Professional Documents

Culture Documents

Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)

Uploaded by

sundarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)

Uploaded by

sundarCopyright:

Available Formats

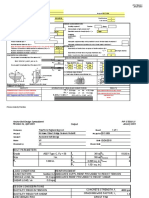

Appendix A.

1 Monorail Beam design with 3MT SWL, S2 type ( Fy = 250 Mpa)

Structural Design calculations - Monorail, as per MOQ-DDE-DUI-002

1. Trolley Technical Data

Carrying capacity of the trolly SWL = 20 MT

Hoist weight SWHoist = 2.4 kg

Total weight of trolley SWTrolley = 0 kg

Geometry & Dimension

No of wheels = 4 Nos

A= mm

N= 150 mm

C = b + 70 >> = 224 + 70 = 294 mm

Max bottom flange thickness tf.max = 24 mm

Max bottom flange width bf.max = 224 mm

Min bottom flange width bf.min = 224 mm

2. Monorail beam data

No of continous Span = 1

Maximum Span Length L= 4.0 m

Cantilever Span ( if required) Lcant = 1.5 m

Section parameter

Section NPB 600X220X154.5

Depth of section h= 610 mm

Flange Width b= 224 mm ( bf.min > bf > bf.max ) \ O.K

Thickness of flange tf = 24 mm (tf > tf.max) \ Revise

Thickness of web tw = 15 mm

Root Radius r1 = 24 mm

Root Radius r2 = 1 mm

Distance d= 610 mm

Section area A= 196.8 cm2

Second moment of area (major axis) Iz = 118302 cm4

Second moment of area (minor axis) Iy = 4520.8 cm4

Elastic modulus (major axis) Zz = 3678.8 cm3

Elastic modulus (minor axis) Zy = 403.6 cm3

Elastic modulus Bottom flange Zy.bf = 200.7 cm3

Radious of gyration (major axis) rz = 24.517913 cm

Radious of gyration (minor axis) ry = 4.7928639 cm

Self weight of member w= 154.488 kN/m

File No.: 341.01.0006 RevB Job No. 131440006 Page B.1 of 10

3. Check the stopping arrangement for Trolley as per EN1993 -6

m+n = 0.5 * (b - tw) - 0.8*r1 >>

m+n = 0.5*(224-15)-0.8*24

m+n = 85.300 mm

Minimum Distance from wheel to End of monorail

Xe.min = 2*Sqrt(2) *(m+n)

= 0.5*(1-196.8)-0.8*118302

= 241.26 mm

Distance from beam end to trolley edge

Xe1 = 145 mm

Distance from trolley edge to centre of outer wheel

Xe2 = (A-N)/2 >> Xe2 = -75 mm

Distance provided from the outer wheel to End of monorail

Xe = 70 mm < 241.26 Revise

Xe1 Xe2 SL = N

4. Design Load

Weight of lift SWL = 10.0 MT

Total weight of Trolley and hoist assumed for design

SW = 1.5 MT >= SWHoist +SWTrolley = 0.002MT

Dynamic Amplification factor DAF = 1.25 (BS-2853 : Cl 4.1)

Design Vertical load Fv = (SWL+SW) *DAF

= (10+1.5)*1.25

= 14.4 MT

= 143.75 kN

Design Lateral load FL = 0.1 SWL

= 0.1 * 10

= 1 MT

= 10 kN

UDL on the beam due to self wt wsw = 154.49 kN/m

File No.: 341.01.0006 RevB Job No. 131440006 Page B.2 of 10

5 Design of Monrail beam as per BS2853-1957

5.1 Case1 : Load at centre of span

5.1.1 Results from Analysis

ANALYSIS OF SIMPLY SUPPORTED BEAM FOR MOVING LOAD Span in mm

0 2000 4000 6000 8000 10000

Moment - kN.m

40900 N 40900 N 40900 N 40900 N -20000000

0

20000000

200 mm 1200 mm 200 mm 40000000

60000000

80000000

100000000

120000000

a

Span in mm

L= 4000 mm 0 2000 4000 6000 8000 10000

-100000

Shear - N

-50000

0

Run 50000

Modulus of Elasticity 2.05E+05 N/mm2

100000

Momenet of inertia 1.18E+09 mm4 150000

Deflection at N points 50

Span in mm

0 2000 4000 6000 8000 10000

Deflection - mm

0

Results 0

Location Distance "a" 0

0

mm mm 0

Max M 1.10E+08 N.mm 2320 2520 1

1

Max V 130471.00 N 0 1610 1

Min V -127608.00 N 3920 3920 1

Max Delta 0.7513 mm 2000 2800

Load case No =

Maximum Span L = 4.0 m

Maximum bending moment (Major axis) Mz = 110.0 kN.m

Maximum shear force Fv = 130.5 kN

Maximum bending moment (Minor axis) My = 5.5 kN.m

Actual Deflection = 0.8 mm

File No.: 341.01.0006 RevB Job No. 131440006 Page B.3 of 10

5.1.2 Check for Longitudinal bending stress

Maximum bending moment Mz = 110.0 kN.m

Longitudinal bending stress f1 = Mz/Zz.e

= (110*10^6)/(3678.8*10^3)

= 29.9 N/mm2

= 1.9 tonf/in2 (i.e 15.44 Mpa = 1 tonf/in2)

Allowable longitudinal bending stress in tension ( Bottom flange) (BS-2853 : Cl 4b.1)

PbT = 10.7 tonf/in2 >= 1.9 SAFE

= 165.0 N/mm2 U.R = 0.18

Allowable longitudinal bending stress in Compression ( Top flange) (BS-2853 : Cl 4b.1)

Effective Length factor = 1

Effective Length Leff = 4000.0 mm

h/tf = =610/24 = 25.4

L/ry = =4000/47.928639366716 = 83.5

Interpolation for Values of P bc

h/tf

L/ry

25 30 25.4

80 11.1 11.1 11.10

85 10.5 10.5 10.50

83.5 10.69 10.69 10.69

Allowable bending stress in Compression PbT = 10.7 tonf/in2 >= 1.9 SAFE

165.0 N/mm2 U.R = 0.18

5.1.3 Check for Transverse bending stress

2

Transverse stress f2 = 1.4*C*W / (K1*T )

Where

W = FV = Effective loads = 143.75 kN

= 14.43 tonf (i.e 9.964 kN = 1 tonf)

T = tf = Mean Thickness of flange = 24 mm

= 0.945 in

b = Flange width = 224 mm

= 8.819 in

N = Trolley Wheels centres Longitudinal = 150 mm

= 5.906 in

Interpolation for Values of C

Flange Four Wheeled trolley wheel centres

Width 5 6 5.9

5.25 0.575 0.515 0.52

5.75 0.6 0.55 0.55

8.82 0.75 0.76 0.76

File No.: 341.01.0006 RevB Job No. 131440006 Page B.4 of 10

C = a constant from Table 3 of BS2853 = 0.76

K1 = a constant from Table 4 of BS2853 = 1.0

2

Transverse stress f2 = 1.4*C*W / (K1*T )

= 1.4*0.76376028*14.43/(1*0.945^2)

= 17.3 tonf/in2

(i.e 15.44 Mpa = 1 tonf/in 2 ) = 266.8 N/mm2

Allowable trasverse bending stress (BS-2853 : Cl 4b.ii)

PbT = 14.5 tonf/in 2

< 17.3 UNSAFE

= 223.9 N/mm2 U.R = 1.19

5.1.4 Check for Combined bending stress

Longitudinal bending stress f1 = 1.9 tonf/in2

Transverse stress f2 = 17.3 tonf/in2

f1 & f2 falling under the hatch area hence safe

16

15

14

13

12

11

10

0

20 18 16 14 12 10 8 6 4 2 0

5.1.5 Check for shear stress

Maximum shear force Fv = 130.5 kN

Applied shear stress fv = Fv/ (h.tw)

= 130.5*1000/(610*15)

= 14.3 N/mm2

Allowable shear stress PbT = 8.5 tonf/in2 (BS-2853 : Cl 4e)

= 131.2 N/mm 2

>= 14.3 SAFE

U.R = 0.11

File No.: 341.01.0006 RevB Job No. 131440006 Page B.5 of 10

5.1.6 Check for weak axis bending

Maximum bending moment My = 5.5 kN.m

Actual bending stress fweak = M/Zy.bf

= (5.5*10^6)/(200.7*10^3)

= 27.4 N/mm2

Allowable bending stress fall = 0.75 fy

PbT = 258.8 N/mm2 >= 27.4 SAFE

U.R = 0.11

5.1.7 Check for Combined weak axis bending & Transverse bending

Combined utilisation ratio = 1.19+0.11

= 1.30 >= 1.0 UNSAFE

U.R = 1.30

5.1.8 Check for Deflection

Actual Deflection = 0.8 mm

Allowable deflection for runway beams = L /500 (BS-2853 : Cl 4k)

= 8.0 mm >= 0.8 SAFE

U.R = 0.09

5.1.9 Check for weld

Weld thickness tweld = 15.0 mm (Thickness of stiffener considered)

Length of weld (Portion of stiffener) Lweld = 420.0 mm

(Conservatively the length of weld between stiffener and the monorail web location is considered)

Weld meterial strength fu.weld = 410 Mpa

Maximum force on weld V = 130.5 kN

Shear stress on weld = V/(tweld*Lweld)

= 130.5*1000/(15*420)

= 20.7 N/mm2

Allowable shear stress on weld fv.all = 0.3 fu.weld (AISC manual-9ed : Table 25)

= 0.3*410

fv.all = 123.0 N/mm2 >= 20.7 SAFE

U.R = 0.17

File No.: 341.01.0006 RevB Job No. 131440006 Page B.6 of 10

5.2 Case2 : Load at Cantilever edge

5.2.1 Results from Sacs

Load case No = 301

Maximum Span L = 1.5 m

Maximum bending moment (Major axis) Mz = 187.8 kN.m

Maximum shear force Fv = 139.5 kN

Maximum bending moment (Minor axis) My = 13.6 kN.m

Actual Deflection = 2.9 mm

File No.: 341.01.0006 RevB Job No. 131440006 Page B.7 of 10

5.2.2 Check for Longitudinal bending stress

Maximum bending moment Mz = 187.8 kN.m

Longitudinal bending stress f1 = M/Zz.e

= (187.84*10^6)/(3678.8*10^3)

= 51.1 N/mm2

= 3.3 tonf/in2 (i.e 15.44 Mpa = 1 tonf/in2)

Allowable longitudinal bending stress in tension (BS-2853 : Cl 4b.1)

PbT = 14.5 tonf/in 2

>= 3.3 SAFE

= 223.9 N/mm2 U.R = 0.23

Allowable longitudinal bending stress in Compression (BS-2853 : Cl 4b.1)

Effective Length factor = 2

Effective Length Leff = 3000.0 mm

h/tf = =610/24 = 25.4

L/ry = =3000/47.928639366716 = 62.6

Interpolation for Values of P bc

h/tf

L/ry

15 20 25.4

85 13.2 12.1 10.91

90 12.8 11.5 10.09

62.6 14.99 14.79 14.57

Allowable bending stress in Compression PbT = 14.6 tonf/in2 >= 3.3 SAFE

224.9 N/mm 2

U.R = 0.23

5.2.3 Check for Transverse bending stress

2

Transverse stress f2 = 1.4*C*W / (K1*T )

Where

W = FV = Effective loads = 143.75 kN

= 14.43 tonf (i.e 9.964 kN = 1 tonf)

T = tf = Mean Thickness of flange = 24 mm

= 0.945 in

b = Flange width = 224 mm

= 8.819 in

N = Trolley Wheels centres Longitudinal = 150 mm

= 5.906 in

Interpolation for Values of C

Flange Four Wheeled trolley wheel centres

Width 9 10 5.9

6.5 0.5 0.5 0.50

6.75 0.5 0.5 0.50

8.82 0.50 0.50 0.50

File No.: 341.01.0006 RevB Job No. 131440006 Page B.8 of 10

C = a constant from Table 3 of BS2853 = 0.50

K1 = a constant from Table 4 of BS2853 = 1.00

2

Transverse stress f2 = 1.4*C*W / (K1*T )

= 1.4*0.5*14.43/(1*0.945^2)

= 11.3 tonf/in2

(i.e 15.44 Mpa = 1 tonf/in 2 ) = 174.6 N/mm2

Allowable trasverse bending stress (BS-2853 : Cl 4b.ii)

PbT = 14.5 tonf/in2 >= 11.3 SAFE

= 223.9 N/mm 2

U.R = 0.78

5.2.4 Check for Combined bending stress

Longitudinal bending stress f1 = 3.3 tonf/in2

Transverse stress f2 = 11.3 tonf/in2

f1 & f2 falling under the hatch area hence safe

16

15

14

13

12

11

10

0

20 18 16 14 12 10 8 6 4 2 0

5.2.5 Check for shear stress

Maximum shear force Fv = 139.54 kN

Applied shear stress fv = Fv/ (h.tw)

= 139.54*1000/(610*15)

= 15.3 N/mm2

Allowable shear stress PbT = 8.5 tonf/in2 (BS-2853 : Cl 4e)

= 131.2 N/mm 2

>= 15.3 SAFE

U.R = 0.12

File No.: 341.01.0006 RevB Job No. 131440006 Page B.9 of 10

5.2.6 Check for weak axis bending

Maximum bending moment My = 13.6 kN.m

Actual bending stress fweak = M/Zy.bf

= (13.55*10^6)/(200.7*10^3)

= 67.5 N/mm2

Allowable bending stress fall = 0.75 fy

PbT = 258.8 N/mm2 >= 67.5 SAFE

U.R = 0.26

5.2.7 Check for Combined weak axis bending & Transverse bending

For Cantilever case combined weak axis bending and transverse bending is not required. Since for max weak

axis bending moment at support the trasverse bending will be at end and both will be at different location

5.2.8 Check for Deflection

Deflection = 2.9 mm

Allowable deflection for runway beams = L /250 (BS-2853 : Cl 4k)

= 6.0 mm >= 2.9 SAFE

U.R = 0.48

5.2.9 Check for weld

Weld thickness tweld = 15.0 mm (Thickness of stiffener considered)

Length of weld (Portion of Stiffener) Lweld = 420.0 mm

(Conservatively the length of weld between stiffener and the monorail web location is considered)

Weld meterial strength fu.weld = 410 Mpa

Maximum force on weld V = 139.5 kN

Shear stress on weld = V/(tweld*Lweld)

= 139.54*1000/(15*420)

= 22.2 N/mm2

Allowable shear stress on weld fv.all = 0.3 fu.weld (AISC manual-9ed : Table 25)

= 0.3*410

fv.all = 123.0 N/mm2 >= 22.2 SAFE

U.R = 0.18

File No.: 341.01.0006 RevB Job No. 131440006 Page B.10 of 10

You might also like

- Ratz Version 4-2: Load Transfer Analysis of Axially Loaded PilesDocument46 pagesRatz Version 4-2: Load Transfer Analysis of Axially Loaded PilesSerj DavidNo ratings yet

- Ductile Details To Seismic Forces - Is 13920Document4 pagesDuctile Details To Seismic Forces - Is 13920MUTHUKKUMARAMNo ratings yet

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- COMPARISON OF COMPOSITE BEAM DESIGNDocument8 pagesCOMPARISON OF COMPOSITE BEAM DESIGNMohamed Abo-ZaidNo ratings yet

- Base Plate Design - LRFD-1Document7 pagesBase Plate Design - LRFD-1k.m.ariful islamNo ratings yet

- Steel Column Base Plate Analysis: Blue Cells Are Input DataDocument1 pageSteel Column Base Plate Analysis: Blue Cells Are Input DataHansal Soni0% (1)

- Design of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit RemarksDocument5 pagesDesign of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit Remarkskiran_karki_8No ratings yet

- Foundation Engineering Exam QuestionsDocument3 pagesFoundation Engineering Exam QuestionsRamiz Keyra0% (1)

- Structural Designsteel BeamDocument7 pagesStructural Designsteel BeamAtienza Design StudioNo ratings yet

- 06) UB254x146x43TOUB356x171x51 Beam To Beam End PlateDocument121 pages06) UB254x146x43TOUB356x171x51 Beam To Beam End PlateAsaru DeenNo ratings yet

- Weld ConnectionDocument70 pagesWeld ConnectionSudhakar KrishnamurthyNo ratings yet

- 1.1 Design of Pipe Racks Writeup PDFDocument5 pages1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasNo ratings yet

- Pinned Base PlateDocument31 pagesPinned Base PlateAlphyl BalasabasNo ratings yet

- Beam To Column End Plate ConnectionDocument10 pagesBeam To Column End Plate ConnectionParchuri PraveenNo ratings yet

- Ring Wall Foundation Design CalculationsDocument6 pagesRing Wall Foundation Design Calculationsraghav abudhabiNo ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- Steel Cap Plate Connections DesignDocument18 pagesSteel Cap Plate Connections DesignVinoth KumarNo ratings yet

- Beam design and reinforcement detailsDocument3 pagesBeam design and reinforcement detailsmegunNo ratings yet

- SX019a-Example Column Base Connection Under Axial Compression PDFDocument5 pagesSX019a-Example Column Base Connection Under Axial Compression PDFdvelchev100% (1)

- Design of Grating For PlatformDocument5 pagesDesign of Grating For Platformvj8584100% (2)

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Weld Strengths To BS5950 01.01.03Document1 pageWeld Strengths To BS5950 01.01.03Pallavi DalviNo ratings yet

- Angle Brace ConnectionDocument20 pagesAngle Brace Connectionmaheshbandham100% (1)

- Staad Pro DFF, DJ1 and DJ2Document10 pagesStaad Pro DFF, DJ1 and DJ2syed AffanNo ratings yet

- Base Plate Design SummaryDocument3 pagesBase Plate Design SummarySơn Nguyễn-LêNo ratings yet

- Vertical Equation Foundation-Spread Sheet PDFDocument6 pagesVertical Equation Foundation-Spread Sheet PDFmassive85No ratings yet

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADocument23 pagesAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNo ratings yet

- Insert Plate CheckDocument6 pagesInsert Plate CheckSatish KumarNo ratings yet

- Anchor Bolt Design Spreadsheet Revision 0a, April 2003Document12 pagesAnchor Bolt Design Spreadsheet Revision 0a, April 2003Vietanh PhungNo ratings yet

- Brace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Document44 pagesBrace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Antonio LópezNo ratings yet

- Column Splice End Plate DesignDocument3 pagesColumn Splice End Plate DesigninnovativekarthiNo ratings yet

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Document11 pagesWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleNo ratings yet

- Pinned Base As Per AISC-Detail-A-R0Document5 pagesPinned Base As Per AISC-Detail-A-R0Sunil Pulikkal100% (1)

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- Design of Base Plate by EurocodeDocument13 pagesDesign of Base Plate by EurocodeBharati MajlekarNo ratings yet

- Sample Shear ConnectionDocument1 pageSample Shear ConnectionmaheshbandhamNo ratings yet

- Insert Plate DesignDocument8 pagesInsert Plate DesignPiyushNo ratings yet

- AISC ASD Base Plate Thickness V2016-2Document9 pagesAISC ASD Base Plate Thickness V2016-2yusuf_jtNo ratings yet

- Four Bolt Moment Connection DesignDocument12 pagesFour Bolt Moment Connection DesignDarshan Panchal0% (1)

- Base Plate Design1Document24 pagesBase Plate Design1John Paul UmaliNo ratings yet

- ASD-Insert Plate CheckDocument12 pagesASD-Insert Plate CheckJvv GudboyNo ratings yet

- Steel ConnectionDocument34 pagesSteel ConnectionDiana100% (1)

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Beam to column connection design analysisDocument2 pagesBeam to column connection design analysisHAZIRACFS SURATNo ratings yet

- Four Bolt Unstiffened End PlateDocument7 pagesFour Bolt Unstiffened End PlateRnD2013No ratings yet

- Anchor Bolt DesignDocument1 pageAnchor Bolt Designnishant131No ratings yet

- FILLET WELD STRENGTH CALCULATIONSDocument8 pagesFILLET WELD STRENGTH CALCULATIONSshadab521No ratings yet

- Bolted Cover Plate Splice Connection B1Document4 pagesBolted Cover Plate Splice Connection B1ikanyu79No ratings yet

- Column Base Plate (Fixed Type)Document13 pagesColumn Base Plate (Fixed Type)KM YapNo ratings yet

- Welded connection designDocument16 pagesWelded connection designAnkit SinghNo ratings yet

- Peb BuildingDocument4 pagesPeb BuildingHiren DesaiNo ratings yet

- CivilBay engineering beam splice connection design project summaryDocument17 pagesCivilBay engineering beam splice connection design project summarymaheshbandhamNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNo ratings yet

- AnchorageDocument8 pagesAnchorageRicha MunjalNo ratings yet

- 6 - CE 511 - Base Plate Design PDFDocument33 pages6 - CE 511 - Base Plate Design PDFJayson RamosNo ratings yet

- Crane Beam Web Splice DesignDocument7 pagesCrane Beam Web Splice DesignCrystal JaneNo ratings yet

- DESIGN CALCULATION SHEETDocument9 pagesDESIGN CALCULATION SHEETElie MenassaNo ratings yet

- 2 0 Insert Plate Calculations Type 14 PDFDocument4 pages2 0 Insert Plate Calculations Type 14 PDFKho C AhlNo ratings yet

- Brace ConnectionDocument10 pagesBrace ConnectionAhmed Ben HmidaNo ratings yet

- Rectangular Beam Design Calculations for Flexure, Torsion and ShearDocument9 pagesRectangular Beam Design Calculations for Flexure, Torsion and ShearSamir PrajapatiNo ratings yet

- Analisa Pier Head P.0 - Simpang Perawang - 20190930 PDFDocument12 pagesAnalisa Pier Head P.0 - Simpang Perawang - 20190930 PDFDio Akbar HakimNo ratings yet

- SM II - Global WindWind Load On Main ModelDocument31 pagesSM II - Global WindWind Load On Main ModelsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument6 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument13 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument13 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument6 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Lift Machine Room LoadsDocument8 pagesLift Machine Room LoadssundarNo ratings yet

- Column Splice For Double - 20170522Document13 pagesColumn Splice For Double - 20170522sundarNo ratings yet

- Clip Angle Connection Design for Beam to Column JointDocument4 pagesClip Angle Connection Design for Beam to Column JointsundarNo ratings yet

- Column Splice For Double - 20170522Document13 pagesColumn Splice For Double - 20170522sundarNo ratings yet

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Premium Break UpDocument1 pagePremium Break UpsundarNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Monthly PRKNG Fare Dtls PDFDocument1 pageMonthly PRKNG Fare Dtls PDFsundarNo ratings yet

- FP b2b Tier#2 Obra 20170723 FinalDocument3 pagesFP b2b Tier#2 Obra 20170723 FinalsundarNo ratings yet

- Grating CatlogDocument11 pagesGrating CatlogsundarNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFsundarNo ratings yet

- Ashirvad CPVC Pipe PDFDocument12 pagesAshirvad CPVC Pipe PDFsundarNo ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignFarid SedekyNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Measuring Friction in PipesDocument6 pagesMeasuring Friction in PipessundarNo ratings yet

- Honda Motorcycle & Scooter India (PVT) LTDDocument1 pageHonda Motorcycle & Scooter India (PVT) LTDsundarNo ratings yet

- Guide To Offshore Wind Farm 2019Document128 pagesGuide To Offshore Wind Farm 2019sundarNo ratings yet

- JapanDocument367 pagesJapanAndrés García Casero100% (1)

- Çok Katlı Yapılara Giriş - Ders 8Document13 pagesÇok Katlı Yapılara Giriş - Ders 8İÜ İnşaat Mühendisliği BölümüNo ratings yet

- Beams IS 13920 2016Document12 pagesBeams IS 13920 2016TEJ BAHADUR KARKINo ratings yet

- ETABS 2016 RC Frame ExampleDocument43 pagesETABS 2016 RC Frame ExampleSandy KavitakeNo ratings yet

- Hagia Sophia Earthquake AnalysisDocument15 pagesHagia Sophia Earthquake AnalysisMudith RakhechaNo ratings yet

- Mechanical Coupler For RebarDocument12 pagesMechanical Coupler For Rebarkranthi kumarNo ratings yet

- Numerical Simulation of Mixedmode Progressive Delamination in Composite MaterialsDocument24 pagesNumerical Simulation of Mixedmode Progressive Delamination in Composite Materials蕭佩杰No ratings yet

- ISRM-11CONGRESS-2007-097 - Stress Paths in Laboratory Rock Joint Shear TestsDocument4 pagesISRM-11CONGRESS-2007-097 - Stress Paths in Laboratory Rock Joint Shear Testscastille1956No ratings yet

- SEE 2 - Rizkita ParithustaDocument14 pagesSEE 2 - Rizkita ParithustaFaishol Arif StNo ratings yet

- Module 4 HIgh Cycle and Low Cycle FatigueDocument21 pagesModule 4 HIgh Cycle and Low Cycle FatiguerohanNo ratings yet

- Finite Element Analysis of Thin - Walled Composite Laminated Beams With Warping BehaviourDocument10 pagesFinite Element Analysis of Thin - Walled Composite Laminated Beams With Warping BehaviourSohini MishraNo ratings yet

- Design of Concrete StructureDocument22 pagesDesign of Concrete StructureSIDDHARTHA MAITYNo ratings yet

- Biaxial fatigue tests with zero mean stresses using tubular specimensDocument19 pagesBiaxial fatigue tests with zero mean stresses using tubular specimensDavid C HouserNo ratings yet

- Is 7894 1975 PDFDocument44 pagesIs 7894 1975 PDFLibin VargheseNo ratings yet

- CEEN 3160 - Geotechnical Engineering Example Exam 2 Questions - Fall 2012Document3 pagesCEEN 3160 - Geotechnical Engineering Example Exam 2 Questions - Fall 2012Devendrasinh PadhiyarNo ratings yet

- Strength Evaluation of Interior Slab-Column Connections: Aci Structural Journal Technical PaperDocument9 pagesStrength Evaluation of Interior Slab-Column Connections: Aci Structural Journal Technical PaperangthiankongNo ratings yet

- Appendix I Borehole Location PlanDocument6 pagesAppendix I Borehole Location PlanAnonymous 6yxz80dNo ratings yet

- Fracpro Course PresentationDocument111 pagesFracpro Course PresentationUmar Rasheed100% (1)

- Chapter 5 Normal Stress: Learning ObjectivesDocument28 pagesChapter 5 Normal Stress: Learning ObjectivesIrfan KabirNo ratings yet

- Crank Shaft Stress Analysis Solid WorksDocument12 pagesCrank Shaft Stress Analysis Solid Worksmomtaz14No ratings yet

- 70 Post-Tensioned Concrete - Principles and PracticeDocument17 pages70 Post-Tensioned Concrete - Principles and PracticeMinh TríNo ratings yet

- Nonlinear Finite Element Analysis of An RC FrameDocument12 pagesNonlinear Finite Element Analysis of An RC Framearash250100% (1)

- Cama Lab1Document63 pagesCama Lab1pachieduNo ratings yet

- Appendix 13 Vessels of Noncircular Cross PDFDocument46 pagesAppendix 13 Vessels of Noncircular Cross PDFNoppolNorasriNo ratings yet

- Elastic Constants KetulDocument21 pagesElastic Constants KetulRambabu Vurimi67% (3)

- Calibration Chart: Applied Force (KN)Document4 pagesCalibration Chart: Applied Force (KN)Vishal ShrivastavaNo ratings yet

- International Conference on Steel, Space and Composite Structures Parameters Design Optimisation Anchor JointDocument10 pagesInternational Conference on Steel, Space and Composite Structures Parameters Design Optimisation Anchor JointMiguel Rivera100% (1)