buried in the pipe trench at a distance of 0.5 m from the pipe at the 3 or 9 o'clock

position (i.e. halfway between bottom and top of pipe depth). Anode splicing shall be done using splice kits and shall

E = 1789.500

E= 2097.750

be done as per approved procedure and drawings. Anode tail cables shall be terminated at designated AJB. Sufficient

watering shall be carried out after anode laid in the trench and before backfilling. In any case anodes shall not be in

W400 INSTRUMENTAL BURIED EXISTING

touch/in electrical contact with the pipe.

A380-DO-12"-A01BU-006

14" EXISTING WF LINE

2000.000FGL 2000.000FGL 3. Where there are branching pipes, the sock anode will run all around the branching pipe if the branch length is lower

than five meters, while the sock anode will be spliced to a branching sock anode if the pipe branch length is above five

metres.

4. Bonding cables shall be installed to maintain electrical continuity at locations such as nonwelded joints, mechanical

L OF EXISTING

(R-012-10) 8"-WF-71-0827-A01BU-N

A800-DO-MH-010 joints, flanges, couplings, concrete pits and locations where there is no electrical continuity within the piping system

EXISTING FIRE WATER

EY-DB-EXISTING EXISTING FIRE WATER TO BE

PIT to be cathodically protected. Bonding/Jumper among the pipes shall be provided outside the pits.

ROAD

WITH SPACER RING

PIT

1 2 200-PVC TO BE

DEMOLISHED 5. The piping shall be isolated with neoprene rubber from any reinforced concrete support / wall to minimize current

BD-IY-W400

C

TRENCH

1999.500 DEMOLISHED drains from rebars in reinforced concrete structures.

TOC TP 341

1999.100 BOC 6. Soil access shall be installed next to the test posts and junction boxes at paved areas.

(FV-011-01) N= 2301.150

7. The number of Permanent Magnesium Anodes at TP Type 3 locations shall be as per "DETAILED DESIGN CALCULATION

WF-VP-EXISTING 14"-WF-71-0847-A01BU-N

E= 1986.300

B.J. W400 INSTRUMENTAL BURIED EXISTING

REPORT " document no. 4058-VW-CX-00OO000013 (Ref. No. 19).

BB2-3

N= 2299.228

N= 2300.565

E= 1971.300

E= 1995.412

14" EXISTING WF LINE TRENCH 8. CP cable shall not be laid in instrument / ELECT Trench. A separate cable tray shall be used for CP at least 300mm away

14" EXISTING WF LINE

6"-WF-71-0828-A01BU-N

14" EXISTING WF LINE from ELECT cable in order to avoid the interference. All cables shall be laid without coils or kinks, buried in sand at a

(TYP.)

14" EXISTING WF LINE TP 313 6"-WF-71-0848-A01BU-N W400 INSTRUMENTAL BURIED EXISTING depth of at least 0.75 m, provided with cable protection tiles and warning tape installed 250 mm above the cable. The

TRENCH A TP25 trench shall be 300 mm wide.

INSTALL PE / PVC SHEET TO 6"-WF-71-0837-A01BU-N

705-XM-71-09

14"-WF-71-0847-A01BU-N (FV-012-02) EXISTING 9. Distance from piping to junction boxes and test posts shall be approx 1.5 m.

MITIGATE INTERFERENCE W400 ELECTRICAL BURIED EXISTING WF-VP-EXISTING

10. For the Cable Schedule, please refer to the relevant Document (Ref. No. 27).

A800-DO-12"-A01BU-002

14"-WF-71-0858-A01BU-N TRENCH

6"-WF-71-0812-A01BU-N

14"-WF-71-0051-1A01BU-N

(EXISTING)

11. For the basic requirement/guidelines to be followed by construction personnel during installation, and for brief

EXISTING LIGHT guidelines/precautions, please refer to the Intallation Specification document (Ref. No. 23) and to the Installation

(TYP.)

POLE

TP 346 Drawings (Ref. No. 24).

EXISTING LIGHT 741-XM-71-05 W400 ELECTRICAL BURIED EXISTING 14" EXISTING WF LINE 12. For the Schematic Drawing, please refer to the relevant Document (Ref. No. 25).

(TYP.)

POLE TRENCH

13. All installation works associated with the Cathodic Protection system shall be conducted in accordance with this

drawing and the complete CP design package (see documents Ref No. 16 to 29 for full list). Any conflict between this

14" EXISTING WF LINE

drawing and other CP drawings and / or other project specifications and drawings shall be brought to the attention of

EXISTING LIGHT POLE

1999.100 14" EXISTING WF LINE

LP1 EXISTING ROAD the CP Engineer in writing for clarification as soon as it is discovered.

A800-DO-12"-A01BU-002

EXISTING ROAD

BOC TP 347 14. The final location of the TR Units, Junction Boxes and Test Posts shall be checked by the CP Engineer in consultation

(TYP) with the installation Sub-contractor and client. The TR Units, Junction Boxes and Test Posts shall, where practicable, be

installed in such a fashion that safe and convenient access to them is maintained.

BD-EYL-W400

Under no circumstances shall the TR Units, Junction Boxes and Test Posts be installed in a location where they could

BD-EYL-W400 be damaged and / or cause an obstruction or interference to the regular activities of the operator.

DRAWING LIMIT

DRAWING LIMIT

(RCF-006-1) BD-EYL-W400 15. Wherever there is a pit, Electrical continuity among the pipes like DO, DOV shall be provided at all the locations using

A210-DO-SM-021

14"-WF-71-0872-A01BU-N bonding Jumper cable (1c 25 mm2) and thermite welding.

LP1 W400 ELECTRICAL BURIED EXISTING TRENCH BD-IY-W300

16. Packaged Sacrificial anodes shall be installed 1.5 m away from the pipes and shall be installed at the bottom level of

BD-IY-W300

pipe.

BD-EYL-W400

TP 355

3"-DC-57-5825-A01BUCD-N

14"-WF-71-0872-A01BU-N

17. Sacrificial anodes shall be laid horizontally. Anodes shall be soaked in water 24 hours prior to installation.

BD-IY-W300

A210-DO-12"-A01BU-001

18. Test station shall be installed 1.5 m away from the pipe.

A210-DOV-4"-A01BU-002

(FDF-006-3) INSTALL PE / PVC SHEET TO 19. AJB/PDB/BB/NDB/NJB shall be installed 1.5 m away from the pipe. Cables inside the TP/JB shall be terminated with

A210-DC-VP-003

N= 2274.599

E= 1999.430

BB1-1 proper tagging for easy identifications.

EXISTING LIGHT POLE MITIGATE INTERFERENCE

BD-IY-W300

BD-EY-W600 20. Polarisation coupon and permanent reference cells shall be installed 100 mm away from the pipe and shall be 1/3rd of

N= 2269.550

pipe depth from pipe bottom level.

E= 1977.700 6"-DC-57-0811-A01BUCD-N

BD-IY-W300

N= 2268.400

PLEASE SEE SHEET 7 FOR ADDITIONAL NOTES

N= 2269.275

E= 1968.850 6"-DC-57-0811-A01BUCD-N C TP43 E= 2089.000

CL OF ROAD 4.0M. WIDE

14"-WF-71-0874-A01BU-N

3"-DC-57-5819-A01BUCD-N

N= 2268.300

EXISTING FENCE TYPE 2 E= 2041.376 BD-EY-W800

A A210-DC-VP-004

3"-DC-57-5818-A01BUCD-N

NOTE-7

MAP VIEW

E= 1979.900

3"-DC-57-5817-A01BUCD-N

TP42 300X300 A N= 2266.000

4"-DC-57-0812-A01BUCD-N

EXTRA WIDTH

EXISTING FENCE TYPE 1

CL OF ROAD 4.0M. WIDE

E= 2052.040

3"-DC-57-0814-A01BUCD-N G01-UO-42-02 X400DEEP SUMP A

NOTE-7

TP01

EXTRA WIDTH

3"-DC-57-1001-A01BUCD-N PVC PIPE SLEEVE

EXTRA WIDTH

EXTRA WIDTH

BD-EYL-W400

CL OF OC1-VL-57-11

BD-EYL-W400

PVC PIPE SLEEVE PIPE DIA + 100mm

3"-DC-57-0813-A01BUCD-N

PIPE DIA + 100mm WITH ENCASING

A210-DO-4"-A01BU-007

BD-EY-W800 3"-DC-57-5822-A01BUCD-N DRAWING LIMIT DRAWING LIMIT

WITH ENCASING

BD-EY-W600 3"-DC-57-5823-A01BUCD-N

50 THK. GALVANIZED

DRAWING LIMIT

EXISTING LIGHT POLE (FDF-006-2)

14"-WF-71-0872-A01BU-N

GRATING COVER

3"-DC-57-1001-A01BUCD-N A210-DC-VP-002 TP 356

EXISTING WATER SUPPLY LINE (FDF-006-1)

3"-DC-57-5737-A01BUCD-N

N= 2261.300

3"-DC-57-5819-A01BUCD-N

(TO BE DISMANTLE AND RELOCATE) A210-DC-VP-001

E= 2086.518

DRAWING LIMIT

BD-EY-W1500

PVC PIPE SLEEVE

PIPE DIA + 100mm

WITH ENCASING

DRAWING

LIMIT

N= 2255600

E= 2061500

DRAWING LIMIT

N= 2253.296

E= 2068.071

TP44

N= 2254.304

E= 2062.326

LP1

3"-DC-57-5816-A01BUCD-N

AJB1-2

14" EXISTING WF LINE

AJB1-1

N= 2253.388

E= 2070.045

3"-DC-57-5832-A01BUCD-N

BD-IY-W300 N= 2254.186 N= 2253.476

E= 2072.197 E= 2079.560 A

DRAWING

N= 2252.956

LIMIT

MATCH

LINE-A

CL OF 430-VL-64-04 3"-DC-57-5816-A01BUCD-N

E= 2082.703

FUN-036-6"x4"

G09-VD-45-03

150 THK.x300H. CURB 2000.000 FGL N= 2252.020

(RD-006-1)

E= 2019.500

3"-DC-57-5812-A01BUCD-N

WALL (TYP)

EXISTING FENCE TYPE 1

EXISTING FENCE TYPE 2

(TO BE DISMANTLE AND RELOCATE)

A710-DO-CO-013

N= 2251.300 CL OF G09 CL OF G09 CL OF G09 CL OF G09 CL OF G09

THIS PAGE

DRAWING LIMIT

N= 2250.119

E= 2053.700

EXISTING WATER SUPPLY LINE

E= 2015.092 -VD-23-03 -VD-23-04 -VD-23-02 -VD-23-01 -MB-23-01

3"-DC-57-5836-A01BUCD-N

2000.000 FGL

DRAWING LIMIT

A710-DO-4"-A01BU-003

NJB1-3 N= 2251.100

LP1 (RCF-006-3) E= 2076.070

3"-DC-57-5820-A01BUCD-N

6" EXISTING WF

DRAWING LIMIT

NOTE-7

A710-DO-6"-A01BU-004

NOTE-7

CL OF 410

TP08 -MB-45-02A & B A210-DO-SM-017 N= 2251.800

BD-IY-W300

E= 2083.860

3"-DC-57-5834-A01BUCD-N

(TYP) DRAWING LIMIT

BD-EYL-W400 (TYP)

200W X 600H TR-EY-W500

BD-EYL-W200 DRAWING LIMIT DRAWING LIMIT

(TYP) CUTOUT N= 2245.400

E= 2064.440

DRAWING LIMIT

DROP AREA

C

LINE

(R-006-2)

N= 2243.620

A210-DO-MH-015

E= 2047.600

A210-DO-6"-A01BU-004 Acceptance status Eng. Dept. Date

A210-DO-6"-A01BU-003

430-UN-64-06 code

EXISTING NATURAL N= 2240.700

A710-DO-CB-001E= 2014.000

A710-DO-10"-A01BU-002 A710-DO-SM-028 N= 2243.620

N= 2240.050 N= 2240.050 N= 2237326 E= 2061.500

E= 2010.300 E= 2012.714 E= 2058425 N= 2239.550

E= 2060.200 (RD-006-5)

AC B.LENKA PROCS 14-08-2020

N= 2241.000 FOR CONTINUATION REFER SHEET 5 Comment status code:

A - Accepted CR - Commented. Resubmit for Acceptance

AC - Accepted with Comment, NA

Resubmit

- Not accepted, Resubmit

LEGEND

TRANSFORMER RECTIFIER UNIT (TRU) IMPORTANT: CONTRACTOR acceptance of this Document does not relieve the

VENDOR from full compliance with contractual obligation

NEGATIVE DISTRIBUTION BOX (NDB) - OR

NEGATIVE JUNCTION BOX (NJB) - OR 5 25MAR21 25MAR21 REVISED PER CLIENT COMMENTS N.SIPPEL A.BONETTI S.FILMORE

BOND BOX (BB)

POSITIVE DISTRIBUTION BOX (PDB) 4 10FEB21 23FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

ANODE JUNCTION BOX (AJB)

3 10FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

TEST BOX (TB) - TYPE 1 (PSP AND TCP)

TEST BOX (TB) - TYPE 2 (PSP AND TCP) 2 15DEC20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

TEST BOX (TB) - TYPE 3 (PCP) BOND CABLE

1 23SEP20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

TEST BOX (TB) - TYPE 4 (INTERFERENCE MITIGATION)

ANODE SOCK

TEST BOX (TB) - TYPE 5 (PVC CASING) 0 15JUL20 ISSUED FOR APPROVAL L.HULL N.SIPPEL A.BONETTI

STRUCTURE CONNECTION

SPLICE KIT

PIPE LEGEND

PERMANENT CSE REFERENCE ELECTRODE

WS: WATER SOURCE C COUPON

FD: FUEL DIESEL

AND THERMOWELD CONNECTIONS)

WF: FIRE WATER 7.7kg MAGNESIUM ANODE

A

OWS: OILY WATER SYSTEM

(TEMPORARY CP)

Realisation du 4eme Train GPL a ZCINA, Hassi Messaoud

14.5kg MAGNESIUM ANODE

DOV: VENT PIPE A

(PERMANENT CP) CT-EPC/001/SH/EPM-G/EP/18

DO: OPEN DRAIN (NON-HAZ)

DC: CLOSED DRAIN A 2x ZINC RIBBON ANODES

(PERMANENT CP)

DP: PROCESS DRAIN

NEGATIVE WELD PAD/CLEAT CONNECTION

HM: HEATING MEDIUM

GENERAL LAYOUT DRAWINGS

29 PRE-COMMISSIONING AND COMMISSIONING CHECK SHEETS 4058-VW-RC-00OO000026

14 LAYOUT OF HAZARDOUS AREA CLASSIFICATION PROCESS TRAIN 4 4058-SN-DH-00OO000003-IS0 28 PRE-COMMISSIONING AND COMMISSIONING PROCEDURE 4058-VW-PC-00OO000025

13 LAYOUT OF HAZARDOUS AREA CLASSIFICATION OVERALL LPG TRAIN 4 4058-SN-DH-00OO000001-IS0 27 CABLE SCHEDULE 4058-VW-LK-00OO000023

12 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A800 4058-AQ-DA-A800000009 26 FOUNDATION AND BASE FRAME DETAIL DRAWINGS 4058-VW-DW-00OO000022

4058-VW-DG-00OO000020 4/7

11 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A630, A710 & A720 4058-AQ-DA-A630000008 25 SCHEMATIC WIRING DRAWINGS 4058-VW-DN-00OO000021

10 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A430 4058-AQ-DA-A430000011 24 INSTALLATION DRAWINGS 4058-VW-DW-00OO000018 EPC001-00-DD-EU-CPC-00020-M 1:250 5

9 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A340 & A350 4058-AQ-DA-A340000003 23 INSTALLATION SPECIFICATION 4058-VW-SG-00OO000017

8 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A330, A360 & A380 4058-AQ-DA-A330000005 22 BILL OF MATERIAL LIST 4058-VW-LM-00OO000016

7 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A310, A320 & A370 4058-AQ-DA-A310000004 21 MATERIALS SPECIFICATION 4058-VW-SG-00OO000015 Grantham, Lincs, UK, NG31 7XS Tel. +44(0)1476 590666

6 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A210 & A220 4058-AQ-DA-A220000002 20 POWER SUPPLY REQUIREMENTS 4058-VW-LN-00OO000014 E-mail cpc@cathodic.co.uk Web www.cathodic.co.uk

5 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A100, A101 & A102 4058-AQ-DA-A100000001 19 DETAILED DESIGN CALCULATION REPORT 4058-VW-CX-00OO000013

4 UNDERGROUND GENERAL DRAWINGS - KEY PLAN 4058-AQ-DX-A100000001 18 DESIGN PHILOSOPHY & SPECIFICATION 4058-VW-SG-00OO000012

3 COATING SPECIFICATION FOR BURIED SURFACES 4058-VW-SG-0000000005 17 PRE-DESIGN SITE SURVEY REPORT 4058-VW-RT-00OO000011

2 MATERIAL SPECIFICATION AND DATASHEET 4058-VW-SG-00OO000007-IS0 16 PRE-DESIGN SITE SURVEY SPECIFICATION 4058-VW-SG-00OO000010 VENDOR DOCUMENT NO.

1 CATHODIC PROTECTION SPECIFICATION 4058-VW-SG-00OO000006-ISA 15 LAYOUT OF HAZARDOUS AREA CLASSIFICATION COMPRESSOR 4058-SN-DH-00OO000004-IS0

42119-CLO-029

REF NO. DOCUMENT TITLE DOCUMENT NUMBER REF NO. DOCUMENT TITLE DOCUMENT NUMBER

LEGEND 1. Please refer to the Coordinates Table for the Tag numbers and Coordinates of each component of CP Equipment.

TRANSFORMER RECTIFIER UNIT (TRU) 2. The ICCP continuous anode will be buried in the pipe trench at a distance of 0.5 m from the pipe at the 3 or 9 o'clock

position (i.e. halfway between bottom and top of pipe depth). Anode splicing shall be done using splice kits and shall

LIMIT

FOR CONTINUATION REFER SHEET 4

N= 2241.000 NEGATIVE DISTRIBUTION BOX (NDB) - OR be done as per approved procedure and drawings. Anode tail cables shall be terminated at designated AJB. Sufficient

A210-DO-6"-A01BU-003

NEGATIVE JUNCTION BOX (NJB) - OR watering shall be carried out after anode laid in the trench and before backfilling. In any case anodes shall not be in

touch/in electrical contact with the pipe.

DRAWING

BOND BOX (BB)

E= 2097.750

E= 2060.200 (RD-006-5)

N= 2240.375 N= 2238.595 A210-DO-CO-014

POSITIVE DISTRIBUTION BOX (PDB) 3. Where there are branching pipes, the sock anode will run all around the branching pipe if the branch length is lower

EXISTING ROAD

TP07 A710-DO-4"-A01BU-005 E= 2019.500 E= 2062.540

N= 2237856 than five meters, while the sock anode will be spliced to a branching sock anode if the pipe branch length is above five

430-UN-64-05A ANODE JUNCTION BOX (AJB)

E = 1789.500

A220-DOV-4"-A01BU-001

A N= 2236.275

E= 2091220

metres.

E= 2019.500

A710-DO-10"-A01BU-006

TEST BOX (TB) - TYPE 1 (PSP AND TCP) 4. Bonding cables shall be installed to maintain electrical continuity at locations such as nonwelded joints, mechanical

3"-DC-57-5803-A01BUCD-N

A710-DO-10"-A01BU-001

N= 2236.530 A710-DO-4"-A01BU-007 A220-DO-6"-A01BU-013 joints, flanges, couplings, concrete pits and locations where there is no electrical continuity within the piping system

3"-DC-57-5808-A01BUCD-N

E= 2010.300

TEST BOX (TB) - TYPE 2 (PSP AND TCP)

A220-DO-4"-A01BU-001

(RCF-006-2) to be cathodically protected. Bonding/Jumper among the pipes shall be provided outside the pits.

A710-DO-10"-A01BU-001

E= 2090.658

2000.000 FGL (RCF-006-4) A220-DO-2"-A01BU-002

A710-DO-SM-016 CRD-6"x4"

5. The piping shall be isolated with neoprene rubber from any reinforced concrete support / wall to minimize current

A220-DO-10"-A01BU-004

430-UN-64-05B A220-DO-SM-018N= 2236.275

TEST BOX (TB) - TYPE 3 (PCP) BOND CABLE

G09-PG-23-07

E= 2047.600

A710-DOV-4"-A01BU-002

A710-DOV-4"-A01BU-001 drains from rebars in reinforced concrete structures.

TEST BOX (TB) - TYPE 4 (INTERFERENCE MITIGATION)

FUN-053-6"x4"

A220-DO-4"-A01BU-012 ANODE SOCK 6. Soil access shall be installed next to the test posts and junction boxes at paved areas.

TEST BOX (TB) - TYPE 5 (PVC CASING) 7. The number of Permanent Magnesium Anodes at TP Type 3 locations shall be as per "DETAILED DESIGN CALCULATION

2000.000 FGL N= 2231.256

E= 2075.980 REPORT " document no. 4058-VW-CX-00OO000013 (Ref. No. 19).

(RD-006-3) STRUCTURE CONNECTION

N= 2228.110

E= 2019.778

A720-DO-CO-011

8. CP cable shall not be laid in instrument / ELECT Trench. A separate cable tray shall be used for CP at least 300mm away

BD-EY-W1000

SPLICE KIT from ELECT cable in order to avoid the interference. All cables shall be laid without coils or kinks, buried in sand at a

A220-DO-10"-A01BU-005

N= 2226.459

FUN-038-6"x4"E= 2013.000 depth of at least 0.75 m, provided with cable protection tiles and warning tape installed 250 mm above the cable. The

A720-DO-4"-A01BU-006 PERMANENT CSE REFERENCE ELECTRODE

A720-DO-6"-A01BU-007

CL OF ACCESS WAY 6.0M. WIDE trench shall be 300 mm wide.

TR-EY-W600

N= 2224.451

E= 2067.725

N= 2224.736

C COUPON 9. Distance from piping to junction boxes and test posts shall be approx 1.5 m.

E= 2067.725

A220-DO-10"-A01BU-008

CL OF 420-VL-63-04

10. For the Cable Schedule, please refer to the relevant Document (Ref. No. 27).

A220-DOV-4"-A01BU-002

EXISTING WELL

11. For the basic requirement/guidelines to be followed by construction personnel during installation, and for brief

BD-IY-W300

AND THERMOWELD CONNECTIONS)

A220-DO-SM-019

TR-EY-W600

guidelines/precautions, please refer to the Intallation Specification document (Ref. No. 23) and to the Installation

NOTE-2

CHROMATOGRAPH

A220-DO-DT-001-W400

CO2-FIRE

(RCF-006-5)

EXTINGUISHING 7.7kg MAGNESIUM ANODE

BOTTLE

A Drawings (Ref. No. 24).

GAS

BD-EY-W600 (TEMPORARY CP)

12. For the Schematic Drawing, please refer to the relevant Document (Ref. No. 25).

50 THK. A220-DO-6"-A01BU-015 14.5kg MAGNESIUM ANODE 13. All installation works associated with the Cathodic Protection system shall be conducted in accordance with this

GALVANIZED

HYDRAULIC

A220-DO-4"-A01BU-014 A

GRATING COVER

STARTING SKID

N= 2217.250

(PERMANENT CP) drawing and the complete CP design package (see documents Ref No. 16 to 29 for full list). Any conflict between this

FUN-039-6"x4" E= 2076.700

drawing and other CP drawings and / or other project specifications and drawings shall be brought to the attention of

EXTRA WIDTH

EXTRA WIDTH

N= 2217.000

A720-DO-4"-A01BU-008

the CP Engineer in writing for clarification as soon as it is discovered.

DRAWING LIMIT

E= 2091.220

CL OF ROAD 4.0M. WIDE

N= 2216.252

E= 2010.648

N= 2213.297

420-UO-63-05A A 2x ZINC RIBBON ANODES 14. The final location of the TR Units, Junction Boxes and Test Posts shall be checked by the CP Engineer in consultation

BOT OF CUT AT 1998900

E= 2011.920

A720-DO-4"-A01BU-009

TR-EY-W1500 (PERMANENT CP) with the installation Sub-contractor and client. The TR Units, Junction Boxes and Test Posts shall, where practicable, be

200Wx600H CUTOUT

(RCF-006-6)

A720-DO-SM-020 BD-EY-W600 installed in such a fashion that safe and convenient access to them is maintained.

RAMP

FUN-040-6"x4" A720-DO-10"-A01BU-003 (R-006-8)

N= 2212.024

A720-DO-CB-001

N= 2212.575

N= 2212.200

E= 2019.778

A220-DO-MH-009 NEGATIVE WELD PAD/CLEAT Under no circumstances shall the TR Units, Junction Boxes and Test Posts be installed in a location where they could

E= 2010.648

E= 2015.000

CONNECTION be damaged and / or cause an obstruction or interference to the regular activities of the operator.

420-UO-63-05B

TP02 15. Wherever there is a pit, Electrical continuity among the pipes like DO, DOV shall be provided at all the locations using

BD-IY-W800

(TYP)

N= 2207.720 N= 2207.720

A720-DOV-4"-A01BU-002

E= 2009.949 E= 2016.000 BD-EY-W400 bonding Jumper cable (1c 25 mm2) and thermite welding.

A720-DO-10"-A01BU-004 150 THK. CURB WALL (TYP)

A720-DOV-4"-A01BU-001 N= 2205.600

E= 2009.524 N= 2205.600 16. Packaged Sacrificial anodes shall be installed 1.5 m away from the pipes and shall be installed at the bottom level of

A A720-DO-10"-A01BU-001

E= 2047.600

pipe.

BD-IY-W300

17. Sacrificial anodes shall be laid horizontally. Anodes shall be soaked in water 24 hours prior to installation.

A220-DO-10"-A01BU-009

A720-DO-8"-A01BU-002 A720-DO-10"-A01BU-001

BD-EY-W1500

742-XM-71-01 18. Test station shall be installed 1.5 m away from the pipe.

A220-DO-MH-007

6"-WF-71-0834-A01BU-N

BD-IY-W800

TP32 A720-DO-MH-005 N= 2205.600 INSTALL PE / PVC SHEET TO 6" EXISTING WF 19. AJB/PDB/BB/NDB/NJB shall be installed 1.5 m away from the pipe. Cables inside the TP/JB shall be terminated with

E= 2019.778

BB1-2 proper tagging for easy identifications.

INSTALL PE / PVC SHEET TO MITIGATE INTERFERENCE LINE

EXISTING ROAD

DIESEL STORAGE

20. Polarisation coupon and permanent reference cells shall be installed 100 mm away from the pipe and shall be 1/3rd of

TANK MITIGATE INTERFERENCE BD-IY-W300

pipe depth from pipe bottom level.

A220-DO-10"-A01BU-010

A720-DO-6"-A01BU-017

N= 2200.137

E= 2014.220

A720-DO-4"-A01BU-016

AJB1-3 A220-DO-MH-016

A220-DO-10"-A01BU-006 A220-DO-10"-A01BU-006 (R-006-7) A220-DO-10"-A01BU-007 N= 2199.300

E= 2091.220

PLEASE SEE SHEET 7 FOR ADDITIONAL NOTES

A220-DO-MH-014

A220-DO-10"-A01BU-011

N= 2199.300 N= 2199.300

E= 2047.600 E= 2071.511

N= 2195.284

A220-DO-10"-A01BU-003

A720-DO-4"-A01BU-015

E= 2019.031

NJB1-1

A220-DO-SM-024

TP03 N= 2194.419 DRAWING LIMIT

MAP VIEW

NJB1-2 LP1

E = 2154.756

DRAWING LIMIT

A220-DOV-4"-A01BU-003

10" EXISTING DO LINE

N= 2191.700

E= 2018.750 DRAWING LIMIT DRAWING LIMIT

A720-DO-4"-A01BU-014

N= 2190.807

E= 2011.776

A720-DO-10"-A01BU-005 C A 2"-FD-62-0804-A01BU-N (EXISTING)

2"-FD-62-0804-A01BU-N 2"-FD-62-0804-A01BU-N

DRAWING LIMIT

A720-DO-CB-002 N= 2191.700

E= 2047.600

A720-DO-4"-A01BU-013 (R-007-2)

A720-DO-4"-A01BU-012 C N= 2188.500

420-UO-63-06A E= 2117.500

N= 2189.125

DRAWING LIMIT

E= 2011.756

TP06

DRAWING

N= 2185.895

LIMIT

E= 2011.756

2000.000 FGL

DRAWING LIMIT

CL OF EXISTING ROAD 4.0M. WIDE

2"-FD-62-0808-A01BU-N

A720-DO-4"-A01BU-011 C OF ROAD 4.0M. WIDE

L

A720-DO-4"-A01BU-010

EXTRA WIDTH

430-UO-63-06B

DRAWING

N= 2184.215

LIMIT

MATCH

LINE-A

E= 2011.756

2000.000 FGL

TP33 INSTALL PE / PVC SHEET TO

DRAWING LIMIT

N= 2183.000

MITIGATE INTERFERENCE

E= 2009.199

DRAWING LIMIT

PDB1 TRU1 N= 2176.300

E= 2052.600

N= 2177.075

E= 2076.600

DRAWING LIMIT

NDB1

A720-DO-CO-012

A630-DO-10"-A01BU-009 A630-DO-10"-A01BU-007

A630-DO-6"-A01BU-005

DRAWING LIMIT

(RD-006-4)

10" EXISTING DO LINE

BENTINI SCOPE

BD-IY-W1500

THIS PAGE

CL OF EXISTING ROAD 6.0M. WIDE

N= 2176.475 DRAWING LIMIT

EMERGENCY DIESEL GENERATOR

E= 2108.520

(R-006-10)

N= 2173.302 DRAWING LIMIT DRAWING LIMIT

E= 2119.300

EXTRA WIDTH

A630-DO-MH-021 DRAWING LIMIT

(R-006-5)

A630-DO-6"-A01BU-006

A630-DO-MH-022

EXISTING LIGHT POLE

BD-EY-W600

WATER DISTILLED ROOM

N= 2175.098

4MO-MA-50-02A A630-DOV-4"-A01BU-001

E= 2055.625 A630-DO-MH-005

(R-006-11)

14"-WF-71-0872-A01BU-N 4MO-MA-50-02B Acceptance status Eng. Dept. Date

code

FOR SUBSTATION BUILDING REFER DETAIL DRAWING NO.

6PO-EG-84-02

A630-DO-10"-A01BU-008

OBC2019-07-HMD-682ARC-LAY-0001 & 0010 BD-IY-W1000

2"-FD-62-0806-A01BU-N

SWITCHGEAR ROOM

INSTRUMENT ROOM BATTERY ROOM NOTE 8 Comment status code:

CONCRETE HOLLOW

BLOCK (EXISTING) A - Accepted CR - Commented. Resubmit for Acceptance

ECS ROOM (R-007-9)

(EXISTING)

EXTRA WIDTH

BD-IY-W400 N= 2164.540

(R-007-14)

AC - Accepted with Comment, NA

Resubmit

- Not accepted, Resubmit

E= 2046.600

DO-TIE-IN-003

EXISTING

TIE-IN TP-317 702-XM-71-01

N= 2162.409

E= 2130.115 IMPORTANT: CONTRACTOR acceptance of this Document does not relieve the

TRANSFERFOR

(R-006-9) N= 2162.409

VENDOR from full compliance with contractual obligation

E= 2119.300

TRANSFERFOR

CLEAN AGENT 6" EXISTING WF LINE A630-DO-MH-008 A630-DO-10"-A01BU-001 10" EXISTING DO LINE 12" EXISTING DO LINE

BAY

BD-IY-W400

BENTINI SCOPE SYSTEM

14" EXISTING WF LINE TIE-IN TP-348

BAY

BD-EY-W2000

14" EXISTING WF LINE

2000.200 TOC 5 25MAR21 25MAR21 REVISED PER CLIENT COMMENTS N.SIPPEL A.BONETTI S.FILMORE

4" EXISTING WF LINE TIE-IN TP-353 PAVING FOR HVAC

2000.000 FGL BENTINI SCOPE

BD-IY-W300 A630-OWS-8"-A01BU-002

(FV-006-01) 14"-WF-71-0873-A01BU-N

N= 2159.600

4 10FEB21 23FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

WF-VP-EXISTING E= 2148.650

2000.000 FGL CONCRETE HOLLOW

EXISTING FENCE

A630-OWS-8"-A01BU-001 N= 2155.550

E= 2072.130 AJB1-4 N= 2155.840

BLOCK

TYPE 3

N= 2155.550

E= 2066.130 N= 2156.650

E= 2114.840 3 10FEB21 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

LP1 (TYP.) A630-OWS-8"-A01BU-003 A630-OWS-8"-A01BU-004 E= 2079.600

(TYP.) W400 ELECTRICAL BURIED EXISTING TRENCH

BD-EYL-W200 4"-WF-71-0864-A01BU-N TP05 A A 2 15DEC20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

BD-EYL-W400 (TYP.)

W400 ELECTRICAL BURIED EXISTING TRENCH TP04 N= 2155.840

E= 2088.250

EXTRA WIDTH

A630-DOV-4"-A01BU-003

N= 2152.600

2"-WS-62-0807-A01BU-N

E= 2046.600 EXTRA WIDTH 1 23SEP20 REVISED PER CLIENT COMMENTS L.HULL N.SIPPEL A.BONETTI

A630-OWS-MH-001 EXISTING

TIE-IN TP-349 EXISTING A630-OWS-MH-002

INSTALL PE / PVC SHEET TO N= 2152.600

E= 2035.583 LIGHT POLE LIGHT POLE

0 15JUL20 ISSUED FOR APPROVAL L.HULL N.SIPPEL A.BONETTI

(TYP.) (TYP.) 12" EXISTING DO LINE

MITIGATE INTERFERENCE A

NOTE 7 CL OF EXISTING ROAD 6.0M. WIDE

NEW ROAD EXISTING

TIE-IN TP-354

NOTE-3

EXISTING GATE

OWS COLLECTION PIT

FOR DETAILS REFER DWG.

N = 2131.000 DRAWING LIMIT DRAWING LIMIT

EXISTING FENCE

ROAD TYPE 3

NO. 4058-AADC-A630000101 PIPE LEGEND

EXTRA WIDTH

WS: WATER SOURCE

N= 2143.400

NEW FENCE TYPE 3 2000.000 FGL E= 2089.000

(NOTE 5) 14" EXISTING WF LINE

4" EXISTING WF LINE W400 ELECTRICAL BURIED EXISTING TRENCH FD: FUEL DIESEL

WF: FIRE WATER

FENCE TIE-IN

POINT J2

(SEE NOTE 4

EXISTING FENCE

TYPE 3

TO BE RETAINED

TP26 OWS: OILY WATER SYSTEM

Realisation du 4eme Train GPL a ZCINA, Hassi Messaoud

A DOV: VENT PIPE

FENCE FOUNDATION 1999.200 FGL

CT-EPC/001/SH/EPM-G/EP/18

E = 2154.756

6"-WF-71-0833-A01BU-N

14" EXISTING WF LINE

DO: OPEN DRAIN (NON-HAZ)

14" EXISTING WF LINE

(FV-002-03) (FV-002-01) TIE-IN TP-319 DC: CLOSED DRAIN

EXISTING ROAD WF-VP-EXISTING WF-VP-EXISTING

TO BE DEMOLISH 14" EXISTING WF LINE

8" EXISTING WF LINE

AND REINSTALL DP: PROCESS DRAIN

EXTRA WIDTH

EXTRA WIDTH

NEW FENCE

DRAWING LIMIT HM: HEATING MEDIUM

DRAWING LIMIT

DRAWING LIMIT N= 2131.000

GENERAL LAYOUT DRAWINGS

29 PRE-COMMISSIONING AND COMMISSIONING CHECK SHEETS 4058-VW-RC-00OO000026

14 LAYOUT OF HAZARDOUS AREA CLASSIFICATION PROCESS TRAIN 4 4058-SN-DH-00OO000003-IS0 28 PRE-COMMISSIONING AND COMMISSIONING PROCEDURE 4058-VW-PC-00OO000025

13 LAYOUT OF HAZARDOUS AREA CLASSIFICATION OVERALL LPG TRAIN 4 4058-SN-DH-00OO000001-IS0 27 CABLE SCHEDULE 4058-VW-LK-00OO000023

12 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A800 4058-AQ-DA-A800000009 26 FOUNDATION AND BASE FRAME DETAIL DRAWINGS 4058-VW-DW-00OO000022

4058-VW-DG-00OO000020 5/7

11 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A630, A710 & A720 4058-AQ-DA-A630000008 25 SCHEMATIC WIRING DRAWINGS 4058-VW-DN-00OO000021

10 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A430 4058-AQ-DA-A430000011 24 INSTALLATION DRAWINGS 4058-VW-DW-00OO000018 EPC001-00-DD-EU-CPC-00020-M 1:250 5

9 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A340 & A350 4058-AQ-DA-A340000003 23 INSTALLATION SPECIFICATION 4058-VW-SG-00OO000017

8 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A330, A360 & A380 4058-AQ-DA-A330000005 22 BILL OF MATERIAL LIST 4058-VW-LM-00OO000016

7 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A310, A320 & A370 4058-AQ-DA-A310000004 21 MATERIALS SPECIFICATION 4058-VW-SG-00OO000015 Grantham, Lincs, UK, NG31 7XS Tel. +44(0)1476 590666

6 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A210 & A220 4058-AQ-DA-A220000002 20 POWER SUPPLY REQUIREMENTS 4058-VW-LN-00OO000014 E-mail cpc@cathodic.co.uk Web www.cathodic.co.uk

5 UNDERGROUND LAYOUT CONSTRUCTION DRAWINGS-WBS A100, A101 & A102 4058-AQ-DA-A100000001 19 DETAILED DESIGN CALCULATION REPORT 4058-VW-CX-00OO000013

4 UNDERGROUND GENERAL DRAWINGS - KEY PLAN 4058-AQ-DX-A100000001 18 DESIGN PHILOSOPHY & SPECIFICATION 4058-VW-SG-00OO000012

3 COATING SPECIFICATION FOR BURIED SURFACES 4058-VW-SG-0000000005 17 PRE-DESIGN SITE SURVEY REPORT 4058-VW-RT-00OO000011

2 MATERIAL SPECIFICATION AND DATASHEET 4058-VW-SG-00OO000007-IS0 16 PRE-DESIGN SITE SURVEY SPECIFICATION 4058-VW-SG-00OO000010 VENDOR DOCUMENT NO.

1 CATHODIC PROTECTION SPECIFICATION 4058-VW-SG-00OO000006-ISA 15 LAYOUT OF HAZARDOUS AREA CLASSIFICATION COMPRESSOR 4058-SN-DH-00OO000004-IS0

42119-CLO-029

REF NO. DOCUMENT TITLE DOCUMENT NUMBER REF NO. DOCUMENT TITLE DOCUMENT NUMBER

1. Please refer to the Coordinates Table for the Tag numbers and Coordinates of each component of CP Equipment.

2. The ICCP continuous anode will be buried in the pipe trench at a distance of 0.5 m from the pipe at the 3 or 9 o'clock

position (i.e. halfway between bottom and top of pipe depth). Anode splicing shall be done using splice kits and shall

be done as per approved procedure and drawings. Anode tail cables shall be terminated at designated AJB. Sufficient

watering shall be carried out after anode laid in the trench and before backfilling. In any case anodes shall not be in

N = 2423.000 DRAWING LIMIT

touch/in electrical contact with the pipe.

E = 2423.970

E = 2465.000

3. Where there are branching pipes, the sock anode will run all around the branching pipe if the branch length is lower

than five meters, while the sock anode will be spliced to a branching sock anode if the pipe branch length is above five

metres.

4. Bonding cables shall be installed to maintain electrical continuity at locations such as nonwelded joints, mechanical

W400 ELECTRICAL BURIED EXISTING joints, flanges, couplings, concrete pits and locations where there is no electrical continuity within the piping system

2000.000FGL

TRENCH to be cathodically protected. Bonding/Jumper among the pipes shall be provided outside the pits.

5. The piping shall be isolated with neoprene rubber from any reinforced concrete support / wall to minimize current

drains from rebars in reinforced concrete structures.

PIPE LEGEND 6. Soil access shall be installed next to the test posts and junction boxes at paved areas.

7. The number of Permanent Magnesium Anodes at TP Type 3 locations shall be as per "DETAILED DESIGN CALCULATION

WS: WATER SOURCE REPORT " document no. 4058-VW-CX-00OO000013 (Ref. No. 19).

8. CP cable shall not be laid in instrument / ELECT Trench. A separate cable tray shall be used for CP at least 300mm away

FD: FUEL DIESEL from ELECT cable in order to avoid the interference. All cables shall be laid without coils or kinks, buried in sand at a

depth of at least 0.75 m, provided with cable protection tiles and warning tape installed 250 mm above the cable. The

WF: FIRE WATER trench shall be 300 mm wide.

9. Distance from piping to junction boxes and test posts shall be approx 1.5 m.

OWS: OILY WATER SYSTEM

W400 ELECTRICAL BURIED EXISTING 10. For the Cable Schedule, please refer to the relevant Document (Ref. No. 27).

TRENCH

DOV: VENT PIPE 11. For the basic requirement/guidelines to be followed by construction personnel during installation, and for brief