Professional Documents

Culture Documents

4 Column Presses: Built For Your Application

Uploaded by

abdullah yousefiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Column Presses: Built For Your Application

Uploaded by

abdullah yousefiCopyright:

Available Formats

4 Column Presses

Built for your Application

Four-post hydraulic presses, also known as 4-column presses, can be designed to accommodate dies of any

size and are well suited for part manufacturing that requires superior rigidity and precise bed-to-ram

parallelism. 4-column presses are advantageous because they are typically more economical than gib-guided

presses, and allow four-sided access to the working area.

Multipress offers a wide variety of hydraulic post or 4 column presses ranging from 20 to 1000 ton in capacity.

While we offer several “standard” sizes based on typical use, Multipress routinely builds customized models

based on individual client application and production requirements. Our experienced engineering staff partners

closely with clients to ensure their press is built to their specifications.

Multipress equipment is always built with our signature rugged, heavy duty construction, designed to meet

demanding production schedules with years of trouble-free operation.

Typical Configurations:

• 2 Post to multiple post (4 post most common)

• With and without moving platen(s)

• Heated Platens

• Cushion or knock-out

• Bolster Plate

Customizable Press Options

• T-slots

• Die lifters

• Die clamps

• Dowel holes

• Slug holes

• Moving platens

• Die cushions

• Ejectors

• Up-acting design

• Indexers

• Shuttle Tables (manual and powered)

• Multiple position slides

• Press to press transfer (in multiple strain rod,

station to station with common bed).

• Chutes

• Conveyors

• Pick & Place

Multipress Inc. • 1250 Refugee Lane • Columbus, OH 43207

Email: sales@multipress.com • Phone: 614.228.0185 • Fax: 614.228.2358

Control Choices: Electrical Configurations:

• Single axis pressure reversal with • Ranging from basic single cycle to

position speed change automatic cycle with robotic interface

• Single axis position reversal with • PLC control with operator push buttons

position speed change. and switches

• Multiple Axis: • PLC with Touch screen

• Knockout (ejector) • Touch Screen with Industrial

• Cushion: single pressure Computer/PLC

• Cushion: proportional • Windows driven Touch Screen with

(cushion pressure is variable Industrial Computer/PLC

relative to ram position). • Explosive environment

Hydraulics Options: Quality Control:

• Standard directional valve type • Confirmed press position (monitor)

circuits • Confirmed press force (monitor)

• Open loop proportional • Confirm desired tonnage achieved

• Closed loop proportional within a pre-set position window

• Servo • Process signature analysis & storage

• Pass/fail notification

Operator Safety:

• Barrier guards

• Sliding guards

• Light Curtain

• Presence sensing

50-ton double action press 300-ton custom sheer press 100-ton forming press

with joystick control

Multipress Inc. • 1250 Refugee Lane • Columbus, OH 43207

Email: sales@multipress.com • Phone: 614.228.0185 • Fax: 614.228.2358

YOU DESIGN IT…WE’LL QUOTE IT. CUSTOMER SPECIFICATIONS:

SIMPLY FILL IN THE BLANKS AND SEND THIS PAGE TO STRUCTURE:

SALES@MULTIPRESS.COM, AND WE’LL SEND YOU A FORCE: _________TONS

PROMPT QUOTATION. □ DOWN ACTING

□ UP ACTING

□ WITH GUIDED PLATEN

□ WITHOUT GUIDED PLATEN

ELECTRIC:

□ DUAL PUSHBUTTONS

□ PRESSURE REVERSAL

□ POSITION REVERSAL

□ TIME DELAY DOWN

OPERATING VOLTAGE

□ 230/3/60

□ 460/3/60

HYDRAULIC:

□ FLOOR MOUNTED PUMP UNIT

□ CROWN MOUNTED PUMP UNIT

□ WATER TO OIL HEAT EXCHANGER

□ AIR TO OIL HEAT EXCHANGER

□ DIE CUSHION. FORCE: ____TONS

□ BOTTOM CYLINDER, EJECTOR. FORCE:

____TONS

SPEEDS (IF OTHER THAN THOSE LISTED BELOW):

ADVANCE: ___________ IPM

PRESS: ______________ IPM

RETURN: ____________ IPM

GUARDING:

□ LIGHT CURTAIN

□ FIXTED GUARDING (DESCRIBE): ___________

__________________________________________

__________________________________________

OTHER: ___________________________________

TYPICAL SPECIFICATION

LEFT TO TIGHT FRONT TO BACK RAM SPEED (IPM)

TONNAGE DAYLIGHT STROKE HP

BETWEEN POSTS OVERALL ADVANCE PRESS RETURN

20 24 18 24 12 20 749 290 475

30 36 24 24 18 25 515 250 495

40 36 24 24 18 30 495 220 395

50 36 30 24 18 30 320 160 330

75 36 30 30 18 40 260 125 235

100 36 30 30 18 40 220 110 210

150 48 36 30 18 50 190 85 150

200 48 36 36 18 50 120 60 125

300 60 48 36 18 75 120 45 75

400 60 48 36 18

PRESS SPEEDS AND HORSEPOWER ARE

500 72 60 36 18

QUOTED TO MEET CUSTOMER CYCLE RATE

750 72 60 36 24

REQUIREMENTS

1000 72 72 42 24

Multipress Inc. • 1250 Refugee Lane • Columbus, OH 43207

Email: sales@multipress.com • Phone: 614.228.0185 • Fax: 614.228.2358

About Multipress

For more than 80 years, Multipress has been trusted as the premier provider of hydraulic press solutions.

Whether you are interested in a standard machine, or a completely customized design, Multipress’ experts

take the time to select the right machine to fit your specifications and fulfill your production requirements.

With experience in a wide variety of industries and applications, you can trust Multipress to bring reliability,

productivity and precision to your operation. We proudly design and build every machine at our headquarters

in Columbus, Ohio.

Top Notch Support

Multipress is proud to have a service department that is

equipped to provide many types of expert technical assistance,

including telephone, e-mail, on-site help for your press.

With years of technical problem-solving experience, the

Multipress Service Department stands ready to assist our

customers with their service concerns. Our Service Department

is committed to the maximum uptime and longevity of our

customers' equipment investment. It is your assurance of

prompt, reliable, and precise solutions to whatever problems

you may encounter in your day-to-day production.

Multipress Inc. • 1250 Refugee Lane • Columbus, OH 43207

Email: sales@multipress.com • Phone: 614.228.0185 • Fax: 614.228.2358

You might also like

- Maxon Motor & Motor Controller ManualDocument16 pagesMaxon Motor & Motor Controller ManualNguyen Sy100% (1)

- LaserWash 360 Plus Remote Control CommandsDocument21 pagesLaserWash 360 Plus Remote Control CommandsAathi MudhaliyarNo ratings yet

- 110cs 3a Foy enDocument2 pages110cs 3a Foy enGusztav MatheNo ratings yet

- A11VO Rexroth PumpDocument64 pagesA11VO Rexroth PumpAntonio CardosoNo ratings yet

- Accutron CT-D EngDocument2 pagesAccutron CT-D EngXquang Kỹ Thuật SốNo ratings yet

- ProductOverview 2023 EN-83Document1 pageProductOverview 2023 EN-83Ismail AliNo ratings yet

- PP NVT Manual WheelchairDocument6 pagesPP NVT Manual WheelchairAdel ZubairNo ratings yet

- Hydraulic injection moulding machine controls heat cyclesDocument10 pagesHydraulic injection moulding machine controls heat cyclesnagarajanbr24No ratings yet

- ProductOverview 2023 EN-38Document1 pageProductOverview 2023 EN-38Ismail AliNo ratings yet

- Regulating Pumps For Open LoopDocument24 pagesRegulating Pumps For Open LoopxxshNo ratings yet

- Axial Piston Variable Pump A4VSO Series 1x and 3x: RE 92050/10.2018, Bosch Rexroth AGDocument76 pagesAxial Piston Variable Pump A4VSO Series 1x and 3x: RE 92050/10.2018, Bosch Rexroth AGMichail ArmitageNo ratings yet

- CL44eN BAS F40453Document12 pagesCL44eN BAS F40453lihaokingkongNo ratings yet

- GMI B3+B4 Ver1Document21 pagesGMI B3+B4 Ver1Familia mantilla rodriguezNo ratings yet

- Technical Manual for OCS Series Electronic Crane ScalesDocument24 pagesTechnical Manual for OCS Series Electronic Crane ScalesMakombe RonnyNo ratings yet

- Semi-Automatic, Large Format Vacuum Forming Machines: Key FeaturesDocument2 pagesSemi-Automatic, Large Format Vacuum Forming Machines: Key FeaturesibadwonNo ratings yet

- Multiple Generator Automatic Synchronising System: Millennium Power Manufacturing CorpDocument10 pagesMultiple Generator Automatic Synchronising System: Millennium Power Manufacturing CorpPaijo nDesoNo ratings yet

- Full-Auto Electric Washing Machine: Model: DWF-800WPDocument17 pagesFull-Auto Electric Washing Machine: Model: DWF-800WPoana72No ratings yet

- Regulating Pumps for Open Loop SystemsDocument24 pagesRegulating Pumps for Open Loop SystemsxxshNo ratings yet

- AviationDocument2 pagesAviationBharath Subramania RajaNo ratings yet

- Hyd 10-1Document4 pagesHyd 10-1Riyan AditiaNo ratings yet

- Presostato Caldera On OffDocument8 pagesPresostato Caldera On OffSergio Riberos MonteroNo ratings yet

- Ksb-Multitec 32-8-2.1Document38 pagesKsb-Multitec 32-8-2.1Luis M. ChamosoNo ratings yet

- 375 - 375L Specalog (AEHQ3850) PDFDocument28 pages375 - 375L Specalog (AEHQ3850) PDFsuwarjitechnic100% (1)

- Re92705 - 2023 04 24Document76 pagesRe92705 - 2023 04 24Zamuel Torres GarcíaNo ratings yet

- ActuatorDocument8 pagesActuatorMuhammed Ali PisuwalaNo ratings yet

- ProductOverview 2023 EN-86Document1 pageProductOverview 2023 EN-86Ismail AliNo ratings yet

- 01EN0v1 Brochure Working With Dough (EN)Document24 pages01EN0v1 Brochure Working With Dough (EN)EmmanuelNo ratings yet

- Wiz-Ec SeriesDocument13 pagesWiz-Ec SeriesJohan SneiderNo ratings yet

- Truck-Mounted Cranes: HB-R Series, The Perfect Solution For Applications With Large VehiclesDocument4 pagesTruck-Mounted Cranes: HB-R Series, The Perfect Solution For Applications With Large VehiclesRodrigo LealNo ratings yet

- Electrical AlarmsDocument6 pagesElectrical AlarmsCiprian MariusNo ratings yet

- Trailer Mounted Cement Pumper with LAM Mixer and Auto ControlDocument2 pagesTrailer Mounted Cement Pumper with LAM Mixer and Auto ControlGonzalo GabrielNo ratings yet

- Re92701 - 2023 04 24Document60 pagesRe92701 - 2023 04 24Brian Guzman RamirezNo ratings yet

- 13-YMPV螺杆流量计Document20 pages13-YMPV螺杆流量计jackNo ratings yet

- Appa305 ManualDocument33 pagesAppa305 ManualMarian AldeaNo ratings yet

- Pneumatic Hoists Pendant/Wall Mounted Controls/Air Service EquipmentDocument1 pagePneumatic Hoists Pendant/Wall Mounted Controls/Air Service EquipmentAhmedNo ratings yet

- Diesel Engine Fire Pump Controllers: Americas Europe Middle East AsiaDocument2 pagesDiesel Engine Fire Pump Controllers: Americas Europe Middle East AsiaAle LabraNo ratings yet

- Sany 250Document9 pagesSany 250arifNo ratings yet

- Accurate Solutions DispensingDocument3 pagesAccurate Solutions Dispensingram_babu_59No ratings yet

- C6097 Amercian Pressure Swtich Model PDFDocument8 pagesC6097 Amercian Pressure Swtich Model PDFMarcelo SilvaNo ratings yet

- Pump PresentationDocument66 pagesPump PresentationAnonymous K3FaYFlNo ratings yet

- AVC DeviceDocument1 pageAVC DeviceMUFİTNo ratings yet

- 07 Contr Syst-2p-31 01 12Document2 pages07 Contr Syst-2p-31 01 12hellixNo ratings yet

- Axial Piston Variable Pump A10VSO Series 32 - R902462477 - Data SheetDocument56 pagesAxial Piston Variable Pump A10VSO Series 32 - R902462477 - Data SheetSunny KumarNo ratings yet

- truckmanualshub.com_Hidromek HMK 220 LCLR Technical SpecificationDocument2 pagestruckmanualshub.com_Hidromek HMK 220 LCLR Technical Specificationboypiti30No ratings yet

- Re92701 - 2023 04 24Document60 pagesRe92701 - 2023 04 24Cesar SanchezNo ratings yet

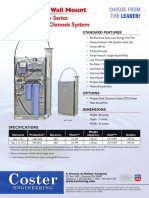

- Commercial Wall Mount Ro System Coster BrochureDocument1 pageCommercial Wall Mount Ro System Coster BrochureLuis Alberto Serrano MesaNo ratings yet

- 30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsDocument19 pages30XW-VZE/30XWHVZE: Water-Cooled Variable-Speed Screw Chillers Water-Sourced Variable-Speed Screw Heat PumpsMechanical PowerNo ratings yet

- Digital Timer with Wide Range of Delay TimesDocument2 pagesDigital Timer with Wide Range of Delay TimesCsaba VargaNo ratings yet

- AdditelCatalog 2017-www - Eigroup.biz PDFDocument76 pagesAdditelCatalog 2017-www - Eigroup.biz PDFkarkar ManhNo ratings yet

- DX-A Operation and MaintenanceDocument73 pagesDX-A Operation and MaintenanceZawminhtun100% (1)

- Case-450 DXDocument4 pagesCase-450 DXPavan SunkaraNo ratings yet

- Aichi Vertical Lift Mast Spec SheetDocument8 pagesAichi Vertical Lift Mast Spec SheettestNo ratings yet

- Wichita Tension Control Systems Catalogue en 2009Document44 pagesWichita Tension Control Systems Catalogue en 2009Ali RazuNo ratings yet

- Muc 11. WKTB PDFDocument14 pagesMuc 11. WKTB PDFHongLam LÊNo ratings yet

- Stable. Strong. Steady.: Material Handling Machine 350MhDocument20 pagesStable. Strong. Steady.: Material Handling Machine 350MhPeterNo ratings yet

- Excavator Cu Braț Lung Hidromek HMK 220 LCLRDocument2 pagesExcavator Cu Braț Lung Hidromek HMK 220 LCLRdiconNo ratings yet

- Data Sheet-Ship Building PressesDocument2 pagesData Sheet-Ship Building PressesClover BlackNo ratings yet

- 30xa 100t PDFDocument162 pages30xa 100t PDFleung ka kitNo ratings yet

- Tapasya Product Catalogue PDFDocument104 pagesTapasya Product Catalogue PDFMahesh Patil KahatulNo ratings yet

- Near-Field Acoustic Levitation and Applications To Bearings: A Critical ReviewDocument21 pagesNear-Field Acoustic Levitation and Applications To Bearings: A Critical Reviewabdullah yousefiNo ratings yet

- Product Focus Steering Stability Control SensorsDocument9 pagesProduct Focus Steering Stability Control Sensorsabdullah yousefiNo ratings yet

- US009109965B2 - Torque Angle Sensor MiniaturizationDocument11 pagesUS009109965B2 - Torque Angle Sensor Miniaturizationabdullah yousefiNo ratings yet

- Biblia Cables SEW PDFDocument448 pagesBiblia Cables SEW PDFAlvaroNo ratings yet

- 10-Design - Fabrication and Manufacturing of 100 Ton HydraulicPress To Perform Equal Channel Angular Pressing (ECAP)Document6 pages10-Design - Fabrication and Manufacturing of 100 Ton HydraulicPress To Perform Equal Channel Angular Pressing (ECAP)abdullah yousefiNo ratings yet

- Optimization Design of Guiding Device On Hydraulic Press Column Based On Axiomatic Design TheoryDocument5 pagesOptimization Design of Guiding Device On Hydraulic Press Column Based On Axiomatic Design Theoryabdullah yousefiNo ratings yet

- Utkarsh U. Yadav Yib0Document8 pagesUtkarsh U. Yadav Yib0abdullah yousefiNo ratings yet

- Design & Fabrication of Hydraulic PressDocument4 pagesDesign & Fabrication of Hydraulic PressEngr Adeel Ahmed AbbasiNo ratings yet

- Design and Fabrication of A Manually Operated Hydraulic PressDocument10 pagesDesign and Fabrication of A Manually Operated Hydraulic PressHoàng Tâm LêNo ratings yet

- Design and Manufacture of A 30-Ton Hydraulic Press: February 2011Document6 pagesDesign and Manufacture of A 30-Ton Hydraulic Press: February 2011MaheshNo ratings yet

- IndexDocument145 pagesIndexabdullah yousefiNo ratings yet

- Design of Shafts: ME 423: Machine Design Instructor: Ramesh SinghDocument31 pagesDesign of Shafts: ME 423: Machine Design Instructor: Ramesh SinghVijayaNo ratings yet

- Ernst Müller (Auth.) - Hydraulic Forging Presses-Springer Berlin Heidelberg (1968)Document285 pagesErnst Müller (Auth.) - Hydraulic Forging Presses-Springer Berlin Heidelberg (1968)Claudio RodriguesNo ratings yet

- Design & Manufacturing of 20 Ton Horizontal Hydraulic Press Machine For Pipe Squeezing & Flaring OperationDocument5 pagesDesign & Manufacturing of 20 Ton Horizontal Hydraulic Press Machine For Pipe Squeezing & Flaring Operationabdullah yousefiNo ratings yet

- Design of Power-Transmitting Shafts: Reference Publication 1123Document30 pagesDesign of Power-Transmitting Shafts: Reference Publication 1123Rodrigo MachadoNo ratings yet

- Hydraulicpressdesign PDFDocument11 pagesHydraulicpressdesign PDFPradeep RavalNo ratings yet

- Computer-Architecture 1 PDFDocument0 pagesComputer-Architecture 1 PDFwww.bhawesh.com.npNo ratings yet

- OM Manuals TemplateDocument9 pagesOM Manuals TemplatejanempatricioNo ratings yet

- ABBREV. Description: //tango/01053/Training/Courses/Course Library/K-Chief 700/7.3/Basic/Abbreviation ListDocument12 pagesABBREV. Description: //tango/01053/Training/Courses/Course Library/K-Chief 700/7.3/Basic/Abbreviation Listalternativblue100% (2)

- AUTMT247GB - CBM and PCMS Integration With - InternalDocument4 pagesAUTMT247GB - CBM and PCMS Integration With - Internaloska150No ratings yet

- USTURBOFLYR - PillAeratorSeries - Turbo Blowers - 03-2020 - 46-95106Document4 pagesUSTURBOFLYR - PillAeratorSeries - Turbo Blowers - 03-2020 - 46-95106Engenharia PetranovaNo ratings yet

- Omron CP1E Data sheet-IndMALL PDFDocument48 pagesOmron CP1E Data sheet-IndMALL PDFAnonymous kTeFFJCs2No ratings yet

- 3BSE020925R301 S800 IO Fieldbus Communication Interface For Advant Fieldbus 100 Users GuideDocument86 pages3BSE020925R301 S800 IO Fieldbus Communication Interface For Advant Fieldbus 100 Users GuideMatringeNo ratings yet

- Integration Techniques of The Embedded Distributed Systems Using Programming Environments and Industrial Standard Communication ProtocolsDocument12 pagesIntegration Techniques of The Embedded Distributed Systems Using Programming Environments and Industrial Standard Communication ProtocolsSabine CrihanNo ratings yet

- Operation Manual: Fx-20P-E Handy Programming PanelDocument128 pagesOperation Manual: Fx-20P-E Handy Programming Panel25det20f1060No ratings yet

- Visual PLC: Indu Stry F IrstDocument14 pagesVisual PLC: Indu Stry F IrstPhan GiangNo ratings yet

- 04 Catalogue ManHinhHienThi IND570Document4 pages04 Catalogue ManHinhHienThi IND570Tùng Hồ ThanhNo ratings yet

- ACS880 - Diode Supply CNTRL Prog - FW Manual - Rev BDocument126 pagesACS880 - Diode Supply CNTRL Prog - FW Manual - Rev BerrikcoyNo ratings yet

- Gate Valve DN500 Instruction Manual 404896A - LK - Valves - DN500 - INMDocument58 pagesGate Valve DN500 Instruction Manual 404896A - LK - Valves - DN500 - INMBùi Công LộcNo ratings yet

- Versamax Ip: Programmable Control ProductsDocument54 pagesVersamax Ip: Programmable Control ProductsEDBNo ratings yet

- M4000Standard OI GBDocument116 pagesM4000Standard OI GBVlad ChioreanNo ratings yet

- (XPANEL) To Communicate With Siemens S7-200 PPI Direct PDFDocument7 pages(XPANEL) To Communicate With Siemens S7-200 PPI Direct PDFMarkesoNo ratings yet

- Recent Successful Fuzzy Logic Applications in Industrial AutomationDocument7 pagesRecent Successful Fuzzy Logic Applications in Industrial Automationjhosset20112539cNo ratings yet

- S7 Communication With Put/Get: S7-1200 Cpus / S7-300 CpusDocument35 pagesS7 Communication With Put/Get: S7-1200 Cpus / S7-300 CpusHoang Tran DinhNo ratings yet

- SINKING AND SOURCINGDocument2 pagesSINKING AND SOURCINGchandushar1604No ratings yet

- Siemens S7 400 EthernetDocument8 pagesSiemens S7 400 Ethernetari___wicaksonoNo ratings yet

- HMI Toolbox WinCC Professional V17 DOC enDocument113 pagesHMI Toolbox WinCC Professional V17 DOC enpress pressNo ratings yet

- PLC Chapter 2 Input-Out DevicesDocument21 pagesPLC Chapter 2 Input-Out DevicesANIK Kumar SannasiNo ratings yet

- I605e V104 N3000-OperatingSoftwareDocument18 pagesI605e V104 N3000-OperatingSoftwareAyobo RolandNo ratings yet

- Sunrise Cnc-CatalogDocument49 pagesSunrise Cnc-CatalogAdan Serrano CaroNo ratings yet

- Melsec FX ManualDocument116 pagesMelsec FX ManualChawa RightNo ratings yet

- Intelimains Bus-Tie Breaker Control in Aut Mode: Application SheetDocument6 pagesIntelimains Bus-Tie Breaker Control in Aut Mode: Application SheetYuriyNo ratings yet

- MasterLogic 50Document26 pagesMasterLogic 50PLC SwaNo ratings yet

- Automatic Punching MachineDocument10 pagesAutomatic Punching MachineShailesh KmrNo ratings yet

- SOG EngineeringManual v3.0Document132 pagesSOG EngineeringManual v3.0Himansu Sekhar PradhanNo ratings yet

- Readme v31 EDocument10 pagesReadme v31 Ealex140979No ratings yet