Professional Documents

Culture Documents

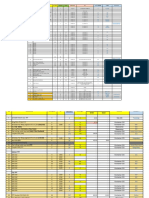

Clip Angle Connection Design for Beam to Column Joint

Uploaded by

sundarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clip Angle Connection Design for Beam to Column Joint

Uploaded by

sundarCopyright:

Available Formats

Prepared by SLP

CLIP ANGLE CONNECTION

IS800-2007 Checked by SUNDAR

DOOSAN POWER SYSTEMS INDIA (Working Stress Method)

PRIVATE LIMITED Approved by SUNEEL 2 of 4

Document No : 0 Date 08 June 2017

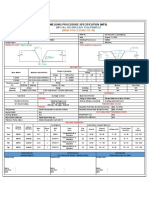

1 Connection ID 1156 SAP No 5E+07

Type B2B

Supported Beam Data N300

h bf tw tf Ag Izz Iyy rz ry r1 fy fu

2 4 4

Grade 2

mm mm mm mm mm mm mm mm mm mm N/mm N/mm2

306.6 165.7 6.7 11.8 5875 0 0 137.84 39.27 8.9 E250 250 410

Supporting Beam/Column Data BH400X250X10X15

h bf tw tf Ag Izz Iyy rz ry r1 fy fu

2 4 4

Grade 2

mm mm mm mm mm mm mm mm mm mm N/mm N/mm2

400 250 10 15 11200 4E+08 4E+07 179.9 59.08 8 E350 350 490

2 Capacity calculation for Beam

Shear Capacity of Supporting Beam

IS800-07-Cl.11.4.2 Shear Capacity Vd = 0.4 * fy AV = 0.4* 250*( 306.6* 6.7)/1000 = 205 kN

3 Connection Design Forces Case: Actual

Vertical Shear Horizontal Shear

Compression (kN) Tension (kN) Design Forces

(kN) (kN)

Actual 370 100 15 0 VV (kN) Vh (kN) P (kN) T (kN)

IS800-07-Cl.10.7 /75

Min 155 370 100 15 0

OR 80%CAP

Max 370 100 15 0

4 Connection Design Clip Angle VV (kN) Vh (kN) P (kN) T (kN)

370 100 15 0

L100X10 Double Angle Stiffener

Clip Angle A B t1 r1 Ag Length ns tsp dsp fy fu

2

Grade 2

mm mm mm mm mm mm mm mm N/mm N/mm2

ISA100X100X10 100 100 10 9 1,903 220 0 0 90 E250 250 410

d do Asb Anb Bolts Lv(e) Lh(e1) p g G1 Lv(e2) Bolt fy,b fu,b mf

Bolt 2 2 2 2

mm mm mm mm nc nr N mm mm mm mm mm mm Grade N/mm N/mm N/mm2

data

22 24 380 297 1 3 6 40 43 70 70 80 40 10.9 900 1,000 0.48

Min 76

C/C c Cope dct dcb dc Space Clear tpk ηe Kh

Bolt

mm (mm) type (mm) (mm) (mm) Check Space mm

data

120 120 1 27 0 27 Ok 19.9 0 1 1

Type Sr Sr-throat Weld size Weld fy,w fu,w

2

Weld mm mm Check Grade N/mm N/mm2

Fillet 6.0 4 0.8955 E70XX 400 490

Max 6.7

4a Check Bolt capacity

Shear Force per bolt = SQRT(370^2+100^2)/6 = V= 63.9 kN

Prying Force for bolt in tension, Q = (lv/2le) x [Te-βxηxfoxbext^4/27xlexlv^2] Q= 0.0 kN

lv = (C/C)/2-tw/2-t-r/2 = 42.4 mm β be η Fo nn ns

le = 1.1xt√βxfo/fy = 18.4 mm mm N/mm2

1.0 70.0 1.5 700 1.0 0.0

Tension Force per bolt = 0/6+0.0 = T= 0.0 kN

Reduction factor for long joints βlj = 1.075-0.005 x (lj / d)

= (MAX(MIN(1.075-0.005*((3-1)*70/22),1),0.75)) = 1.0

Reduction factor large grip lengths βlg = 8 x d / (3 x d + lg) = MIN(8*22/(3*22+( 10+10)),1) = 1.0

Reduction factor for packing plates βpk = (1 - 0.0125 x tpk) = (1-0.0125*0) = 1.0

Slip Critical strength

Vdsf =0.6 x (μf x ηe x Kh x Fo)xAnbxb = 0.6*0.48*1*1*700*297/1000*1.0 = 60 kN < 64 kN Revise UR=1.07

Shear strength after Slip

Vdsb = 0.6*( fub / (√3) x (nn x Anb + ns x Asb))xb = 0.6*(1,000/SQRT(3)*(1.0*297+0.0*380))/1000*(1.0*1.0*1.0) = 103 kN >= 64 kN Safe UR=0.62

Bearing strength for Clip angle / supporting beam

Vnpb =0.6*( 2.5*kb*d*t* fu)

= 0.6*(2.5*0.56*22*MIN(10,IF(String="B2CF", 15, 10))*(MIN( 410, 410)))/1000 = 75 kN >= 64 kN Safe UR=0.85

where kb =Min(e/3do, p/3do-0.25, fub/fu,1.0)

= MIN((40/3/24),(70/3/24-0.25),(1,000/(MIN( 410, 410))),1) = 0.56

Prepared by SLP

CLIP ANGLE CONNECTION

IS800-2007 Checked by SUNDAR

DOOSAN POWER SYSTEMS INDIA (Working Stress Method)

PRIVATE LIMITED Approved by SUNEEL 3 of 4

Document No : 0 Date 08 June 2017

Tension Capacity

Tnb =0.6 x (0.9 x fubxAnb) = 0.6*(0.9*1,000*297)/1000 = 160 kN >= 0 kN Safe UR=0.00

Combined shear and Tension

(V/Vnb )^2 + (T/Tnb)^2 = 1.14 < 1 Revise UR=1.14

4b-1 Check Clip Angle

4b-1 Moment Capacity

Actual tensile force per Clip T= = 0/4 = 0.0 kN

Actual Moment M= = 0.0*42.4/1000 = 0.0 kN.m

Section modulus Zp= = 220*10^2/4+0*(0*90^2)/6 = 5500.0 mm3

Bending Capacity, Md = 0.75 fy *Zp = 0.75* 250*5500.0/10^6 = 1.0 kN.m Safe UR=0.00

4b-2 Shear Capacity

Avg Avn Atg Atn Av

gm0 gm1 2 2 2 2

mm mm mm mm mm2

1.1 1.25 1,800 1,200 434 314 2,200

IS800-07-Cl.11.2.1 c Block Shear Capacity

Tdb1 =0.69*(Avgfy/3gm0 + 0.9Atnfu/gm1) = 0.69*(1,800* 250/SQRT(3)/1.1+0.9*314* 410/1.25)/1000 = 227 kN

Tdb2 = 0.69*(0.9Avnfu/3gm1 + Atgfy/gm0) = 0.69*(0.9*1,200* 410/SQRT(3)/1.25+434* 250/1.1)/1000 = 209 kN

IS800-07-Cl.11.4.2.a Shear Capacity

Vdb1 =0.4 x fy x Av = 0.4* 250*2,200/1000 = 220 kN

Design Shear Strength Vd = 209 kN >= 185 kN Safe UR=0.89

4b-3 Check for Weld capacity

FT w

Geometry of weld

h = 220.0 mm

SY

w = 90.0 mm FR r

L = 400.0 mm

Cyy = 20.3 mm

eo = 79.7 mm e0 o h

Properties of weld treated as line

Izz = 30,65,334 mm^3

IYY = 4,80,599 mm^3

Cyy

Ip = 35,45,933 mm^3

r = 130 mm

Cosθ = 0.54

Load on weld per single clip angle

Shear, Vd = 185 kN

Axial P = 8 kN

Fs = (P+ Vd ) / (L*Ww) = (8+185)*1000/(400.0*4) = 113.4 N/mm2

FT = Vd x e x r / (Ip*Ww) = (185*1000*79.7*130)/(3,545,933*4) = 127.6 N/mm2

FR = (Fs2+FT2+2FSFTCosθ)1/2 = 212 N/mm2

2 2

IS800-07-Cl.11.6.3 Allowable stress of the weld = MIN((0.6*490/SQRT(3)),0.4* 250)*1.00 = 100 N/mm < 212 N/mm Revise UR=2.12

βjw = 1.2 - 0.2 x lj / (150 te) = MIN(1,1.2-0.2* 220/(150*4)) = 1.00

5 Connection Design Supported beam VV (kN) Vh (kN) P (kN) T (kN)

370 100 15 0

5a Check for coped beam web

Resultant force on coped beam R= Sqrt(V2+T2) = SQRT(370^2+MAX(15, 0)^2) = 370.3 kN

IS800-07-Cl.11.4.2.a Shear Capacity

Vdb1 =0.4 x fy x Av = 0.4* 250*( 306.6-27)* 6.7/1000 = 188 kN < 370 kN Revise UR=1.97

5a-2 Block Shear Capacity

Resultant force on coped beam R= Sqrt(V2+T2) = 370.0 kN

IS800-07-Cl.11.2.1 c Block Shear Capacity

Tdb1 =0.69*(Avgfy/3gm0 + 0.9Atnfu/gm1) = 0.69*(1206 * 250 / Sqrt(3) 1.1 + 0.9 * 1474 * 410 / 1.25 )/1000 = 409 kN

Tdb2 = 0.69*(0.9Avnfu/3gm1 + Atgfy/gm0) = 0.69*(0.9 * 1206 * 410 / Sqrt(3) 1.25 + 1474 * 250 / 1.1)/1000= 373 kN

fy fu Avg Avn Atg Atn

2 2

gm0 gm1 2 2 2

N/mm N/mm mm mm mm mm2

250 410 1.1 1.3 1,206 1,206 1,474 1,474

Design Block Shear Strength Tdb = 373 kN >= 370 kN Safe UR=0.99

Prepared by SLP

CLIP ANGLE CONNECTION

IS800-2007 Checked by SUNDAR

DOOSAN POWER SYSTEMS INDIA (Working Stress Method)

PRIVATE LIMITED Approved by SUNEEL 4 of 4

Document No : 0 Date 08 June 2017

5b Check for flexure strength of the coped beam web

Distance from support to the notch e = 130 mm

Height of notch ho = 280 mm

Eccentric moment due to shear Mz= =370*130/1000 = 48.1 kN.m

Mn = 0.6 x Fcr x Ze = #NUM! kN.m #NUM! 48 kN.m #NUM! #NUM!

Fcr = critical stress of flexure with the von - Mises

= shear Fy2 - 3 fv2 )

√( reduction = #NUM! N/mm2

fv = required shear

required

stress

shear stress = Ru / (tw x ho) = 197.5 N/mm2

Ze = section modulus of plate about the principal

= axes = 1.4E+05 mm3

N.A

bf

fy fu tw ho tf from I Ze Zzbeam cope

bottom

bottom

N/mm2 N/mm2 mm mm mm mm mm

250 410 7 280 159 12 73 3.E+07 1.E+05 0.E+00 1

5c Check for shear buckling of the coped beam web

Shear Buckling strength

IS800-07-Cl.11.4.2 Vab = 0.7 x Vn = 189.4 kN < 370 kN Revise UR=1.95

Where

IS800-07-Cl.8.4.4.2 Vn = Vcr = Av x tb =1875.33 * 144.3/1000 = 270.6 kN

lw = Sqrt { fyw/(3 tcr.e)} = 0.50

tcr.e = 2

Kv p E

= 582 N/mm2

12(1-m2)(d/tw)2

m = 0.3 Kv = 5.35

d/tw = 42

when lw 0.8 >> tb = fyw / Sqrt(3) = 144.3 N/mm2

when 0.8 < lw < 1.2 >> tb = [1-0.8(lw-0.8)] [fyw / Sqrt(3)] = N.A N/mm2

when lw 1.2 >> tb = fyw / {Sqrt(3)*l }

2

= N.A N/mm2

tb = 144.3 N/mm2

fy fu Av d tw d/tw

N/mm2 N/mm2 mm2 mm mm

250 410 1,875 280 7 42

6 Connection Design Supporting beam /Column VV (kN) Vh (kN) P (kN) T (kN)

370 100 15 0

6a Check for tying capacity of supporting beam web APPLICABLE

TYING FORCE ON SUPPORTING BEAM WEB

A

L fy fu LeA LeB tw

B L

2 2

gm0

T N/mm N/mm mm

B

350 490 1 115 120 350 10

A

LeB LeA

LeA

Tying capacity of supporting beam web

Tc.w= 0.6 * (2(MuA+MuB)/L) = 42.9 kN >= 15 kN Safe UR=0.35

MuA = (fy)*(LeA*tw2 /4) = 1.05 kN.m

MuB = (fy)*(LeB*tw2 /4) = 3.06 kN.m

Stiffener size = 0 mm

6b Check for supporting column flange

Tension per bolt = 0 kN NOT APPLICABLE

Dispersion flange width = min(e/2+p/2 , p) = 55 mm

Eccentricity = 47 mm

Actual Moment per dispersion width M = 0.000 kNm

Allowable bending stress 0.66fy = =0.66*350= 231 Mpa

Moment Capacity of flange =231*55*15^2/6/1000000 = 0.5 kN.m >= 0 kN.m Safe UR=0.00

Stiffener size = 0 mm

fy fu e p ecc

gm0

N/mm2 N/mm2

350 490 1 40 70 47

Prepared by SLP

CLIP ANGLE CONNECTION

IS800-2007 Checked by SUNDAR

DOOSAN POWER SYSTEMS INDIA (Working Stress Method)

PRIVATE LIMITED Approved by SUNEEL 5 of 4

Document No : 0 Date 08 June 2017

6c Check for tying capacity of supporting column web NOT APPLICABLE

pu = fu / 1.25 = 392.0 N/mm2

2

Mu = pu tw / 4) = 9.8 kNm /m

η1 = (nr-1)p - nr/2 d0 = 0.294

dc

β1 = g/dc = 0.339

γ1 = do/dc = 0.068

Tying Capacity of web = = 174.50 kN

Allowable tying capacity of web = 0.6*174.5 = 104.7 kN >= 15 kN Safe UR=0.14

Stiffener size = 0 mm

fy fu gm0 tw dc g (i.e C/C) do nr p

N/mm2 N/mm2 mm mm mm mm mm

350 490 1 10 354 120 24 3 70

7 SUMMARY

Supported Beam N300

Supporting Beam BH400X250X10X15

Bolt Data Clip angle

Grade 10.9 Size ISA100x100x10

Bolt Φb= 22 mm Type Double

Bolt hole = 24 mm Stiffener

nr = 3 Nos ns= 0

nc = 1 Nos ts= 0 mm

p = 70 mm Weld

g = 70 mm Type Fillet

e1 = 43 mm Sr1 = 6 mm

e = 40 Flase flange #NUM!

G1= 80 mm Vertical Stiffener Yes

C/C= 120 mm Supporting beam stiffener

dct= 27 tsiff= 0 mm

dcb= 0 bf/2 = 73 mm

dc= 27 (supported beam)

Chamfer2 0 mm

DESIGN SUMMARY

Clip Angle

4a Check Bolt capacity 4b-1 Check Clip Angle

Slip Critical strength 1.07 4b-1 Moment Capacity 0.00

Shear strength after Slip 0.62 4b-2 Shear Capacity 0.89

Bearing strength for Clip angle / supporting beam 0.85 4b-3 Check for Weld capacity 2.12

Tension Capacity 0.00 weld size check 0.90

Combined shear and Tension 1.14

Supported beam Supporting beam /Column

5a Check for coped beam web 1.97 6a Check Tying capacity of column/ beam UR=0.4

5a-2 Check for block shear strength of web 0.99

5b Check for flexure strength of the coped beam web #NUM! Stiffemer size 0

5c Check for shear buckling of the coped beam web 1.95

You might also like

- Black & Decker The Complete Guide To ShedsDocument257 pagesBlack & Decker The Complete Guide To Shedsrobertrussellny96% (28)

- Pavement Design, Construction and Maintenance for Bituminous RoadsDocument62 pagesPavement Design, Construction and Maintenance for Bituminous RoadsMadhavpokaleNo ratings yet

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarNo ratings yet

- FP b2b Tier#2 Obra 20170723 FinalDocument3 pagesFP b2b Tier#2 Obra 20170723 FinalsundarNo ratings yet

- Shank Dia. Before Thread Rolling Ø8: Machining Drawing Critical ComponentDocument1 pageShank Dia. Before Thread Rolling Ø8: Machining Drawing Critical ComponentGauravNo ratings yet

- WFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtDocument2 pagesWFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtApichai ZankerNo ratings yet

- ACME-LEAD ScrewsDocument23 pagesACME-LEAD ScrewsNitinNo ratings yet

- Venu1717X Spec SheetDocument4 pagesVenu1717X Spec Sheet郑书毅No ratings yet

- Information Standards Quarterly: Special Edition: Year in Review and State of The StandardsDocument8 pagesInformation Standards Quarterly: Special Edition: Year in Review and State of The StandardsFrederico José Fernandes SerôdioNo ratings yet

- Assembly of a Mini Conveyor OvenDocument31 pagesAssembly of a Mini Conveyor OvenciptoNo ratings yet

- Radiator Panel Parts ListDocument1 pageRadiator Panel Parts ListDhoviIrvanNo ratings yet

- m0043 016 2 PDFDocument1 pagem0043 016 2 PDFajarekarga ajarekarNo ratings yet

- Mark Piece Information: For Weld Details, See Sheet: 3Document5 pagesMark Piece Information: For Weld Details, See Sheet: 3Proorocu MikyNo ratings yet

- Isometric: 52 I/ D PIP E 40 (I/ D) (LI NIN G)Document1 pageIsometric: 52 I/ D PIP E 40 (I/ D) (LI NIN G)b_m_leeNo ratings yet

- TURNING FIX (04-005) - Sheet - 1Document1 pageTURNING FIX (04-005) - Sheet - 1daryosh hassanyNo ratings yet

- GP475029R0 PDFDocument1 pageGP475029R0 PDFapurvNo ratings yet

- Preliminary Design of Entrance CanopyDocument4 pagesPreliminary Design of Entrance CanopyMoustafaNo ratings yet

- Designed by Checked by Approved by Date DateDocument1 pageDesigned by Checked by Approved by Date Date1D Davalos Mendoza HarryNo ratings yet

- TRLHM WF000 - Sheet1Document2 pagesTRLHM WF000 - Sheet1Budi MaryantoNo ratings yet

- A8 A8 Typ. 11: Document Control GCCDocument4 pagesA8 A8 Typ. 11: Document Control GCCProorocu MikyNo ratings yet

- Control panel documentationDocument104 pagesControl panel documentationابويحيىالمراديNo ratings yet

- Package Number 1: No. Specification Unit Observation Steel Plate QuantityDocument1 pagePackage Number 1: No. Specification Unit Observation Steel Plate QuantityJoel MontoyaNo ratings yet

- Pillow Block Housings For Insert Bearings: DimensionsDocument4 pagesPillow Block Housings For Insert Bearings: DimensionsRoland PongráczNo ratings yet

- Fr4sheet AssemblyDocument3 pagesFr4sheet Assemblyvenkatesh sankaramanchiNo ratings yet

- Sample IsoDocument1 pageSample IsoPankaj SahuNo ratings yet

- Uf1000a02 1Document1 pageUf1000a02 1MARTIN GONZALEZNo ratings yet

- Section Properties: 08-Mar-17 08-Mar-2017 14:33 S164 (EMS 08032017) .STDDocument7 pagesSection Properties: 08-Mar-17 08-Mar-2017 14:33 S164 (EMS 08032017) .STDDellTaNo ratings yet

- Scalacoustic FTDocument2 pagesScalacoustic FTCiro Nero MaguleNo ratings yet

- Idn27943 - SCN1200 F2.5 - Ga+alDocument2 pagesIdn27943 - SCN1200 F2.5 - Ga+alAbdul JabbarNo ratings yet

- P790 Electrical Circuit 336-E4169 - 1 - plm-2Document11 pagesP790 Electrical Circuit 336-E4169 - 1 - plm-2shivji007No ratings yet

- F - Brass Inserts PLDocument12 pagesF - Brass Inserts PLecto8totoNo ratings yet

- Section A-A: General NotesDocument1 pageSection A-A: General NotesADRIAN SILVESTRE HERNANDEZNo ratings yet

- PID - Lube Oil SkidDocument1 pagePID - Lube Oil SkidTalha AamirNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- Ps 0412 0612obh WDocument1 pagePs 0412 0612obh WHunterNo ratings yet

- 0420 - 118T3440 - Cooling WaterDocument2 pages0420 - 118T3440 - Cooling WaterfaisalnadimNo ratings yet

- ANILLA SIMPLE CM USADocument1 pageANILLA SIMPLE CM USAjm467191No ratings yet

- SM-T385 SVC ManualDocument12 pagesSM-T385 SVC Manualasish dalalNo ratings yet

- Piping Isometric - 4Document1 pagePiping Isometric - 4CosminMarianNo ratings yet

- Intoval T62 CR15Document2 pagesIntoval T62 CR15Calvin CooksonNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- Zppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Ahmed ThaerNo ratings yet

- TECO Air Conditioning Variable Refrigerant Flow (VRF), VRF System 5-150 TRDocument6 pagesTECO Air Conditioning Variable Refrigerant Flow (VRF), VRF System 5-150 TRirtedyNo ratings yet

- Posch News Eng 11 09Document6 pagesPosch News Eng 11 09uripssgmailNo ratings yet

- CorrelationsDocument11 pagesCorrelationsdewiNo ratings yet

- Annexure 2 PDFDocument1 pageAnnexure 2 PDFHaitNo ratings yet

- PF Pump SpecificationDocument2 pagesPF Pump Specificationjohnny sabinNo ratings yet

- Ford 4R-5R44E InteractiveDocument1 pageFord 4R-5R44E InteractiveMauricio Exequiel ChavezNo ratings yet

- DRW 2916699130 02Document1 pageDRW 2916699130 02davi mooreNo ratings yet

- SE3 Series Compact Rotary Paddle Point Level Sensor: CertifiedDocument8 pagesSE3 Series Compact Rotary Paddle Point Level Sensor: CertifiedUniquityNo ratings yet

- Caster PDFDocument2 pagesCaster PDFRatko KečaNo ratings yet

- PSP Profile, TPU Piston Cap SealDocument3 pagesPSP Profile, TPU Piston Cap SealSamira 1986No ratings yet

- 25LPO10Document1 page25LPO10karthikNo ratings yet

- Parts Manual: CascadeDocument10 pagesParts Manual: CascadeLuca FroliNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Screenshot 2023-10-22 at 2.51.52 PMDocument16 pagesScreenshot 2023-10-22 at 2.51.52 PMxkm8zj2mh6No ratings yet

- 089245-2-0-Configuration 4H0 973 323 + cap uniDocument2 pages089245-2-0-Configuration 4H0 973 323 + cap unimirelusha_lovely3829No ratings yet

- 01 DRP Cat Side Pin TeethDocument12 pages01 DRP Cat Side Pin TeethNicoleta CosteaNo ratings yet

- Enna07900 T 05Document8 pagesEnna07900 T 05Andalucía EspañaNo ratings yet

- Env-F014 A & B Noise MonitoringDocument1 pageEnv-F014 A & B Noise MonitoringnagaaNo ratings yet

- Daniel Edward 6/16/2017: Drawn Checked QA MFG Approved DWG No TitleDocument1 pageDaniel Edward 6/16/2017: Drawn Checked QA MFG Approved DWG No TitleDaniel Edward OmondiNo ratings yet

- Lift Machine Room LoadsDocument8 pagesLift Machine Room LoadssundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument13 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument13 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- SM II - Global WindWind Load On Main ModelDocument31 pagesSM II - Global WindWind Load On Main ModelsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument6 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Column Splice For Double - 20170522Document13 pagesColumn Splice For Double - 20170522sundarNo ratings yet

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Document10 pagesAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument6 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Column Splice For Double - 20170522Document13 pagesColumn Splice For Double - 20170522sundarNo ratings yet

- Santa Maria II 1 X 400 MW: Doosan Power Systems LTDDocument7 pagesSanta Maria II 1 X 400 MW: Doosan Power Systems LTDsundarNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Ashirvad CPVC Pipe PDFDocument12 pagesAshirvad CPVC Pipe PDFsundarNo ratings yet

- Baseplate Anchor Bolt Is800 SSM VerificationDocument5 pagesBaseplate Anchor Bolt Is800 SSM VerificationsundarNo ratings yet

- Design of Isolated Footing to BS-8110Document29 pagesDesign of Isolated Footing to BS-8110sundarNo ratings yet

- Grating CatlogDocument11 pagesGrating CatlogsundarNo ratings yet

- Premium Break UpDocument1 pagePremium Break UpsundarNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationSanje1024No ratings yet

- Honda Motorcycle & Scooter India (PVT) LTDDocument1 pageHonda Motorcycle & Scooter India (PVT) LTDsundarNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFsundarNo ratings yet

- Guide To Offshore Wind Farm 2019Document128 pagesGuide To Offshore Wind Farm 2019sundarNo ratings yet

- Pump Branch DesignDocument7 pagesPump Branch DesignFarid SedekyNo ratings yet

- Monthly PRKNG Fare Dtls PDFDocument1 pageMonthly PRKNG Fare Dtls PDFsundarNo ratings yet

- Measuring Friction in PipesDocument6 pagesMeasuring Friction in PipessundarNo ratings yet

- Unit-5: Partition and Cavity Wall Partition and Cavity WallDocument15 pagesUnit-5: Partition and Cavity Wall Partition and Cavity Wallसमिर भण्डारीNo ratings yet

- CM303Document28 pagesCM303api-3849444No ratings yet

- CE (PC) 601 Constructi On Engineering & ManagementDocument2 pagesCE (PC) 601 Constructi On Engineering & ManagementshoummoNo ratings yet

- The Vitruvian Man: Learning From Leonardo'sDocument8 pagesThe Vitruvian Man: Learning From Leonardo'sSushant Pradhan100% (1)

- Seven Wonders of The Ancient World - WikipediaDocument14 pagesSeven Wonders of The Ancient World - WikipediaSabir HussainNo ratings yet

- No Kebutuhan Nos/Span Nos/Span 7 Grup Kedatangan Ket Total Ordered Vendor KeteranganDocument3 pagesNo Kebutuhan Nos/Span Nos/Span 7 Grup Kedatangan Ket Total Ordered Vendor KeteranganBima Fitra Prasetya ZeyanNo ratings yet

- الله نور السماوات و الأرضDocument260 pagesالله نور السماوات و الأرضPrf El-SakhawyNo ratings yet

- Art Gallary+Library Building Nagpur 18 08 2018 ElectricalDocument111 pagesArt Gallary+Library Building Nagpur 18 08 2018 ElectricalhariomkhungarNo ratings yet

- Juno Lighting Recessed Lighting Catalog 1988Document72 pagesJuno Lighting Recessed Lighting Catalog 1988Alan MastersNo ratings yet

- Two Way Flat Plate Concrete Floor Slab Design Detailing - CSA23.3 14 PDFDocument67 pagesTwo Way Flat Plate Concrete Floor Slab Design Detailing - CSA23.3 14 PDFJGFUYGKIUGUNo ratings yet

- 20105-AR-GED-04-001-02 Rev 02Document1 page20105-AR-GED-04-001-02 Rev 02Bahaa MohamedNo ratings yet

- Research Methodology Example Thesis ArchitectureDocument7 pagesResearch Methodology Example Thesis Architecturenicoleyoungaurora100% (3)

- Chapter 7: Box Girder BridgesDocument26 pagesChapter 7: Box Girder BridgesPacha Khan KhogyaniNo ratings yet

- (Armesto) Quince Casas Americanas de Marcel Breuer PDFDocument22 pages(Armesto) Quince Casas Americanas de Marcel Breuer PDFAngelica CombarizaNo ratings yet

- BOQ Thrmal Protection 3.6Document4 pagesBOQ Thrmal Protection 3.6Moath AlhajiriNo ratings yet

- A Publication of The James F. Lincoln Arc Welding FoundationDocument24 pagesA Publication of The James F. Lincoln Arc Welding Foundationionescu alexandruNo ratings yet

- The Human Side of MicroservicesDocument5 pagesThe Human Side of MicroservicesAlain CésarNo ratings yet

- Office of The Secretary: Use of Slip-Form Paver in Portland Cement Concrete Pavement ConstructionDocument2 pagesOffice of The Secretary: Use of Slip-Form Paver in Portland Cement Concrete Pavement ConstructionrrpenolioNo ratings yet

- Minisplit Lennox LXG Ahtcxxx130p4-Lxg Sctxxx130p4Document4 pagesMinisplit Lennox LXG Ahtcxxx130p4-Lxg Sctxxx130p4Alberto NavarroNo ratings yet

- FA000 Palace-of-Bubbles COMPLETE AIR v001Document1 pageFA000 Palace-of-Bubbles COMPLETE AIR v001baoshi3382No ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- Antalya - Muğla OtellerDocument76 pagesAntalya - Muğla Otellersibel gökçeNo ratings yet

- Ductable Air-Cooled Liquid Chillers and Heat Pumps (30RBY/30RQYDocument32 pagesDuctable Air-Cooled Liquid Chillers and Heat Pumps (30RBY/30RQYBulat IııNo ratings yet

- Dzexams 4am Anglais 182813Document2 pagesDzexams 4am Anglais 182813Khouloud SedNo ratings yet

- Drywall Tool BrochureDocument6 pagesDrywall Tool BrochureknudsenDenmarkNo ratings yet

- Towards A New Classification For Responsive Kinetic Facades: April 2017Document16 pagesTowards A New Classification For Responsive Kinetic Facades: April 2017Layan AlhaddadNo ratings yet

- INTRODUCTIONDocument65 pagesINTRODUCTIONAshu KhanNo ratings yet