Professional Documents

Culture Documents

Beam to column connection design analysis

Uploaded by

HAZIRACFS SURATOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beam to column connection design analysis

Uploaded by

HAZIRACFS SURATCopyright:

Available Formats

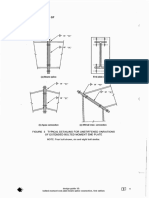

BEAM TO COLUMN RIGID CONNECTION RESULTS RATIOS:-

FRICTION TYPE CONNECTION Tb ratio = 0.907

USING HIGH STRENGTH BOLTS qb ratio = 0.213

ACCORDING E.C.O.P.2001 E. PL. 1 = 0.738 E. PL. 2 = 0.551

MOHAMED HUSSAIN

PROJECT :. 0ID-Project Name Frame No. Beam No. Joint No. Design:. Eng. M.Hussain

TITLE :

Date & Time : 1/16/2022 12:19 Conn. No. Column No Comb. No. Approval:. Dr. Fouad Fayez

BUILDING TYPE :- Ordinary Steel Work

STRAINING ACTIONS :- BEAM SECTION :- COLUMN SECTION :-

Mx 65 m.t. h (total) 800 mm h 500 mm

N (+ve) 0 ton. tw 8 mm tw 8 mm

N (-ve) 8 ton. b 200 mm b 300 mm

Qy 13 ton. tf 16 mm tf 25 mm

sw (if fillet) 0 mm

q Bot.Flange incl. 0 degrees

CONNECTION DETAILS :-

Bolts Detail :.

No.Rows of Bolts (in tension side) 3 Rows Distances between Bolts :.

No.Rows of Bolts (in comp. side) 2 Rows a 50 mm

No.Bolts/row 4 Bolts a1 120 mm

Bolts Diameter M-22 a2 100 mm

Bolts Grade 10.9 a3 280 mm

End Plate Detail :.

Yield Stress for Plate fy 3.6 t/cm2 with stiffeners

Depth of Plate dp 1000 mm No.stiff. 3 stiff.

Width of Plate bp 300 mm ts = 8 mm

Thickness of Plate tp 30 mm L = 100 mm

L* = 100 mm

CHECK SAFETY OF BOLTS :- Lmax= 100 mm

Stressed Area of Bolt As 3.03 cm2 Prying Force Parameter (cm) :.

Pretension Force / Bolt Tpre 19.08 ton. a 5 cm

Shear Resistance / Bolt Ps 7.63 ton. b* 5 cm

Plate Area Ap 3000 cm2 w 7.5 cm

Plate Inertia Ip 2500000 cm4 tp 3 cm

Width/Bolt w 7.5 cm

Max T (external/Bolt) T ext/b 9.545 ton.

Prying Force(percentage) P 0.45 T ext/b

Prying Force (Value) P 4.30 ton.

Total Tension/Bolt T ext/b + P = 13.85 ton. < 15.26 ton. O.K.

Shear strength of Bolts Qall 61.04 ton. > 13 ton. O.K.

CHECK SAFETY OF END PLATE :-

C.G. of Cross Section y` 28.68 mm.

Inertia of Cross Section I 1068.03 cm4

Modules of Cross Section Z 105.42 cm3

Moment at sec (1) M1 86.02 cm.ton.

Moment at sec (2) M2 121.25 cm.ton.

Critical Bending Stress f1 1.91 t/cm2 < 2.59 t/cm2 O.K.

Critical Bending Stress f2 1.15 t/cm2 < 2.09 t/cm2 O.K.

CHECK OF COLUMN WEB CRIPPLING:

Applied Area = 32.00 cm2

Resisting Area = 26.08 cm2 USE 'TWO STIFFENERS AT COMPRESION ZONE'

Area req / stiffner = 2.96 cm2

b (stiffner) = (Recom.) 145 mm

t (stiffner) = (Recom.) 14 mm

weld size = 6 mm

weld (No.sides) = 2

L (stiffner) = 50 mm O.K.

CHECK OF COLUMN FLANGE TENSION:

tf-col. (min) = 24 mm O.K.

CHECK OF COLUMN WEB BUCKLING:

Applied Force (F) = 86.91 ton.

Resisting Force (R) = 45.36 ton. USE 'TWO DIAGONAL STIFFENERS' OR 'DOUBLER PLATES'

Use Diagonal Stiffener :. Use Doubler Plates :.

Applied Force(F-R/cos45) 58.76 ton.

OR Applied Force (F-R) = 41.55 ton.

Area req / stiffner = 14.07 cm2 No.Plates = 2

b (stiffner) = (Recom.) 145 mm t/Plate = 4 mm

t (stiffner) = (Recom.) 14 mm

weld size = 6 mm

weld (No.sides) = 2

L (stiffner) = 240 mm o.k.

CHECK SAFETY OF WELDS :-

Weld for Flanges :. Weld for web :.

weld size = 30 mm weld (No.sides) = 2

Area (weld) = 225.6 cm2 weld size = 4 mm o.k.

Inertia (weld) = 350456.016 cm4

Normal Stress = 0.83 t/cm2 < 1.04 t/cm2 USE BUTT WELD ALL AROUND THE FLANGE

Ordenary Buildings Bridges & Cranes

Bolt Astr (cm2) Tpre (ton)

Ps (st-37)Ps (st-52)Ps (st-37)Ps (st-52)

M-12 0.84 5.29 1.69 2.11 1.32 1.65

M-16 1.57 9.89 3.16 3.95 2.47 3.09

M-20 2.45 15.43 4.93 6.17 3.85 4.82

M-22 3.03 19.08 6.1 7.63 4.77 5.96

M-24 3.53 22.23 7.11 8.89 5.55 6.94

M-27 4.59 28.91 9.25 11.56 7.22 9.03

M-30 5.61 35.34 11.3 14.13 8.83 11.04

M-36 8.17 51.47 16.47 20.58 12.86 16.08

You might also like

- Roof TrussDocument4 pagesRoof TrussShamie Dela Cruz CaldeaNo ratings yet

- Computer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)Document9 pagesComputer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)April IngramNo ratings yet

- Structural Analysis and Design: STAAD - Pro Steel Design (FAQ)Document19 pagesStructural Analysis and Design: STAAD - Pro Steel Design (FAQ)Suhas NatuNo ratings yet

- Apex HaunchDocument34 pagesApex HaunchDanny ArimaNo ratings yet

- Design Data:: 5.16.14 Example 5.33: Inverted T-Beam Combined FoundationDocument7 pagesDesign Data:: 5.16.14 Example 5.33: Inverted T-Beam Combined FoundationThimira ShehanNo ratings yet

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ADocument23 pagesAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Load Combination For Steel Design Per BS en 1990 EditionDocument2 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru Deen100% (1)

- Design of Steel BeamDocument19 pagesDesign of Steel BeamAnonymous tBhJoH5wgMNo ratings yet

- Seismic design loads and combinationsDocument15 pagesSeismic design loads and combinationsAmey Gudigar100% (1)

- Tower Design SheetDocument41 pagesTower Design Sheet14pcashNo ratings yet

- Project MezzanineDocument2 pagesProject Mezzaninepujan77No ratings yet

- Peb BuildingDocument4 pagesPeb BuildingHiren DesaiNo ratings yet

- Bondek I - Calculation Note - 1 Row of SupportDocument7 pagesBondek I - Calculation Note - 1 Row of Supporttrung1983No ratings yet

- Appendix 1 - Scope of WorkDocument13 pagesAppendix 1 - Scope of WorkNimra NaveedNo ratings yet

- S&T Purlins & Girts Catalogue PDFDocument36 pagesS&T Purlins & Girts Catalogue PDFNguyen Duc CuongNo ratings yet

- Column Beam Seismic ConnectionDocument8 pagesColumn Beam Seismic ConnectionPrakash Singh RawalNo ratings yet

- Corrugated Sheets Design GuideDocument12 pagesCorrugated Sheets Design GuideRama KrishnaNo ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- Design of Base Plate and Anchor BoltsDocument7 pagesDesign of Base Plate and Anchor BoltsShaikh Muhammad AteeqNo ratings yet

- Metal Building Systems: Pdhonline Course S120 (1 PDH)Document11 pagesMetal Building Systems: Pdhonline Course S120 (1 PDH)SunilBhargavSanathiNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjNo ratings yet

- Tubular Profiles For Telecom Structures PDFDocument8 pagesTubular Profiles For Telecom Structures PDFJitendraNo ratings yet

- Fabrication Tolerances for Cold-Formed and Built-Up Structural MembersDocument4 pagesFabrication Tolerances for Cold-Formed and Built-Up Structural MembersSyed Tauseef ShahNo ratings yet

- How Do You Calculate Chequered Plate WeightDocument2 pagesHow Do You Calculate Chequered Plate Weightssr11700% (1)

- Reference Description of Problem Values Units: Infomile SolutionsDocument3 pagesReference Description of Problem Values Units: Infomile SolutionsdhawanaxitNo ratings yet

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocument56 pagesSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNo ratings yet

- STAAD Pro CE RAM Connection TrainingDocument13 pagesSTAAD Pro CE RAM Connection TrainingtigersronnieNo ratings yet

- GlazingsDocument9 pagesGlazingsVikas Singh ChandelNo ratings yet

- Connection Design - Its Role in Steel DetailingDocument9 pagesConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.No ratings yet

- Fatigue CheckDocument1 pageFatigue CheckSunil PulikkalNo ratings yet

- MM Met D19084 RP 012Document96 pagesMM Met D19084 RP 012Dass DassNo ratings yet

- Multi-storey building load analysisDocument24 pagesMulti-storey building load analysisV.m. RajanNo ratings yet

- Corbel Design Spreadsheet To ACI318Document6 pagesCorbel Design Spreadsheet To ACI318LAU TONo ratings yet

- Load Combination Is 800-2007Document5 pagesLoad Combination Is 800-2007Jitendra PNo ratings yet

- Beam To Column End Plate ConnectionDocument10 pagesBeam To Column End Plate ConnectionParchuri PraveenNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument1 pageLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Suitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationDocument4 pagesSuitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationKarthik SgNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Is800-2007 Appendix PDFDocument85 pagesIs800-2007 Appendix PDFDebasish MondalNo ratings yet

- Flitch Plate BeamDocument1 pageFlitch Plate Beamdnl_vicarsNo ratings yet

- TMDocument471 pagesTMAhmed KhanNo ratings yet

- Steel Connection DesignDocument16 pagesSteel Connection DesignHazza JumaaNo ratings yet

- Anchorage and Development LengthsDocument2 pagesAnchorage and Development LengthsSimo AliNo ratings yet

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- Structural Designsteel BeamDocument7 pagesStructural Designsteel BeamAtienza Design StudioNo ratings yet

- Structural Analysis and Design of Fuel Gas Coalescer Platform FoundationDocument29 pagesStructural Analysis and Design of Fuel Gas Coalescer Platform FoundationsridharNo ratings yet

- Eccentric FootingDocument13 pagesEccentric FootingMegatech Engineering Consultants100% (1)

- Joist Girder DesignDocument42 pagesJoist Girder DesignsravanNo ratings yet

- Repport Steel Structure PDFDocument111 pagesRepport Steel Structure PDFAnonymous fxqnhfKNo ratings yet

- View Topic - Pile Cap Design Using SafeDocument5 pagesView Topic - Pile Cap Design Using SafeParameswaran GanesanNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNo ratings yet

- Design of Circular Wall (Tank Wall) : Case: 1 Only Water From InsideDocument6 pagesDesign of Circular Wall (Tank Wall) : Case: 1 Only Water From InsidecivilceejiNo ratings yet

- Section A-A: Wall Cheq'D PlateDocument1 pageSection A-A: Wall Cheq'D PlateAL BASTAKI CONTRACTING L.L.C.50% (2)

- DESIGN OF DOUBLY REINFORCED BEAMDocument13 pagesDESIGN OF DOUBLY REINFORCED BEAMLikith Gowda MNo ratings yet

- MONORAIL STOPPER DESIGNDocument4 pagesMONORAIL STOPPER DESIGNrajasekhar.cheruvu8635No ratings yet

- Seafastening For Pelikan - 12mm Thickness PlateDocument12 pagesSeafastening For Pelikan - 12mm Thickness PlateHafidNo ratings yet

- Cantlver SlabDocument8 pagesCantlver SlabsheikNo ratings yet

- Single Composite Beam With Deck Slab Design - ISMBDocument94 pagesSingle Composite Beam With Deck Slab Design - ISMBHAZIRACFS SURAT100% (1)

- BBS For J72 FoundationsDocument25 pagesBBS For J72 FoundationsHAZIRACFS SURATNo ratings yet

- Base Plate Design1Document2 pagesBase Plate Design1Rafael GarciaNo ratings yet

- Design of anchor bolts for column base plateDocument2 pagesDesign of anchor bolts for column base plate4geniecivilNo ratings yet

- Nikola TeslaDocument19 pagesNikola TeslaAshok Nani100% (4)

- Mcse 004Document170 pagesMcse 004Urvashi RoyNo ratings yet

- Module One Lesson Three AssignmentDocument5 pagesModule One Lesson Three AssignmentChesney Anne GaskinNo ratings yet

- Algebra II Honors Midterm ReviewDocument11 pagesAlgebra II Honors Midterm ReviewRuhani MalikNo ratings yet

- Partial Differential Equations: Paul Heckbert Computer Science Department Carnegie Mellon UniversityDocument13 pagesPartial Differential Equations: Paul Heckbert Computer Science Department Carnegie Mellon UniversityDon eladioNo ratings yet

- Design Load CalculationDocument12 pagesDesign Load CalculationV.m. Rajan100% (1)

- A Simplified Analysis of Well Blow-Outs: June 2003Document13 pagesA Simplified Analysis of Well Blow-Outs: June 2003hamida yaakoubiNo ratings yet

- Data Modulus ElastisitasDocument5 pagesData Modulus ElastisitasYohan S.No ratings yet

- A Comparative Assessment of Stabilization Potential of Cement, Lime & GeopolymerDocument13 pagesA Comparative Assessment of Stabilization Potential of Cement, Lime & GeopolymeroNo ratings yet

- Lect 7Document27 pagesLect 7Omar Abdulrhman AlqadasiNo ratings yet

- Manual Energy MeterDocument1 pageManual Energy Meterda88No ratings yet

- Mechanical Measurements Lab ManualDocument26 pagesMechanical Measurements Lab ManualseminarprojectNo ratings yet

- Measuring Weight - Metric Units: Name: ScoreDocument2 pagesMeasuring Weight - Metric Units: Name: ScoreNifa Asya WinaNo ratings yet

- Wellflo - GUIDE STEP BY STEPDocument14 pagesWellflo - GUIDE STEP BY STEPAngel NgoNo ratings yet

- Cambridge Mathematics Reading-ListDocument11 pagesCambridge Mathematics Reading-Listvitor constantino100% (1)

- 3d Printing of Concrete StructuresDocument110 pages3d Printing of Concrete StructuresGabriel ComerlatoNo ratings yet

- Chapter 4 - Dynamic AnalysisDocument16 pagesChapter 4 - Dynamic AnalysisDimple Sharma100% (1)

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 pagesLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANo ratings yet

- Cooper Bussmann Safety Basics Electrical HazardsDocument46 pagesCooper Bussmann Safety Basics Electrical HazardsAtika Rahma HadianaNo ratings yet

- ML Practice 1Document106 pagesML Practice 1Jing DongNo ratings yet

- GEOCHEMISTRY: THE STUDY OF ELEMENT DISTRIBUTION ON EARTHDocument12 pagesGEOCHEMISTRY: THE STUDY OF ELEMENT DISTRIBUTION ON EARTHJohn Rhey Almojallas BenedictoNo ratings yet

- Ansys FlutterDocument2 pagesAnsys Flutterfhd_bdNo ratings yet

- 03a.magnetism (171 - 201)Document31 pages03a.magnetism (171 - 201)Mupli RajeshNo ratings yet

- Traceable® Products CatalogDocument88 pagesTraceable® Products Catalogmdlc6878No ratings yet

- Seismic Earth Pressures Against Structures With Restrained DisplaDocument9 pagesSeismic Earth Pressures Against Structures With Restrained DisplavttrlcNo ratings yet

- Module 2 (Physics)Document4 pagesModule 2 (Physics)Miguel Oliveira100% (1)

- The Application of Cellulose Acetate Replication Sheets in Enamel Wear InvestigationsDocument10 pagesThe Application of Cellulose Acetate Replication Sheets in Enamel Wear InvestigationsKara WhiteNo ratings yet

- Uta BarthDocument12 pagesUta Barthapi-381291798No ratings yet

- 26 PDFDocument280 pages26 PDFHumberto Medina100% (1)

- CESURVE Problem Set 1Document2 pagesCESURVE Problem Set 1Rheina VelasquezNo ratings yet