Professional Documents

Culture Documents

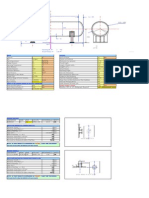

API 653 Minimum Thk. Calculation

API 653 Minimum Thk. Calculation

Uploaded by

Siva baalan0 ratings0% found this document useful (0 votes)

9 views1 pageCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageAPI 653 Minimum Thk. Calculation

API 653 Minimum Thk. Calculation

Uploaded by

Siva baalanCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

API653-THK.

CALCULATION Page 1

MINIMUM THICKNESS CALCULATION FOR WELDED TANK SHELL

1.0 DESIGN CODE & SPECIFICATION

: API 653, 5th Edition

1.1 TANK

Service : Fire Water Tank

Tag Number : T-7001

:

1.2 GEOMETRIC DATA

Inside diameter, Di 45.93 ft = 14000 mm

Tank height, H 49.21 ft = 15000 mm

Specific gravity of operating liquid , S.G. = 1.02

Nominal capacity = 2310.00 m³

Design liquid level, H = 15000 mm

Shell Course Number (1 if 2 & below, 2 if 3 & above) = 1

1.3 MATERIAL & MECHANICAL PROPERTIES

Component = Shell Plate

Material = A 36

Tensile Stress T (psi) = 58000.00

Yield Stress Y (psi) = 36000.00

Corrosion Allowance CA (mm) = 3.00

2.0 SHELL DESIGN THICKNESS CALCULATION

2.1 MATERIAL & MECHANICAL PROPERTIES

Material used : A 36

Specified minimum tensile stress, T = 58000 psi

Specified minimum yield stress, Y = 36000 psi

Joint Efficiency, E = 0.85

Max.allowable design stress,S = 24882 psi

(As per 4.3.3.1 and Table 4.1 )

2.2 TANK SHELL THICKNESS CALCULATION

D = Inside diameter of tank 14000 mm = 45.93 ft

H = Design liquid level 15000 mm = 49.21 ft

G = Specific gravity of liquid = 1.02

CA = corrosion allowance 3 mm = 0.12 in

S = Allow. stress for design condition 172 N/mm² = 24882 psi

Minimum acceptable thickness (tmin) + CA

= 10.20 mm

One-half the minimum acceptable tank shell thickness exclusive of the corrosion allowance (tmin/2)

(As per requirement of 4.3.2.2)

tmin/2 = 3.60 mm

06/01/2021

You might also like

- Invocation of LilithDocument4 pagesInvocation of Liliths.bheeshmar100% (2)

- Section 3 API-650 Practice QuestionsDocument49 pagesSection 3 API-650 Practice QuestionsJosephInbarajan100% (5)

- GottmanDocument106 pagesGottmanesteban brizuelaNo ratings yet

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- 43) API 653 Day 6 Book (1 To 96) IndoDocument96 pages43) API 653 Day 6 Book (1 To 96) IndoSHAHIDALI100% (2)

- 40) Api 653 Day 3 Book (1-56)Document58 pages40) Api 653 Day 3 Book (1-56)SHAHIDALINo ratings yet

- 39) API 653 DAY 2 BOOK (1 To 46)Document46 pages39) API 653 DAY 2 BOOK (1 To 46)SHAHIDALI100% (1)

- BAY.t-510 Open Prac Exam #3Document14 pagesBAY.t-510 Open Prac Exam #3Karim MamdouhNo ratings yet

- 8.inspection CalculationDocument38 pages8.inspection CalculationAMAL VISHNUNo ratings yet

- API 653 CalculationDocument29 pagesAPI 653 Calculationsheikmoin100% (2)

- 44) API 653 Day 7 Book (1 To 52)Document53 pages44) API 653 Day 7 Book (1 To 52)SHAHIDALI100% (1)

- Section 2 API-653 Practice QuestionsDocument56 pagesSection 2 API-653 Practice QuestionsAliDadKhan100% (4)

- API 653 Tank Inspection Code - 04 PDFDocument70 pagesAPI 653 Tank Inspection Code - 04 PDFvignesh100% (1)

- API 653 Vol 1Document128 pagesAPI 653 Vol 1Vicky Kumar92% (12)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Home Making Arts I SyllabusDocument10 pagesHome Making Arts I SyllabusJunar SantiagoNo ratings yet

- Western Home Elevator Design Guide 2011 PDFDocument21 pagesWestern Home Elevator Design Guide 2011 PDFTuấn NamNo ratings yet

- Api 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationDocument2 pagesApi 653 Preparatory Important Closed Book Questions: Professional Training and ConsultationNuwan RanaweeraNo ratings yet

- Api 635 Exam PDFDocument40 pagesApi 635 Exam PDFAhmad Rizki100% (2)

- 38) Api 653 Day 1 Book (1-112)Document115 pages38) Api 653 Day 1 Book (1-112)SHAHIDALI100% (1)

- API 653 QuestionsDocument4 pagesAPI 653 QuestionsRama Jeyam100% (6)

- Final Exam (Open) : InstructionsDocument8 pagesFinal Exam (Open) : InstructionssujadevNo ratings yet

- Api 653Document15 pagesApi 653Sana Alzaki100% (2)

- Api 653 PDFDocument18 pagesApi 653 PDFAhmad Rizki100% (1)

- 653 QB 3Document55 pages653 QB 3Mohamed KHODJA100% (1)

- Api - 653 20-7-2016Document7 pagesApi - 653 20-7-2016Engr Shahid AliNo ratings yet

- Api 653Document11 pagesApi 653raghava1975No ratings yet

- 42) API 653 DAY 5 BOOK (1 To 58)Document58 pages42) API 653 DAY 5 BOOK (1 To 58)SHAHIDALI100% (2)

- Question 36 Begins The Closed Book Portion of This ExamDocument25 pagesQuestion 36 Begins The Closed Book Portion of This ExamBeantickNo ratings yet

- API653 Closed Book QDocument23 pagesAPI653 Closed Book Qabsarya100% (8)

- API 653 NotesDocument10 pagesAPI 653 Notesamine bouizarNo ratings yet

- Api 653 QuestionsDocument28 pagesApi 653 Questionskorichi100% (2)

- API 653 - Section 650 Flashcards - QuizletDocument6 pagesAPI 653 - Section 650 Flashcards - Quizletام يمنى ايمنNo ratings yet

- API 653 Quiz 1answersDocument4 pagesAPI 653 Quiz 1answersfazeel mohammedNo ratings yet

- API 510 Data Sheets - QuizletDocument1 pageAPI 510 Data Sheets - Quizletads_1203No ratings yet

- Above Ground Storage Tanks PresentationDocument28 pagesAbove Ground Storage Tanks PresentationRamesh sivanNo ratings yet

- TDI33 Tank Inspection Suitaility For Service API 653 Sec 4Document29 pagesTDI33 Tank Inspection Suitaility For Service API 653 Sec 4Faizal SattuNo ratings yet

- Understanding API ICP653 Reading 18-Worksheet-12Document144 pagesUnderstanding API ICP653 Reading 18-Worksheet-12Charlie Chong100% (2)

- Important Closed Book Quiz-API-653Document3 pagesImportant Closed Book Quiz-API-653Basel Mohammad100% (1)

- Understanding API ICP653 Reading 8-Worksheet-03Document231 pagesUnderstanding API ICP653 Reading 8-Worksheet-03Charlie Chong100% (5)

- Chapter3API653 Tank InspectionDocument106 pagesChapter3API653 Tank InspectioniraprobotNo ratings yet

- API 653 Quiz 1Document3 pagesAPI 653 Quiz 1fazeel mohammedNo ratings yet

- 1 API 653 Memories March 2014 ExamDocument16 pages1 API 653 Memories March 2014 ExammajidNo ratings yet

- API653 Practice QuestionsDocument2 pagesAPI653 Practice QuestionsemadazNo ratings yet

- API-570 - Data Sheets (2018 Test)Document6 pagesAPI-570 - Data Sheets (2018 Test)mahmoud alwasif100% (1)

- 44) API 653 DAY 7 BOOK (1 To 52)Document53 pages44) API 653 DAY 7 BOOK (1 To 52)SHAHIDALI100% (2)

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- 26feb05 4 ClosedDocument5 pages26feb05 4 Closedmitesh100% (1)

- Optimum CosineDocument17 pagesOptimum CosinetomcanNo ratings yet

- Api-653 QBDocument15 pagesApi-653 QBgurdeepsarora8738100% (5)

- API 653 PC 26feb05 Question BankDocument80 pagesAPI 653 PC 26feb05 Question Bankraobabar21No ratings yet

- API-653-Vol 2Document122 pagesAPI-653-Vol 2Vicky Kumar100% (7)

- API 653 Exam 2 ClosedDocument5 pagesAPI 653 Exam 2 ClosedAriq FauzanNo ratings yet

- CKRC API 653 WORKBOOK MODULE 2 AIT Rev 1Document18 pagesCKRC API 653 WORKBOOK MODULE 2 AIT Rev 1CHANDRA BHUSHAN KESARI100% (1)

- API 510 QUIZ No.4Document5 pagesAPI 510 QUIZ No.4Hatem RagabNo ratings yet

- 1 API 653 Memories March 2014 ExamDocument20 pages1 API 653 Memories March 2014 ExamHaris Khan83% (6)

- Section 1 - Scope: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Document49 pagesSection 1 - Scope: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Shaalan AliNo ratings yet

- Api Tank 400M3 HCDocument10 pagesApi Tank 400M3 HCCharles DogneNo ratings yet

- API 650 Storage Tank 2400Document34 pagesAPI 650 Storage Tank 2400PANOLI PROJECTNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Raw Water Tank-DataDocument1 pageRaw Water Tank-DataSivaArabiNo ratings yet

- Binder 1Document68 pagesBinder 1Anh KyNo ratings yet

- ASME BPVC VIII MinT CalculationsDocument2 pagesASME BPVC VIII MinT CalculationsSbuZikalalaNo ratings yet

- Calculation Sheet: Act IDocument2 pagesCalculation Sheet: Act IFazri CMENo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Saddle Support CstanDocument19 pagesSaddle Support CstanSiva baalanNo ratings yet

- Support Leg DesignDocument4 pagesSupport Leg DesignSiva baalanNo ratings yet

- How To Calculate Flat Plate Thickness of Flat Bottom Storage TankDocument3 pagesHow To Calculate Flat Plate Thickness of Flat Bottom Storage TankSiva baalan100% (1)

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNo ratings yet

- GOFLI9bf5d1455876270 AI908 HTYBGDocument1 pageGOFLI9bf5d1455876270 AI908 HTYBGSiva baalanNo ratings yet

- Chennai To MuscutDocument1 pageChennai To MuscutSiva baalanNo ratings yet

- Sangfor IAM V12.0.17 Associate 2019 01 IntroductionDocument22 pagesSangfor IAM V12.0.17 Associate 2019 01 IntroductionGilangNo ratings yet

- Ich M4Q Common Technical Document For The Registration of Pharmaceuticals For Human Use - QualityDocument22 pagesIch M4Q Common Technical Document For The Registration of Pharmaceuticals For Human Use - QualityShiraz KhanNo ratings yet

- Game Sounds Ambient GenericDocument10 pagesGame Sounds Ambient GenericdanchristianoNo ratings yet

- NG Gan Zee v. Asian Crusader Life Assurance CorpDocument7 pagesNG Gan Zee v. Asian Crusader Life Assurance Corpmisty-sunNo ratings yet

- FMCPDAW07 Application Form Permitto OperateDocument2 pagesFMCPDAW07 Application Form Permitto OperateLorena CelestinoNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesCarl AnthonyNo ratings yet

- Entrepreneurship and Business Development PlanDocument16 pagesEntrepreneurship and Business Development PlanBidulaNo ratings yet

- Nurses LE 11-2022Document242 pagesNurses LE 11-2022PRC Baguio33% (3)

- Formulation and Molecular Docking Simulation Study of LuliconazoleDocument18 pagesFormulation and Molecular Docking Simulation Study of LuliconazoleMuhammad Shehr YarNo ratings yet

- S1062359022700030 PDFDocument7 pagesS1062359022700030 PDFVengateshwaran TDNo ratings yet

- Obstetrical Nursing AntepartumDocument28 pagesObstetrical Nursing AntepartumAyeza DuaNo ratings yet

- ML 071690245Document215 pagesML 071690245Silviu MihaiNo ratings yet

- Modulus II PlusDocument10 pagesModulus II PlusMiguelNo ratings yet

- Antiseptics & DisinfectantsDocument33 pagesAntiseptics & DisinfectantsChoice OrganoNo ratings yet

- Van Der Waal's Constants For Real Gases: Molecular Formula NameDocument14 pagesVan Der Waal's Constants For Real Gases: Molecular Formula NameDragan PavlovicNo ratings yet

- Defects in PaintDocument6 pagesDefects in Paintsonu024100% (1)

- PVP2000-PVP5200 Data Sheet PDFDocument2 pagesPVP2000-PVP5200 Data Sheet PDFRES SupplyNo ratings yet

- Form 3 - Chemistry - Assignment - 237 - 1590689559732-CHEM-F3Document157 pagesForm 3 - Chemistry - Assignment - 237 - 1590689559732-CHEM-F3JosephNo ratings yet

- A Technical Note: A Short Note On Processing of Bamboo JuiceDocument4 pagesA Technical Note: A Short Note On Processing of Bamboo JuiceLe Fidus MalauNo ratings yet

- Municipal Hall Subproject DescriptionDocument4 pagesMunicipal Hall Subproject DescriptionJamil B. AsumNo ratings yet

- Rwanda Defence Force 27Document28 pagesRwanda Defence Force 27Eustache NIJEJENo ratings yet

- 04 - Arsari Putri AkhsantiDocument3 pages04 - Arsari Putri AkhsantiMasnaini AndrianaNo ratings yet

- 12 EnterobacteriaciaeDocument29 pages12 EnterobacteriaciaeASECO LISH50% (2)

- Esquema EquipoDocument152 pagesEsquema EquipoHernan SamNo ratings yet

- B1 Quiz 2Document2 pagesB1 Quiz 2Назар КуликNo ratings yet

- Datasheet of ACS730Document25 pagesDatasheet of ACS730Nguyên NghĩaNo ratings yet