Professional Documents

Culture Documents

Shackle G 2130

Shackle G 2130

Uploaded by

Hunnymijie NorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shackle G 2130

Shackle G 2130

Uploaded by

Hunnymijie NorCopyright:

Available Formats

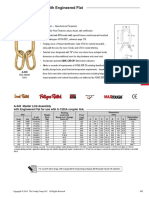

Crosby® Bolt Type Shackles

• Capacities 1/3 thru 150 metric tons, grade 6.

• Working Load Limit and grade “6” permanently shown on every shackle.

• Forged – Quenched and Tempered, with alloy bolts.

• Hot Dip galvanized or self colored. (85, 120, and 150 metric ton shackles

Shackles

are all hot dip galvanized bows and the bolts are Dimetcoted® and painted red)

• Sizes 3/8 and below are mechanically galvanized.

• Fatigue rated (1/3t - 55t).

• Shackles 25t and larger are RFID EQUIPPED.

G-2130 / S-2130

Bolt Type Anchor shackles with • Approved for use at -40° C (-40° F) to 204° C (400° F).

thin head bolt - nut with cotter pin. • Meets or exceeds all requirements of ASME B30.26.

Meets the performance requirements

of Federal Specification RR-C • Shackles 85 metric tons and larger are individually proof tested to 2.0 times the

271G Type IVA, Grade A, Class

3, except for those provisions working load limit.

required of the contractor. For • Type Approval certification in accordance with ABS 2016 Steel Vessel Rules

additional information, see page 475.

ABS Guide for Certification of Lifting Appliances available. Certificates available

when requested at time of order and may include additional charges.

• 3.1 Certification as standard available for charpy and statisti al proof test from 3.25t

up to 25 tons to DNV2.7-1 and EN13889.

• Crosby 3.25t through 25t G2130OC anchor shackles are type approved to DNV Certification

Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and impact

tested to 42 Joules (31 ft•lbf) min. avg. at -20° C (-4° F). The tests are conducted by Crosby

and 3.1 test certification is available upon request. Refer to page 87 for Crosby COLD

TUFF® shackles that meet the additional requirements of DNV rules for certification of lifting

applications - Loose Gear.

• All other 2130 shackles can meet charpy requirements of 42 Joules (31 ft•lbf) avg at -20° C

(-4° F) when requested at time of order.

• Look for the Red Pin® . . . the mark of genuine Crosby quality.

®

SEE APPLICATION INFORMATION

On Page 92 of the General Catalog

Para Español: www.thecrosbygroup.com

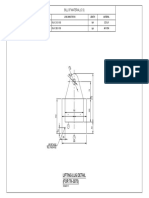

G-2130 / S-2130 Bolt Type Anchor Shackles

Stock Dimensions Tolerance

Nominal Working No. Weight (mm) +/-

Size Load Limit Each

(in) (t)* G-2130 S-2130 G-2130OC (kg) A B C D E F H L M N C A

3/16 1/3 ‡ 1019464 – – .03 9.65 6.35 22.4 4.85 15.2 14.2 37.3 24.9 32.8 4.85 1.50 1.50

1/4 1/2 1019466 – – .05 11.9 7.85 28.7 6.35 19.8 15.5 46.7 32.5 39.6 6.35 1.50 1.50

5/16 3/4 1019468 – – .10 13.5 9.65 31.0 7.85 21.3 19.1 53.0 37.3 46.2 7.85 1.50 1.50

3/8 1 1019470 – – .15 16.8 11.2 36.6 9.65 26.2 23.1 63.0 45.2 55.1 9.65 3.30 1.50

7/16 1-1/2 1019471 – – .22 19.1 12.7 42.9 11.2 29.5 26.9 74.0 51.5 63.8 11.2 3.30 1.50

1/2 2 1019472 1019481 – .36 20.6 16.0 47.8 12.7 33.3 30.2 83.5 58.5 71.1 12.7 3.30 1.50

5/8 3-1/4 1019490 1019506 1262013 .62 26.9 19.1 60.5 16.0 42.9 38.1 106 74.5 90.4 17.5 3.30 1.50

3/4 4-3/4 1019515 1019524 1262022 1.23 31.8 22.4 71.5 19.1 51.0 46.0 126 89.0 105 20.6 6.35 1.50

7/8 6-1/2 1019533 1019542 1262031 1.79 36.6 25.4 84.0 22.4 58.0 53.0 148 102 122 24.6 6.35 1.50

1 8-1/2 1019551 1019560 1262040 2.28 42.9 28.7 95.5 25.4 68.5 60.5 167 119 137 26.9 6.35 1.50

1-1/8 9-1/2 1019579 1019588 1262059 3.75 46.0 31.8 108 28.7 74.0 68.5 190 131 150 31.8 6.35 1.50

1-1/4 12 1019597 1019604 1262068 5.31 51.5 35.1 119 31.8 82.5 76.0 210 146 170 35.1 6.35 1.50

1-3/8 13-1/2 1019613 1019622 1262077 7.18 57.0 38.1 133 35.1 92.0 84.0 233 162 183 38.1 6.35 3.30

1-1/2 17 1019631 1019640 1262086 8.62 60.5 41.4 146 38.1 98.5 92.0 254 175 196 41.1 6.35 3.30

1-3/4 25 1019659 1019668 1262095 15.4 73.0 51.0 178 44.5 127 106 313 225 246 57.0 6.35 3.30

2 35 1019677 1019686 – 23.7 82.5 57.0 197 51.0 146 122 348 253 275 61.0 6.35 3.30

2-1/2 55 1019695 1019702 – 44.6 105 70.0 267 66.5 184 145 453 327 345 79.5 6.35 6.35

3 † 85 1019711 – – 70 127 82.5 330 76.0 200 165 546 365 384 92.0 6.35 6.35

3-1/2 † 120 ‡ 1019739 – – 120 133 95.5 372 92.0 229 203 626 419 432 105 6.35 6.35

4 † 150 ‡ 1019757 – – 153 140 108 368 104 254 229 653 468 451 116 6.35 6.35

* NOTE: Maximum Proof Load is 2 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. For Working Load Limit reduction due to side loading ap-

plications, see page 94. † Individually Proof Tested with certification. ‡ Furnished in Anchor style only and furnished with eyebolts for handling.

Copyright © 2019 The Crosby Group LLC All Rights Reserved 79

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Dream ControlDocument5 pagesDream ControlHennie Namløs Thorne100% (2)

- IELTS Exam Form and Answer Sheet SamplesDocument39 pagesIELTS Exam Form and Answer Sheet SamplesNay AungNo ratings yet

- Wisc VDocument32 pagesWisc VAnaaaerobios100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Strategic Aspects of Woolworths Supermarkets.Document13 pagesStrategic Aspects of Woolworths Supermarkets.Jai Shivam Sharma100% (2)

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3Hunnymijie NorNo ratings yet

- Australian Aboriginal ArtDocument7 pagesAustralian Aboriginal ArtPatrick Niel Gicanal Gelvolea100% (1)

- Case Study 5 ChangeDocument9 pagesCase Study 5 ChangeShubhangi Kesharwani100% (1)

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- Lifting Lug For Tanks (TK-3075)Document1 pageLifting Lug For Tanks (TK-3075)Hunnymijie NorNo ratings yet

- Min Gasket Width CalculationDocument1 pageMin Gasket Width CalculationHunnymijie NorNo ratings yet

- ISO 7919 5 1st Edition 1997 PDFDocument14 pagesISO 7919 5 1st Edition 1997 PDFHunnymijie NorNo ratings yet

- Uni-Drive Catalogue-1Document317 pagesUni-Drive Catalogue-1Hunnymijie NorNo ratings yet

- AEROlite NA3900 Technical Data - TBJ 2Document1 pageAEROlite NA3900 Technical Data - TBJ 2Hunnymijie NorNo ratings yet

- Leadership ThesisDocument61 pagesLeadership ThesisVidyaa India100% (1)

- Criteria For Evaluating The Quality of Online Courses: General InformationDocument11 pagesCriteria For Evaluating The Quality of Online Courses: General InformationDayaNo ratings yet

- Jamb Econs Questions 1 5Document50 pagesJamb Econs Questions 1 5princewills130No ratings yet

- STRAIN ENERGY - The Work Done in Straining The Material, Within The Elastic Limit, Is Known As Strain EnergyDocument2 pagesSTRAIN ENERGY - The Work Done in Straining The Material, Within The Elastic Limit, Is Known As Strain EnergyAshish KhatriNo ratings yet

- Netflix UserbaseDocument119 pagesNetflix UserbaseSundar MNo ratings yet

- Revision CHNDocument27 pagesRevision CHNMary Samantha NableaNo ratings yet

- Deleliste Atlas Copco DKR 36Document16 pagesDeleliste Atlas Copco DKR 36Nuno PaivaNo ratings yet

- SAP Document ServiceDocument60 pagesSAP Document ServiceAbhishek Sinha100% (1)

- Machine Learning in Python Essential Techniques Fo... - (Cover) PDFDocument4 pagesMachine Learning in Python Essential Techniques Fo... - (Cover) PDFBobby BobbersonNo ratings yet

- Smart Learning SuiteDocument3 pagesSmart Learning Suitemoussaouikarim2005No ratings yet

- Dental Wax UpDocument4 pagesDental Wax UpJoselyn RodriguezNo ratings yet

- Enchanted_Mesa_4Document11 pagesEnchanted_Mesa_4Natalia LugovayaNo ratings yet

- Location Factors: RJ1040-010 Building SystemsDocument6 pagesLocation Factors: RJ1040-010 Building SystemsRyanNo ratings yet

- Mboho Mkparawa Ibibio v. Okon - Third Amended Complaint PDFDocument38 pagesMboho Mkparawa Ibibio v. Okon - Third Amended Complaint PDFMark JaffeNo ratings yet

- Elcometer 224 S Operating ManualDocument3 pagesElcometer 224 S Operating ManualDale WadeNo ratings yet

- Accessories AH2342-CA Ȝ: SpecificationDocument1 pageAccessories AH2342-CA Ȝ: SpecificationhoiNo ratings yet

- Sound: 1) Longitudinal Wave Motion and 2) Transverse Wave MotionDocument31 pagesSound: 1) Longitudinal Wave Motion and 2) Transverse Wave MotionVinothNo ratings yet

- ALIA AUF770 Sanitary Type Ultrasonic FlowmeterDocument4 pagesALIA AUF770 Sanitary Type Ultrasonic FlowmeterRexCrazyMindNo ratings yet

- Teza 11 FiloDocument2 pagesTeza 11 FiloSebaNo ratings yet

- MRCHDocument27 pagesMRCHFijimol FranklineNo ratings yet

- Saljnikov AleksandarDocument8 pagesSaljnikov AleksandarMatias MancillaNo ratings yet

- Midterm Examination in Statistics and Probability (GRADE 11)Document9 pagesMidterm Examination in Statistics and Probability (GRADE 11)Andrea MoragaNo ratings yet

- Graham House BrochureDocument2 pagesGraham House BrochureD.M. TrizmegistusNo ratings yet

- Salamat Aking Ina (Tula-Tulaan) - MODERNONGKABATAAN - WattpadDocument3 pagesSalamat Aking Ina (Tula-Tulaan) - MODERNONGKABATAAN - WattpadJomer Ruego0% (1)