Professional Documents

Culture Documents

Column Splice For Double - 20170522

Uploaded by

sundarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column Splice For Double - 20170522

Uploaded by

sundarCopyright:

Available Formats

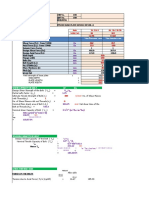

Doc No 0

COLUMN SPLICE DESIGN 1 of1

Rev 0

DOOSAN POWER SYSTEMS

CS - F1/A - F1-1 - C1/A-2

INDIA PVT LTD

Prepared 0

Ref Dwg No:

Load details received on

1 Connection type Ref SAP Force INPUT Reference

1 SAP member No / Load Comp CS - F1/A - F1-1 - C1/A-2

SAP node No C1/A-2

Grid / Position F1/A

Column Splice type Bearing type Flange & Web plate type

Bolt type Friction grip type (Pretension & slip critical at working (service load))

Code IS 800-2007

Design Method x Working stress method

Mz

Mz / D Mz / D x

My / 2

Tx

Fy Fz /2

Fz (R) /2

Fy (R)

Tx (R)

Mz (R) / Mz (R) / My (R) / 2

Mz (R)

x

x

VIEW A-A VIEW B-B

Fz

z

Mz

My

Fy

y` y

y y

A A

PLAN

Column Splice design Page 1 of 13

2 Maximum Analysis force

Working stress design load

AXIAL Fx SHEAR MOMENT

Load Tx Px Fy Fz Mx My Mz

comb KN KN KN KN KN.m KN.m KN.m

0 391 2038 6 4 0 0 0

3 Member property

3.1 Column Splice plate

Grade fu(c) fy(f) fy(w) Grade fu(p) fy(fp) fy(wp)

2 2 2 2 2 2

N/mm N/mm N/mm N/mm N/mm N/mm

E350 490 330 350 E350 490 350 350

Governed by yielding or Buckling gm0 = 1.1

Governed by ultimate stress gm1 = 1.25

3.2 Bolts

Bolt type Grade fu(b) fy(b)

2 2

N/mm N/mm

HSFG 10.9 1040 940

4 Section properties

4.1 Lower Column 450X450X30X15

Ag h bf tf tw An Ay Az

2 2 2 2

mm mm mm mm mm mm mm mm

32850 450 450.00 30 15 32590 5850 27000

I(zz) I(yy) Ze(zz) Ze(yy) Zp(zz) Zp(yy) rzz ryy

4 4 3 3 3 3

mm mm mm mm mm mm mm mm

1.27E+09 4.56E+08 5.63E+06 2.03E+06 6.2E+06 3.1E+06 196 118

4.2 Upper Column 400X400X25X12

Ag h bf tf tw An Ay Az

2 2 2 2

mm mm mm mm mm mm mm mm

24200 400 400.00 25 12 23940 4200 20000

I(zz) I(yy) Ze(zz) Ze(yy) Zp(zz) Zp(yy) rzz ryy

4 4 3 3 3 3

mm mm mm mm mm mm mm mm

7.47E+08 2.67E+08 3.74E+06 1.33E+06 4.1E+06 2.0E+06 176 105

4.3 Web cover plate 2 Nos

4.3.1 L(wp) B(wp) t(wp) Ag(wp) An(wp) Space

Web cover plate

mm mm mm 2 2

mm mm

330x165x12 330 165 12 3960 2712 OK

Column Splice design Page 2 of 13

4.3.2 d(w) d0(w) No of bolts

mm mm nr(w) nv(w) N(w)

24 26 2 2 4

e(w) e1(w) p(w) g(w)

mm mm mm mm

45 45 75 75

OK OK OK OK Min & Max check

4.4 Flange cover plate per flange

4.4.1 External cover plate

Flange External L(fpe) B(fpe) t(fpe) Ag(fpe) An(fpe) Space

cover plate 2 2

mm mm mm mm mm

480x390x12 480 390 12 4680 3432 OK

4.4.2 Internal cover plate 2 Nos

Flange Internal cover L(fpi) B(fpi) t(fpi) Ag(fpi) An(fpi) Space

plate 2 2

mm mm mm mm mm

480x165x12 480 165 12 3960 2712 OK

Column Flange to Web Fillet weld + clearence = 20 mm

4.4.3 Flange cover plate - Bolt per side of the splice

d(f) d0(f) No of bolts

mm mm nr(f) nv(f) N(f)

24 26 3 4 12

Min & Max check

e(f) e1(f) p(f) g(f) gc(f) e1(fo)

mm mm mm mm mm mm

45 45 75 75 150 45

OK OK OK OK OK OK

4.4.4 Packing plate

Flange = 5 mm

Web = 1.5 mm

Max packing plate thickness = 20 mm

Check OK

4.4.5 Erection Feasibility

Clearence between web and flange bolt = 125.5 mm

Min clearence needed = 70 mm

Check OK

5 Member Capacity of the smaller connected section 12.8.4.2

Material grade

Column

Grade fu(c) fy(f) fy(w)

2 2 2

N/mm N/mm N/mm

E350 490 330 350

Column Splice design Page 3 of 13

5.1 Max Tension Capacity of the Member at working (service load)

Tension Capacity of Member Ts = 0.6 * fy * Ag = 4792 KN 11.2.1

5.2 Shear Capacity of Member at working (service load)

Design shear Capacity Major axis

Vs = 0.4*fy * Av = 554 KN 11.4.2 a

Vs = 0.7*fy * Av/ 3 = 560 KN 11.4.2 b

Design shear Capacity Minor axis

Vs = 0.4*fy * Av = 2640 KN 11.4.2 a

Vs = 0.7*fy * Av/ 3 = 2667 KN 11.4.2 b

5.3 Flexural Capacity of Member

5.4.1 Flexural Capacity of Member - Major axis (zz) bending 11.4.1

0.5

2 E IY hf

2

L / r

Mcr = 1+ 1 LT y

2L 20 hf / t f

2

LT

K = 1

l LT = b Z P f y / M cr 1.2 Z e f y / M cr

lLT > 0.4 Laterally unsupported

fLT = 0.5 [1+ aLT (aLT - 0.2)+λLT^2)

χLT = 1/[ΦLT+(ΦLT^2-λLT^2)^0.5] ≤ 1

fbd = cLT * fy / gmo

Md (LSM) = bbZpfbd

Md (WSD) = 0.6*Md

Actual length of member along z- z axis = Lzz

Actual length of member along y-y axis = Lyy

Lzz Mcr lLT fLT χLT fbd Md (LSM) Md(zz) (WSD)

mm KN.m N/mm2 KN.m KN.m

14200 1100.7 1.11 1.34 0.48 143.52 590.95 354.57

Laterally unsupported

5.4.2 Beams bending about minor axis (yy)

Design flexural strength

M(yy) = 0.66*fy = 290 KN.m

6 Minimum Design action on connection

Axial Fx Shear Moment

Tx Px Fy Fz My Mz

KN KN KN KN KN.m KN.m

0.3 * Cap 1437 40 40 87 106 10.7

Actual

forces 391 2038 6 4 0 0

Design 1437 2038 40 40 87 106

Column Splice design Page 4 of 13

7 Check - Web splice

7.1.1 Portion of Axial tension Load carried by Web T (w)

T(w) = T* Aw / Ag

7.1.2 Portion of Axial compression Load carried by Web P(w)

Since For Bearing type splice, Compression force is transferd through end bearing,

Compression check is not needed

7.1.3 Shear Fy is transfed by Web F(w) y

F(w) y = Fy

7.2 Summary of Portion of Load carried by Web

Ag Aw T(w) x F(w) y

2 2

mm mm KN KN

24200 4800 285.1 40

7.3 Force per bolt in bolt group

Vertical Horizontal

shear shear Resultant shear

Fx Fy FR

(Fx + Fy )

2 2

T(w) x / n F(w) y / n

KN KN KN

71 10 72

7.4 Joint Reduction Factor for Web splice Plate

7.4.1 The reduced factor for long joints

If lj > 15d, βlj = 1.075-0.005 x (lj / d) = 1.00 10.3.3.1

7.4.2 The reduced factor for large grip lengths of the joint

If g > 5d, βlg = 8 x d / (3 x d + lg) = 1.00 10.3.3.2

7.4.3 The reduced factor for packing plates of the joint

If tpk > 6mm, βpk = (1 - 0.0125 x tpk) = 1.00 10.3.3.3

7.5 Check - Capacity of Web Cover Plate Bolt Group before Slip

7.5.1 Design Slip - critical strength per bolt

Vdsf = βlj * Vnsf / Ω / g1

Nominal shear capacity Vnsf = μf x ne x Kh x Fo 10.4.3

μ ne Kh Fo Anb fo Vnsf Ω

KN mm2 N/mm2 KN

0.48 2 1.0 256.9 352.9 728 246.6 1.5

7.5.2 Check

Vsb Vdsf Check Ratio

KN KN

72 149 Safe 0.482

7.6 Check - Capacity of Web Cover Plate Bolt Group after Slip

7.6.1 Shear Capacity of Bolt

7.6.1.1 Shear Capacity of Bolt

Design shear strength per bolt Vsb = 0.60 * Vnsb * βlj * βlg* βpk

Vnsb(wp) = fub/(Ѵ3)*(nn*Anb+ns*Asb) 10.3.3

Asb ns Anb nn fy(b) fu(b) Vnsb

mm2 Nos mm2 Nos N/mm2 N/mm2 KN

452 0 353 2 940 1040 423

Column Splice design Page 5 of 13

7.6.1.2 Check

Vsb Vdsf Check Ratio

KN KN

72 254.03 Safe 0.283

7.6.2 Bearing Capacity of Bolt

7.6.2.1 Permissible bearing stress of bolt / plate

fapb = 0.60 * Vnpb * βlj * βlg* βpk

Vnpb(wp) = 2.5*kb*d*t* fu(b)

kb = Min ( e/3d0, p/3d0-0.25, fub/fu,1)

t = Min(tw, twp)

t = Summation of the thicknesses of the connected plates 10.3.4

(p/3d0) -

e/3d0 0.25 fub/fu kb t Vnpb(wp ) Apb

2

mm KN mm

0.577 0.712 2.122 0.577 12 432 288.0

7.6.2.3 Check 11.6.2.1

Vsb Vdpb Check Ratio

KN KN

72 259.2 Safe 0.278

7.7 Check - Web Cover Plate for Tension

7.7.1 Actual tensile stress ft = Ts(w) x / Ag

7.7.2 Permissible tensile stress

fat(wp) = Min ( fatg(wp), fatn(wp), fatb(wp) )

7.7.3 Permissible tensile stress as governed by yielding of gross section 11.2.1

fat = 0.6*fy(wp)

7.7.4 Permissible tensile stress as governed by rupture of net section for plates 11.2.1

Avg , Avn fatn(wp) = 0.69 * Tdn / Ag

Design strength due to rupture of critical section for plates 6.3.1

Tdn(wp) = 0.9*An(wp)*fu / gm1

7.7.5 Permissible tensile 1 11.2.1

L stress as governed by block shear

v

4

fatb(wp) = 0.69 * Tdb / Ag

2 3

Lt

Atg, Atn

Web Cover plates

Fig 7A, 7B

Column Splice design Page 6 of 13

Design strength due to block shear for bolted connection 6.4.1

For Column web plate

Tdb(wp) = Min ( Tdb1(wp), Tdb2(wp) )

Tdb1(wp) = Avg(wp)*fy / (Ѵ3*gm0) + 0.9*Atn(wp)*fu / gm1

Tdb2(wp) = 0.9*Avn(wp)*fu / (Ѵ3*gm1) + Atg(wp)*fy / gm0

Lvg Lvn Avg(wp) Avn(wp) Ltg Ltn Atg(w) Atn(w)

mm mm mm2 mm2 mm mm mm2 mm2

120 81 5760 3888 75 49 1800 588

Tdb1(wp) Tdb2(wp) Tdb(wp)

KN KN KN

1265.6 1364.7 1265.6

Lvg = ( nr(w) - 1 ) * p(w) + e(w)

Lvn = Lvg - ( nr(w) - 0.5 ) * d0(w)

For 2 sided web cover plate

Avg(wp) = 4*Lvg *t(wp)

Avn(wp) = 4*Lvn *t(wp)

Ltg = ( nv(w) - 1 ) * g(w)

Ltn = Ltg - ( nv(w) - 1 ) * d0(w)

Atg(w) = 2*Ltg *t(wp)

Atn(w) = 2*Ltn *t(wp)

Tdb1(wp) = Avg(wp)*fy / (Ѵ3*gm0) + 0.9*Atn(wp)*fu / gm1

Tdb2(wp) = 0.9*Avn(wp)*fu / (Ѵ3*gm1) + Atg(wp)*fy / gm0

Tdb(wp) = Min ( Tdb1(wp), Tdb2(wp) )

7.7.6 Check ft < fat 11.2.1

ft ftg Tdn fatn fatb fat Check Ratio

2 2 2 2 2

N/mm N/mm KN N/mm N/mm N/mm

72.0 210 957 166.71 220.52 166.7 safe 0.432

7.8 Check - Web Cover Plate for Shear

7.8.1 Actual shear stress = tb = Vs/Av

2

For plates and solid bars Av = 3960 mm 8.4.1

7.8.2 Permissible shear stress for member under pure shear 11.4.2

tab = 0.4* fy

T

7.8.3 Check Mz tb ≤ tab My 11.4.2

Fy Fz

tb tab Check Ratio

2 2

N/mm N/mm

10.101 140.000 safe 0.072

ft f bty

+ 1

f at f abty

Column Splice design Page 7 of 13

8 Check - Flange splice

8.1.1 Portion of Axial tension Load carried by each Flange T (f) x

= T(f)

T* Af / Ag

8.1.2 Portion of Axial compression Load carried by each Flange P(f) x

Since For Bearing type splice, Compression force is transferd through end bearing,

8.1.3 Shear Fz is transfed by each Flange F(f) z

F(f) z = Fz / 2

8.1.4 Major axis Moment (Mz) is transferred as Tension and compression through Flanges

Tension due to moment T(fm) = Mz / (h-tf)

Compression due to moment P(fm) = Mz / (h-tf)

8.1.5 Minor axis Moment (My) is transferred through Flange bolts

M(f) y

Minor axis Moment (My) per Flange M(f) y = My / 2

x

1,nv VRCos θ

8.2 Summary of Portion of Load carried by Flange

1,1 1, 2 1, j 90° θ

VRSin θ VR

θ

Ag Af2,1 T(f) x F(f) z T(fm) x P(fm) x M(f) y

i,j i ,nv

mm2 mm2 KN KN C.G KN KN zKN.m

24200 10000 593.8

g(f) 20gc(f) 282.7 282.7 p 43.5

nh,j nh ,nv

nh,1

z11 = -150 mm

x11 = 75 mm

2 2 2

∑(z +x ) = 213750 mm

Column Splice design Page 8 of 13

8.3 Force

Verticalon Extreme

shear due tobolt in bolt

tension T (f)group

x Fx1 = T(f) / n 6.1

Vertical shear due moment Mz Fx2 = T(fm) / n

Max Vertical shear due to My Fx3 = M(f) y * z11 / ∑(z2 +x2) Ref 4

Horizontal shear due to Shear

Fz Fz1 = Fz / n

2 2

Max Horizontal shear due to My Fz2 = M(f) y * x11 / ∑(z +x ) Ref 4

2 2

Resultant shear = FR = Ѵ((Fx1 + Fx2 + Fx3) +(Fz1 + Fz2) )

Actual max shear per bolt Vsb = MAX (Fx1 , Fx2 , Fx3 , Fx1 , Fx2)

8.3.1 Force on Extreme bolt (per bolt) in bolt group

Resultant

Vertical shear Horizontal shear shear

Fx1 Fx2 Fx3 Fz1 Fz2 FR

KN KN KN KN KN KN

49 23.56 30.5 2 15.3 105

8.4 Joint Reduction Factor for Flange splice Plate

8.4.1 The reduced factor for long joints

If lj > 15d, βlj = 1.075-0.005 x (lj / d) = 1.00 10.3.3.1

8.4.2 The reduced factor for large grip lengths of the joint

If g > 5d, βlg = 8 x d / (3 x d + lg) = 1.00 10.3.3.2

8.4.3 The reduced factor for packing plates of the joint

If tpk > 6mm, βpk = (1 - 0.0125 x tpk) = 1.00 10.3.3.3

8.5 Check of slip critical strength of Flange cover plate bolts at service load 10.4.3

8.5.1 Design Slip - critical strength per bolt

Vdsf = βlj * Vnsf / Ω / g1

IS 800 - Cl.

Nominal shear capacity Vnsf = μf x ne x Kh x Fo 10.4.3

μ ne Kh Fo Anb fo Vnsf Ω

2 2

KN mm N/mm KN

0.48 2 1.0 256.9 352.9 728 246.6 1.5

8.5.2 Check

Vsb Vdsf Check Ratio

KN KN

105 149 Safe 0.702

8.6 Check - Capacity of Flange Cover Plate Bolt Group at strength load

8.6.1 Shear Capacity of Bolt at strength load

8.6.1.1 Permissible shear stress = Vdsb = 0.60 * Vnsb * βlj * βlg* βpk

Vnsb(fp) = fub/(Ѵ3)*(nn*Anb+ns*Asb) 10.3.3

Asb ns Anb nn fy(b) fu(b) Vnsb

mm2 Nos mm2 Nos N/mm2 N/mm2 KN

452 0 353 2 940 1040 424

8.6.1.2 Check

Column Splice design Page 9 of 13

Vsb Vdsf Check Ratio

KN KN

105 254 Safe 0.413

8.6.2 Bearing Capacity of Bolt at strength load

8.6.2.1 Permissible bearing stress of bolt / plate

fapb = 0.60 * Vnpb * βlj * βlg* βpk

Vnpb(fp) = 2.5*kb*d*t* fu(b)

kb = Min ( e/3d0, p/3d0-0.25, fub/fu,1)

t = Min(tw, twp)

t = Summation of the thicknesses of the connected plates 10.3.4

(p/3d0) -

e/3d0 0.25 fub/fu kb t Vnpb(fp ) Apb

mm KN mm2

0.577 0.712 2.122 0.577 24 864 576.0

8.6.2.2 Check

Vsb Vdpb Check Ratio

KN KN

105 518.5 Safe 0.202

8.7 Check - Flange Cover Plate for Tension

8.7.1 Actual tensile stress = ft = Ts / Ag

Avg , Atensile

Max vn force per flange Ts = T(f) + T(fm)

Ts = 876.5 KN

8.7.2 Permissible tensile stress Avg , Avn

1 4

Lv fat(wp) = Min ( fatg(wp), fatn(wp), fatb(wp) )

8.7.2.1 2

Permissible 3

tensile stress as governed by yielding of gross section 11.2.1

Lt fat = 0.6*fy(wp)

8.7.2.2 Permissible tensile stress as governed by rupture of net section for plates 11.2.1

Atg, Atn

fatn(wp) = 0.69 * Tdn / Ag

Lt2

Design strength due to rupture of critical section for plates 6.3.1

Tdn(wp) = Atg*fu, A/ tngm1

0.9*An(wp)

8.7.2.3 Externaltensile

Permissible Flangestress

Coverasplate

governed by block shear 11.2.1

fatb(wp) =

Internal 0.69 *Cover

Flange Tdb / Aplates

g

Fig 7A, 7B

Column Splice design Page 10 of 13

Design strength due to block shear for bolted connection 6.4.1

For Column flange and flange plate

Tdb(fp) = Min ( Tdb1(fp), Tdb2(fp) )

Tdb1(fp) = Avg(fp)*fy / (Ѵ3*gm0) + 0.9*Atn(fp)*fu / gm1

Tdb2(fp) = 0.9*Avn(fp)*fu / (Ѵ3*gm1) + Atg(fp)*fy / gm0

External cover plate Internal cover plate

Lvg Lvn Avg(fp) Avn(fp) Ltg Ltn Lt2g Lt2n

mm mm mm2 mm2 mm mm mm mm

195 130 14040 9360 300 222 112.5 35

Atg(f) Atn(f) Tdb1(fp) Tdb2(fp) Tdb(fp)

mm2 mm2 KN KN KN

6300 3492 3811.2 3911.1 3811.2

Lvg = ( nr(f) - 1 ) * p(f) + e(f)

Lvn = Lvg - ( nr(f) - 0.5 ) * d0(f)

For 2 sided Flange cover plate

Avg(fp) = 2*Lvg *t(fpe) + 4*Lvg *t(fpi)

Avn(fp) = 2*Lvn *t(fpe) + 4*Lvn *t(fpi)

For external cover plate Ltg = ( nv(f) - 2 ) * g(f) + gc(f)

Ltn = Ltg - ( nv(f) - 1 ) * d0(f)

For internal cover plate Lt2g = ( nv(f) - 1 )/2 * g(f)

Lt2n = Ltg - ( nv(f) - 1 ) * d0(f)

Atg(f) = Ltg *t(fe) + 2 * Lt2g*t(fi)

Atn(f) = Ltn *t(fe) + 2 * Lt2n*t(fi)

Tdb1(fp) = Avg(fp)*fy / (Ѵ3*gm0) + 0.9*Atn(fp)*fu / gm1

Tdb2(fp) = 0.9*Avn(fp)*fu / (Ѵ3*gm1) + Atg(fp)*fy / gm0

Tdb(fp) = Min ( Tdb1(fp), Tdb2(fp) )

8.7.3 Permissible tensile stress

fat(fp) = Min ( fatg(fp), fatn(fp), fatb(fp) )

8.7.4 Check ft < fat 11.2.1

ft(fp) fatg(fp) Tdn(fp) fatn(fp) fatb(fp) fat(fp) Check Ratio

2 2 2 2 2

N/mm N/mm KN N/mm N/mm N/mm

101.44 210 2.2E+06 173.1072 304.36 173.11 safe 0.586

8.8 Check - Flange Cover Plate for Shear

8.8.1 Actual shear stress = tb = Vs/Av

For plates and solid bars Av = A 8.4.1

2

Av = 8640 mm

8.8.2 Permissible shear stress for member under pure shear 11.4.2

tab = 0.4* fy

Column Splice design Page 11 of 13

8.8.3 Check tb ≤ tab 11.4.2

tb tab Check Ratio

2 2

N/mm N/mm

2.31 140 safe 0.017

f t for fCompression

9 Check + 1

bty

strength

f at f abty

Since For Bearing type splice, Compression force is transferd through end bearing,

Compression check is not needed

10 Check - Column (Web & flange) for Tension

10.1 Actual tensile stress = ft = Ts / Ag

10.2 Permissible tensile stress = fat(c) = Min ( fatg(c), fatn(c), fatb(c) )

10.2.1 Permissible tensile stress as governed by yielding of gross section 11.2.1

fatg(c) = 0.6*fy(c)

10.2.2 Permissible tensile stress as governed by rupture of net section 11.2.1

fatn(c) = 0.69 * Tdn / Ag

Design strength due to rupture of critical section for plates 6.3.1

Tdn(c) = 0.9*An(c)*fu / gm1

10.2.3 Permissible tensile stress as governed by block shear 11.2.1

Flange Web Column

Lvg (f) Lvn(f) Lvg (w) Lvn(w) Avg(c) Avn(c)

mm mm mm mm mm2 mm2

195 130 120 81 22380 14944

Flange Web Column

Ltg (f) Ltn (f) Ltg (w) Ltn (w) Atg(f) Atn(f)

mm mm mm mm mm2 mm2

120 81 75 49 12900 8688

Tdb1(fp) Tdb2(fp) Tdb(fp)

KN KN KN

6941.5 6913.9 6913.9

10.2.4 Permissible tensile stress fat(c) = Min ( fatg(c), fatn(c), fatb(c) )

10.2.5 Check ft < fat 11.2.1

ft(c) fatg(c) Tdn(c) fatn(c) fatb(c) fat(c) Check Ratio

2 2 2 2 2

N/mm N/mm KN N/mm N/mm N/mm

71.06 198.00 8446.0 240.82 197.13 197.13 safe 0.360

ft f bty

+ 1

f at f abty

Column Splice design Page 12 of 13

11 Result of the column splice design

11.1 Web

Bolt

Slip critical capacity = 0.48

Shear capacity = 0.28

Bearing capacity = 0.28

Splice Plate

Tension capacity = 0.43

Shear capacty = 0.07

11.2 Flange

Bolt

Slip critical capacity = 0.70

Shear capacity = 0.41

Bearing capacity = 0.20

Splice Plate

Tension capacity = 0.59

Shear capacty = 0.02

11.3 Column

Tension capacity = 0.36

11.4 Location Details

Web

Edge, Pitch, Gauge = OK OK

Flange Edge, Pitch, Gauge = OK

12 Hence Column splice is safe

Column Splice design Page 13 of 13

You might also like

- EQ06 - Shear Wall and B.E. DesignDocument124 pagesEQ06 - Shear Wall and B.E. DesignrahuljainNo ratings yet

- Ductile Detailing Criteria.Document5 pagesDuctile Detailing Criteria.NikhilNo ratings yet

- Design of Pinned Base ConnectionDocument21 pagesDesign of Pinned Base ConnectionShawkat Ali KhanNo ratings yet

- Base Plate With BoltsDocument3 pagesBase Plate With BoltsAbu KhatriNo ratings yet

- Column Splice Detail (UC 203x203x86)Document2 pagesColumn Splice Detail (UC 203x203x86)Sudhakar KrishnamurthyNo ratings yet

- Warehouse-Base Plate CalculationDocument20 pagesWarehouse-Base Plate CalculationVikram GaikwadNo ratings yet

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDocument4 pagesShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNo ratings yet

- Section Properties: Left Beam Member MC 400: Major MinorDocument12 pagesSection Properties: Left Beam Member MC 400: Major MinorshaimenneNo ratings yet

- Beam To Beam Bolted Moment End Plate Connection - Sample Calculation (As 4100)Document4 pagesBeam To Beam Bolted Moment End Plate Connection - Sample Calculation (As 4100)Tiam MarapeNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- Data Unfactored LoadDocument10 pagesData Unfactored LoadElakiya RajanNo ratings yet

- Day 10 - Wind AnalysisDocument18 pagesDay 10 - Wind AnalysisMaitrayee AdityaNo ratings yet

- Composite Beam Design CalculationsDocument5 pagesComposite Beam Design CalculationsEdson NhabetseNo ratings yet

- 09) UB356x171x51TOUB610X305X149-B2CW - MC-1Document126 pages09) UB356x171x51TOUB610X305X149-B2CW - MC-1Asaru DeenNo ratings yet

- Seismic - Response Spectrum MethodDocument11 pagesSeismic - Response Spectrum MethodRajib Maharjan100% (1)

- Anchorage DetailDocument3 pagesAnchorage DetailShyamontika Choudhury ChakrabartiNo ratings yet

- Spread Sheet of Plate Girder-Is800-2007Document3 pagesSpread Sheet of Plate Girder-Is800-2007yedida v r aviswanadhNo ratings yet

- Ep HSSDocument191 pagesEp HSSJane NishaNo ratings yet

- Standard Drawing - Column ConnectionDocument21 pagesStandard Drawing - Column ConnectionAhmad Basshofi HabiebNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Design Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992Document2 pagesDesign Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992OmPrakashNo ratings yet

- N. Prabhakar: Job No.: Design By: Date: Page NoDocument22 pagesN. Prabhakar: Job No.: Design By: Date: Page NoVikram GaikwadNo ratings yet

- Beam Design and Vibration AnalysisDocument9 pagesBeam Design and Vibration AnalysisjatinNo ratings yet

- Determine The Bearing Plate DimensionsDocument9 pagesDetermine The Bearing Plate DimensionsNiranjan ShresthaNo ratings yet

- Steel Moment-Connection-Beam-Column (IS800)Document11 pagesSteel Moment-Connection-Beam-Column (IS800)Selva KumarNo ratings yet

- Sample DBR With MonoslopeDocument27 pagesSample DBR With MonoslopeNitish TakalkarNo ratings yet

- Sheet1 A-B Bay CM: Properties of Gantry SectionDocument2 pagesSheet1 A-B Bay CM: Properties of Gantry SectionadihindNo ratings yet

- Design of Open Well StaircaseDocument2 pagesDesign of Open Well StaircaseAnish Neupane100% (1)

- Design Parameters For Corbel:1: B D D D 450Document3 pagesDesign Parameters For Corbel:1: B D D D 450Living LifeNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Reference: Sheet 0: Preliminary Design of Plate GirderDocument13 pagesReference: Sheet 0: Preliminary Design of Plate GirderFranklyn Genove100% (1)

- Design of AbutmentDocument5 pagesDesign of AbutmentPAWANNo ratings yet

- 3 Pile CapDocument40 pages3 Pile Capsoumi bhattacharyaNo ratings yet

- Design of Welded Splice Connection (DET.-D-04) : From Staad OutputDocument10 pagesDesign of Welded Splice Connection (DET.-D-04) : From Staad Outputvikas WaghmareNo ratings yet

- Foundation Design for Air Compressor Shed ColumnsDocument7 pagesFoundation Design for Air Compressor Shed Columnsmvap2856No ratings yet

- Beam Design Analysis and Steel Reinforcement CalculationDocument18 pagesBeam Design Analysis and Steel Reinforcement CalculationBuddhiraj kadelNo ratings yet

- Design of Dog-Legged Stair ReinforcementDocument15 pagesDesign of Dog-Legged Stair Reinforcementmathews josephNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- End Plate Moment Connection (Bolt)Document72 pagesEnd Plate Moment Connection (Bolt)mengxiao74No ratings yet

- Design of Base Plate LKP Arm 4-F-30.01.2018Document5 pagesDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaNo ratings yet

- Load Calculation of BeamDocument5 pagesLoad Calculation of BeamNikhilNo ratings yet

- Corbel Design Spreadsheet To ACI318Document6 pagesCorbel Design Spreadsheet To ACI318LAU TONo ratings yet

- Design of rigid connection detail 85Document215 pagesDesign of rigid connection detail 85Umer AziqNo ratings yet

- Superstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Document14 pagesSuperstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Himal KafleNo ratings yet

- DESIGN CODE IS:800-2007 SPLICE PLATEDocument2 pagesDESIGN CODE IS:800-2007 SPLICE PLATEmaheshbandhamNo ratings yet

- Bracket DesignDocument4 pagesBracket DesignAnonymous JUn5jis0No ratings yet

- Isolated Footing For ColumnsDocument8 pagesIsolated Footing For Columnskushaljp8989No ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- From RCC Col To Steel ColDocument9 pagesFrom RCC Col To Steel ColJanya AssociatesNo ratings yet

- PEB and IS-800-2007Document8 pagesPEB and IS-800-2007Gautam Paul100% (1)

- Beam DesignDocument9 pagesBeam Designمحمد شاويNo ratings yet

- End Plate Moment ConnectionDocument3 pagesEnd Plate Moment ConnectionIndustry Standard Structural DesignNo ratings yet

- Purlins & GirtsDocument10 pagesPurlins & GirtsRaviKiranNo ratings yet

- Nagarjuna Construction Company Limited: Iisco Steel Plant, Blast Furnace Complex (Package 07)Document21 pagesNagarjuna Construction Company Limited: Iisco Steel Plant, Blast Furnace Complex (Package 07)rammohanNo ratings yet

- Corbel Design ExcelDocument6 pagesCorbel Design ExcelVIJAY PARMARNo ratings yet

- Design of BracingDocument10 pagesDesign of BracingdineshNo ratings yet

- STAAD.Pro Report AnalysisDocument4 pagesSTAAD.Pro Report AnalysisNixcaNo ratings yet

- Report. (Assignment 02)Document9 pagesReport. (Assignment 02)Abdul WahabNo ratings yet

- ETABS 2016 Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Document2 pagesETABS 2016 Steel Frame Design: AISC 360-10 Steel Section Check (Strength Summary)Khaled Abdel SalamNo ratings yet

- Lift Machine Room LoadsDocument8 pagesLift Machine Room LoadssundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument13 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument13 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- SM II - Global WindWind Load On Main ModelDocument31 pagesSM II - Global WindWind Load On Main ModelsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument6 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Column Splice For Double - 20170522Document13 pagesColumn Splice For Double - 20170522sundarNo ratings yet

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Document10 pagesAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument6 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- FP b2b Tier#2 Obra 20170723 FinalDocument3 pagesFP b2b Tier#2 Obra 20170723 FinalsundarNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Ashirvad CPVC Pipe PDFDocument12 pagesAshirvad CPVC Pipe PDFsundarNo ratings yet

- Clip Angle Connection Design for Beam to Column JointDocument4 pagesClip Angle Connection Design for Beam to Column JointsundarNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Grating CatlogDocument11 pagesGrating CatlogsundarNo ratings yet

- Premium Break UpDocument1 pagePremium Break UpsundarNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Honda Motorcycle & Scooter India (PVT) LTDDocument1 pageHonda Motorcycle & Scooter India (PVT) LTDsundarNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFsundarNo ratings yet

- Guide To Offshore Wind Farm 2019Document128 pagesGuide To Offshore Wind Farm 2019sundarNo ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignFarid SedekyNo ratings yet

- Monthly PRKNG Fare Dtls PDFDocument1 pageMonthly PRKNG Fare Dtls PDFsundarNo ratings yet

- Measuring Friction in PipesDocument6 pagesMeasuring Friction in PipessundarNo ratings yet

- Android Activity Lifecycle OverviewDocument8 pagesAndroid Activity Lifecycle OverviewMario FedericiNo ratings yet

- Cifra Club - Bon Jovi - AlwaysDocument4 pagesCifra Club - Bon Jovi - Alwayslurilululu0% (1)

- Calculate the proof strength of 70% v/v alcohol.Step 1) 70% v/v x 1.753 = 122.71Step 2) 122.71 - 100 = 22.71The proof strength of 70% v/v alcohol is 22.71% over proofDocument46 pagesCalculate the proof strength of 70% v/v alcohol.Step 1) 70% v/v x 1.753 = 122.71Step 2) 122.71 - 100 = 22.71The proof strength of 70% v/v alcohol is 22.71% over proofPrashant307100% (1)

- VW Crafter 2f Component Locations EngDocument118 pagesVW Crafter 2f Component Locations EngHugo Emilio Garcia Gonzalez100% (2)

- Asme A112.4.14-2004 PDFDocument14 pagesAsme A112.4.14-2004 PDFAmer AmeryNo ratings yet

- Muhammad Farrukh QAMAR - Assessment 2 Student Practical Demonstration of Tasks AURAMA006 V2Document19 pagesMuhammad Farrukh QAMAR - Assessment 2 Student Practical Demonstration of Tasks AURAMA006 V2Rana Muhammad Ashfaq Khan0% (1)

- Vedic Healing Through Gems4Document3 pagesVedic Healing Through Gems4gesNo ratings yet

- Introduction To Engineering Economy: Title of The LessonDocument16 pagesIntroduction To Engineering Economy: Title of The LessonsdanharoldNo ratings yet

- GARAM ModelDocument40 pagesGARAM ModelprasunmathurNo ratings yet

- Biotensegrity and Myofascial Chains A Global Approach To An Integrated Kinetic ChainDocument8 pagesBiotensegrity and Myofascial Chains A Global Approach To An Integrated Kinetic ChainMohamed ElMeligieNo ratings yet

- Second Travel of Rizal: Week 8 Unit 3Document22 pagesSecond Travel of Rizal: Week 8 Unit 3John Russell GasangNo ratings yet

- Probability Concepts and Random Variable - SMTA1402: Unit - IDocument105 pagesProbability Concepts and Random Variable - SMTA1402: Unit - IVigneshwar SNo ratings yet

- Timbering Week 5Document22 pagesTimbering Week 5FikaduKitessa0% (1)

- Course 1 ProjectDocument6 pagesCourse 1 ProjectDhruvNo ratings yet

- Dip HIV Man (SA) Past Papers - 2015 2nd Semester 24-1-2017Document2 pagesDip HIV Man (SA) Past Papers - 2015 2nd Semester 24-1-2017matenten100% (1)

- Medical Education For Healthcare Professionals: Certificate / Postgraduate Diploma / Master of Science inDocument4 pagesMedical Education For Healthcare Professionals: Certificate / Postgraduate Diploma / Master of Science inDana MihutNo ratings yet

- The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6. The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6Document1 pageThe Next Questions Will Depend On Your Answer(s) in Question Number 4: 6. The Next Questions Will Depend On Your Answer(s) in Question Number 4: 6cgranzore8833% (3)

- Lamb To The Slaughter EssayDocument5 pagesLamb To The Slaughter Essaypflhujbaf100% (2)

- Emd MPC 543Document25 pagesEmd MPC 543jaskaran singhNo ratings yet

- a9ff9ISM - Business DefinitionDocument7 pagesa9ff9ISM - Business DefinitionVikram Kumar100% (1)

- SIHI - Control Narrative Proc Compressor UnitDocument5 pagesSIHI - Control Narrative Proc Compressor Unitman_y2k100% (1)

- Inspire Physics 9 AdvanceDocument285 pagesInspire Physics 9 AdvanceJenan Zriak100% (2)

- Writing Part 2 - An Essay: (120-180 Words)Document7 pagesWriting Part 2 - An Essay: (120-180 Words)María Daniela BroccardoNo ratings yet

- Small BusinessDocument22 pagesSmall BusinessAngelie Dela CruzNo ratings yet

- Types of DC Motors Notes Electric DrivesDocument77 pagesTypes of DC Motors Notes Electric DrivesJyothish VijayNo ratings yet

- Vivekananda's Role as Revivalist Reformer and His Ideas of Equality and Spiritual RevolutionDocument2 pagesVivekananda's Role as Revivalist Reformer and His Ideas of Equality and Spiritual RevolutionMartin VanlalhlimpuiaNo ratings yet

- MS6711 Data Mining Homework 1: 1.1 Implement K-Means Manually (8 PTS)Document6 pagesMS6711 Data Mining Homework 1: 1.1 Implement K-Means Manually (8 PTS)Yihan WangNo ratings yet

- Mil STD 882eDocument104 pagesMil STD 882ecihan dağNo ratings yet

- ST Patrick Lodge 199 BibleDocument5 pagesST Patrick Lodge 199 Bibletofique_fatehiNo ratings yet

- Learn Meanings of 96 Difficult WordsDocument400 pagesLearn Meanings of 96 Difficult WordsVaishali Venkatesh PrasadNo ratings yet