Professional Documents

Culture Documents

CK Mill: Long-Lifetime CK Mill That Achieved Remarkable Power Savings and Reduced Vibrations

Uploaded by

Bülent BulutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CK Mill: Long-Lifetime CK Mill That Achieved Remarkable Power Savings and Reduced Vibrations

Uploaded by

Bülent BulutCopyright:

Available Formats

Long-lifetime CK Mill that achieved remarkable power savings and reduced vibrations

Energy consumption has been lowered by

30%–50%, thanks to improved grinding

CK Mill energy efficiency. The weight and vibration

level were reduced by around 10% and

Vibration measurement values

of pedestal

50%, respectively, by switching the support Concrete pedestal Concrete Steel plates

structure (pedestal) for the main pressing Under 50μm 100–200μm

mechanism from steel plates to concrete.

Initial registration: 2016

Product Description Special Features

A high-efficiency roller mill for cement plants Achieves significant energy savings through improvements to configurations of grinding roller and

with highly efficient grinding and classification fine powder separator

mechanisms and a concrete pedestal to meet Offers significant reductions in product weight and vibrations during grinding process, through

the demands for reduced energy and resources. switching pedestal for main pressing mechanism from steel plates to concrete

Nearly doubled its service life, thanks to superhard metal welded onto surface of grinding rollers and

mill table liners

You might also like

- Bragonzi - ENG - Mod - 02E-01 - A3Document7 pagesBragonzi - ENG - Mod - 02E-01 - A3anggada satriaNo ratings yet

- Built For Construction Flyer EN Einzelseiten WEBDocument6 pagesBuilt For Construction Flyer EN Einzelseiten WEBjp5rysvvzfNo ratings yet

- Datasheet Creusabro 4800 PDFDocument2 pagesDatasheet Creusabro 4800 PDFPercy TorresNo ratings yet

- High Speed Shearing of Stainless Steel Tube UpdatedDocument3 pagesHigh Speed Shearing of Stainless Steel Tube UpdatedOzetoNo ratings yet

- Quotation Sheet Without Motor of Hammer MillDocument14 pagesQuotation Sheet Without Motor of Hammer MillJorge Castro ManriqueNo ratings yet

- Spares BrochureDocument6 pagesSpares BrochureRagul AnandNo ratings yet

- Cop 4050 SeriesDocument12 pagesCop 4050 Serieskannonzk100% (4)

- Series: Where Innovation FlowsDocument12 pagesSeries: Where Innovation FlowsandresNo ratings yet

- Bombas AllweilerDocument14 pagesBombas AllweilerCARLOS ANDRES CARVAJAL SUAREZNo ratings yet

- Application of Composites For Centrifugal PumpsDocument4 pagesApplication of Composites For Centrifugal Pumpsravide76No ratings yet

- Structural Steel For BridgesDocument6 pagesStructural Steel For BridgesFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Daikin Ducted BrochureDocument4 pagesDaikin Ducted BrochureMULTI B AIRCON & ELECTRICAL SUPPLY INCNo ratings yet

- Estructuras Aisladas en La BaseDocument10 pagesEstructuras Aisladas en La BaseNataly RamírezNo ratings yet

- 1254 Revised BOQDocument20 pages1254 Revised BOQAnthony MainaNo ratings yet

- Nit Project Mould EnbrDocument10 pagesNit Project Mould EnbrdonsieNo ratings yet

- This Is A Case Study of Multiple: May/June 2009Document6 pagesThis Is A Case Study of Multiple: May/June 2009Anonymous mcHqIfbnV1No ratings yet

- Iso 2858 Standard End Suction Centrifugal Pumps: Southern Cross Iso SovereignDocument2 pagesIso 2858 Standard End Suction Centrifugal Pumps: Southern Cross Iso SovereignJason PaquibulanNo ratings yet

- 2 - Text - An Industrial Comparative Study of Cement Clinker Grinding Systems Regarding The PDFDocument6 pages2 - Text - An Industrial Comparative Study of Cement Clinker Grinding Systems Regarding The PDFEstefanía Gómez RodríguezNo ratings yet

- Prestressed Concrete: BY:-Dr. Mohd Ashraf Iqbal Associate Professor Department of Civil Engineering, IIT, RoorkeeDocument153 pagesPrestressed Concrete: BY:-Dr. Mohd Ashraf Iqbal Associate Professor Department of Civil Engineering, IIT, RoorkeeAllyson DulfoNo ratings yet

- Imp Die ArticlesDocument64 pagesImp Die ArticlesprabhuNo ratings yet

- Strike-Bar Crusher - Draft1Document5 pagesStrike-Bar Crusher - Draft1Luis CaballeroNo ratings yet

- CATALOGO-Bombas WarrenDocument4 pagesCATALOGO-Bombas Warrenjlrllfn81No ratings yet

- Click Here To Download Boq 1Document20 pagesClick Here To Download Boq 1emanNo ratings yet

- 2008 - Precast Post Tensioned Concrete Towers For High Power Wind Turbines Antonio MariDocument6 pages2008 - Precast Post Tensioned Concrete Towers For High Power Wind Turbines Antonio MariAmela ShahiniNo ratings yet

- MJ Series: Jaw CrushersDocument24 pagesMJ Series: Jaw Crusherskalluk1966100% (1)

- Sandvik Cs550 Cone Crusher: Technical SpecificationDocument8 pagesSandvik Cs550 Cone Crusher: Technical SpecificationLmf DanielNo ratings yet

- Cone Crusher - Mineral Processing & Extractive MetallurgyDocument23 pagesCone Crusher - Mineral Processing & Extractive MetallurgyArdh0072No ratings yet

- V I B R A T O R S: Consolidating ConcreteDocument13 pagesV I B R A T O R S: Consolidating ConcreteShubham JainNo ratings yet

- It's A Paper For ConcreteDocument5 pagesIt's A Paper For ConcreteManojkumarNo ratings yet

- Atlas Copco Hydraulic Feeds: BMH 2000 Series Technical DataDocument2 pagesAtlas Copco Hydraulic Feeds: BMH 2000 Series Technical DataDuber Cáceres Malaver100% (2)

- WallFenceBillOfQuantities (BOQ) - 1Document35 pagesWallFenceBillOfQuantities (BOQ) - 1Myless MukendiNo ratings yet

- D8R IiDocument24 pagesD8R IiSandyNo ratings yet

- K3VL Presentation 2010 MDDocument15 pagesK3VL Presentation 2010 MDHamza Lashin100% (2)

- BCU Trainnig Material - Concrete Practice-Reinforcement - PresentationDocument35 pagesBCU Trainnig Material - Concrete Practice-Reinforcement - PresentationanhkhabkNo ratings yet

- Compaction of Concrete Using Immersion and Surface Vibrators PDFDocument12 pagesCompaction of Concrete Using Immersion and Surface Vibrators PDFmehdi_hoseinee0% (1)

- BCRFS Centrifugal Rooftop Filtered Supply Fan Catalog 4310Document12 pagesBCRFS Centrifugal Rooftop Filtered Supply Fan Catalog 4310borclenmercantileNo ratings yet

- pp69-72 MSI10Document4 pagespp69-72 MSI10imetallurgyNo ratings yet

- Soraluce KB 150 W Horizontal Boring MachineDocument12 pagesSoraluce KB 150 W Horizontal Boring MachineEXCELGERENCIANo ratings yet

- South Horr Police StationDocument18 pagesSouth Horr Police Stationcliff machukaNo ratings yet

- CM400 Hammar Mills Low Res PDFDocument8 pagesCM400 Hammar Mills Low Res PDFKrishna prasadNo ratings yet

- CNC Damping System Using Viscous Shear Damper and Hydro Static BearingsDocument3 pagesCNC Damping System Using Viscous Shear Damper and Hydro Static BearingsFabrizio GrassoNo ratings yet

- AB0034 Alloy25Document12 pagesAB0034 Alloy25Scott LongmireNo ratings yet

- PrecastDocument2 pagesPrecastsmithNo ratings yet

- Soft Eye Case StudyDocument4 pagesSoft Eye Case Studypabulumzeng100% (1)

- Creusabro: Industeel, The Right Steel at The Right PlaceDocument9 pagesCreusabro: Industeel, The Right Steel at The Right PlaceLuân LêNo ratings yet

- Basf Masterbrace Fib 300 TdsDocument3 pagesBasf Masterbrace Fib 300 TdsNolosaurusNo ratings yet

- BIR BrochureDocument16 pagesBIR BrochureVijay KumarNo ratings yet

- BrochureDocument4 pagesBrochureSatish BabuNo ratings yet

- Performance of Concrete Slabs With Different ReinforcingDocument8 pagesPerformance of Concrete Slabs With Different ReinforcingDiego SilvaNo ratings yet

- KG Brochure Butterfly BTDocument12 pagesKG Brochure Butterfly BTmmmlormamNo ratings yet

- A Seminar Presentation On Effect of Using High Strength Conecret Higher Grade of RebarDocument13 pagesA Seminar Presentation On Effect of Using High Strength Conecret Higher Grade of RebarNitinNo ratings yet

- Ficha Cat Plow en 11 CepilloDocument12 pagesFicha Cat Plow en 11 CepilloWilson RiveraNo ratings yet

- 9851 3499 01 - L Feed Beams 6000 BMH6818Document9 pages9851 3499 01 - L Feed Beams 6000 BMH6818Zhang JieNo ratings yet

- Usf 1250Document3 pagesUsf 1250Ahad-Ur RahmanNo ratings yet

- Essa LM2 Pulverising MillDocument3 pagesEssa LM2 Pulverising MillAlberto LobonesNo ratings yet

- Air Cooled Single Double Skinned Evaporator UnitDocument12 pagesAir Cooled Single Double Skinned Evaporator UnitMohazil Ajil MohamedNo ratings yet

- 19J018 Synopsis Phase-2Document15 pages19J018 Synopsis Phase-2GopiNo ratings yet

- Jaw Crusher BB 300Document3 pagesJaw Crusher BB 300MGRenJcNo ratings yet

- Bearing FailuresDocument2 pagesBearing FailuresBülent BulutNo ratings yet

- Lighting CopDocument48 pagesLighting CopMohamed ZamriNo ratings yet

- PV Risk Management Guidelines GIZ ENG FinalDocument64 pagesPV Risk Management Guidelines GIZ ENG FinalBülent BulutNo ratings yet

- EMS Water Pumps (Low-Res)Document16 pagesEMS Water Pumps (Low-Res)Bülent BulutNo ratings yet

- EMS Water Pumps (Low-Res)Document16 pagesEMS Water Pumps (Low-Res)Bülent BulutNo ratings yet

- Guidelines CCMSDocument31 pagesGuidelines CCMSThinh TranNo ratings yet

- 4600en 0119fleDocument40 pages4600en 0119fledeni jakaNo ratings yet

- CK Mill: Long-Lifetime CK Mill That Achieved Remarkable Power Savings and Reduced VibrationsDocument1 pageCK Mill: Long-Lifetime CK Mill That Achieved Remarkable Power Savings and Reduced VibrationsBülent BulutNo ratings yet

- Vertical Roller Mill UpgradeDocument2 pagesVertical Roller Mill UpgradeBülent BulutNo ratings yet

- Vibration Analysis of Unbalance On Axial Fan Engine 5.5 KWDocument8 pagesVibration Analysis of Unbalance On Axial Fan Engine 5.5 KWIJAERS JOURNALNo ratings yet

- Vertical Roller Mill UpgradeDocument2 pagesVertical Roller Mill UpgradeBülent BulutNo ratings yet

- ATOX Split SealDocument4 pagesATOX Split SealBülent BulutNo ratings yet

- Loesche - Loesche Cement Mills Concept Large CapacityDocument26 pagesLoesche - Loesche Cement Mills Concept Large Capacityphucdc095041No ratings yet

- Raw Mill SpectrumsDocument27 pagesRaw Mill SpectrumsBülent BulutNo ratings yet

- Predicting The Future - Trends For Predictive Maintenance: Dr. Dirk WoldtDocument24 pagesPredicting The Future - Trends For Predictive Maintenance: Dr. Dirk WoldtBülent BulutNo ratings yet

- FICEM Christian Pfeiffer 2017Document37 pagesFICEM Christian Pfeiffer 2017Geeta NandNo ratings yet

- KEP Presentation NCJWDocument28 pagesKEP Presentation NCJWfilu786No ratings yet

- Abb Industry 4.0 Icr Dec 2019 Reprint HRDocument2 pagesAbb Industry 4.0 Icr Dec 2019 Reprint HRJuliano. PQMNo ratings yet

- Kawasaki Green Product Conformity AssessmentDocument1 pageKawasaki Green Product Conformity AssessmentBülent BulutNo ratings yet

- Air TreatmentDocument3 pagesAir TreatmentBülent BulutNo ratings yet

- The Enduradrive Fan System Retrofit KitDocument2 pagesThe Enduradrive Fan System Retrofit KitBülent BulutNo ratings yet

- 5 - Energy ConsiderationChristian Pfeiffer Products 20110824Document42 pages5 - Energy ConsiderationChristian Pfeiffer Products 20110824Bülent BulutNo ratings yet

- Bricks Calculator-V.3Document10 pagesBricks Calculator-V.3Bülent Bulut100% (3)

- 5 - Energy ConsiderationChristian Pfeiffer Products 20110824Document42 pages5 - Energy ConsiderationChristian Pfeiffer Products 20110824Bülent BulutNo ratings yet

- K Urbaniec Eds Modern Energy Economy in Beet Sugar Factories 1989 PDFDocument393 pagesK Urbaniec Eds Modern Energy Economy in Beet Sugar Factories 1989 PDFBülent BulutNo ratings yet

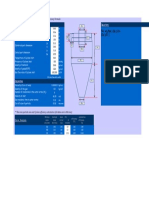

- Copia de Cyclone EfficiencyDocument1 pageCopia de Cyclone Efficiency1968caNo ratings yet

- Ring Formation in Rotary KilnsDocument30 pagesRing Formation in Rotary Kilnsmohamed ElsayedNo ratings yet

- THIELE Catalog Bucket-Elevator-Chains E 2014 PDFDocument20 pagesTHIELE Catalog Bucket-Elevator-Chains E 2014 PDFNuzuliana EnuzNo ratings yet

- Maintenance Notes: Ensure That Roller Chains Are Properly TensionedDocument8 pagesMaintenance Notes: Ensure That Roller Chains Are Properly TensionedBülent BulutNo ratings yet