Professional Documents

Culture Documents

Vestfrost Solutions: Service and Maintenance Instructions: VLS200/300/350/400

Vestfrost Solutions: Service and Maintenance Instructions: VLS200/300/350/400

Uploaded by

Mateo PerezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vestfrost Solutions: Service and Maintenance Instructions: VLS200/300/350/400

Vestfrost Solutions: Service and Maintenance Instructions: VLS200/300/350/400

Uploaded by

Mateo PerezCopyright:

Available Formats

Vestfrost Solutions

Service and maintenance instructions: VLS200/300/350/400

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Topics

1: General required maintenance

2: Vital components

3: Warning

4: Required basic Tools

5: Replacement of components

6: Trouble shooting

7: On site Checklist

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

General required maintenance

Daily Check:

Monitor Temperature

Internal lid is placed properly

Lid fits and lock tight to cabinet

Lid gasket not faulty

Monthly:

Clean grill for compressor compartment

6 Month:

Clean condenser coils

Yearly:

Check electrical connections and components

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Vital Components

Position Item no Description

129 8-036038255 Compressor

5717 7020274 Thermostat

071 A921115 Starting Device

5714 7020144 Thermostat sensor

5851 520229 Run capacitor

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Warning!

Before any repair job be aware of following!

WARNING:

Before servicing or cleaning the appliance, disconnect it from

power source.

WARNING:

Danger risk of fire or explosion. Flammable refrigerant used.

To be repaired only by trained personnel.

(R600a)

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Required Basic Tools

1. Flexible socket wrench

2. Socket wrench - size 6+7+12mm

3. Nose plier

4. Phillips screwdriver

5. Torx screwdriver - size t10+t20

6. Screwdriver - size 1,0x6,0

7. Screwdriver – size 0,6x3,5

8. Multimeter

Proposed additional service

kit/items

Sealing kit

Tar tape

Extra self-tapping screws

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Replacement of components

1. Motor Compartment 4. Starting Device Replacement

2. Thermostat Replacement 5. Thermostat sensor

3. Thermostat Adjustment VLS 6. Run Capasitor Replacement

4. Wiring Diagram 7. Thermometer replacement

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Motor Compartment

How to get acces to the

motor compartment.

Use a screwdriver to

remowe grill

Unluck all 4 clamps

Pull the compressor grill

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat Replacement

The thermostat is placed in the left

corner of the compressor

compartment on the back of the

cabinet

Front with wire 3x Front with 3x wire

sockets sockets

Side view

Back

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat Replacement

1: Dismount 2: Bring the

thermostat from thermostat to

bracket by using a front

socket wrench size

14

2: Use the nose plier

to unmount the 3x

cable sockets

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat Replacement

3: Exchange the

cable sockets/wires

1/1 from the old

thermostat to the

new

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat Adjustment VLS

Warning!

Thermostat is factory set default at 4,5⁰

If adjustment is required only to be

performed by trained technicians.

1: The thermostat is placed in the

left corner of the compressor

compartment on the back of the

cabinet

2: To adjust the thermostat use a small screw

driver and turn either right or left

Right = Colder setpoint

Left = Warmer setpoint

Adjustment interval for thermostat 3-6 ⁰

Importent!

When adjusting monitor appliance carefully

over min. 24 hours

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat Adjustment

Warning!

Thermostat is factory set

default at 4,5⁰

If adjustment is required

only to to be performed by Anticlock wise = Warmer Clock wise = Colder

trained technicians.

Use a small

screwdriver

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat

Wiring Diagram

Fan

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Starting Device Replacement

Front with Back with Side view

terminals connection plug

The starting device

is mounted on the

left side of the

compressor

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Starting Device Replacement

1: Dismount the 2: Push the

cover for starting plastic cover up

device by loosen

the phillips screw

3: Pull the cover 4: Use a screw

back to loosen driver and gently

remowe the

starter from the

socket of

compressor

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Starting Device Replacement

5: Starting device 6: Use a small

loose from socket screwdriver or a

wrench size 6 – to

unmount the wire

fastener

7: Push the 8: Use a nose

plastic bracket up plier to unmount

the wire sockets

from starting

device

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Starting Device Replacement

6: Exchange the

wires 1/1 from

the old starting

device to the new

one

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Run Capasitor Replacement

The run capasitor

is placed in the left

side of the

compressor

compartment on

the bottom frame

1: Loosen the bolt 2: The run

that secures the capasitor is loose

capasitor from

the bottom of

appliance by

using a wrench or

a socket wrench

M13

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Run Capacitor Replacement

2: Unmount the 2 3: Exchange the

wires by using a wires 1/1 from the

nose plier. old capasitor to

the new one

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermometer replacement

Thermometer

The thermometer is

display

placed in at the front

of the appliance

The temperature

1: Dismount the

probe is placed

temperature

inside the

sensor cover by

compartment of the

loosen the 2xtorx

appliance

screws – size 10

2: Open the 3x 3: Remove

clamps fixing the sealing kit

temperature

sensors

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermometer replacement

4: Gently pull the 5: Temperature

white wire until sensor is loose

the probe is visible from refrigeration

compartment

6: Use a screw 7: Temperature

driver to gently monitor is loose

push the socket from cabinet

ofo the

thermometer

8: Thermometer 9: IMPORTANT!

comes with wire

and sensor When re-mounting the

new thermometer senor

in refrigeration

compartment remember

to properly seal the wire

feedthrough

Sealing Kit

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermometer replacement

10: Installation of 11: Push untill

thermometer display is fixed to

display cabinet

12: Thermometer

display is in place

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat sensor replacement

The thermostat

1: Dismount the

sensor is placed

temperature

inside the

sensor cover by

compartment of the

loosen the 2xtorx

appliance

screws – size 10

2: Open the 3x 3: Remove

clamps fixing the sealing kit

temperature

sensors Thermostat

sensor

5: Gently pull the

white wire until

the probe is

visible

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Thermostat sensor replacement

6: Thermostat

temperature 7: The thermostat

sensor sensor comes with

Probe

Wire

Cable sockets

8: IMPORTANT!

When re-mounting

the new

thermometer

remember to

properly seal the

wire feedthrough

Sealing Kit

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Compressor Replacement

Procedure of compressor switch.

1: WARNING! Drain coolant R600a from refrigeration system by vacuum suction

2: IMPORTANT! Blow refrigeration system with NO/Nitrogen

3: Cut

A: Suction and pressure tube

B: Capillary tube

C: Dry filter

4: Dismount starting device ECU

5: Dismount old compressor

6: Insert new compressor

7: Install starting device ECU

8: Solder

A. Suction and pressure tube

B. Capillary tube

C. Dry filter

Filling of new refrigerant

8: Drain refrigeration system by vacuum suction

9: Fill 50g of R600a refrigerant on the system

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Trouble-shooting

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

On-site Checklist

Service technician to check

Is the green diode in the control panel on (Power check)

Is the internal temperature inside the acceptable range of +2° to +8°

Is the vaccine compartment clean and without condensation (water)

Is the Compressor is running

Is baskets used and in place

Is the appliance placed according to instruction in the manual.

Does the lid close tight to cabinet and is the lid gasket in good condition

Is the grill for compressor compartment clean

Is the condenser coils on the backside clean

Is all electrical components working properly

Is there condensation on electric parts (water condensation)?

Over all condition of the cabinet –internal and external: any corrosion, rusting, cracks?

Inspection of the refrigeration line ( the condenser, evaporator, the whole refrigeration circuit/line)

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

Technical Support

If contacting Vestfrost Solutions technical support please supply below

information:

1. Model

2. Serial number

3. What is the issue

Rating plate Serial no

Model

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

CORPORATE PRESENTATION

Downloaded from www.Manualslib.com manuals search engine

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Lock Stock and BarrelDocument2 pagesLock Stock and BarrelBob Andrepont100% (3)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- 6991 5084 62e - Diamec U6 PHCDocument260 pages6991 5084 62e - Diamec U6 PHCRıfat Bingül0% (1)

- Clutch Booster Japanese Commercial VehiclesDocument12 pagesClutch Booster Japanese Commercial VehiclesferNo ratings yet

- Practical 7 Lathe MachineDocument5 pagesPractical 7 Lathe MachineTendayiBonzo100% (7)

- Western Pistol 1972 (.22 Caliber Single Shot) Plans - JACO DesignsDocument5 pagesWestern Pistol 1972 (.22 Caliber Single Shot) Plans - JACO DesignsAride4ever100% (3)

- Lower Drive - 24" Assy: Item Part Number Description QtyDocument6 pagesLower Drive - 24" Assy: Item Part Number Description QtyFreddy Martínez Avendaño100% (1)

- APMA-370 Operation Manual en GZ0000051249IDocument111 pagesAPMA-370 Operation Manual en GZ0000051249Ifauzy fawwaz100% (1)

- All Mep SuppliersDocument55 pagesAll Mep SuppliersAhmed MagedNo ratings yet

- MSDS Hema M-30Document19 pagesMSDS Hema M-30Irvanda ENVIOUSNo ratings yet

- Als Safety Cabinet UserDocument62 pagesAls Safety Cabinet UserHussein Abo aliNo ratings yet

- Transportation, Rigging, Installation, Operation & Maintenance Manual (Summarized Version)Document28 pagesTransportation, Rigging, Installation, Operation & Maintenance Manual (Summarized Version)Abraham Rodriguez100% (1)

- 공기조화 실험장비 KTE-1000AHUDocument133 pages공기조화 실험장비 KTE-1000AHUzalomxisNo ratings yet

- Accessories Filter Cartridge Lifetime Computer: Operating Manual and Spare Parts ListDocument6 pagesAccessories Filter Cartridge Lifetime Computer: Operating Manual and Spare Parts ListWilson BernalNo ratings yet

- E-Catalogue Product List 2021-2023 (1 Des 23)Document104 pagesE-Catalogue Product List 2021-2023 (1 Des 23)deri anggri yarosahNo ratings yet

- Monitoring Suhu Kelembapan Dan Ruangan Di Ruang Operasi Rsia Kendangsari MerrDocument4 pagesMonitoring Suhu Kelembapan Dan Ruangan Di Ruang Operasi Rsia Kendangsari MerrEstining RahayuNo ratings yet

- Production Process Flow ChartDocument5 pagesProduction Process Flow ChartKenny RojasNo ratings yet

- Sigma 3 Servo Motor Er20 50 Pre 2003Document51 pagesSigma 3 Servo Motor Er20 50 Pre 2003Nishanth KallingentavidaNo ratings yet

- Peristaltic Pump ManualDocument74 pagesPeristaltic Pump ManualJoe Vito Morabito100% (1)

- Caterpillar D9R 250 Hrs Service No Unit: Date: HM: ShiftDocument12 pagesCaterpillar D9R 250 Hrs Service No Unit: Date: HM: ShiftTLK Channel100% (1)

- MK 304Document88 pagesMK 304Andres DiazNo ratings yet

- Product Guideline MembrapureDocument66 pagesProduct Guideline MembrapureHoa Nguyen Thai100% (1)

- Produk PT. KP E-Katalog (TM-PD-2021)Document64 pagesProduk PT. KP E-Katalog (TM-PD-2021)wawan1010No ratings yet

- Gamal A. HamidDocument90 pagesGamal A. HamidDaniel VargasNo ratings yet

- Brosur Bubble CPAP Pigeon BaruDocument2 pagesBrosur Bubble CPAP Pigeon Baruteguh nugrohoNo ratings yet

- User Manual Spirometer Datospir 110 1201Document131 pagesUser Manual Spirometer Datospir 110 1201Boyke WinterbergNo ratings yet

- Ophthalmic and Diagnostic Instruments: Ophthalmoscope / Retinoscope / OtoscopeDocument37 pagesOphthalmic and Diagnostic Instruments: Ophthalmoscope / Retinoscope / OtoscopeKhelifa RadiaNo ratings yet

- MVU-1A Service ManualDocument14 pagesMVU-1A Service ManualNguyễn Mai Thanh LộcNo ratings yet

- Data Alkes KalibrasiDocument41 pagesData Alkes Kalibrasianisa13No ratings yet

- SP 24 ManualDocument7 pagesSP 24 ManualOrlando Meza MachadoNo ratings yet

- Top Safe 80021021 Enit12 r09 A4fr - Ts EurDocument164 pagesTop Safe 80021021 Enit12 r09 A4fr - Ts EurCARLOTTANo ratings yet

- Manual Operacion Aas 100 SeriesDocument104 pagesManual Operacion Aas 100 Seriesdéborah_rosalesNo ratings yet

- CS2024MANUALDocument41 pagesCS2024MANUALRiaz AhmedNo ratings yet

- Philips InnerCool Product BrochureDocument8 pagesPhilips InnerCool Product BrochurephilipsinnercoolNo ratings yet

- Daftar Inventaris Melati 2019Document8 pagesDaftar Inventaris Melati 2019FitriaNo ratings yet

- B08179 IFU Gentian Cystatin C Reagent Kit AU Systems REF1103 7725-V09usaDocument9 pagesB08179 IFU Gentian Cystatin C Reagent Kit AU Systems REF1103 7725-V09usaAlberto Marcos100% (1)

- CardioServ SpecificationDocument2 pagesCardioServ SpecificationMadhavesh Kulkarni100% (1)

- RZ Electro Surgical G400Document7 pagesRZ Electro Surgical G400sigmakarsaNo ratings yet

- Manual GaiaDocument38 pagesManual Gaialary topNo ratings yet

- Medical Suction Unit YNK-SU100 Operating Manual: Master@yuilcorp - Co.kr WWW - Yuilcorp.co - KRDocument16 pagesMedical Suction Unit YNK-SU100 Operating Manual: Master@yuilcorp - Co.kr WWW - Yuilcorp.co - KRAntifly Control100% (1)

- Safemate Eco 80021202-Enit12-R05 - SM Eco+ Eur - BioairDocument202 pagesSafemate Eco 80021202-Enit12-R05 - SM Eco+ Eur - BioairCARLOTTANo ratings yet

- Nidek Mark 5 Plus Concentrator - Service ManualDocument35 pagesNidek Mark 5 Plus Concentrator - Service ManualΜοσχοβακος ΣωτηρηςNo ratings yet

- 3066 - York YCWM 90 - 2Document52 pages3066 - York YCWM 90 - 2Eng-Morhaf AL-KhudaryNo ratings yet

- Troubleshooting GuideDocument2 pagesTroubleshooting GuideAngelo PalamingNo ratings yet

- DLAB Manual-Pipettes Micropipette-Plus ManualDocument20 pagesDLAB Manual-Pipettes Micropipette-Plus ManualMax MustermannNo ratings yet

- Installation Manual InventorDocument156 pagesInstallation Manual InventorGeopas GreeceNo ratings yet

- Racks Ventilados Tecniplast BlueLineDocument81 pagesRacks Ventilados Tecniplast BlueLinepablo elviraNo ratings yet

- BT-250 Quick Guide (250-EN-QG-R00) 20140314Document2 pagesBT-250 Quick Guide (250-EN-QG-R00) 20140314Gustavo CarranzaNo ratings yet

- Manual Usuario - EscoDocument32 pagesManual Usuario - EscobioservanesNo ratings yet

- Color Monitor: Service ManualDocument23 pagesColor Monitor: Service ManualtaviNo ratings yet

- EMACO Product Catalog 2018 V 1 d19032018 (LR)Document59 pagesEMACO Product Catalog 2018 V 1 d19032018 (LR)Yasir ArafatNo ratings yet

- Anasthesia Mesin WATO 20 & 30 PDFDocument2 pagesAnasthesia Mesin WATO 20 & 30 PDFjoko ErwantoroNo ratings yet

- 3G3EV Installation ManualDocument55 pages3G3EV Installation ManualHajrudin SinanovićNo ratings yet

- Manual of Transformer NV 128 PRO V20150601Document19 pagesManual of Transformer NV 128 PRO V20150601Josue Abner Arizabal Vera100% (1)

- 60-065483 - Rev C - Dionex ICS-5000 Plus, ICS-6000 Dual Pump and Single Pump Preventive Maintenance ProcedureDocument15 pages60-065483 - Rev C - Dionex ICS-5000 Plus, ICS-6000 Dual Pump and Single Pump Preventive Maintenance ProcedureWilmer AriasNo ratings yet

- 1393un 2023-03Document94 pages1393un 2023-03Marcela Martínez100% (1)

- Manual For 200EVMA-U2 - ReduceDocument43 pagesManual For 200EVMA-U2 - ReduceMuhammad Edo RaynaldoNo ratings yet

- Rotary Vane Pumps DS 602 VARIANDocument29 pagesRotary Vane Pumps DS 602 VARIANjorgeNo ratings yet

- Fix RK BMHP, Reagen, Bahan Gigi 2021 Untuk PKM 2Document13 pagesFix RK BMHP, Reagen, Bahan Gigi 2021 Untuk PKM 2laboratorium biatanNo ratings yet

- Manual BS600HE-8 Balance ManulDocument30 pagesManual BS600HE-8 Balance ManulAsad MuhammadNo ratings yet

- ARISTON Freeze Mba 4033 CviDocument20 pagesARISTON Freeze Mba 4033 CviLjupco MihajlovskiNo ratings yet

- INIFLAIR IsaIsc InstructionManualDocument60 pagesINIFLAIR IsaIsc InstructionManualPrieto RamiroNo ratings yet

- Amk 3000 P 22Document60 pagesAmk 3000 P 22Adil AgoumiNo ratings yet

- RIQAS Instrument and Reagent Supplier CodesDocument20 pagesRIQAS Instrument and Reagent Supplier CodesM.AhmedNo ratings yet

- As 1807.26-2004 Cleanrooms Workstations Safety Cabinets and Pharmaceutical Isolators - Methods of Test DeterDocument3 pagesAs 1807.26-2004 Cleanrooms Workstations Safety Cabinets and Pharmaceutical Isolators - Methods of Test DeterSAI Global - APACNo ratings yet

- C-ABS Bleed Notes V8Document17 pagesC-ABS Bleed Notes V8Panthukalathil RamNo ratings yet

- 4.4 Cu. Ft. W & B C: 126 Can CapacityDocument16 pages4.4 Cu. Ft. W & B C: 126 Can CapacityRoxana LorenteNo ratings yet

- Coolant ValveDocument13 pagesCoolant ValvechrideerNo ratings yet

- Domestic Appliances - Cook-TablewareDocument8 pagesDomestic Appliances - Cook-TablewareJay M RajaNo ratings yet

- Panaflex in Word FormatDocument12 pagesPanaflex in Word FormatRaheel Neo AhmadNo ratings yet

- Wheatly TDV-N TSV-NDocument2 pagesWheatly TDV-N TSV-NWilvir MurilloNo ratings yet

- Catalog Utilaje Si MasinariiDocument494 pagesCatalog Utilaje Si MasinariiAndrei PoseaNo ratings yet

- DIP JB TerminationDocument21 pagesDIP JB TerminationPapcel InstrumentNo ratings yet

- Hydraulic COP 1838ME Rock Drills COP 1838HE: Overhauling Instructions ForDocument72 pagesHydraulic COP 1838ME Rock Drills COP 1838HE: Overhauling Instructions ForrolandNo ratings yet

- Scarifier 9 Piecies Tooth TypeDocument2 pagesScarifier 9 Piecies Tooth Typeangga setyawanNo ratings yet

- 5 8366 PDFDocument68 pages5 8366 PDFguillermoNo ratings yet

- Planet Eclipse Ego 11 Manual PDFDocument84 pagesPlanet Eclipse Ego 11 Manual PDFikanNo ratings yet

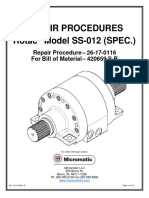

- Roatary Actuators - Micromatic Repair Manual - 26-17-0116Document10 pagesRoatary Actuators - Micromatic Repair Manual - 26-17-0116tungNo ratings yet

- Switch Guards & Shields Switch Guards MIL-G-7703 and Industrial GradeDocument5 pagesSwitch Guards & Shields Switch Guards MIL-G-7703 and Industrial Gradefayez zuwaidNo ratings yet

- Fed STD H28 21B 1984Document14 pagesFed STD H28 21B 1984zulal.dogruelNo ratings yet

- Air Flow Test of Filter'sDocument2 pagesAir Flow Test of Filter'sArun GuptaNo ratings yet

- Electrical Manual EN PDFDocument194 pagesElectrical Manual EN PDFHernan de ReinNo ratings yet

- Show cHJvZHVjdF9jYXRlZ29yeQ 4 enDocument3 pagesShow cHJvZHVjdF9jYXRlZ29yeQ 4 enadriyasper97No ratings yet

- Manual ING DFB 1404 PDocument10 pagesManual ING DFB 1404 Pricardo assaf marchetiNo ratings yet

- 2Document77 pages2Pothuri SuneeldathNo ratings yet

- Ballpoint Pen: Jump To Navigationjump To SearchDocument3 pagesBallpoint Pen: Jump To Navigationjump To SearchEllaineNo ratings yet

- GE3271 - Civil Set 2Document6 pagesGE3271 - Civil Set 2KLBNo ratings yet

- Vacuum Gauge Model KJLC615TC K/H: Vacuum Controller With Relays, RS232, and Analog OutDocument2 pagesVacuum Gauge Model KJLC615TC K/H: Vacuum Controller With Relays, RS232, and Analog OutmahradNo ratings yet

- Simple MachinesDocument1 pageSimple MachinesHartford CourantNo ratings yet