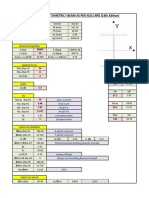

BASEPLATE DESIGN PINNED BASE Prepared by SUNDAR

IS800-2007 Checked by SUNEEL

(Working Stress Method) Date 24-04-2017

Project No : 101 Document No : 101

My

Fx

Fz

[Link] 1

Grid Load case Shear Vertical Shear

Forces

Fx Fy Fz

L/C kN kN kN

F1-A/1 0 780 3150 11

BH450x450x15x30

Column Data

Depth Width Web tk flange tk Area Grade Orientatio

h bf tw tf Ag fy fu n, q

mm mm mm mm mm2 N/mm2 N/mm2 mm

450 450 15 30 E250 240 410 0

Thickness Width Length Stiffener Edge condition Grade

Base Plate

A B C fy fu

mm mm mm N/mm2 N/mm2

35 850 850 Yes 2S Fixed-2Side Free E350 330 490

No. of

bolt [Link] Dia hole [Link] Net Area PL TL L Grade

Bolt Data

Embedment

d do Asb Anb Length Lanc fyb fub

n mm mm mm2 mm2 mm mm mm mm N/mm2 N/mm2

8 42 55 1385 1081 865 220 270 1085 E250 230 410 IS 1732

Bolt Location

Distance Pitch Check

Edge Dist Edge Dist

M N p X dir X dir Min Edge Dist (1.5 do)

mm mm mm mm mm mm

315 325 315 110 100 83 Safe

Depth Thickness

D Rotation t1 t2 fy fu

2

Provision Profile mm degrees mm mm Grade N/mm N/mm2

Shear Key

Yes PT450x20 350 0 0 0 E350 330 490

Distance F Distance G Section modulus Zx Section modulus Zz

^r to Xdir ^r to Z dir ^r to Xdir ^r to Zdir

mm mm mm3 mm3

450 20 6,75,000 30,000

Depth Width Thickness Compressive strength Allowable Comp stress Allowable Bond stress

Pedestal

scc tbd

Grout

fck

2 2

mm mm mm Grade N/mm N/mm N/mm2

1,050 1,050 50 M25 25 6.0 0.9

IS 456 : Table 21 IS 456 : Table 21

Allowable Shear stress

Column to Base Plate Shear Key to tbd

Rib to Flange

Flanges Web Base Plate Yeild Ultimate N/mm2

0.3

Weld

U V U V RU RV ZU ZV fy,w fu,w

2 2

mm mm mm mm mm mm mm mm Grade N/mm N/mm IS 456 : Table 23 (pt

12 12 8 8 8 6 8 6 E70XX 400 490 =0.5)

Thickness Length No Plate

Grade

Rib Plate

J Lrib per side fy fu

mm mm N/mm2 N/mm2

20 200 2 E350 350 490

2 Base Plate for Compression CASE 2 1

1 of 5

� Compression force on Column C= 3150 kN

Actual bearing stress on concrete = 3150*1000/(850*850) = 4.36 N/mm2

Allowable bearing stress on concrete = 6.00 N/mm2 >= 4.36 N/mm2 Safe UR=0.73

2A Case 1 : Unstiffended base plate

IS800:

Effective Bearing area A = 525000 mm2

Table

[Link]

Area 1

Area 2

Area 3

L1 L2 L3

Assumed C 141.00 mm Variation 0.93

Effective Area Calc

Length Width y2 Total Area

i Nos

mm mm mm2 mm2

Area 1 732 171 2 250344

Area 2 732 141 2 206424 b1 b2 b3

Area 3 108 297 1 32076 488844

IS800:

Minimum Thickness required

Table

[Link] [Link] = SQRT{ 3*scc*c2 / (0.75*fy)} = SQRT(3*4.36*141.00*141.00/(0.75*330)) = 32 mm < 35 Safe UR=0.00

tBp > tf tf = 30 mm < 35 Safe o.k

2B Case 2: Stiffended base plate with 2 adjacent sides supported.

Y a

a 190.00 Reference from Roarks Table 11.4- 11

b 150.00 1 2 3 4 5 6 For Interpolation

a/b 0.79 a/b 0.125 0.25 0.375 0.5 0.75 1 0.75 1

b

b1 1.3286 b1 0.05 0.182 0.353 0.631 1.246 1.769 1.246 1.769

b2 1.2781 b2 0.047 0.188 0.398 0.632 1.186 1.769 1.186 1.769

Pressure on base plate = 3150*1000/(850*850) = 4 N/mm2

Min. Thickness of plate reqd, tBp1 =SQRT{ b 1*q*b /(0.75*f y )}

2

= SQRT( 1.32857894736842*4*150.00*150.00/(0.75*330)) = 23 mm < 35 Safe UR=0.66

Min. Thickness of plate reqd, tBp2 =SQRT{ b 2*q*b /(0.75*f y )}

2

= SQRT( 1.27805263157895*4*150.00*150.00/(0.75*330)) = 23 mm < 35 Safe UR=0.64

2C Case 3: Stiffended base plate with 3 adjacent sides supported.

Y a Dimensions

a 190.00 Reference from Roarks Table 11.4 -10

b 150.00 1 2 3 4 5 6 For Interpolation

a/b 0.79 a/b 0.25 0.5 0.75 1 1.5 2 3 0.75 1

b

b1 0.1964 b1 0.02 0.081 0.173 0.321 0.727 1.226 2.105 0.173 0.321

b2 0.1655 b2 0.016 0.066 0.148 0.259 0.484 0.605 0.519 0.148 0.259

b3 0.1655 b3 0.031 0.126 0.286 0.511 1.073 1.568 1.982 0.148 0.259

Pressure on base plate = 3150*1000/(850*850) = 4 N/mm2

Min. Thickness of plate reqd, tBp1 =SQRT{ b 1*q*b /(0.75*f y )}

2

= SQRT( .196368421052632*4*150.00*150.00/(0.75*330)) = 9 mm < 35 Safe UR=0.00

Min. Thickness of plate reqd, tBp2 =SQRT{ b 2*q*b 2 /(0.75*f y )}

= SQRT( .165526315789474*4*150.00*150.00/(0.75*330)) = 8 mm < 35 Safe UR=0.00

Min. Thickness of plate reqd, tBp3 =SQRT{ b 3*q*b /(0.75*f y )}

2

= SQRT( .165526315789474*4*150.00*150.00/(0.75*330)) = 8 mm < 35 Safe UR=0.00

2D Shear Resistance by Friction

Design

Coefficient of Friction between base plate and Grout m= 0.30

Criteria

6.2.d

Compression force on Column C= 3150 kN

Shear resistance by Friction V c = m *F y = 0.30*3150 = 945 mm

Resultant Shear force Vx = SQRT ( Fx2 + Fz2) = SQRT(780^2+11^2) = 780 kN < 945 Safe 0.8:SK-0.83

2 of 5

� 3 Base Plate for Tension 0 0

*** Shear force are assumed to be transferred through Friction or through Shear key only)****

3A Check for Anchor Bolt for Tension

Tension force on Column T= 0 kN

Max Tension on bolt Ts = {T/n} = (0/8) = 0 kN

IS800: cl Tension Capacity

[Link] Tnb =0.6 x (0.9 x fubxAnb) = 0.6*(0.9*410*1081)/1000 = 239 kN >= 0 kN Safe UR=0.00

Tng =0.6 x (fybxAnbxgmb/gm0) = 0.6*(230*1081*1.25/1.1)/1000 = 169 kN >= 0 kN Safe

3B Length of anchor bolts embedded in concrete-Based on Bonding only

ss = Stress on anchor bolt = 0*1000/1385 = 0.000 N/mm2

IS456: Development legth of bar

cl 26.2 Ld = d * ss / ( 4* tbd ) = 42*0.000/(4*0.9) = 0 mm < 865 Safe

3B1 Bolt Pullout strength

Bond Strength = (3.14*42*865)*0.9/1000 = 103 kN

Bearing of Bolt head/Nut/Washer (Diameter Nut assumed 1.5d)

2 2

Bearing area, A2 = 3.14*[(1.5*d) -d ] /4 = 3.14*((1.5*42)^2-42^2)/4 = 1731 mm2 (Concrete pedestal shall be min +200mm

Effective dispersment area, A1 = (110+200)*(100+200) = 93000 mm2 from edge of base plate )

IS456: Bearing pressure amplification factor (SQRT (A1/A2)) = MIN(SQRT(93000/1731),2) = 2

Cl34.4

IS456: Allowable bearing stress on concrete, scc = 2*6.0 = 12 N/mm2

Table 21

End bearing strength = 1731*12/1000 = 21 kN

Total Tensile Resistance of Bolt = 103+21 = 123 kN >= 0 kN Safe UR=0.00

3B2 Concrete Cone Breakout strength ( Rough Check only - Pedestal shall be sized & reinforced by Foundation Engg)

Concervatively assumption on Cone diameter = MIN(83+200,315,325) = 283 mm

Height of cone (35degree dispersion) = 198 mm

Surface area of cone = 175466 mm2

Cone Shear Stress, = 0.00 N/mm2

Allowable Shear stress in concrete = 0.31 N/mm2 >= 0 N/mm2 Safe UR=0.00

3C Case 1 : Unstiffened Base Plate a1

Max Tension force on each bolt Ts= 0 kN

Distance from nearest stiffened edge a1= 100.00 mm 2a1

Moment Due to Ts, M = Ts * a1 = 0*100.00/1000 = 0 kN.m

treqd1= SQRT{ 6 M / ( 2*a1 0.75*fy)} = SQRT(6*0*10^6/(2*100.00*0.75*330)) = 0 mm < 35 Safe UR=0.00

3D Case 2 : 2 Sides Fixed - 2 Side Free

Max Tension force on each bolt Ts= 0 kN

a1 Dimensions d1 = T 1 a1 3 /3EI

a1 100.00 d2 = T 2 b1 3 /3EI

b1 75.00 By equating d 1 & d 2 , 3

T 1 = T 2 b1 /a1

3

--- (1)

T1 + T2= Ts --- (2)

3 3

2a1

Solving Eq (1) & (2) T2 T 2 = T/(1+b1 /a1 )

T2= = 0/(1+(75.00^3)/(100.00^3)) = 0 kN

b1

T1= = 0-0 = 0 kN

2b1

Moment Due to T1, M1 = T1 * a1 = 0*100.00/1000 = 0 kN.m

treqd1= SQRT{ 6 M1 / ( 2*a1* 0.75*fy)} = SQRT(6*0*10^6/(2*100.00*0.75*330)) = 0 mm < 35 Safe UR=0.00

Moment Due to T2, M2 = T2 * b1 = 0*75.00/1000 = 0 kN.m

treqd2= SQRT{ 6 M2 / ( 2*b1 *0.75*fy)} = SQRT(6*0*10^6/(2*75.00*0.75*330)) = 0 mm < 35 Safe UR=0.00

3E Case 3 : 3 Sides Fixed - 1 Side Free

Max Tension force on each bolt Ts= 0 kN

a

3 of 5

� Dimensions

a 190

b 150

b b1 75

b1

Ref. EQ. 3.68, 'STORAGE STRUCTURES' by [Link]

treqd2= SQRT {3.91* Ts / [ fy*(2b/a + a/2b1-d*(2/a+1/2b1) ] }

= SQRT((3.91*0*1000)/(330*(2*150/190)+(190/2/75)-(42*(2/190+1/2/75)))) = 0 mm < 35 Safe UR=0.00

4 Design of Shear Key

Check for bearing stresses in Concrete

Shear Force on X direction Fx = 780 kN

Shear Force on Z direction FZ = 11 kN

IS456: Allowable bearing stress on concrete, scc = 6.00 N/mm2

Table 21

Bearing Stress on concrete X dir, Fx/ (D*F) = 780*1000/(350*450) = 5 N/mm2 < 6.00 N/mm2 Safe UR=0.83

Bearing Stress on concrete Z dir , Fz/ (D*G) = 11*1000/(350*20) = 2 N/mm2 < 6.00 N/mm2 Safe UR=0.26

Check shear plate for bending

Allowable bending stress in shear plate , 0.75 fy = 0.75*330 = 248

Allowable bending stress in Section , 0.66 fy = 0.66*330 = 218

Bending stress due to Fx, =(Fx *D/2)/ (Zx) = (780*1000*350/2)/675,000 = 202 N/mm2 < 217.80 N/mm2 Safe UR=0.93

Bending stress due to Fz, =(Fz *D/2)/ (Zz) = (11*1000*350/2)/30,000 = 64 N/mm2 < 247.50 N/mm2 Safe UR=0.26

5 Weld Design

5a Colum to base plate

Resultant force on weld Vw = SQRT ( Fx2 +Fy2+ Fz2) = SQRT(780^2+3150^2+11^2) = 3245 kN

Type of weld

Allowable stress of the Fillet weld = MIN(0.6*490/SQRT(3),0.4*MIN(330,240)) = 96 N/mm2 0.6 *Fu/SQRT(3)

Allowable stress of the Butt Weld = 0.6*MIN(330,240) = 144 N/mm2

Flange of weld

Length of weld considered for design = 1740 mm

Flange weld Strength = ((0.707*12*1740*96)+(12*1740*144))/1000 = 4,424 kN

Web of weld

Length of weld considered for design = 780 mm

Web weld Strength = ((0.707*8*780*96)+(8*780*144))/1000 = 1,322 kN

Total Weld Strength = 4,424+1,322 = 5,746 kN >= 3245.15 kN Safe UR=0.56

5b Shear Key to base plate

Resultant force on weld Vw = SQRT ( Fx2 + Fz2) = SQRT(780^2+11^2) = 780 kN

Type of weld

Allowable stress of the Fillet weld = MIN(0.6*490/SQRT(3),0.4*MIN(330,330)) = 132 N/mm2 0.6 *Fu/SQRT(3)

Allowable stress of the Butt Weld = 0.6*MIN(330,330) = 198 N/mm2

Weld Along X dir

Length of weld considered for design = 900 mm

Weld Strength = ((0.707*8*900*132)+(6*900*198))/1000 = 1,741 kN >= 780.00 kN Safe UR=0.45

Weld Along Z dir

Length of weld considered for design = 40 mm

Weld Strength = ((0.707*8*40*132)+(6*40*198))/1000 = 77 kN >= 11.00 kN Safe UR=0.14

Total Weld Strength = 1,741+77 = 1,819 kN >= 780.08 kN Safe UR=0.43

6 Design of Rib Plate -(Considering Two plate at each face)

6a Bending about X dir

Span = (850-450)/2 = 200 mm

Section properties with Rib plate

Base plate Width = 850 = 850 mm

Base plate Thickness = 35 = 35 mm

Stiffener Depth = 200 = 200 mm

Stiffener Thickness = 20 = 20 mm

Area of Cross section = 850*35+2*200*20 = 37750 mm2

N.A Depth from top = (2*20*200*200/2+850*35*(35/2+200))/(2*20*200+850*35) = 193 mm

Moment of inertia , I [Link]

= 2*(20*(200^3)/12+200*20*(193-200/2)^2)+(850*(35^3)/12+850*35*(200+35-193-35/2)^2) = 1.E+08 mm4

Section modulus about top, Zr = 1.E+08/193 = 606165 mm3

4 of 5

� Bending Moment Mrib=

= IF(Address Error,8/2*0*((850-450)/2-110)/1000,4.36*850*200*200/2/10^6) = 74 kN.m

Shear force = IF(Address Error,8/2*0,4.36*850*200/10^3) = 741 kN

Allowable bending stress in Section , 0.66 fy = 0.66*350 = 231 N/mm2

Bending stress Mrib/Zr = 74*10^6/606165 = 122 N/mm2 < 231.00 N/mm2 Safe UR=0.53

Allowable Shear stress in Section , 0.4 fy = 0.4*350 = 140 N/mm2

Shear stress = 741*1000/(2*200*20) = 93 N/mm2 < 140.00 N/mm2 Safe UR=0.66

6b Bending about Y dir

Span = (850-450)/2 = 200 mm

Section properties with Rib plate

Base plate Width = 850 = 850 mm

Base plate Thickness = 35 = 35 mm

Stiffener Depth = 200 = 200 mm

Stiffener Thickness = 20 = 20 mm

2

Area of Cross section = 850*35+2*200*20 = 37750 mm

N.A Depth from top = (2*20*200*200/2+850*35*(35/2+200))/(2*20*200+850*35) = 193 mm

Moment of inertia , I [Link]

= 2*(20*(200^3)/12+200*20*(193-200/2)^2)+(850*(35^3)/12+850*35*(200+35-193-35/2)^2) = 1.E+08 mm4

Section modulus about top, Zr = 1.E+08/193 = 606165 mm3

Bending Moment Mrib=

= IF(Address Error,8/2*0*((850-450)/2-100)/1000,4.36*850*200*200/2/10^6) = 74 kN.m

Shear force = IF(Address Error,8/2*0,4.36*850*200/10^3) = 741 kN

Allowable bending stress in Section , 0.66 fy = 0.66*350 = 231 N/mm2

Bending stress Mrib/Zr = 74*10^6/606165 = 122 N/mm2 < 231.00 N/mm2 Safe UR=0.53

Allowable Shear stress in Section , 0.4 fy = 0.4*350 = 140 N/mm2

Shear stress = 741*1000/(2*200*20) = 93 N/mm2 < 140.00 N/mm2 Safe UR=0.66

6c Rib Plate weld

Allowable stress of the Fillet weld = MIN(0.6*490/SQRT(3),0.4*MIN(330,350)) = 132 N/mm2 0.6 *Fu/SQRT(3)

Allowable stress of the Butt Weld = 0.6*MIN(330,350) = 198 N/mm2

Horizontal weld

Maximum Shear force, Vrib = MAX(741,741) = 741 kN

Hori Shear force per unit width (Vrib. Ab yt/I) = 741*1000*(850*35)*(200+35-193-35/2)/(1.E+08) = 4703.0 N/mm 612 N/mm

= 741*1000*(850*35)*(200+35-193-35/2)/(1.E+08) =

Weld Strength = 2*(2*(0.707*8*1000*132)+2*(6*1000*198))/1000 = 7738 N/mm >= 4703 N/mm Safe UR=0.61

5 of 5