Professional Documents

Culture Documents

Qty. Description SP 46-5: Further Product Details

Uploaded by

agieyogaswaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qty. Description SP 46-5: Further Product Details

Uploaded by

agieyogaswaraCopyright:

Available Formats

Qty.

Description

1 SP 46-5

Note! Product picture may differ from actual product

Product No.: 15A21905

Submersible borehole pump, suitable for pumping clean water. Can be installed vertically or horizontally. All steel

components are made in stainless steel, EN 1.4301 (AISI 304), that ensures high corrosive resistance. This pump

carries drinking water approval.

The pump is fitted with a 7.5 kW MS6000 motor with sand shield, mechanical shaft seal, water-lubricated journal

bearings and a volume compensating diaphragm. The motor is a canned type submersible motor offering good

mechanical stability and high efficiency. Suitable for temperatures up to 40 °C.

The motor is fitted with the Grundfos Tempcon sensor that, by use of powerline communication together with a

MP204 control panel, enables temperature monitoring.

The motor is for direct-on-line starting (DOL).

Further product details

The pump is suitable for applications similar to the following:

- raw-water supply

- irrigation

- groundwater lowering

- pressure boosting

- fountain applications.

The Grundfos SP pump is renowned for its high efficiency and already complies with the requirements of the

Minimum Efficiency Index, and therefore Grundfos is amongst the best in class within submersible pumps.

Pump

All pump surfaces that are in contact with pumped liquids are made in stainless steel which makes them

corrosion- and wear-resistant. The corrosion diagram below shows the capabilities of the pump and motor in

relation to the temperature in Celsius (y-axis) and the concentration of chloride in ppm (x-axis).

The elastomer parts in the pump are made of NBR (Nitrile-Butadiene Rubber) which ensures good wear

resistance and long service intervals.

Printed from Grundfos Product Centre [2021.06.007] 1

Qty. Description

In case the pump is used for pumping water with high content of hydrocarbons or solvents, Grundfos offers FKM

rubber parts (Fluorocarbon) which are oil and temperature-resistant up to 90 °C.

The pump is built with octagonal bearings with sand flush channels that minimise wear. As wear of the pump is

inevitable, the pump design allows for easy replacement of all internal wear parts (bearings, impeller, wear rings

and seal rings) to maintain high performance and a long lifetime.

The suction interconnector is fitted with a strainer to prevent large particles from entering the pump. The suction

interconnector is designed to comply with NEMA standards for motor mounting/dimensions.

Motor

The stator is hermetically encapsulated in stainless steel and the windings are embedded in polymer compound.

This results in high mechanical stability, optimum cooling and reduces the risk of short circuits in the windings.

The shaft seal faces are ceramic/carbon. The material combination provides good dry-running resistance.

Together with the shaft seal housing, the sand shield forms a labyrinth seal, which during normal operating

conditions prevents penetration of sand particles into the shaft seal.

The motor is fitted with the Grundfos Tempcon temperature sensor device that includes a NTC-resistor which

senses the temperature.

The resistor is built-in close to the winding.

The temperature is converted into a high-frequency signal which is sent via the submersible drop cable and which

can be converted into a temperature reading by means of Grundfos MP204.

The MP204 is an electronic motor protection device that also monitors the supply network quality to protect the

submersible motor against supply network disturbances.

Liquid:

Pumped liquid: Water

Maximum liquid temperature: 40 °C

Max liquid t at 0.15 m/sec: 40 °C

Selected liquid temperature: 20 °C

Density: 998.2 kg/m³

Technical:

Pump speed on which pump data are based: 2900 rpm

Actual calculated flow: 50.82 m³/h

Resulting head of the pump: 3.615 bar

Shaft seal for motor: CER/CARNBR

Approvals on nameplate: CE,GOST2

Curve tolerance: ISO9906:2012 3B

Motor version: T40

Materials:

Pump: Stainless steel

EN 1.4301

AISI 304

Impeller: Stainless steel

EN 1.4301

AISI 304

Motor: Stainless steel

DIN W.-Nr. 1.4301

AISI 304

Installation:

Pump outlet: RP3

Motor diameter: 6 inch

Printed from Grundfos Product Centre [2021.06.007] 2

Qty. Description

Electrical data:

Motor type: MS6000

Rated power - P2: 7.5 kW

Power (P2) required by pump: 7.5 kW

Mains frequency: 50 Hz

Rated voltage: 3 x 380-400-415 V

Rated current: 17.8-17.2-17.2 A

Starting current: 460-510-530 %

Cos phi - power factor: 0.84-0.82-0.79

Rated speed: 2850-2870-2880 rpm

Start. method: direct-on-line

Enclosure class (IEC 34-5): IP68

Insulation class (IEC 85): F

Built-in temp. transmitter: yes

Motor No: 78195512

Others:

Minimum efficiency index, MEI ≥: 0.40

ErP status: EuP Standalone/Prod.

Net weight: 56.6 kg

Gross weight: 82.4 kg

Shipping volume: 0.2 m³

Danish VVS No.: 388462005

Printed from Grundfos Product Centre [2021.06.007] 3

15A21905 SP 46-5 50 Hz

H SP 46-5, 3*400 V, 50Hz eta

[bar] [%]

Q = 50.82 m³/h

H = 3.615 bar

Es = 0.1756 kWh/m³

n = 2878 rpm

7.0 Pumped liquid = Water

Liquid temperature during operation = 20 °C

Density = 998.2 kg/m³

6.5

6.0

5.5

5.0 100

4.5 90

4.0 80

3.5 70

3.0 60

2.5 50

2.0 40

1.5 30

1.0 20

0.5 10

Eta pump = 70.7 %

Eta pump+motor = 57.2 %

0.0 0

0 5 10 15 20 25 30 35 40 45 50 55 Q [m³/h]

P NPSH

[kW] [bar]

10 1.0

P1

8 0.8

P2

6 0.6

4 0.4

2 0.2

P1 = 8.923 kW

P2 = 7.214 kW

NPSH = 0.37 bar

0 0.0

Printed from Grundfos Product Centre [2021.06.007] 4

H SP 46-5, 3*400 V, 50Hz eta

Description Value [bar] [%]

Q = 50.82 m³/h

General information: H = 3.615 bar

7.0

Product name: SP 46-5 Es = 0.1756 kWh/m³

6.5 n = 2878 rpm

Product No: 15A21905 Pumped liquid = Water

EAN number: 5700391151088 6.0 Liquid temperature during operation = 20 °C

Density = 998.2 kg/m³

Price: 5.5

Technical:

5.0 100

Pump speed on which pump data are 2900 rpm

based: 4.5 90

Actual calculated flow: 50.82 m³/h 4.0 80

Resulting head of the pump: 3.615 bar 3.5 70

Stages: 5

3.0 60

Impeller reduc.: NONE

2.5 50

Shaft seal for motor: CER/CARNBR

Approvals on nameplate: CE,GOST2 2.0 40

Curve tolerance: ISO9906:2012 3B 1.5 30

Model: B 1.0 20

Valve: YES

0.5 Eta pump = 70.7 % 10

Motor version: T40 Eta pump+motor = 57.2 %

Materials: 0.0 0

0 10 20 30 40 50 Q [m³/h]

Pump: Stainless steel P NPSH

[kW] [bar]

Pump: EN 1.4301

10 1.0

Pump: AISI 304 P1

Impeller: Stainless steel 8 0.8

Impeller: EN 1.4301

P2

Impeller: AISI 304 6 0.6

Motor: Stainless steel

4 0.4

Motor: DIN W.-Nr. 1.4301

Motor: AISI 304 2 P1 = 8.923 kW 0.2

Installation: P2 = 7.214 kW

NPSH = 0.37 bar

Pump outlet: RP3 0 0.0

Motor diameter: 6 inch 139.5

RP3

577

Liquid: 148 GN

1423

846

GN 148

RP3

Pumped liquid: Water

Maximum liquid temperature: 40 °C

Max liquid t at 0.15 m/sec: 40 °C

Selected liquid temperature: 20 °C

Density: 998.2 kg/m³

846

Electrical data:

Motor type: MS6000

1423

Applic. motor: GRUNDFOS

Rated power - P2: 7.5 kW

Power (P2) required by pump: 7.5 kW

Mains frequency: 50 Hz

Rated voltage: 3 x 380-400-415 V

577

Rated current: 17.8-17.2-17.2 A

Starting current: 460-510-530 % 139.5

Cos phi - power factor: 0.84-0.82-0.79

Rated speed: 2850-2870-2880 rpm

Start. method: direct-on-line

Y DOL

Enclosure class (IEC 34-5): IP68

L1 L2 L3 PE L1 L2 L3 PE

Insulation class (IEC 85): F

Motor protec: NONE

Thermal protec: external

Built-in temp. transmitter: yes

Motor No: 78195512

W2 U2 V2 U1 V1 W1

Others: U1 V1 W1 PE PE

Minimum efficiency index, MEI ≥: 0.40

M M

ErP status: EuP Standalone/Prod. 3 3

Net weight: 56.6 kg U1, W2 Brown

Gross weight: 82.4 kg V1, U2 Black

Shipping volume: 0.2 m³ W1, V2 Grey

Danish VVS No.: 388462005

Printed from Grundfos Product Centre [2021.06.007] 5

15A21905 SP 46-5 50 Hz

RP3

148 GN

846

1423

577

139.5

Note! All units are in [mm] unless others are stated.

Disclaimer: This simplified dimensional drawing does not show all details.

Printed from Grundfos Product Centre [2021.06.007] 6

You might also like

- K. Jarrett - CountryDocument16 pagesK. Jarrett - Countrykasiula28111100% (2)

- TM 11398Document592 pagesTM 11398krill.copco50% (2)

- Autosys commands guideDocument39 pagesAutosys commands guidesantosh_panditpurNo ratings yet

- BP Approved Connection ListDocument10 pagesBP Approved Connection ListEDWIN M.PNo ratings yet

- Engine Block Manufacturing ProcessDocument5 pagesEngine Block Manufacturing ProcessDavid U. AnyegwuNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- FPGA Based SVM Comtroller Report FinalDocument34 pagesFPGA Based SVM Comtroller Report FinalShiva Prasad MNo ratings yet

- MG07B302 Design Guide FC 280Document104 pagesMG07B302 Design Guide FC 280Dave DuasoNo ratings yet

- A Project Report On PLC and Its ApplicationDocument28 pagesA Project Report On PLC and Its Applicationpoonam00140% (1)

- VAPOR PRESSURE TESTER SETTINGSDocument22 pagesVAPOR PRESSURE TESTER SETTINGSKratos EspejoNo ratings yet

- Sea Water Intake PumpDocument10 pagesSea Water Intake PumpmbgprsmsNo ratings yet

- Grundfos - SP 5A 21Document12 pagesGrundfos - SP 5A 21godbugNo ratings yet

- SP5A-12 1.1kW 3x380-415V 50Hz: Grundfos Pump 5001912Document12 pagesSP5A-12 1.1kW 3x380-415V 50Hz: Grundfos Pump 5001912DENOUNo ratings yet

- GRUNFOS SP 5A-25.3x220V.2,2kW.50Hz: Description Value General InformationDocument1 pageGRUNFOS SP 5A-25.3x220V.2,2kW.50Hz: Description Value General InformationFahmi NurjananiNo ratings yet

- En 98390031 Grundfos Cre 5 9 a Fgj a e HqqeDocument14 pagesEn 98390031 Grundfos Cre 5 9 a Fgj a e Hqqevalentin.hernandezNo ratings yet

- Grundfos - SP 160 7Document11 pagesGrundfos - SP 160 7Majid abdulNo ratings yet

- Qty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsDocument7 pagesQty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsBrata PatandeanNo ratings yet

- SP14-15 Rp2 4"3X380-415/50 4.0kW: Grundfos Pump 98699358Document12 pagesSP14-15 Rp2 4"3X380-415/50 4.0kW: Grundfos Pump 98699358Media PlatformNo ratings yet

- GRUNDFOS SP 5A-17.3x380V.50Hz: Description Value General InformationDocument1 pageGRUNDFOS SP 5A-17.3x380V.50Hz: Description Value General InformationFahmi NurjananiNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description SP 5A-60Document9 pagesCompany Name: Created By: Phone: Date:: Qty. Description SP 5A-60Guilherme VenturaNo ratings yet

- CR 10-7 A-A-A-E-HQQE: Position Qty. Description Single PriceDocument3 pagesCR 10-7 A-A-A-E-HQQE: Position Qty. Description Single Pricerachman hardianNo ratings yet

- Grundfos - TP 150 220 4 A F A BAQEDocument12 pagesGrundfos - TP 150 220 4 A F A BAQEYoesoef HasyimNo ratings yet

- Grundfos - TP 25 50 2 A O A GQQEDocument11 pagesGrundfos - TP 25 50 2 A O A GQQEJovisa MaricNo ratings yet

- Pompa Qarkulluese Per Kthim Ne Kembyes PDFDocument11 pagesPompa Qarkulluese Per Kthim Ne Kembyes PDFASNo ratings yet

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroNo ratings yet

- Qty. Description SP 46-9: Company Name: Created By: Phone: DateDocument2 pagesQty. Description SP 46-9: Company Name: Created By: Phone: Dateatiek zaNo ratings yet

- SP 307Document10 pagesSP 307super exoNo ratings yet

- Description Value General Information:: Printed From Grundfos Product Centre (2023.12.002)Document2 pagesDescription Value General Information:: Printed From Grundfos Product Centre (2023.12.002)Fahmi NurjananiNo ratings yet

- Groundfos Pompa Submersible 98826883 - SP - 918Document3 pagesGroundfos Pompa Submersible 98826883 - SP - 918teknisiptpakkodianNo ratings yet

- Grundfos CM5-3Document13 pagesGrundfos CM5-3Kiyimba DanielNo ratings yet

- Permen Esdm 7Document8 pagesPermen Esdm 7DangolNo ratings yet

- Grundfos - CM10 3 A R G V AQQVDocument12 pagesGrundfos - CM10 3 A R G V AQQVD Manmath RaoNo ratings yet

- CR 313 AfgjaehqqeDocument10 pagesCR 313 AfgjaehqqeTatiana Mejías SeguraNo ratings yet

- Spesifikasi Pompa Air Grunfos SP 9-21Document2 pagesSpesifikasi Pompa Air Grunfos SP 9-21supriyantoNo ratings yet

- Grundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetDocument13 pagesGrundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetLeduța DomnescuNo ratings yet

- CR 5-4 A-A-A-E-HQQE: Position Qty. Description Single PriceDocument5 pagesCR 5-4 A-A-A-E-HQQE: Position Qty. Description Single Pricesunil kumarNo ratings yet

- POMPA Grundfos CM 5-2Document2 pagesPOMPA Grundfos CM 5-2Deby Eka ChandraNo ratings yet

- Grundfos - SEG 40 31 2 50BDocument17 pagesGrundfos - SEG 40 31 2 50BMarina CoskovicNo ratings yet

- Grundfos CRN 1s 10 A FGJ G e HqqeDocument15 pagesGrundfos CRN 1s 10 A FGJ G e HqqeANDRESNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Grundfos - CM10 2 A R A E AQQEDocument11 pagesGrundfos - CM10 2 A R A E AQQEmanusnair247No ratings yet

- Grundfos Cm3 2 a r i e AqqeDocument12 pagesGrundfos Cm3 2 a r i e Aqqevksolarsystems2020No ratings yet

- en-96122027-grundfos-cr-32-11-a-f-a-e-hqqeDocument13 pagesen-96122027-grundfos-cr-32-11-a-f-a-e-hqqeNguyễn Kỳ TúNo ratings yet

- Pompa 212CA1913 - SP - 17-13NDocument15 pagesPompa 212CA1913 - SP - 17-13NDddelta RampockNo ratings yet

- Grundfos Tpe2!50!240 N A F A BqqeDocument10 pagesGrundfos Tpe2!50!240 N A F A BqqeLuca OvidiuNo ratings yet

- CR 536 AfgjaehqqeDocument6 pagesCR 536 AfgjaehqqeAriesNo ratings yet

- Cri - 3 25 - A FGJ I e HqqeDocument6 pagesCri - 3 25 - A FGJ I e HqqeJorge InostrozaNo ratings yet

- Position Qty. Description CR 10-1 A-A-A-E-HQQE: Printed From Grundfos CAPS (2014.05.023)Document5 pagesPosition Qty. Description CR 10-1 A-A-A-E-HQQE: Printed From Grundfos CAPS (2014.05.023)rachman hardianNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description SP 30-16Document9 pagesCompany Name: Created By: Phone: Date:: Qty. Description SP 30-16ali jabarNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description SP 30-16Document9 pagesCompany Name: Created By: Phone: Date:: Qty. Description SP 30-16ali jabarNo ratings yet

- TATA CIPTA UTAMA SP 7-51 Submersible Pump SpecsDocument10 pagesTATA CIPTA UTAMA SP 7-51 Submersible Pump SpecsBahtiar AntanaNo ratings yet

- Grundfos 98826884 - SP - 921Document9 pagesGrundfos 98826884 - SP - 921dumbadamboNo ratings yet

- Qty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateVitor AntunesNo ratings yet

- Qty. Description CM 5-7 A-S-I-E-AVBE E-A-A-N: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CM 5-7 A-S-I-E-AVBE E-A-A-N: Company Name: Created By: Phone: DateBogdan PanaitNo ratings yet

- Grundfos - CRI 3 23 A P I E HQQEDocument15 pagesGrundfos - CRI 3 23 A P I E HQQEHeinium DannemannNo ratings yet

- Grundfos - CR 10 2 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 2 A FJ A E HQQEMario PatarroyoNo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- Recirculation Pump CalculationDocument4 pagesRecirculation Pump Calculationsenthilkumar_5425717No ratings yet

- Qty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DateDocument5 pagesQty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DatePriyanka KumariNo ratings yet

- Groundfos Pompa Submersible 98826918 - SP - 1420Document3 pagesGroundfos Pompa Submersible 98826918 - SP - 1420teknisiptpakkodianNo ratings yet

- Grundfos - MAGNA1 D 40 60 FDocument8 pagesGrundfos - MAGNA1 D 40 60 FMilan MilosavljevicNo ratings yet

- Qty. Description CR 45-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CR 45-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateJulio César MirandaNo ratings yet

- NB 50-160-169 (167) - 74m3-h. 36m. 11KW PDFDocument4 pagesNB 50-160-169 (167) - 74m3-h. 36m. 11KW PDFViệt Đặng XuânNo ratings yet

- Position Qty. Description TPE3 80-120-S A-F-A-BQQE: Company Name: Created By: Phone: DateDocument8 pagesPosition Qty. Description TPE3 80-120-S A-F-A-BQQE: Company Name: Created By: Phone: Datevili00No ratings yet

- Grundfos - CR 15 10 A F A E HQQE PDFDocument15 pagesGrundfos - CR 15 10 A F A E HQQE PDFdimasNo ratings yet

- Spek PompaDocument4 pagesSpek PompaTri YuniantoNo ratings yet

- Grundfos CM5-3Document2 pagesGrundfos CM5-3zippooriNo ratings yet

- Grundfos - CR 5 3 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 3 A A A E HQQE PDFabhe prasetyaNo ratings yet

- Qty. Description CRN 32-1-1 A-F-A-V-HQQV: Company Name: Grundfos Created By: Phone: DateDocument6 pagesQty. Description CRN 32-1-1 A-F-A-V-HQQV: Company Name: Grundfos Created By: Phone: DateJNo ratings yet

- PegasusDocument3 pagesPegasusagieyogaswaraNo ratings yet

- OFFLINE/ LUAR JEJARING (LURING) Pembelajaran Tatap Muka Terbatas Dan ONLINE (DARING)Document1 pageOFFLINE/ LUAR JEJARING (LURING) Pembelajaran Tatap Muka Terbatas Dan ONLINE (DARING)agieyogaswaraNo ratings yet

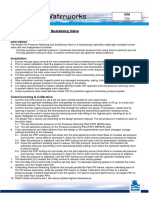

- WW ACC PILOT Model 3HC - 1Document1 pageWW ACC PILOT Model 3HC - 1agieyogaswaraNo ratings yet

- Spesifikasi Booster PumpDocument5 pagesSpesifikasi Booster PumpagieyogaswaraNo ratings yet

- Sofrel LS/LT Range: GSM/GPRS Data LoggersDocument6 pagesSofrel LS/LT Range: GSM/GPRS Data LoggersagieyogaswaraNo ratings yet

- Avk Double Eccentric Butterfly Valve, PN 10/16 756/100Document3 pagesAvk Double Eccentric Butterfly Valve, PN 10/16 756/100agieyogaswaraNo ratings yet

- WW Ordering Guide 700 SeriesDocument4 pagesWW Ordering Guide 700 SeriesagieyogaswaraNo ratings yet

- Sostenedora Presion BERMADDocument6 pagesSostenedora Presion BERMADguzman_10No ratings yet

- Spesifikasi Bolt, Nut & WasherDocument7 pagesSpesifikasi Bolt, Nut & WasheragieyogaswaraNo ratings yet

- Bermad: Pressure Sustaining and Reducing ValveDocument4 pagesBermad: Pressure Sustaining and Reducing Valveagieyogaswara100% (1)

- Watergems: Water Distribution Modeling and ManagementDocument2 pagesWatergems: Water Distribution Modeling and ManagementagieyogaswaraNo ratings yet

- WW Mun Iom 723 EnglishDocument2 pagesWW Mun Iom 723 EnglishagieyogaswaraNo ratings yet

- Watergems: Water Distribution Modeling and ManagementDocument2 pagesWatergems: Water Distribution Modeling and ManagementagieyogaswaraNo ratings yet

- Westernport Water Uses Watergems To Achieve Automated Distribution SystemDocument2 pagesWesternport Water Uses Watergems To Achieve Automated Distribution SystemagieyogaswaraNo ratings yet

- Spesifikasi Bolt, Nut & WasherDocument7 pagesSpesifikasi Bolt, Nut & WasheragieyogaswaraNo ratings yet

- Borda CarnotDocument52 pagesBorda CarnotSamujawal Kumar SumanNo ratings yet

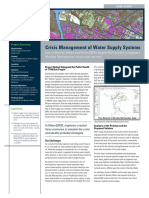

- Crisis Management of Water Supply SystemsDocument2 pagesCrisis Management of Water Supply SystemsagieyogaswaraNo ratings yet

- WIFIDocument11 pagesWIFIpounupr@gmail.comNo ratings yet

- Python Date TimeDocument6 pagesPython Date TimeNataliaNo ratings yet

- Allotement LetterDocument2 pagesAllotement LetterDarshan SolankiNo ratings yet

- Opentext Imaging Enterprise Scan 1050 Installation Guide English Cles100500 Igd en PDFDocument46 pagesOpentext Imaging Enterprise Scan 1050 Installation Guide English Cles100500 Igd en PDFMihai PaunescuNo ratings yet

- PW - RENTALS - Catalog A5 EN - US 2021 7 1Document72 pagesPW - RENTALS - Catalog A5 EN - US 2021 7 1Shih-Bou WangNo ratings yet

- Ps SecurityDocument27 pagesPs SecurityMaster RajaNo ratings yet

- Lesson 1 Cultural BackgroundDocument5 pagesLesson 1 Cultural BackgroundAngel Angeleri-priftis.No ratings yet

- Aeroscout Scout B1-100 BrochureDocument4 pagesAeroscout Scout B1-100 BrochureSebastian RentschNo ratings yet

- Measuring RC Decay Rates of Capacitors in Different Circuit ConfigurationsDocument11 pagesMeasuring RC Decay Rates of Capacitors in Different Circuit ConfigurationsThịnh NguyễnNo ratings yet

- UART Component Examples and Interrupt-Driven Serial CommunicationDocument5 pagesUART Component Examples and Interrupt-Driven Serial CommunicationCarlos Morales CarbajalNo ratings yet

- Omar Elwan 900-07-3202 POLS 415: " Is There A Difference Between The US Position and The Israeli Position On Iran"Document10 pagesOmar Elwan 900-07-3202 POLS 415: " Is There A Difference Between The US Position and The Israeli Position On Iran"Omar ElwanNo ratings yet

- 1032 Fy Fxe Duplex Power Pump PDFDocument2 pages1032 Fy Fxe Duplex Power Pump PDFJunior Francisco QuijanoNo ratings yet

- Joyce Annor Kwakye Recognized As A Professional of The Year by Strathmore's Who's Who Worldwide PublicationDocument2 pagesJoyce Annor Kwakye Recognized As A Professional of The Year by Strathmore's Who's Who Worldwide PublicationPR.comNo ratings yet

- Ultra-low voltage high gain OTA for biomedical appsDocument4 pagesUltra-low voltage high gain OTA for biomedical apps90413027No ratings yet

- Catalogue Standard Air Handling Units Blauair PDFDocument24 pagesCatalogue Standard Air Handling Units Blauair PDFIonut CatalinNo ratings yet

- Ed 2500 Joel Heese Resume 2016Document2 pagesEd 2500 Joel Heese Resume 2016api-320659196No ratings yet

- SID-CPD-03 Rev 02 Self DirectedDocument2 pagesSID-CPD-03 Rev 02 Self DirectedJeff Tingin MarceloNo ratings yet

- Lesson 10 Data and Hardware Protection: Computer Literacy Basics: A Comprehensive Guide To IC, 5 EditionDocument39 pagesLesson 10 Data and Hardware Protection: Computer Literacy Basics: A Comprehensive Guide To IC, 5 EditionJeriz Marie GamboaNo ratings yet

- River View Luxury Homes Clover By The RiverDocument24 pagesRiver View Luxury Homes Clover By The RiverE. PoornimaNo ratings yet

- Ribbon Blenders: and Other Horizontal MixersDocument8 pagesRibbon Blenders: and Other Horizontal MixersHằng NgaNo ratings yet