Professional Documents

Culture Documents

Fatigue Check

Uploaded by

Sunil PulikkalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fatigue Check

Uploaded by

Sunil PulikkalCopyright:

Available Formats

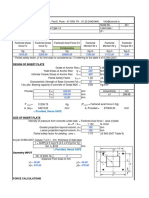

Design Check for Fatigue

Job No: Rev Date 04-12-2013

Building No 1 1 Designed by

Crane Beam No. Checked by

Fatigue Strength Calculation as per IS-800 : 2007

Crane Classification = 2

Number of applications / day n1 = 50 cycles/ day

Number of days n2 = 365 no of days

Life span of building y = 25 years

Number of stress cycles Nsc n1xn2xy 456250 cycles

Major Axis Moment ( Mz ) = 2176 kN.m ( For Member - 6 )

Minor Axis Moment ( My ) 45 kN.m ( For Member - 6 )

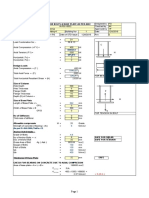

Beam I- Section

dw, Web Depth = 1850 mm

tw, Web Thickness = 12 mm

bf, Top Flange Width = 400 mm

tfo, Top Flange Thickness = 20 mm

bf, Bottom Flange Width = 400 mm

tfi, Bottom Flange Thickness = 20 mm

D, Total Depth = 1890 mm

Y

Top Flange = 400x20

Z Z

Web =1850x12

Bot Flange=400x20

Y

Properties of I - Beam

Z is the bending major axis, Y is the bending minor axis

2

A, Area = 38200 mm

yg, centroid of section from bottom flange = 945.00 mm

4

Iz, Inertia about major axis = 20319758333 mm

4

Iy, Inertia about minor axis = 213599733 mm

3

Zzo, section modulus, top flange = 21502390 mm

3

Zzi, section modulus, bottom flange = 21502390 mm

3

Zy, section modulus, minor axis = 1067999 mm

2

Actual Bending stress Major Axis = = 101.20 N/mm

2

Actual Bending stress Minor Axis = = 42.13 N/mm

2

Total Normal struss = 143.33 N/mm

6 1/3

Fatigue strength = ff = ffn x ( ( 5 x 10 ) / Nsc )

ffn = 92.00 (IS-800:2007,Table - 26 (b))

ff = 204.35

Partial saftey factor for strength, gmft = 1.25 (IS-800:2007,Refer Table - 25)

Allowable stress = ff / gmft = 163.48

Unity Check = Actual stress / Allowable stress = 0.877 < 1.0, Hence OK

You might also like

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Connections I V2.0.6b FinalDocument71 pagesConnections I V2.0.6b FinalNick Andrews50% (2)

- Design of anchor bolts and base plate for pinned H-columnDocument4 pagesDesign of anchor bolts and base plate for pinned H-columnSunil PulikkalNo ratings yet

- Beam To Column End Plate ConnectionDocument10 pagesBeam To Column End Plate ConnectionParchuri PraveenNo ratings yet

- WorksheetDocument4 pagesWorksheetMarrin MarquesNo ratings yet

- Carbohydrates: Organic Vs Inorganic CompoundsDocument16 pagesCarbohydrates: Organic Vs Inorganic CompoundsTsu Wei Chua100% (5)

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFDocument36 pagesSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianNo ratings yet

- Safe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFDocument36 pagesSafe - ErectioSafe Erection of Structural Steel For Buildingsns - Web PDFFarid RezaeianNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- OL-1 Failure of Steel StructureDocument0 pagesOL-1 Failure of Steel StructureSunil PulikkalNo ratings yet

- Base PlateDocument6 pagesBase PlateJigarNo ratings yet

- Composite Beam DesignDocument4 pagesComposite Beam DesignSunil PulikkalNo ratings yet

- Pinned Base As Per AISC-Detail-A-R0Document5 pagesPinned Base As Per AISC-Detail-A-R0Sunil Pulikkal100% (1)

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Purlin Design PDFDocument3 pagesPurlin Design PDFUday Udmale100% (1)

- Is 800-2007 Interpretation by INSDAGDocument15 pagesIs 800-2007 Interpretation by INSDAGnilesh_yerawar100% (1)

- Tower Design SheetDocument41 pagesTower Design Sheet14pcashNo ratings yet

- EQ06 - Shear Wall and B.E. DesignDocument124 pagesEQ06 - Shear Wall and B.E. DesignrahuljainNo ratings yet

- Saptarshi PDFDocument15 pagesSaptarshi PDFViriato SouzaNo ratings yet

- Drainage Design Document SummaryDocument1 pageDrainage Design Document SummarySunil PulikkalNo ratings yet

- Steel Section Capacity Check For BeamDocument3 pagesSteel Section Capacity Check For BeamChirag JoshiNo ratings yet

- BEAM Moment Connection - UB 254x146x37Document7 pagesBEAM Moment Connection - UB 254x146x37Shriniwas NaikNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- 009 - Steel Column - Without Top Row FinalDocument4 pages009 - Steel Column - Without Top Row FinalVAIBHAVNo ratings yet

- Diagram Drawing Design Forces and DetailsDocument6 pagesDiagram Drawing Design Forces and Detailswaweng22No ratings yet

- End Plate Moment ConnectionDocument3 pagesEnd Plate Moment ConnectionIndustry Standard Structural DesignNo ratings yet

- TOLERANCES COMPARISON IS: 7215, AWS D 1.1, MBMADocument1 pageTOLERANCES COMPARISON IS: 7215, AWS D 1.1, MBMASunil Pulikkal100% (2)

- Brick Masonry Walls Book PDFDocument117 pagesBrick Masonry Walls Book PDFPremalatha Jeyaram100% (1)

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNo ratings yet

- Base Plate Design - LRFD-1Document7 pagesBase Plate Design - LRFD-1k.m.ariful islamNo ratings yet

- Base Plate Design Metric Units Online Calculation ReportDocument7 pagesBase Plate Design Metric Units Online Calculation ReportmaheshbandhamNo ratings yet

- Sheet1 A-B Bay CM: Properties of Gantry SectionDocument2 pagesSheet1 A-B Bay CM: Properties of Gantry SectionadihindNo ratings yet

- Guide Line For Inspection of Overhead Crane StructureDocument43 pagesGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- Design of rigid connection detail 85Document215 pagesDesign of rigid connection detail 85Umer AziqNo ratings yet

- Design of bracing for 1000 KL OHTDocument4 pagesDesign of bracing for 1000 KL OHTankkeshmundra1No ratings yet

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Design bending and shear strength of laterally unsupported beamDocument3 pagesDesign bending and shear strength of laterally unsupported beamhema kumarNo ratings yet

- Deck SheetDocument3 pagesDeck SheetPoulomi BiswasNo ratings yet

- Design of Pinned Base ConnectionDocument21 pagesDesign of Pinned Base ConnectionShawkat Ali KhanNo ratings yet

- RPLC DEEP CONVERSION BRACING CONNECTION DESIGNDocument32 pagesRPLC DEEP CONVERSION BRACING CONNECTION DESIGNHeberth SanchezNo ratings yet

- Moment Connection BBDocument8 pagesMoment Connection BBanandNo ratings yet

- Astm Standard List PDFDocument4 pagesAstm Standard List PDFSunil Pulikkal0% (1)

- Base Plate DesignMS601aDocument3 pagesBase Plate DesignMS601aduazo2009No ratings yet

- Cssbi 57Document69 pagesCssbi 57jachoijachoiNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Design of Sign Board Gantry 20.2 M SpanDocument10 pagesDesign of Sign Board Gantry 20.2 M SpanVrusha BendarNo ratings yet

- Repport Steel Structure PDFDocument111 pagesRepport Steel Structure PDFAnonymous fxqnhfKNo ratings yet

- Moment Connection Design Hea220Document56 pagesMoment Connection Design Hea220Atul WanodeNo ratings yet

- SCC Bucket Elevators For A Variety of Applications: Catalog No. 201Document16 pagesSCC Bucket Elevators For A Variety of Applications: Catalog No. 201sudheer4079100% (2)

- Is Standard ListDocument11 pagesIs Standard ListSunil PulikkalNo ratings yet

- Standards For Pipe LineDocument57 pagesStandards For Pipe Linegopaltry33% (3)

- Rules of Thumb For Steel StructuresDocument5 pagesRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Main Truss Design DetailsDocument19 pagesMain Truss Design Detailsformwork companyNo ratings yet

- Footing Design DimensionsDocument3 pagesFooting Design DimensionsMesfinNo ratings yet

- Design of RCC Column (C1)Document5 pagesDesign of RCC Column (C1)Ramachandra SahuNo ratings yet

- MM Met D19084 RP 012Document96 pagesMM Met D19084 RP 012Dass DassNo ratings yet

- Portal Method: For Transversal/Longitudinal SectionDocument70 pagesPortal Method: For Transversal/Longitudinal SectionJoseph Tan LantoNo ratings yet

- Design of Laminated Elastomeric Bearing for 20m SpanDocument8 pagesDesign of Laminated Elastomeric Bearing for 20m Spannaresh KUMARNo ratings yet

- Base Plate & Anchor BoltDocument40 pagesBase Plate & Anchor BoltSiva baalanNo ratings yet

- Corrected For FoundationDocument121 pagesCorrected For FoundationSaurabh TiwariNo ratings yet

- Load Data:: VSL Middle East Qatar Date Sheet Albustan Street South, Qatar Design of Main Steel Beam Project: Document NoDocument4 pagesLoad Data:: VSL Middle East Qatar Date Sheet Albustan Street South, Qatar Design of Main Steel Beam Project: Document Novrajan1988100% (1)

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- Zee Purlin Design Sheet AnalysisDocument4 pagesZee Purlin Design Sheet AnalysisShawkat Ali KhanNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- 2 0 Insert Plate Calculations Type 14 PDFDocument4 pages2 0 Insert Plate Calculations Type 14 PDFALPHYL BALASABASNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Actual Base Plate Design-V1.2-42-210Document6 pagesActual Base Plate Design-V1.2-42-210Livian TeddyNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Design of Circular Wall (Tank Wall) : Case: 1 Only Water From InsideDocument6 pagesDesign of Circular Wall (Tank Wall) : Case: 1 Only Water From InsidecivilceejiNo ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- Steel ConnectionsDocument83 pagesSteel ConnectionsMEPNo ratings yet

- 5.0 Connection 4Document3 pages5.0 Connection 4Gaurav BhabadNo ratings yet

- Design Calculations For Primary Beam Connections As Welded Connections R2Document6 pagesDesign Calculations For Primary Beam Connections As Welded Connections R2Rajesh PoreNo ratings yet

- Load Combination Is 800-2007Document5 pagesLoad Combination Is 800-2007Jitendra PNo ratings yet

- Gb1 Pump Room 13nov2013Document3 pagesGb1 Pump Room 13nov2013Erickson MalicsiNo ratings yet

- Reinf - conc.Beams-Design Torsional&Axially LoadedDocument1 pageReinf - conc.Beams-Design Torsional&Axially LoadedHermogenesGerardoIII OcanaNo ratings yet

- Appendix - 4ADocument15 pagesAppendix - 4Amoumita mukherjeeNo ratings yet

- Design of Bearing Replacement SchemeDocument10 pagesDesign of Bearing Replacement SchemeShivendra KumarNo ratings yet

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayDocument1 pageEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sNo ratings yet

- Effective Length of Stepped ColumnDocument1 pageEffective Length of Stepped ColumnSunil PulikkalNo ratings yet

- Cold Forms Section Tolerances As Per MbmaDocument1 pageCold Forms Section Tolerances As Per MbmaSunil PulikkalNo ratings yet

- Crane DataDocument1 pageCrane DataSunil PulikkalNo ratings yet

- Torsional PropertiesDocument19 pagesTorsional PropertiesAndrés Felipe HernándezNo ratings yet

- Multi-Storey Building 3D Model & Floor Framing PlanDocument6 pagesMulti-Storey Building 3D Model & Floor Framing PlanSunil PulikkalNo ratings yet

- CFDocument1 pageCFSunil PulikkalNo ratings yet

- Innovations in PlatDocument26 pagesInnovations in PlatSunil PulikkalNo ratings yet

- STEEL STRUCTURE MAGAZINE, Article About Pipe StructureDocument3 pagesSTEEL STRUCTURE MAGAZINE, Article About Pipe StructureSunil PulikkalNo ratings yet

- Light Weight BricksDocument4 pagesLight Weight BricksSunil PulikkalNo ratings yet

- Rayleigh RitzDocument23 pagesRayleigh Ritzjmam1992No ratings yet

- Building Insulation BulletinDocument4 pagesBuilding Insulation BulletinSarath ChukkapalliNo ratings yet

- Bolt Spec ReviewDocument2 pagesBolt Spec ReviewAnonymous Re62LKaACNo ratings yet

- General Safety Rules For Steel Fabricators AISCDocument55 pagesGeneral Safety Rules For Steel Fabricators AISCEdison BecerraNo ratings yet

- Molecular Cell Biology 7Th Edition Lodish Test Bank Full Chapter PDFDocument29 pagesMolecular Cell Biology 7Th Edition Lodish Test Bank Full Chapter PDFrorybridgetewe100% (11)

- Specific Heat Capacity GLY11Document1 pageSpecific Heat Capacity GLY11Alyssa ColeNo ratings yet

- Java CRUD App MySQLDocument6 pagesJava CRUD App MySQLNanda Priyo HutomoNo ratings yet

- SMC Imu Data Sheet Motion SensorDocument2 pagesSMC Imu Data Sheet Motion SensorErwin ArdiasNo ratings yet

- ThermodynamicsDocument9 pagesThermodynamicssamir boseNo ratings yet

- Chapter 4Document100 pagesChapter 4khgvouy hvogyflNo ratings yet

- Wireless - Zone Na Alarmna Centrala Dodatok Za Model 1565Document3 pagesWireless - Zone Na Alarmna Centrala Dodatok Za Model 1565billwillis66No ratings yet

- Thorn User ManualDocument38 pagesThorn User ManualdanNo ratings yet

- E 4000 Medidor GLPDocument56 pagesE 4000 Medidor GLPBode JuniorNo ratings yet

- A Detailed Lesson PlanDocument7 pagesA Detailed Lesson PlanNorol-in SabacanNo ratings yet

- Determine Earth's Magnetic Field Using Tangent GalvanometerDocument26 pagesDetermine Earth's Magnetic Field Using Tangent GalvanometerKusum SukhijaNo ratings yet

- Mensuration: Area of A TrapeziumDocument61 pagesMensuration: Area of A TrapeziumSahil EduNo ratings yet

- Chemistry Webquest Introduction to AtomsDocument3 pagesChemistry Webquest Introduction to AtomsMarx GomesNo ratings yet

- Config Et Use Rslogix500Document76 pagesConfig Et Use Rslogix500Fogape TitiNo ratings yet

- 2017-2018 New CatalogueDocument218 pages2017-2018 New CataloguerobmndzNo ratings yet

- 3064 A CG Assignment-2Document57 pages3064 A CG Assignment-2nokexo6067No ratings yet

- Multiple Organ Failure Post Injury, Pathophysiology and Prevention of ARDS in Trauma PatientDocument37 pagesMultiple Organ Failure Post Injury, Pathophysiology and Prevention of ARDS in Trauma PatientDipo Mas SuyudiNo ratings yet

- Heart Failure Prediction Using ANNDocument13 pagesHeart Failure Prediction Using ANNSHIVANSH KASHYAP (RA2011003010988)No ratings yet

- Lecture Notes 1 - Chapter 1Document5 pagesLecture Notes 1 - Chapter 1sohailahmed714319No ratings yet

- Motion Assignment Class 9Document73 pagesMotion Assignment Class 9Monica SreeNo ratings yet

- Needle Roller Bearing Combined TypeDocument5 pagesNeedle Roller Bearing Combined TypeNemish KanwarNo ratings yet

- In 2 PostDocument4 pagesIn 2 PostHarsha SubbarayappaNo ratings yet

- (Revised) Syllabus+Blue Print (Class-6th)Document9 pages(Revised) Syllabus+Blue Print (Class-6th)vipsinNo ratings yet

- Analysis On Spatial Variation of Rainfall and Groundwater Fluctuation in Hebballa Watershed, Mysore District, Karnataka, IndiaDocument7 pagesAnalysis On Spatial Variation of Rainfall and Groundwater Fluctuation in Hebballa Watershed, Mysore District, Karnataka, IndiaEditor IJTSRDNo ratings yet

- CS134 Web Site Design QuizDocument6 pagesCS134 Web Site Design QuizMoulinaDasNo ratings yet