Professional Documents

Culture Documents

MC ASD Prying Ref 0

Uploaded by

Roberto Ramirez Alcantar0 ratings0% found this document useful (0 votes)

25 views2 pagesOriginal Title

253424225-MC-ASD-Prying-Ref-0

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesMC ASD Prying Ref 0

Uploaded by

Roberto Ramirez AlcantarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

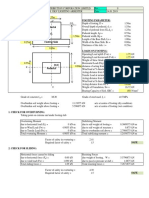

"PRYING9.

xls" Program

Version 2.0

PRYING ACTION ANALYSIS

For Structural Steel Connections

Per AISC 9th Edition Manual (ASD) - Pages 4-89 to 4-95

Job Name: Subject:

Job Number: Originator: Checker:

Input Data:

Total Tension Load, Tt = 53.70 kips bf/2=4.25

Total Shear Load, Vt = 26.80 kips g/2=2.75

Steel Yield, Fy = 36 ksi db=0.75 Q=2.94

Bolt Diameter, db = 0.750 in.

ASTM Bolt Desig. = A325 t=0.625

Bolt Type (N, X, or SC) = N

Bolt Hole Type = Standard T+Q=11.89

Tributary Length/Bolt, p = 4.500 in. tw=1.75 b'=1.5 a'=1.875

Total No. of Bolts, Nb = 6 bolts

Width, bf = 8.5000 in. b=1.875 a=1.5

Thickness, t = 0.6250 in. M2

Thickness, tw = 1.7500 in.

Bolt Gage, g = 5.500 in.

No. of Loading Cycles = 20000 (for 25 years)

M1

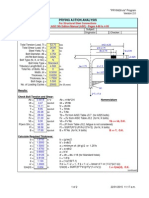

Results:

2*T=17.9

Check Bolt Tension and Shear:

Ab = 0.4418 in.^2 Ab = *db^2/4 Nomenclature

vb = 4.47 kips/bolt vb = Vt/Nb

fv = 10.11 ksi fv = vb/Ab

T= 8.95 kips/bolt T = Tt/Nb

ft = 20.26 ksi ft = T/Ab

Tb = 28.00 kips Tb = Tb from AISC Table J3.7 (for A325 bolts)

Fv = 21.00 ksi Fv = Fv from AISC Table J3.2 (for N, X bolts)

Vb = 9.30 kips/bolt Vb = Fv*Ab Vb >= vb, O.K.

Ft(w/o Shr.) = 44.00 ksi Ft = (Ft from Table J3.2, fatigue is not considered)

Ft = 38.56 ksi Ft = SQRT(Ft^2-(Ft/Fv)^2*fv^2) (for N, X bolts)

B= 17.00 kips/bolt B = Ft*Ab (for N, X bolts) B >= T, O.K.

Calculate Required Thickness:

b = 1.8750 in. b = (g-tw)/2

b' = 1.5000 in. b' = b-db/2

a = 1.5000 in. a = minimum of: (bf-g)/2 or 1.25*b

a' = 1.8750 in. a' = a+db/2

= 0.8000 = b'/a'

d' = 0.8125 in. d' = dh = db+1/16 (for Standard holes)

= 0.8194 = 1-d'/p

= 1.124 = (1/)*(B/T-1)

' = 1.0000 If >= 1: ' = 1, If < 1: ' = lesser of 1 or (1/)*(/(1-))

t(req'd) = 0.604 in. t(req'd) = SQRT(8*T*b'/(p*Fy*(1+*'))) t >= t(req'd), O.K.

(continued)

1 of 2 22/01/2015 11:17 a.m.

"PRYING9.xls" Program

Version 2.0

Calculate Prying Force, Q:

tc = 1.122 in. tc = SQRT(8*B*b'/(p*Fy)) (to develop 'B' in bolts/no prying)

= 0.851 = 1/*((T/B)/(t/tc)^2-1) (Note: 0 <= a <= 1.0)

Q= 2.94 kips Q = B****(t/tc)^2 (prying force per bolt at design load)

Check Allowable Bolt Tension with Prying Action:

' = 1.5076 ' = 1/(*(1+))*((tc/t)^2-1)

Ta = 9.59 kips If ' >1: Ta = B*(t/tc)^2*(1+) , If ' < 0: Ta = B

If 0 <= ' <= 1: Ta = B*(t/tc)^2*(1+*')

Ta >= T, O.K.

Calculate Required Thickness to Eliminate Prying Action:

t(req'd) = 0.814 in. t(req'd) = SQRT(8*T*b'/(p*Fy))

Comments:

2 of 2 22/01/2015 11:17 a.m.

You might also like

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarNo ratings yet

- Calculations of HEB260 beam splice connectionsDocument23 pagesCalculations of HEB260 beam splice connectionsLudovicoVicoNo ratings yet

- Jindal ProfilesDocument15 pagesJindal ProfilesJane NishaNo ratings yet

- Moment To Column WebDocument905 pagesMoment To Column WebAmanpreet SinghNo ratings yet

- Indes Enginnering: Design Code - IS800:2007Document2 pagesIndes Enginnering: Design Code - IS800:2007KARTHIK SGNo ratings yet

- LSP 610 Project Quantities SheetDocument1 pageLSP 610 Project Quantities Sheeteduardox11No ratings yet

- Tubular Sections-Hazira Project (Available)Document3 pagesTubular Sections-Hazira Project (Available)Ouseppachan AmbookenNo ratings yet

- Design Calculation Report for Tower Foundation and SuperstructureDocument10 pagesDesign Calculation Report for Tower Foundation and SuperstructureghansaNo ratings yet

- HILTI RE-500 Rebar ConnectionDocument7 pagesHILTI RE-500 Rebar ConnectionAlma M. LaraNo ratings yet

- Universal Beam and Column Properties SheetDocument11 pagesUniversal Beam and Column Properties SheetkalpanaadhiNo ratings yet

- Eccentric Footing Design Based On ACI 318-14: Input Data Design SummaryDocument3 pagesEccentric Footing Design Based On ACI 318-14: Input Data Design SummaryFatima tuz ZohraNo ratings yet

- Base Plate Ver Brace Connection - Column FlangeDocument27 pagesBase Plate Ver Brace Connection - Column FlangeAnıl Berk SağırNo ratings yet

- For Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Document43 pagesFor Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Mohan BhalmeNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Ankeri SI JediniceDocument30 pagesAnkeri SI Jedinicepperic13No ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Vertical Vessal FoundationDocument27 pagesVertical Vessal FoundationA GNo ratings yet

- 2.3.4 Design Parameters - Design Per AISC 360-05 and 360-10 (Unified)Document6 pages2.3.4 Design Parameters - Design Per AISC 360-05 and 360-10 (Unified)HamdiNo ratings yet

- The - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcreteDocument9 pagesThe - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcretejscuencaNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- B85 - Tie Beam Transverse TB-1Document8 pagesB85 - Tie Beam Transverse TB-1FrederickV.VelascoNo ratings yet

- Combined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZDocument3 pagesCombined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZkiran raghukiranNo ratings yet

- Anchor Bolt Design Apdx D ACI318 05Document4 pagesAnchor Bolt Design Apdx D ACI318 05Mohammed HanafiNo ratings yet

- IP4 design reaction summary and analysisDocument8 pagesIP4 design reaction summary and analysisFarhan DanishNo ratings yet

- Design Criteria/Design Check For Star Deck Sheet (44/130)Document2 pagesDesign Criteria/Design Check For Star Deck Sheet (44/130)Advanced Structural EngineeringNo ratings yet

- Larsen & Toubro Limited - Ecc DivisionDocument1 pageLarsen & Toubro Limited - Ecc DivisionOuseppachan AmbookenNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- 1 VB Connection 2lto HL Beam One G.PL NSFDocument32 pages1 VB Connection 2lto HL Beam One G.PL NSFWintun73No ratings yet

- 1.SHEAR (Or) MOMENT CONNE-GENERALDocument272 pages1.SHEAR (Or) MOMENT CONNE-GENERALbalaNo ratings yet

- Wind Load GTPOGTDocument2 pagesWind Load GTPOGTAnonymous 2CMPbqwBNo ratings yet

- Moment Connection - Beam SpliceDocument3 pagesMoment Connection - Beam SpliceSh MNNo ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- Turkey temporary facility pedestal designDocument23 pagesTurkey temporary facility pedestal designMyunSu GooNo ratings yet

- U G TankDocument5 pagesU G TankVikram GaikwadNo ratings yet

- Welded & Pinned Connection Design CalculationDocument14 pagesWelded & Pinned Connection Design CalculationPrakash Singh RawalNo ratings yet

- 18) UC203x203x46toUC254x254x73-B2CF - MCDocument125 pages18) UC203x203x46toUC254x254x73-B2CF - MCAsaru DeenNo ratings yet

- Connection Design ProcedureDocument3 pagesConnection Design ProcedurewendyNo ratings yet

- Standard Isolated Footing f1Document11 pagesStandard Isolated Footing f1Saajan bhathalNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AKARTHIK SGNo ratings yet

- Fillet Weld Connection DesignDocument1 pageFillet Weld Connection Designbalaji gmscNo ratings yet

- Wind Speed Map IndiaDocument12 pagesWind Speed Map IndiaAn1rudh_Sharma100% (1)

- Assume A Plate Girder of The Following Properties: Span of Beam (L)Document10 pagesAssume A Plate Girder of The Following Properties: Span of Beam (L)D SRINIVASNo ratings yet

- Shiva Infra Solutions Pvt. LTD.: Quote Request / Work Order Form Page 1 of 2Document3 pagesShiva Infra Solutions Pvt. LTD.: Quote Request / Work Order Form Page 1 of 2Naveen RohiraNo ratings yet

- Base Plate - 09-08-2018Document6 pagesBase Plate - 09-08-2018zakaria200811060No ratings yet

- Base Plate - Connection Plate Design-B401 - 12.08.2019Document12 pagesBase Plate - Connection Plate Design-B401 - 12.08.2019Siddharth TiwariNo ratings yet

- Basic Design Parameters:: Concrete Anchor Bolt Design Based On Aci318-11Document18 pagesBasic Design Parameters:: Concrete Anchor Bolt Design Based On Aci318-11onlyikramNo ratings yet

- 33kV lighting arrestand foundation designDocument2 pages33kV lighting arrestand foundation designKausik DewanNo ratings yet

- "Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesDocument16 pages"Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesArdXkillerNo ratings yet

- Base Plate Uc152x152x23Document2 pagesBase Plate Uc152x152x23sonofalexanderNo ratings yet

- StiffenerDocument11 pagesStiffenerAdigwe George ChimaNo ratings yet

- Base Plate Design (Pin) Asd For CompressionDocument54 pagesBase Plate Design (Pin) Asd For CompressionEmdadul HuqNo ratings yet

- HDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Document8 pagesHDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Mohammad Shadab AliNo ratings yet

- Shear Strength Controls 21.65 Kips/bolt: Section at ADocument4 pagesShear Strength Controls 21.65 Kips/bolt: Section at AmaheshbandhamNo ratings yet

- Rev G Connection-Double AngleDocument12 pagesRev G Connection-Double AnglePankaj_Taneja_9684No ratings yet

- Prying Action Analysis: Input DataDocument2 pagesPrying Action Analysis: Input Datarodriguez.gaytanNo ratings yet

- "Prying9" - Aisc 9Th Ed. Prying Action Analysis ProgramDocument5 pages"Prying9" - Aisc 9Th Ed. Prying Action Analysis Programmarina10No ratings yet

- "Prying9" - Aisc 9Th Ed. Prying Action Analysis ProgramDocument5 pages"Prying9" - Aisc 9Th Ed. Prying Action Analysis ProgramGerald JarquinNo ratings yet

- Prying Action Analysis Per AISC 9th Edition (ASD)Document5 pagesPrying Action Analysis Per AISC 9th Edition (ASD)Anonymous w5SJiLsNo ratings yet

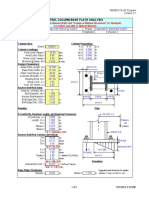

- BASEPLT9.xls Program Version 3.7 Steel Column Base Plate AnalysisDocument1 pageBASEPLT9.xls Program Version 3.7 Steel Column Base Plate AnalysisNagender Kumar0% (1)

- How Can I Play League of Legends (LOL) ?Document5 pagesHow Can I Play League of Legends (LOL) ?Roberto Ramirez AlcantarNo ratings yet

- Methods of Calculation of Resistance To Polarization (Corrosion Rate) Using Astm G 59Document19 pagesMethods of Calculation of Resistance To Polarization (Corrosion Rate) Using Astm G 59Jessica AlejandraNo ratings yet

- Seismic Design of Steel DeckDocument42 pagesSeismic Design of Steel DeckRoberto Ramirez AlcantarNo ratings yet

- ACI Concrete Copyright License InfoDocument1 pageACI Concrete Copyright License InfoRoberto Ramirez AlcantarNo ratings yet

- Aisc Design Examples v14Document125 pagesAisc Design Examples v14Daniyal Ahmed100% (2)

- AEcoupler Acoplador EADocument11 pagesAEcoupler Acoplador EARoberto Ramirez AlcantarNo ratings yet

- Ficha Tecnica AcelerometroDocument7 pagesFicha Tecnica AcelerometroRoberto Ramirez AlcantarNo ratings yet

- IntermediateFEAwithOSS PreviewDocument64 pagesIntermediateFEAwithOSS PreviewjavimmNo ratings yet

- IntermediateFEAwithOSS PreviewDocument64 pagesIntermediateFEAwithOSS PreviewjavimmNo ratings yet

- Ficha Tecnica AcelerometroDocument7 pagesFicha Tecnica AcelerometroRoberto Ramirez AlcantarNo ratings yet

- FEAusingOSS Ed2 PreviewDocument122 pagesFEAusingOSS Ed2 PreviewjavimmNo ratings yet

- Network Operating Systems and Distributed OS ConceptsDocument43 pagesNetwork Operating Systems and Distributed OS ConceptsDr. Atta ur Rehman KhanNo ratings yet

- Practical Application of Refrigerants R600A and R290 in Small Hermetic SystemsDocument20 pagesPractical Application of Refrigerants R600A and R290 in Small Hermetic SystemsTedy Corimanya SoriaNo ratings yet

- CPK Guide 0211 TECH1Document11 pagesCPK Guide 0211 TECH1Mark LacroNo ratings yet

- RatioandRegressionMethodofEstimation Lecture7 10Document30 pagesRatioandRegressionMethodofEstimation Lecture7 10mrpakistan444No ratings yet

- Excel CheatsheetDocument1 pageExcel CheatsheetBoring BlandNo ratings yet

- Research Paper - Allison PorterDocument13 pagesResearch Paper - Allison Porterapi-609389611No ratings yet

- Motor Control Circuit Activity Ladder DiagramDocument11 pagesMotor Control Circuit Activity Ladder DiagramAJ LunaNo ratings yet

- Spekers ProjectDocument2 pagesSpekers ProjectIsa JoyceNo ratings yet

- File (SQL Tutorial)Document81 pagesFile (SQL Tutorial)imranbaiggeekNo ratings yet

- Microprocessors Memory Addressing Modes PaperDocument2 pagesMicroprocessors Memory Addressing Modes PaperMimansha SharmaNo ratings yet

- CSC 222 - Lecture 1Document30 pagesCSC 222 - Lecture 1trenches4446No ratings yet

- Bolted Angle CleatdesignDocument1 pageBolted Angle CleatdesignAnonymous koR9VtfNo ratings yet

- PSSE Power Flow and Steady State Online Course Notes 1Document504 pagesPSSE Power Flow and Steady State Online Course Notes 1Hamza Abarchi Halarou100% (1)

- Throughput Digram - Logistic Operating Curves in Theory and PracticeDocument21 pagesThroughput Digram - Logistic Operating Curves in Theory and PracticeCibelle LimaNo ratings yet

- Quantum Computing With Spin Qubits in Semiconductor Structures (Computer Physics Communications, Vol. 146, Issue 3) (2002)Document8 pagesQuantum Computing With Spin Qubits in Semiconductor Structures (Computer Physics Communications, Vol. 146, Issue 3) (2002)sepot24093No ratings yet

- Rainvue SeriesDocument50 pagesRainvue Seriesradicall8No ratings yet

- Assessment of Customer Relationship Management On Central Hotel in The Case Hawassa CityDocument41 pagesAssessment of Customer Relationship Management On Central Hotel in The Case Hawassa Cityasu manNo ratings yet

- Q4FY23 Investor PresentationDocument49 pagesQ4FY23 Investor PresentationAradhyaNo ratings yet

- Faq NrtsDocument2 pagesFaq NrtsSachin ParamashettiNo ratings yet

- Reading Innovation Via ProFuturo SolutionDocument7 pagesReading Innovation Via ProFuturo SolutionMa Cristina ServandoNo ratings yet

- APCOB Recruitment for 35 Staff Assistant PostsDocument17 pagesAPCOB Recruitment for 35 Staff Assistant Postsgowthami ravinuthalaNo ratings yet

- As Cfe Interop 61850 en PDFDocument29 pagesAs Cfe Interop 61850 en PDFlhuizxNo ratings yet

- Sri Lanka water network flow calculationsDocument2 pagesSri Lanka water network flow calculationsNiroshan SridharanNo ratings yet

- SAP Baseline Security Audit: Essential Technical ControlsDocument5 pagesSAP Baseline Security Audit: Essential Technical ControlsRanjeet SinghNo ratings yet

- AWM 5000 Series Microbridge Mass Airflow Sensor: Installation Instructions For TheDocument2 pagesAWM 5000 Series Microbridge Mass Airflow Sensor: Installation Instructions For ThewidsonmeloNo ratings yet

- Mentorpaper 36762Document24 pagesMentorpaper 36762Sarath BondaruNo ratings yet

- HILTI CE - Ch.9 - Firestop PDFDocument30 pagesHILTI CE - Ch.9 - Firestop PDFValentin A.No ratings yet

- Learning Support G7 2023Document6 pagesLearning Support G7 2023Aiza SulemanNo ratings yet

- Numerical Methods Project TemplateDocument14 pagesNumerical Methods Project TemplateMikaela Dela CruzNo ratings yet

- Smart BeltDocument9 pagesSmart BeltDavid SfkaNo ratings yet