Professional Documents

Culture Documents

Base Plate & Anchor Bolt

Uploaded by

Siva baalanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate & Anchor Bolt

Uploaded by

Siva baalanCopyright:

Available Formats

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 109.70 kN - m

Number of bolts = 4

Lever arm = 0.450

Tension in each bolt = 121.89 kN

Dia of bolt = 30.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 302 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 282.74 KN

Ratio = 0.43

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 41.70 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 10.43 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 169.65 kN

Ratio = 0.06

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.49 Hence safe

Provide 4 Nos. of 30 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 30 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 180 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -15 mm

Required total edge distance = 180 + -15

= 165 mm

Provide min. edge distance of 165 mm

Which takes care of cone pull out and punching shear failure of concrete.

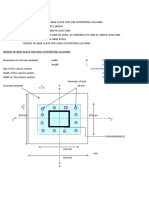

Design of Base Plate

Assumed Base Plate Size, L = 550 mm

B = 550 mm

Size of column = HE340A

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 121.89 kN

Moment due to tension, M = 121.89 x 0.05

= 6.094 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 6.09 / (105.02 x 275x1.33)

= 30.85 mm

= 30 mm Not Safe

Provide thickness of base plate as 30 mm

Hence the size of the base plate = 550 x 550 x 30

Check for Anchor Bolts

Loads

Tension Force per Bolt (max.) Tb = ### kN

Shear Force per Bolt Fb = 10.43 kN

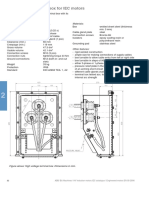

Connection Details

Grade of Anchor Bolt = 8.8 Grade

Diameter of anchor bolt db = 20 mm

Gross area of one bolt Abg = 314.2 mm2

Effective area of one bolt Abn = 251.3 mm2

Shear strength of bolt ps = 240 N/mm2

Tension strength of bolt pt = 400 N/mm2

Shear capacity of one bolt Ps = 75 kN > Fb, SAFE

Tension capacity of one bolt Pt = 126 kN > Tb, SAFE

Check for combined shear and Tension

= Fb / Ps + Tb / Pt

= 1.11 < 1.4, SAFE

Check for Anchorage of Bolt

Assuming tension force is transfer to concrete by bond along embeded length

Length of anchorage required L = Tb

p db fbu

Where

Compressive strength of concrete fcu = 30.00 N/mm2

Design ultimate bond stress fbu = 0.28 fcu N/mm2

(As per cl. 3.12.8.4 of BS8110 part 1) = 1.53 N/mm2

Length of anchorage required L = 1265 mm

Length of anchorage provided L = 750 mm

Provide anchorage length 750 mm if anchorage not possible to provide due to

restriction in RC beam / Column depth, Provide anchor bolt with anchor plate and check for

pull-out strength to be performed.

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 100.10 kN - m

Number of bolts = 4

Lever arm = 0.450

Tension in each bolt = 111.22 kN

Dia of bolt = 30.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 282.74 KN

Ratio = 0.39

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 52.50 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 13.13 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 169.65 kN

Ratio = 0.08

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.47 Hence safe

Provide 4 Nos. of 30 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 30 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 180 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -15 mm

Required total edge distance = 180 + -15

= 165 mm

Provide min. edge distance of 165 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 450 mm

B = 450 mm

Size of column = HE340A

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 111.22 kN

Moment due to tension, M = 111.22 x 0.05

= 5.561 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 5.56 / (105.02 x 275x1.33)

= 29.47 mm

= 30 mm Hence Safe

Provide thickness of base plate as 30 mm

Hence the size of the base plate = 450 x 450 x 30

Check for Anchor Bolts

Loads

Tension Force per Bolt (max.) Tb = ### kN

Shear Force per Bolt Fb = 13.13 kN

Connection Details

Grade of Anchor Bolt = 8.8 Grade

Diameter of anchor bolt db = 20 mm

Gross area of one bolt Abg = 314.2 mm2

Effective area of one bolt Abn = 251.3 mm2

Shear strength of bolt ps = 240 N/mm2

Tension strength of bolt pt = 400 N/mm2

Shear capacity of one bolt Ps = 75 kN > Fb, SAFE

Tension capacity of one bolt Pt = 126 kN > Tb, SAFE

Check for combined shear and Tension

= Fb / Ps + Tb / Pt

= 1.06 < 1.4, SAFE

Check for Anchorage of Bolt

Assuming tension force is transfer to concrete by bond along embeded length

Length of anchorage required L = Tb

p db fbu

Where

Compressive strength of concrete fcu = 30.00 N/mm2

Design ultimate bond stress fbu = 0.28 fcu N/mm2

(As per cl. 3.12.8.4 of BS8110 part 1) = 1.53 N/mm2

Length of anchorage required L = 1154 mm

Length of anchorage provided L = 750 mm

Provide anchorage length 750 mm if anchorage not possible to provide due to

restriction in RC beam / Column depth, Provide anchor bolt with anchor plate and check for

pull-out strength to be performed.

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 65.00 kN - m

Number of bolts = 4

Lever arm = 0.350

Tension in each bolt = 92.86 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.74

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 16.60 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 4.15 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.06

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.79 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 450 mm

B = 450 mm

Size of column = UC203X203X86

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 92.86 kN

Moment due to tension, M = 92.86 x 0.05

= 4.643 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 4.64 / (105.02 x 275x1.33)

= 26.93 mm

= 30 mm Hence Safe

Provide thickness of base plate as 30 mm

Hence the size of the base plate = 450 x 450 x 30

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 65.00 kN - m

Number of bolts = 4

Lever arm = 0.350

Tension in each bolt = 92.86 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.74

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 17.00 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 4.25 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.06

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.80 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 450 mm

B = 450 mm

Size of column = UC203X203X86

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 92.86 kN

Moment due to tension, M = 92.86 x 0.05

= 4.643 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 4.64 / (105.02 x 275x1.33)

= 26.93 mm

= 30 mm Hence Safe

Provide thickness of base plate as 30 mm

Hence the size of the base plate = 450 x 450 x 30

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 7.30 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 14.60 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.12

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 5.20 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 1.30 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.02

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.13 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 14.60 kN

Moment due to tension, M = 14.6 x 0.05

= 0.730 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 0.73 / (105.02 x 275x1.33)

= 10.68 mm

= 16 mm Hence Safe

Provide thickness of base plate as 16 mm

Hence the size of the base plate = 350 x 350 x 16

Check for Anchor Bolts

Loads

Tension Force per Bolt (max.) Tb = 14.60 kN

Shear Force per Bolt Fb = 1.30 kN

Connection Details

Grade of Anchor Bolt = 8.8 Grade

Diameter of anchor bolt db = 20 mm

Gross area of one bolt Abg = 314.2 mm2

Effective area of one bolt Abn = 251.3 mm2

Shear strength of bolt ps = 240 N/mm2

Tension strength of bolt pt = 400 N/mm2

Shear capacity of one bolt Ps = 75 kN > Fb, SAFE

Tension capacity of one bolt Pt = 126 kN > Tb, SAFE

Check for combined shear and Tension

= Fb / Ps + Tb / Pt

= 0.13 < 1.4, SAFE

Check for Anchorage of Bolt

Assuming tension force is transfer to concrete by bond along embeded length

Length of anchorage required L = Tb

p db fbu

Where

Compressive strength of concrete fcu = 30.00 N/mm2

Design ultimate bond stress fbu = 0.28 fcu N/mm2

(As per cl. 3.12.8.4 of BS8110 part 1) = 1.53 N/mm2

Length of anchorage required L = 152 mm

Length of anchorage provided L = 750 mm

Provide anchorage length 750 mm if anchorage not possible to provide due to

restriction in RC beam / Column depth, Provide anchor bolt with anchor plate and check for

pull-out strength to be performed.

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 8.50 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 17.00 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.14

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 6.50 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 1.63 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.02

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.16 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 17.00 kN

Moment due to tension, M = 17 x 0.05

= 0.850 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 0.85 / (105.02 x 275x1.33)

= 11.52 mm

= 16 mm Hence Safe

Provide thickness of base plate as 16 mm

Hence the size of the base plate = 350 x 350 x 16

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 72.80 kN - m

Number of bolts = 4

Lever arm = 0.400

Tension in each bolt = 91.00 kN

Dia of bolt = 30.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 282.74 KN

Ratio = 0.32

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 40.00 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 10.00 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 169.65 kN

Ratio = 0.06

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.38 Hence safe

Provide 4 Nos. of 30 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 30 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 180 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -15 mm

Required total edge distance = 180 + -15

= 165 mm

Provide min. edge distance of 165 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 91.00 kN

Moment due to tension, M = 91 x 0.05

= 4.550 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 4.55 / (105.02 x 275x1.33)

= 26.66 mm

= 16 mm Not Safe

Provide thickness of base plate as 16 mm

Hence the size of the base plate = 350 x 350 x 16

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 20.20 kN - m

Number of bolts = 4

Lever arm = 0.300

Tension in each bolt = 33.67 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.27

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 29.20 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 7.30 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.10

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.36 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 400 mm

B = 400 mm

Size of column = UC203X203X46

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 33.67 kN

Moment due to tension, M = 33.67 x 0.05

= 1.683 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 1.68 / (105.02 x 275x1.33)

= 16.22 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 400 x 400 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 20.20 kN - m

Number of bolts = 4

Lever arm = 0.300

Tension in each bolt = 33.67 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.27

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 32.70 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 8.18 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.11

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.38 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 400 mm

B = 400 mm

Size of column = UC203X203X46

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 33.67 kN

Moment due to tension, M = 33.67 x 0.05

= 1.683 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 1.68 / (105.02 x 275x1.33)

= 16.22 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 400 x 400 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 20.10 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 40.20 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.32

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 22.80 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 5.70 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.08

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.40 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 40.20 kN

Moment due to tension, M = 40.2 x 0.05

= 2.010 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 2.01 / (105.02 x 275x1.33)

= 17.72 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 350 x 350 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 4.00 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 8.00 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.06

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 50.10 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 12.53 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.17

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.23 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 8.00 kN

Moment due to tension, M = 8 x 0.05

= 0.400 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 0.4 / (105.02 x 275x1.33)

= 7.90 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 350 x 350 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 20.00 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 40.00 kN

Dia of bolt = 16.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 80.42 KN

Ratio = 0.50

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 13.50 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 3.38 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 48.25 kN

Ratio = 0.07

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.57 Hence safe

Provide 4 Nos. of 16 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 16 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 96 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -8 mm

Required total edge distance = 96 + -8

= 88 mm

Provide min. edge distance of 88 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 40.00 kN

Moment due to tension, M = 40 x 0.05

= 2.000 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 2 / (105.02 x 275x1.33)

= 17.67 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 350 x 350 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 31.90 kN - m

Number of bolts = 4

Lever arm = 0.300

Tension in each bolt = 53.17 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.42

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 14.50 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 3.63 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.05

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.47 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 400 mm

B = 400 mm

Size of column = UC203X203X46

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 53.17 kN

Moment due to tension, M = 53.17 x 0.05

= 2.658 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 2.66 / (105.02 x 275x1.33)

= 20.38 mm

= 20 mm Not Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 400 x 400 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 22.30 kN - m

Number of bolts = 4

Lever arm = 0.300

Tension in each bolt = 37.17 kN

Dia of bolt = 20.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 125.66 KN

Ratio = 0.30

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 7.30 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 1.83 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 75.40 kN

Ratio = 0.02

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.32 Hence safe

Provide 4 Nos. of 20 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 20 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 120 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -10 mm

Required total edge distance = 120 + -10

= 110 mm

Provide min. edge distance of 110 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 400 mm

B = 400 mm

Size of column = UC203X203X46

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 37.17 kN

Moment due to tension, M = 37.17 x 0.05

= 1.858 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 1.86 / (105.02 x 275x1.33)

= 17.04 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 400 x 400 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 20.20 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 40.40 kN

Dia of bolt = 16.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 80.42 KN

Ratio = 0.50

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 21.00 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 5.25 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 48.25 kN

Ratio = 0.11

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.61 Hence safe

Provide 4 Nos. of 16 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 16 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 96 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -8 mm

Required total edge distance = 96 + -8

= 88 mm

Provide min. edge distance of 88 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 40.40 kN

Moment due to tension, M = 40.4 x 0.05

= 2.020 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 2.02 / (105.02 x 275x1.33)

= 17.76 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 350 x 350 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 15.90 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 31.80 kN

Dia of bolt = 16.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 80.42 KN

Ratio = 0.40

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 14.30 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 3.58 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 48.25 kN

Ratio = 0.07

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.47 Hence safe

Provide 4 Nos. of 16 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 16 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 96 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -8 mm

Required total edge distance = 96 + -8

= 88 mm

Provide min. edge distance of 88 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 31.80 kN

Moment due to tension, M = 31.8 x 0.05

= 1.590 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 1.59 / (105.02 x 275x1.33)

= 15.76 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 350 x 350 x 20

BOLT DESIGN

Critical Uplift = 0.00 kN

Moment = 18.80 kN - m

Number of bolts = 4

Lever arm = 0.250

Tension in each bolt = 37.60 kN

Dia of bolt = 16.00 mm

Allowable tensile stress = 400.00 N/mm2 BOLT Astm A307 grade C

Tension capacity of bolt (Due to wind load stress is increased by 25 % )

= (p x 202 / 4) x ( 400 x 0.8 x 1.25) / 1000

= 80.42 KN

Ratio = 0.47

Allowable Capacity > Actual Tenion Hence safe

Resultant critical Shear = 15.30 kN

(For Load case no. 203, At node no.644 from Staad output)

Shear in Each bolt = 3.83 kN

Allowable Shear stress = 240 N/mm2 BOLT Astm A307 grade C

Shear Capacity of Bolt (Due to wind load stress is increased by 25 % )

= (p x 242 / 4) x ( 240 x 0.8 x 1.25) / 1000

= 48.25 kN

Ratio = 0.08

Allowable Capacity > Actual Shear Hence Safe

Combined Check for Shear and Tension

Ratio = 0.55 Hence safe

Provide 4 Nos. of 16 mm dia. Bolt.

Calculation of edge distance to take care cone pull out and

punching shear failure of the concrete.

Dia of anchor bolt,Do = 16 mm

Dia of sleeve used,Ds = mm

Basic edge distance, 6xDo = 96 mm

Increment in edge dist.due to sleeve = 1/2(Ds-Do)

= -8 mm

Required total edge distance = 96 + -8

= 88 mm

Provide min. edge distance of 88 mm

Which takes care of cone pull out and punching shear failure of concrete.

Design of Base Plate

Assumed Base Plate Size, L = 350 mm

B = 350 mm

Size of column = UC152X152X37

Bending Stress, σbs = 275 N/mm2

Dist of bolt from edge of B.Plate = 0.05 m

Tension = 37.60 kN

Moment due to tension, M = 37.6 x 0.05

= 1.880 kN-m

Width of washer = 0.075 m

Width resisting moment,B = 2 x X + 75

X = 0.026x tan30º = 15.01 mm

Width resisting moment, B = 2 x 15.01 + 75

= 105.02 mm

Thickness = √ 6M/(Bxσbs)

= √ 6 x 1.88 / (105.02 x 275x1.33)

= 17.14 mm

= 20 mm Hence Safe

Provide thickness of base plate as 20 mm

Hence the size of the base plate = 350 x 350 x 20

You might also like

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 pagesShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNo ratings yet

- Footing Design DimensionsDocument3 pagesFooting Design DimensionsMesfinNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- Base Plate Design (Pin) Asd For CompressionDocument54 pagesBase Plate Design (Pin) Asd For CompressionEmdadul HuqNo ratings yet

- Base Plate Design Metric Units Online Calculation ReportDocument7 pagesBase Plate Design Metric Units Online Calculation ReportmaheshbandhamNo ratings yet

- Double Angle ConnectionDocument8 pagesDouble Angle ConnectionrunkirNo ratings yet

- Design of column splice plates and weldsDocument4 pagesDesign of column splice plates and weldsNiraj Shinde100% (1)

- Sheet1 A-B Bay CM: Properties of Gantry SectionDocument2 pagesSheet1 A-B Bay CM: Properties of Gantry SectionadihindNo ratings yet

- Purlins & GirtsDocument10 pagesPurlins & GirtsRaviKiranNo ratings yet

- Rev G Connection-Double AngleDocument12 pagesRev G Connection-Double AnglePankaj_Taneja_9684No ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- Design of rigid connection detail 85Document215 pagesDesign of rigid connection detail 85Umer AziqNo ratings yet

- Purlin SheetDocument5 pagesPurlin SheetSher AfganNo ratings yet

- Diagram Drawing Design Forces and DetailsDocument6 pagesDiagram Drawing Design Forces and Detailswaweng22No ratings yet

- Four Bolt Moment Connection DesignDocument12 pagesFour Bolt Moment Connection DesignDarshan Panchal0% (1)

- Moment Connection Design Hea220Document56 pagesMoment Connection Design Hea220Atul WanodeNo ratings yet

- Calculation of end plate beam connection designDocument1 pageCalculation of end plate beam connection designFortunata Citraningrum SukmonoNo ratings yet

- Simple Bracing ConnectionDocument33 pagesSimple Bracing ConnectionRohit SinghNo ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- A23.3-04 CorbelsDocument3 pagesA23.3-04 CorbelsDivyesh MistryNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- Load calculation and wind analysis of temporary barricationDocument2 pagesLoad calculation and wind analysis of temporary barricationBrandon HaleNo ratings yet

- 16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor BoltsDocument30 pages16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor Boltsafzal samaNo ratings yet

- Base Plate With BoltsDocument3 pagesBase Plate With BoltsAbu KhatriNo ratings yet

- Design of Steel Batten Column: Grid ID K4 1.0 Sectional PropertiesDocument7 pagesDesign of Steel Batten Column: Grid ID K4 1.0 Sectional PropertiesBijay ThapaNo ratings yet

- Wind PDFDocument24 pagesWind PDFnagarajhebbarNo ratings yet

- Shear and Torsion CalDocument6 pagesShear and Torsion Calabdul khaderNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- The - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcreteDocument9 pagesThe - Thickness - of - Base - Plate - by - The - LRFD - The - I - Section Column - and - ConcretejscuencaNo ratings yet

- Gusset Plate Connection DesignDocument3 pagesGusset Plate Connection DesignMin Khant KyawNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Document49 pagesSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgNo ratings yet

- Project Job Ref.: V B T, y T, R CDocument3 pagesProject Job Ref.: V B T, y T, R CM IQbalNo ratings yet

- Basic Design ValuesDocument4 pagesBasic Design Valuesnenpatel-1No ratings yet

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Ext Finplate ConnecDocument78 pagesExt Finplate Connechary9100No ratings yet

- Steel Building Brace Connection DesignDocument4 pagesSteel Building Brace Connection Designmoganna73No ratings yet

- Splice Connection Beam Wide FlangeDocument2 pagesSplice Connection Beam Wide Flangejoneru 04No ratings yet

- REINFORCEMENT CALCULATION FOR 1000MM THICK CF1Document3 pagesREINFORCEMENT CALCULATION FOR 1000MM THICK CF1ARUNKUMAR KNo ratings yet

- RPLC DEEP CONVERSION BRACING CONNECTION DESIGNDocument32 pagesRPLC DEEP CONVERSION BRACING CONNECTION DESIGNHeberth SanchezNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- SL - No Description Reference 1 Load Input For Silo (7M X 7M) 1.1 Basic InputDocument8 pagesSL - No Description Reference 1 Load Input For Silo (7M X 7M) 1.1 Basic Inputkushaljp8989No ratings yet

- Base Plate DesignMS601aDocument3 pagesBase Plate DesignMS601aduazo2009No ratings yet

- 2.3.4 Design Parameters - Design Per AISC 360-05 and 360-10 (Unified)Document6 pages2.3.4 Design Parameters - Design Per AISC 360-05 and 360-10 (Unified)HamdiNo ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- Design of Brace Connection PlateDocument6 pagesDesign of Brace Connection PlateJonatas PrandiniNo ratings yet

- Base Plate Uc152x152x23Document2 pagesBase Plate Uc152x152x23sonofalexanderNo ratings yet

- BEAM Moment Connection - UB 254x146x37Document7 pagesBEAM Moment Connection - UB 254x146x37Shriniwas NaikNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Knee ConnectionsDocument13 pagesKnee ConnectionsNag RajNo ratings yet

- HDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Document8 pagesHDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Mohammad Shadab AliNo ratings yet

- Design of BracingDocument4 pagesDesign of Bracingankkeshmundra1No ratings yet

- Section Properties: Left Beam Member MC 400: Major MinorDocument12 pagesSection Properties: Left Beam Member MC 400: Major MinorshaimenneNo ratings yet

- Fatigue CheckDocument1 pageFatigue CheckSunil PulikkalNo ratings yet

- Base Plate +and Foundation Bolt Design +connection Design 30-08-2021Document9 pagesBase Plate +and Foundation Bolt Design +connection Design 30-08-2021Deepanshu GargNo ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- Anchor Bolt Design CalculationsDocument64 pagesAnchor Bolt Design CalculationsSiva baalanNo ratings yet

- ASME B73 Pump Standards OverviewDocument16 pagesASME B73 Pump Standards Overviewdang2172014No ratings yet

- Support Leg DesignDocument4 pagesSupport Leg DesignSiva baalanNo ratings yet

- Weight Estimation of Vessels AppsDocument26 pagesWeight Estimation of Vessels Appsdhavalesh1No ratings yet

- SADDLE STRESS ANALYSISDocument19 pagesSADDLE STRESS ANALYSISSiva baalanNo ratings yet

- Loading Arms SpecificationDocument9 pagesLoading Arms Specificationm.shehreyar.khanNo ratings yet

- Loading Arm SpecificationDocument15 pagesLoading Arm Specificationyinkaakins2001No ratings yet

- How To Calculate Flat Plate Thickness of Flat Bottom Storage TankDocument3 pagesHow To Calculate Flat Plate Thickness of Flat Bottom Storage TankSiva baalanNo ratings yet

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNo ratings yet

- BP Spec - Air Cooled Heat ExchangerDocument46 pagesBP Spec - Air Cooled Heat Exchangertlili-samir7290100% (2)

- M. F. Sullivan: 9/27/2016 Dr. Sandor Somogyi 1Document38 pagesM. F. Sullivan: 9/27/2016 Dr. Sandor Somogyi 1Muhammad Haris BaigNo ratings yet

- Design of Saddle Support For Horizontal Pressure Vessel PDFDocument5 pagesDesign of Saddle Support For Horizontal Pressure Vessel PDFnizam1372100% (3)

- wrc 예제2 PDFDocument4 pageswrc 예제2 PDFHyoungyoon John MoonNo ratings yet

- Weight Estimation of Vessels AppsDocument26 pagesWeight Estimation of Vessels Appsdhavalesh1No ratings yet

- M. F. Sullivan: 9/27/2016 Dr. Sandor Somogyi 1Document38 pagesM. F. Sullivan: 9/27/2016 Dr. Sandor Somogyi 1Muhammad Haris BaigNo ratings yet

- Wind-Seismic - Basic ConceptDocument21 pagesWind-Seismic - Basic Conceptraja raniNo ratings yet

- Nozzle Loads WRC 107 Ver 1.1Document5 pagesNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- Design of Saddle Support For Horizontal Pressure Vessel PDFDocument5 pagesDesign of Saddle Support For Horizontal Pressure Vessel PDFnizam1372100% (3)

- ASME B73 Pump Standards OverviewDocument16 pagesASME B73 Pump Standards Overviewdang2172014No ratings yet

- 2 5ProjectSupportSystemMay08Document1 page2 5ProjectSupportSystemMay08Siva baalanNo ratings yet

- ASME B73 Pump Standards OverviewDocument16 pagesASME B73 Pump Standards Overviewdang2172014No ratings yet

- Wind Pressure Calculation As per SP-1275Document7 pagesWind Pressure Calculation As per SP-1275Siva baalanNo ratings yet

- Dps-3-1206-013-E1782-A4-2 (Final)Document449 pagesDps-3-1206-013-E1782-A4-2 (Final)Siva baalanNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankHgagselim Selim100% (1)

- API 653 Minimum Thk. CalculationDocument1 pageAPI 653 Minimum Thk. CalculationSiva baalan0% (1)

- Base Plate & Anchor BoltDocument40 pagesBase Plate & Anchor BoltSiva baalanNo ratings yet

- Fixed Cone Roof Tank Design Input DataDocument182 pagesFixed Cone Roof Tank Design Input DataSiva baalanNo ratings yet

- Reference: AISC Anchor Chair /pressure Vessel Handbook by Moss and BasicDocument3 pagesReference: AISC Anchor Chair /pressure Vessel Handbook by Moss and Basicswarnamalini0% (1)

- Wind Seismic CalculationsDocument3 pagesWind Seismic Calculationsraja raniNo ratings yet

- Storage Tank DesignDocument21 pagesStorage Tank Designravi456compNo ratings yet

- Bafang BBS01/BBS02 Installation ManualDocument18 pagesBafang BBS01/BBS02 Installation ManualKirby ChirinosNo ratings yet

- Lathe Cutting TipsDocument51 pagesLathe Cutting TipsDavid KeighleyNo ratings yet

- SX1024 User ManualDocument74 pagesSX1024 User ManualkbncngfgkdNo ratings yet

- DIN 906 - 1983hexagon Socket Pipe PlugsDocument4 pagesDIN 906 - 1983hexagon Socket Pipe PlugsChris StefanouNo ratings yet

- Brick Veneer Masonry: Rev # Description of Change Author WP# DateDocument8 pagesBrick Veneer Masonry: Rev # Description of Change Author WP# DateMatthew Ho Choon LimNo ratings yet

- 192.05 101870341008 101870349999 AG30-Edge Cutter, (FR - Ri) Re - LeDocument14 pages192.05 101870341008 101870349999 AG30-Edge Cutter, (FR - Ri) Re - LeAnonymous cS9UMvhBq100% (1)

- Tesla Model S Rear Door Handle ReplacementDocument12 pagesTesla Model S Rear Door Handle ReplacementAnonymous TjcIWjNo ratings yet

- Demonstration Models For Teaching Structural Mechanics: W. G. GoddenDocument84 pagesDemonstration Models For Teaching Structural Mechanics: W. G. GoddenGuilherme TeixeiraNo ratings yet

- 8900 01003-Up PM LNK 1087854Document187 pages8900 01003-Up PM LNK 1087854Planos MontacargasNo ratings yet

- Yuken EC 1302 PilotDocument7 pagesYuken EC 1302 PilotAli RamosNo ratings yet

- Half Pipe PlansDocument14 pagesHalf Pipe PlansTroy Ivey100% (1)

- WTP Tag Agustus PercepatanDocument114 pagesWTP Tag Agustus Percepatankrisyanto krisyanto100% (1)

- ASPIR Full Size 3D Printed Humanoid RobotDocument45 pagesASPIR Full Size 3D Printed Humanoid RobotCHARLIEBOY77No ratings yet

- Hyster: ElectricalDocument31 pagesHyster: ElectricalMelwyn Fernandes100% (1)

- Voe219920201 SD110 V1.4Document175 pagesVoe219920201 SD110 V1.4Dhru Ti100% (5)

- Operator'S Manual: Propane Powered Line TrimmerDocument22 pagesOperator'S Manual: Propane Powered Line TrimmerjNo ratings yet

- 54990TL - EN - Installation Instructions - Z - 45 - 75 200129 PDFDocument72 pages54990TL - EN - Installation Instructions - Z - 45 - 75 200129 PDFaco100% (2)

- Spindle Belt ReplacementDocument3 pagesSpindle Belt ReplacementAshNo ratings yet

- Mercruiser Installation and AdjustmentDocument66 pagesMercruiser Installation and Adjustmentsalvatore dalessandro100% (1)

- VM 3382 Eriez Feeder Model 85B 105B IOMDocument12 pagesVM 3382 Eriez Feeder Model 85B 105B IOMAvijit ShuklaNo ratings yet

- Installation and Maintenance Manual for M 2.30 F 2-Post Automotive LiftDocument32 pagesInstallation and Maintenance Manual for M 2.30 F 2-Post Automotive LiftWalid0% (1)

- 1447 NCD DoorsDocument25 pages1447 NCD Doorsipsit_das12No ratings yet

- DT&R Maintenance OJT - 2M SpearDocument1 pageDT&R Maintenance OJT - 2M SpearllereadorNo ratings yet

- Instruction Manual Brother LK3-B438EDocument62 pagesInstruction Manual Brother LK3-B438EMaskusyani0% (1)

- Arrow Engine CompanyDocument181 pagesArrow Engine CompanyZule González AldamaNo ratings yet

- Catalago 750 TonDocument84 pagesCatalago 750 TonValmac ServicesNo ratings yet

- Anchor CheckDocument3 pagesAnchor CheckLaurence SarmientoNo ratings yet

- Manual Motor Eaton Serie 46Document32 pagesManual Motor Eaton Serie 46Valentina Lara80% (5)

- BERNSTEIN Standard-EnclosuresDocument60 pagesBERNSTEIN Standard-EnclosuresDacar ValladaresNo ratings yet

- ABB 6kV Terminal Box LayoutDocument2 pagesABB 6kV Terminal Box LayoutAli HashemiNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Water 4.0: The Past, Present, and Future of the World's Most Vital ResourceFrom EverandWater 4.0: The Past, Present, and Future of the World's Most Vital ResourceRating: 3.5 out of 5 stars3.5/5 (9)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet