Professional Documents

Culture Documents

Completely Retooled To Assure Consistent Quality and Performance.

Uploaded by

Leinner RamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Completely Retooled To Assure Consistent Quality and Performance.

Uploaded by

Leinner RamirezCopyright:

Available Formats

“Completely retooled

to assure consistent quality

and performance.”

The Metal DC Contactor has been Designed to fit a variety of

completely retooled to provide dimensional high current switching and

consistency and electrical performance. When pole configurations, Trombetta Metal DC

consistent quality and performance are required, this Contactors can be used in a variety of applications,

Metal has the mettle to come through. The applications ranging from military vehicles to hydraulic controls,

may vary, but the performance never does. from golf cars to stationary equipment.

Lake-View Electronics Corporation 1-800-686-8439 www.lvelectronics.com

TYPICAL DIMENSIONS

Metal DC Contactor Specifications

Coil Terminals 1 or 2 : 10-32 Stud(s)

Contact Studs 5/16-24 Studs Standard & Long (see drawing)

Mounting Bracket Flat or Curved, open or closed slots 2.5

Standard Operating Temperature Range -40º C to 60º C

Contact Terminal Torque 35 lbs

Coil Terminal Torque 15 lbs

2.5

Flat mount, closed slots.

Other options available.

Coils Contact

Model Max Sustained Max Pull In Hold Coil Resist Resistive Load Inductive Load Peak Inductive Electrical Contact

Duty Cycle1 On Time Voltage 2 Voltage 2 Ohms Carry/Interrupt Carry/Interrupt Inrush Capa- Cycle Material

Capability (Amps)3 Capability (Amps)3 bility (Amps)4 Life

2.5

12V 20% 30 5.5 2.0 3.6 300/300 300/300 700 50,000 Copper

Intermit. Seconds

12V 60% 10 6.0 2.3 7.1 250/300 250/300 700 50,000 Copper 3.2

Intermit. Minutes

12V 100% Cont. 7.0 2.5 14.4 125/250 125/250 600 50,000 Copper

Cont.

24V 20% 30 11.0 4.0 14.4 300/300 300/300 600 50,000 Copper

Intermit. Seconds

2.5 2.5

24V 60% 10 12.0 4.6 28.4 200/200 200/200 600 50,000 Copper

Intermit. Minutes

24V 100% Cont. 15.0 5.0 57.0 125/200 125/200 500 50,000 Copper Curved mount, open slots.

Cont. 2.5 2.5 Other options available.

2.5

30˚ 30˚

36V 60% 10 19.0 7.0 64.0 125/200 125/200 500 25,000 Copper

Intermit. Minutes

3.2

36V 100% Cont. 25.0 8.0 130.0 125/125 125/125 500 25,000

2.5 Copper 2.5

Cont.

3.2 3.2

1Nominal coil voltage applied starting from 25° C DC Contactor temperature. Duty Cycle=On Time/(On Time + Off Time). 2Voltages listed are minimum required

at 25° C coil temperature. Minimum voltage requirements will increase with coil temperature. 3Amps at Max Duty Cycle. 4Risetime > 3 milliseconds to 80%

of peak inrush with linear decay to run (carry) current in <.1 seconds.

Rev 10/15

LAKE-VIEW ELECTRONICS CORPORATION

1054 PIONEER ROAD GRAFTON, WI 53024 www.lvelectronics.com

PH: 800-686-8439 FX: 262-375-0109 sales@lvelectronics.com

You might also like

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

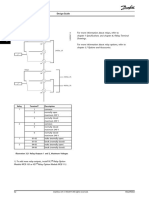

- S55ENDocument18 pagesS55ENValerija SilinaNo ratings yet

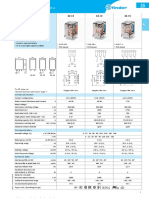

- General purpose relays 7 - 10 A: SеriesDocument18 pagesGeneral purpose relays 7 - 10 A: SеriesMarcelino MoralesNo ratings yet

- OPzV2 250Document2 pagesOPzV2 250Jonás CurielNo ratings yet

- Rele FinderDocument14 pagesRele FinderJosé marinNo ratings yet

- 14pin Relay and BaseDocument16 pages14pin Relay and BaseNaveed AhmadNo ratings yet

- Finder-Industrialrelayseries5532 20160412120109Document16 pagesFinder-Industrialrelayseries5532 20160412120109pouya alizadehNo ratings yet

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument14 pagesFeatures: 55 Series - General Purpose Relays 7 - 10 AveeakumarNo ratings yet

- 3PoleContactors Digital PDFDocument17 pages3PoleContactors Digital PDFGunnie PandherNo ratings yet

- 3PoleContactors Digital PDFDocument17 pages3PoleContactors Digital PDFGunnie Pandher100% (1)

- Relay Finder 55 SeriesDocument18 pagesRelay Finder 55 SeriesBerlianiNo ratings yet

- FF Side Mounting Float Switch - B0Document15 pagesFF Side Mounting Float Switch - B0Mehdi Hajd KacemNo ratings yet

- DatasheetDocument5 pagesDatasheetArjun ParlikkattNo ratings yet

- INCOMING LOADBREAK ELBOW CONNECTOR - Catalog 2LBE1H02C05 PDFDocument2 pagesINCOMING LOADBREAK ELBOW CONNECTOR - Catalog 2LBE1H02C05 PDFparyonoNo ratings yet

- 7PA22 - Lockout RelayDocument6 pages7PA22 - Lockout RelayJack JohnsonNo ratings yet

- Welding RobotDocument1 pageWelding RobotBENGKELTKS88 BENGKELTKS88No ratings yet

- Cynergy3 D S v3Document4 pagesCynergy3 D S v3akeem alturkiNo ratings yet

- Lockout Relay - 7PA26 - Technical DataDocument3 pagesLockout Relay - 7PA26 - Technical DataDoan Anh TuanNo ratings yet

- Stelmec VCBDocument2 pagesStelmec VCBnithinmundackal3623No ratings yet

- Bosch Power RelaysDocument11 pagesBosch Power RelaysAtaa AssaadNo ratings yet

- 06 - 24kV Pole Mount Solid Dielectric Load Break SwitchDocument8 pages06 - 24kV Pole Mount Solid Dielectric Load Break SwitchMauricio VilledaNo ratings yet

- L&T MB34 Model Isolator PDFDocument20 pagesL&T MB34 Model Isolator PDFAnonymous lFFnnXmjUuNo ratings yet

- 7PA26 27 30 Catalog SIP E6Document5 pages7PA26 27 30 Catalog SIP E6tduskoNo ratings yet

- LNT MCCBs Technical CatalogueDocument20 pagesLNT MCCBs Technical CataloguembhangaleNo ratings yet

- 12kV Air Insulated Metal Clad Switchgear PanelDocument2 pages12kV Air Insulated Metal Clad Switchgear PanelHarmanPreetNo ratings yet

- VLT AQUA Drive FC 202 SW 2.2X 65Document1 pageVLT AQUA Drive FC 202 SW 2.2X 65Senterver Equipos IndustrialesNo ratings yet

- Midi Industrial Relay Type RMI. 4-5 5A MonostableDocument2 pagesMidi Industrial Relay Type RMI. 4-5 5A MonostablemuaadhNo ratings yet

- Raychem Screened Elbow/Straight Separable Connectors Rses/RsssDocument2 pagesRaychem Screened Elbow/Straight Separable Connectors Rses/RsssGiovany Vargas QuirozNo ratings yet

- Series: 15 Amp Miniature, PC Board RelayDocument1 pageSeries: 15 Amp Miniature, PC Board RelayIon SudituNo ratings yet

- Item 19 Esk107m050ag3aaDocument1 pageItem 19 Esk107m050ag3aadifa20061168No ratings yet

- ADC225S - Bosch - FolhetoDocument2 pagesADC225S - Bosch - FolhetojeffsonNo ratings yet

- Midi Industrial Relay Type RMI. 2-10 10A MonostableDocument3 pagesMidi Industrial Relay Type RMI. 2-10 10A MonostableSergey LukinNo ratings yet

- Relay 44 SeriesDocument12 pagesRelay 44 SeriesDanielNo ratings yet

- VD4 enDocument13 pagesVD4 enmaruf048No ratings yet

- Resistencia 220 Ohm 5 W PDFDocument2 pagesResistencia 220 Ohm 5 W PDFAndrés JassoNo ratings yet

- Electromechanical Relays-Carlo GavazziDocument6 pagesElectromechanical Relays-Carlo Gavazzinour100% (2)

- FF Side Mounting Float Switch - B0Document15 pagesFF Side Mounting Float Switch - B0dtoxidNo ratings yet

- MCCBDocument56 pagesMCCBAmit NagNo ratings yet

- Weldclad WLDC 3Document1 pageWeldclad WLDC 3furiousgaulNo ratings yet

- Etalko-Technical Data Shading Systems and Roller Shutter ControlDocument1 pageEtalko-Technical Data Shading Systems and Roller Shutter Controlbion.icleNo ratings yet

- WIEM 908: C Si MN MoDocument1 pageWIEM 908: C Si MN MoagrinjoshNo ratings yet

- WEG MSW Switch Disconnectors 50038864 enDocument36 pagesWEG MSW Switch Disconnectors 50038864 enRODRIGO_RALONo ratings yet

- Tall Tubular Gal Battery Platinum NewDocument4 pagesTall Tubular Gal Battery Platinum NewchamilsilvaNo ratings yet

- Ordering Information: Ratchet RelayDocument6 pagesOrdering Information: Ratchet RelayNguyễn Quốc KhaNo ratings yet

- Longi Lr5 72hph 535mDocument2 pagesLongi Lr5 72hph 535mMonster LifeNo ratings yet

- LONGi - LR5 72HPH 540MDocument2 pagesLONGi - LR5 72HPH 540Msales3 iaescoNo ratings yet

- BMY5Document9 pagesBMY5Muhammad SyaifulhaqNo ratings yet

- CATEN - 58Series-Finder RelayDocument11 pagesCATEN - 58Series-Finder RelayjaneeshNo ratings yet

- VD4 E 16zu10 AMC 2014 NXDocument13 pagesVD4 E 16zu10 AMC 2014 NXJatupol PongsirisartNo ratings yet

- Finder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsDocument16 pagesFinder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsJMSNo ratings yet

- Product Information: Toshiba X-Ray Tube D-0711 / D-0711S Stationary Anode X-Ray TubeDocument7 pagesProduct Information: Toshiba X-Ray Tube D-0711 / D-0711S Stationary Anode X-Ray TubeKamilNo ratings yet

- Plug in Power Relay RS: Options and Ordering CodesDocument2 pagesPlug in Power Relay RS: Options and Ordering CodesMarian BaciuNo ratings yet

- Abb 1hdx580120en EnkDocument2 pagesAbb 1hdx580120en Enkksg9731No ratings yet

- Contactor GMC-300Document4 pagesContactor GMC-300Vlademiro Manuel RamosNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SongleAHMAD NUR IMAMNo ratings yet

- Sla 24vdc S L A Songle RelayDocument2 pagesSla 24vdc S L A Songle Relayagus2kNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SongleAHMAD NUR IMAMNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SonglePrecila CanobidaNo ratings yet

- BN 2300 Series Configuration GuideDocument107 pagesBN 2300 Series Configuration Guidebiotech66683% (6)

- M60用户手册enDocument644 pagesM60用户手册enLeinner RamirezNo ratings yet

- 12-24VDC Powered Ignition System: N N N N N N NDocument2 pages12-24VDC Powered Ignition System: N N N N N N NLeinner RamirezNo ratings yet

- UV IRS-datasheetDocument4 pagesUV IRS-datasheetLeinner RamirezNo ratings yet

- 106M5801K Diagramas de Conexionado 2300Document11 pages106M5801K Diagramas de Conexionado 2300Leinner RamirezNo ratings yet

- Intellipack Series 812A/811A Alarms Process Current/Voltage InputDocument18 pagesIntellipack Series 812A/811A Alarms Process Current/Voltage InputLeinner RamirezNo ratings yet

- Altronic D.I.S. Medium Engines, 4-16 Cylinders Service Instructions Form Dis Si 6-91Document14 pagesAltronic D.I.S. Medium Engines, 4-16 Cylinders Service Instructions Form Dis Si 6-91Leinner RamirezNo ratings yet

- Jiskoot 210P-Sd and Jiskoot 210Eh-Sd Severe-Duty Sample ExtractorsDocument4 pagesJiskoot 210P-Sd and Jiskoot 210Eh-Sd Severe-Duty Sample ExtractorsLeinner RamirezNo ratings yet

- CJ TN - : Deluge Valve, External ResettingDocument16 pagesCJ TN - : Deluge Valve, External ResettingLeinner RamirezNo ratings yet

- Chapter 2 Lab 2-4, Named EIGRP Configuration: TopologyDocument18 pagesChapter 2 Lab 2-4, Named EIGRP Configuration: TopologyHarrison HayesNo ratings yet

- Ccnpv7 Route Lab2-3 Eigrp-Ipv6 StudentDocument12 pagesCcnpv7 Route Lab2-3 Eigrp-Ipv6 StudentGC ToolbarNo ratings yet

- Honeywellswitches de Los RaspadoresDocument22 pagesHoneywellswitches de Los RaspadoresLeinner RamirezNo ratings yet

- CCNPv7 ROUTE Lab2-2 EIGRP-Stub-Routing StudentDocument9 pagesCCNPv7 ROUTE Lab2-2 EIGRP-Stub-Routing StudentTharakaNo ratings yet

- Chapter 1 Lab 1-1, Basic Ripng and Default Gateway ConfigurationDocument17 pagesChapter 1 Lab 1-1, Basic Ripng and Default Gateway ConfigurationLeinner RamirezNo ratings yet

- Experiment No. 7 Parallel RLC CircuitDocument3 pagesExperiment No. 7 Parallel RLC Circuitdoaah hakimNo ratings yet

- Sensor Centraje Aventics-830100488Document1 pageSensor Centraje Aventics-830100488FlavioNo ratings yet

- Multipulse Voltage Source ConverterDocument49 pagesMultipulse Voltage Source ConverterOm prakash100% (1)

- 20-Questions of DFCCILDocument3 pages20-Questions of DFCCILTanmay ChakrabortyNo ratings yet

- Massive MIMO EIRP and EMF For VFUKDocument15 pagesMassive MIMO EIRP and EMF For VFUKUmer AftabNo ratings yet

- 理論物理訓練雜項Document62 pages理論物理訓練雜項林靖倫No ratings yet

- 1DPHYS - QUIZ2 (Electric Circuits)Document2 pages1DPHYS - QUIZ2 (Electric Circuits)Anonymous nb6QWz100% (1)

- Some Natural Phenomena Class 8 NotesDocument9 pagesSome Natural Phenomena Class 8 NotesManjula ManjulaNo ratings yet

- Assignment No. 6-1Document13 pagesAssignment No. 6-1JOSEFCARLMIKHAIL GEMINIANONo ratings yet

- 37 - Performance Description - LH350 - Rev03 - GBDocument9 pages37 - Performance Description - LH350 - Rev03 - GBАлександр Корякин100% (1)

- Embroidery Technique Using Programmable Logic Controller: Usman Institute of TechnologyDocument48 pagesEmbroidery Technique Using Programmable Logic Controller: Usman Institute of TechnologyWajahat AliNo ratings yet

- (Ace - Technology) - XDWL 17 65V VT PDFDocument1 page(Ace - Technology) - XDWL 17 65V VT PDFGiang Nguyễn TrườngNo ratings yet

- 1 ModuleDocument24 pages1 ModulejeromeespirituNo ratings yet

- Schneider SR2B201FUDocument5 pagesSchneider SR2B201FUMarcelo SantibañezNo ratings yet

- 2 - Alternating - Currents (Autosaved)Document33 pages2 - Alternating - Currents (Autosaved)kdNo ratings yet

- Strategi Disain Fasad Rumah Tinggal Hemat Energi - EDDY PRIANTODocument11 pagesStrategi Disain Fasad Rumah Tinggal Hemat Energi - EDDY PRIANTOPAGARNo ratings yet

- 3SK11112AB30 Datasheet enDocument8 pages3SK11112AB30 Datasheet enInvotexNo ratings yet

- Section 4.0 Electricity and ElectromagnetismDocument80 pagesSection 4.0 Electricity and Electromagnetismgarikaishumba2005No ratings yet

- Fresnel and Fraunhoffer Diffraction: Doshi Siddharth KalpeshDocument29 pagesFresnel and Fraunhoffer Diffraction: Doshi Siddharth KalpeshRanjith R MenonNo ratings yet

- Module Electricity and MagnetismDocument21 pagesModule Electricity and MagnetismNoorain PurhanudinNo ratings yet

- CE-EMC Test ReportDocument97 pagesCE-EMC Test ReportDuy ChuNo ratings yet

- International Standard: Norme InternationaleDocument19 pagesInternational Standard: Norme InternationaleARUN BNo ratings yet

- BPT-502: Classical Mechanics Assignment 1Document14 pagesBPT-502: Classical Mechanics Assignment 1How to do anything By HimanshuNo ratings yet

- Betriebsanleitung: Instruction ManualDocument56 pagesBetriebsanleitung: Instruction ManualDavid Davidneel DavidsNo ratings yet

- Power Lab Manual 7th Sem 2011 - BGSDocument109 pagesPower Lab Manual 7th Sem 2011 - BGSSumanth Sathyanarayana100% (1)

- Electroventilatoare CatalogDocument58 pagesElectroventilatoare CataloggeorgeNo ratings yet

- General Properties of Nuclei - IDocument6 pagesGeneral Properties of Nuclei - IAaush PradhanNo ratings yet

- Physics Olympiad Syl Lab UsDocument3 pagesPhysics Olympiad Syl Lab UsMohammad ArikNo ratings yet

- PES InstituteDocument17 pagesPES InstituteNaresh SehdevNo ratings yet

- Null 22Document254 pagesNull 22mohamed ibrahimNo ratings yet