Professional Documents

Culture Documents

Quality Assurance Plan For Civil4m

Uploaded by

Mohammed Abdul BaseerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan For Civil4m

Uploaded by

Mohammed Abdul BaseerCopyright:

Available Formats

Quality Assurance Plan (QAP)

QAP is the document which shows the sequence of Quality Control system (QCS) including

frequency and numbers of tests based on the detail work program.

QAP generally presented by the contractor against the specification of the Employer/Client during

the signing of the contract. QAP is the basic document to control the quality of works for contractor

which also help the client/consultant for the supervision of the quality.

QAP contains the following

a) Quality Control Schedule

- test schedule

- testing program

- list of tests

- laboratory; site trials & trial sections

- construction control test & its frequencies

- numbers of tests to be carried out & list of equipment to conduct them

- list of “critical” acceptance testing procedures

- list of staff assigned to the laboratory, their position & responsibilities

b) List of sources of materials and/or of manufactured articles

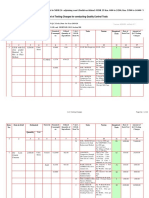

Quality Assurance Plan for the construction materials from Natural resources

Nos. of test to be carried out as per

Specification Name of the Remarks

Material Quantity as Frequency the specification

S.NO reference page tests to be

Description per BOQ of Test Carried

no. or clause no. carried out Required Compliance

Out

Gradation

LAA From each

quarry

1 Aggregate Water source one

Absorption set of tests

FI

From each

Sand for quarry

2a Gradation

Concrete works source one

set of tests

From each

Sand for quarry

2b Gradation

Masonry works source one

set of tests

Water From each

Absorption quarry

3 Stone

Specific source one

set of tests

Gravity

Every 50 m3

4 Filter Material Gradation - 1 set of

tests

Every 1500

Compaction m3 - 1 set of

Soil for tests

5

embankment

500 m2 one

Field Density

nos of tests

Every 3000

Compaction m2 - 1 set of

Subgrade tests

6

Preparation

500 m2 one

Field Density

nos of tests

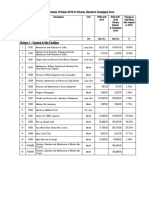

Quality Assurance Plan for the construction materials (Factory Manufactured)

Nos. of test to be carried

Manufacture' out as per the specification

Quantity Name of the

Material s Certificate Frequency of

S.NO Specification as pertests to be Remarks

Description Received & Test Requir Carried

BOQ carried out Compliance

Approved ed Out

Initial setting 2

Final setting For each 200 2

Compressive tons 1 set of

1 Cement 614 377186 2

strength tests on each

test, 3 days supply 2

7 days 2

upto 25 nos

Mass of zinc

of coils 2 nos

coating

sampling,

26 to 50 nos

Adhesion test * of coils-3 nos

sampling

51 to 150 nos

Uniformity test

of coils - 5

2 Gabions 633 37,867.22 *

nos sampling

151 to 3000

Tensile trest nos of coils-8

nos sampling

above 300

nos of coils -

13 nos

sampling

2 Geotextile 627 3,383.60

Tensile strength 1

3 Steel 620 6.68 Each lot

Elongation 1

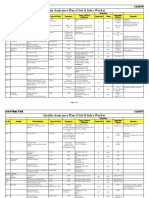

QUALITY ASSURANCE PLAN (QAP) Sample (for a road construction project)

Name of Project: Location

(GPS)

Contract No

Total Rem

Management of Tests

no of rks

Specificat

BoQ Quantity Test Test

ion Description Frequency

Item as per Unit Require Requir

Clause of works of test *

No. BoQ d ed as At

Ref.

per (Site/Lab/

BOQ Equipment Others) By

1

1.Grada i m3

tion n

1

i m3

2.LL-PI n

Embankme 1

m3

nt Filling 3.MDD i m3

& OMC n

1

4. Field i m2

Density n

5. CBR

1

i m2

1.LL-PI n

1

2.MDD i m2

Sub grade 2 & OMC n

m

Preparation 1

3. Field i m2

Density n

1

i m2

4. CBR n

1. 1

Gradati i m3

on n

1

i m3

2.LL- PI n

Supply and

1

laying of

m3 3. MDD i m3

Granular

& OMC n

Subbase

4. 1

Soaked i m3

CBR n

1

5. Field i m2

density n

You might also like

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- Paver Block Rate AnalysisDocument1 pagePaver Block Rate AnalysisTech Guide- HindiNo ratings yet

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Document24 pagesUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangaleNo ratings yet

- GONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Document6 pagesGONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Aamir Anwar100% (1)

- Standard PriceDocument10 pagesStandard PriceNadeesha MihiraniNo ratings yet

- Civil works quality plan for sewage treatment projectsDocument24 pagesCivil works quality plan for sewage treatment projectsShesha ShayanNo ratings yet

- Lot 1 - Expansion Civil WorksDocument6 pagesLot 1 - Expansion Civil WorksJethro AbanadorNo ratings yet

- Rate Analysis - Khulna - Barisal - GopalganjDocument280 pagesRate Analysis - Khulna - Barisal - Gopalganjmd mohiuddinNo ratings yet

- Item Material Unit Remark SR No Material Coeff. Excl Wastage Wastage Factor Material Co-EffDocument9 pagesItem Material Unit Remark SR No Material Coeff. Excl Wastage Wastage Factor Material Co-EffDeepak KaushikNo ratings yet

- FREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghDocument10 pagesFREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghAjit P. SinghNo ratings yet

- GSB Test FormatsDocument4 pagesGSB Test FormatsGaurav TripathiNo ratings yet

- Methodology of Dynamic PileDocument10 pagesMethodology of Dynamic PileRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- AAC BLOCK SUNKEN FILLING CHECKLISTDocument1 pageAAC BLOCK SUNKEN FILLING CHECKLISTASHOKKUMARNo ratings yet

- Amendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering WorksDocument8 pagesAmendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering Worksraviteja036No ratings yet

- 1888 03Document36 pages1888 03Laura MarquezNo ratings yet

- Analysis of Rate PMGSY Bridge-2021Document344 pagesAnalysis of Rate PMGSY Bridge-2021Abhishek Choudhary100% (1)

- Cube RegisterDocument148 pagesCube RegisterShesha ShayanNo ratings yet

- 005 - 24-09-2014 - Material ApprovalDocument1 page005 - 24-09-2014 - Material ApprovalMohammad UmmerNo ratings yet

- Morth 2013Document903 pagesMorth 2013Gunjan KumarNo ratings yet

- Core Cutting Sampling ProformaDocument1 pageCore Cutting Sampling ProformaImran KhanNo ratings yet

- Bitumen Extraction Test Observation SheetDocument2 pagesBitumen Extraction Test Observation SheetramNo ratings yet

- Deviation Statement and Rate Analysis For Civil WorkDocument71 pagesDeviation Statement and Rate Analysis For Civil WorkRajat Sharma100% (1)

- Astm D 2113-14Document20 pagesAstm D 2113-14aswathy annie vargheseNo ratings yet

- Authorisation For Layig GSB and WMM-Rev-R2Document1 pageAuthorisation For Layig GSB and WMM-Rev-R2Guna SekaranNo ratings yet

- Rate Analysis - Gujarat - Pkg-27 PDFDocument200 pagesRate Analysis - Gujarat - Pkg-27 PDFAayush AggarwalNo ratings yet

- Initial Vertical Static Load Test: AgencyDocument5 pagesInitial Vertical Static Load Test: AgencyRavi kumarNo ratings yet

- Checklist For PMGSY Road WorksDocument4 pagesChecklist For PMGSY Road WorksrkpragadeeshNo ratings yet

- QCT For GSB (Formets)Document123 pagesQCT For GSB (Formets)Bilal Ahmed BarbhuiyaNo ratings yet

- Concrete Lab ManualDocument42 pagesConcrete Lab ManualVENKATA RANGANADHNo ratings yet

- TIP-HSE-P03-02-F01 Contractor HSE - Containment For CCTVDocument1 pageTIP-HSE-P03-02-F01 Contractor HSE - Containment For CCTVVijayakumar KarunanidhiNo ratings yet

- Government of Telangana Road Bitumen Extraction TestDocument4 pagesGovernment of Telangana Road Bitumen Extraction TestKreesthu ReddyNo ratings yet

- Summary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCDocument3 pagesSummary of Mix Design Material Description Grade of Concrete M25 RCC M 35 Pile M15 PCC M20 RCC M30 RCC M35 RCC M40 RCC M45 RCC M50 RCCmeerut nazibabad projectNo ratings yet

- Standard Formats All Q013 To Q63Document141 pagesStandard Formats All Q013 To Q63Amjad Pathan100% (1)

- Specs 2019 V2Document756 pagesSpecs 2019 V2jaipalNo ratings yet

- Brickwork - Rate AnalysisDocument7 pagesBrickwork - Rate Analysisjagadeesh nalabothuNo ratings yet

- Quality Control for Subgrade ConstructionDocument8 pagesQuality Control for Subgrade Constructionabhishekks26No ratings yet

- Department of Civil Engineering List of Indian Road Congress (Irc)Document7 pagesDepartment of Civil Engineering List of Indian Road Congress (Irc)senthilncc100% (1)

- 122-354019 GSB-I CoarseDocument32 pages122-354019 GSB-I CoarseARTI PALEKARNo ratings yet

- 3rd Running Bil 353 NH (Act)Document4 pages3rd Running Bil 353 NH (Act)mad21_No ratings yet

- Certification of Plywood For Concrete Shuttering WorkDocument10 pagesCertification of Plywood For Concrete Shuttering WorkJGD123No ratings yet

- Quality assurance plan for civil construction projectsDocument11 pagesQuality assurance plan for civil construction projectsDeviPrasadNathNo ratings yet

- Client Authority Consultant Main Contractor Civil SubcontractorDocument2 pagesClient Authority Consultant Main Contractor Civil SubcontractorJoe PsNo ratings yet

- SMG-SI-10-DG-002-A3 - SHT 81-100 - Rev.1Document27 pagesSMG-SI-10-DG-002-A3 - SHT 81-100 - Rev.1aan zulwiNo ratings yet

- DLC Methodology - Nagpur MumbaiDocument13 pagesDLC Methodology - Nagpur MumbaiGanesh Kumar TulabandulaNo ratings yet

- Submission of Revised Method Staterment Survey Setting Out For Foundations and PiersDocument44 pagesSubmission of Revised Method Staterment Survey Setting Out For Foundations and PiersShubham GaglaniNo ratings yet

- Pert Chart - Limestone Handling System: Times (In Days)Document1 pagePert Chart - Limestone Handling System: Times (In Days)user_nitsNo ratings yet

- Concrete dispatch slip quality planDocument1 pageConcrete dispatch slip quality planShesha ShayanNo ratings yet

- Construction Permit To Work SystemDocument3 pagesConstruction Permit To Work SystemZubair KhanNo ratings yet

- Construction ShadeDocument1 pageConstruction ShadeAnthony AgnerNo ratings yet

- Construction Site Organisation ChartDocument1 pageConstruction Site Organisation ChartsubhaschandraNo ratings yet

- NH Sor 6TH Revision 2018 Combine PDFDocument170 pagesNH Sor 6TH Revision 2018 Combine PDFM/s Gogoi AssociatesNo ratings yet

- Plan and profile drawings from 0+000 to 09+600 kmDocument27 pagesPlan and profile drawings from 0+000 to 09+600 kmNilay GandhiNo ratings yet

- Sieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Document1 pageSieve Analysis Coarse Aggrigate (15-25) - 30!11!2022Mitendra Kumar ChauhanNo ratings yet

- Material Reconciliation - PDF REVISEDDocument32 pagesMaterial Reconciliation - PDF REVISEDlinga2014No ratings yet

- Soil TestsDocument30 pagesSoil TestsdhurviconsultantNo ratings yet

- CADANGAN KERJA-KERJA BAIKPULIH MASJID SAHABATDocument14 pagesCADANGAN KERJA-KERJA BAIKPULIH MASJID SAHABATDinn NsNo ratings yet

- Schedule of TestDocument13 pagesSchedule of TestRam NepaliNo ratings yet

- Rate List FY 2021 Effective From 1.4.21Document2 pagesRate List FY 2021 Effective From 1.4.21keshav antreNo ratings yet

- Number of TestDocument1 pageNumber of TestRaj Raj-hNo ratings yet

- Testing ScheduleDocument4 pagesTesting ScheduleAlpesh JogranaNo ratings yet

- C4M Quality Management Interactive DashboardDocument2,560 pagesC4M Quality Management Interactive Dashboardlinga2014No ratings yet

- Rate Analysis of Highways 1Document65 pagesRate Analysis of Highways 1Mohammed Abdul BaseerNo ratings yet

- Recite Duas for Benefit in Life and HereafterDocument159 pagesRecite Duas for Benefit in Life and Hereaftermailtojikku100% (3)

- Contractor's Bill Check List: OthersDocument8 pagesContractor's Bill Check List: OthersaseerNo ratings yet

- Recite Duas for Benefit in Life and HereafterDocument159 pagesRecite Duas for Benefit in Life and Hereaftermailtojikku100% (3)

- Inspection Test Plan For Building Materials Name of Project: Material: Cement - Opc 53 GradeDocument9 pagesInspection Test Plan For Building Materials Name of Project: Material: Cement - Opc 53 GradeMohammed Abdul BaseerNo ratings yet

- Morning and Evening DuasDocument29 pagesMorning and Evening DuasZamir Ahmed100% (4)

- Project Quality Plan As Per ISODocument118 pagesProject Quality Plan As Per ISORaju100% (1)

- C4M Quality Management Interactive DashboardDocument2,560 pagesC4M Quality Management Interactive Dashboardlinga2014No ratings yet

- Inspection Test Plan For Building Materials Name of Project: Material: Cement - Opc 53 GradeDocument9 pagesInspection Test Plan For Building Materials Name of Project: Material: Cement - Opc 53 GradeMohammed Abdul BaseerNo ratings yet

- Merino Laminates Product Portfolio/TITLEDocument59 pagesMerino Laminates Product Portfolio/TITLEsukavasi1973No ratings yet

- ICMR Testing Update 04april 9PM ISTDocument1 pageICMR Testing Update 04april 9PM ISTRahul MidhaNo ratings yet

- Indian Institute OF Management Indore: Tender Notice No.: IIMI/Project/05/2017/39 File No. 342Document14 pagesIndian Institute OF Management Indore: Tender Notice No.: IIMI/Project/05/2017/39 File No. 342Mohammed Abdul BaseerNo ratings yet

- HW Grade 3Document2 pagesHW Grade 3Mohammed Abdul BaseerNo ratings yet

- Pmbok 6th Edition Free Download PDFDocument3 pagesPmbok 6th Edition Free Download PDFSanjay Kumar Rajpoot24% (135)

- DAR, 2018 Vol. 2Document1,108 pagesDAR, 2018 Vol. 2Charan Electricals94% (16)

- Enhanced Installation: Comparative Properties Softbac Vs Standard BitumenDocument1 pageEnhanced Installation: Comparative Properties Softbac Vs Standard BitumenMohammed Abdul BaseerNo ratings yet

- PMP CertificateDocument1 pagePMP CertificateMohammed Abdul BaseerNo ratings yet

- Enhanced Installation: Comparative Properties Softbac Vs Standard BitumenDocument1 pageEnhanced Installation: Comparative Properties Softbac Vs Standard BitumenMohammed Abdul BaseerNo ratings yet

- Laurie BakerDocument12 pagesLaurie BakerchaplinNo ratings yet

- CyberstalkingDocument22 pagesCyberstalkingManasa M DharNo ratings yet

- Water SprayDocument2 pagesWater SpraySaba SamankanNo ratings yet

- Ethics in Animal-Based Research: Dominik Gross René H. TolbaDocument15 pagesEthics in Animal-Based Research: Dominik Gross René H. TolbaIuliana MogaNo ratings yet

- New Grad RN Resume ObjectiveDocument5 pagesNew Grad RN Resume Objectiveafjzcgeoylbkku100% (2)

- Qatar ScriptDocument1 pageQatar ScriptTheodore Palmares ArellanoNo ratings yet

- Crystal-Phase Transitions and Photocatalysis in Supramolecular Scaffolds (2017)Document8 pagesCrystal-Phase Transitions and Photocatalysis in Supramolecular Scaffolds (2017)Louis Peronet VergaraNo ratings yet

- WRAP EMS Guide Mar2015Document64 pagesWRAP EMS Guide Mar2015mike24872267No ratings yet

- Engineering A New Mouse Model For Vitiligo 2012 Journal of Investigative DermatologyDocument4 pagesEngineering A New Mouse Model For Vitiligo 2012 Journal of Investigative DermatologyAurelian Corneliu MoraruNo ratings yet

- TBT Accident Prevention 1Document2 pagesTBT Accident Prevention 1zaimNo ratings yet

- Nursing Research in Canada 4th Edition Wood Test BankDocument25 pagesNursing Research in Canada 4th Edition Wood Test BankAllisonPowersrjqo100% (51)

- Lucy Mayienga CV RecentDocument3 pagesLucy Mayienga CV Recentlucy.mayiengaNo ratings yet

- Comp Carlyle Torque PDFDocument125 pagesComp Carlyle Torque PDFjsnavarro1o100% (2)

- Intelligence TestDocument8 pagesIntelligence TestAnonymous CmxkmL0880% (10)

- 13th Month Pay Law and JurisprudenceDocument2 pages13th Month Pay Law and JurisprudenceJennylyn Biltz AlbanoNo ratings yet

- How to Give a Woman the Most Powerful OrgasmDocument10 pagesHow to Give a Woman the Most Powerful OrgasmFederico Ceferino BrizuelaNo ratings yet

- Wire Rope Slings Si 2 - 2 EmmDocument2 pagesWire Rope Slings Si 2 - 2 EmmheppyfaebanffNo ratings yet

- Water Hardness Case StudyDocument15 pagesWater Hardness Case StudyTaima GhNo ratings yet

- Sea Cliff Zanzibar E Fact SheetDocument6 pagesSea Cliff Zanzibar E Fact SheetBenedict MuringakumweNo ratings yet

- Ijpcr 22 309Document6 pagesIjpcr 22 309Sriram NagarajanNo ratings yet

- User list of chemistry analyzerDocument1 pageUser list of chemistry analyzerHussain Amir AliNo ratings yet

- 17EEX01-FUNDAMENTALS OF FIBRE OPTICS AND LASER INSTRUMENTATION SyllabusDocument2 pages17EEX01-FUNDAMENTALS OF FIBRE OPTICS AND LASER INSTRUMENTATION SyllabusJayakumar ThangavelNo ratings yet

- The Good NurseDocument2 pagesThe Good NurseKiela Therese LabroNo ratings yet

- Introduction To CommerceDocument30 pagesIntroduction To Commerceapi-24690719591% (11)

- The Death Penalty-Literature ReviewDocument4 pagesThe Death Penalty-Literature Reviewapi-582834189No ratings yet

- Nanostrength Block Copolymers For Epoxy TougheningDocument5 pagesNanostrength Block Copolymers For Epoxy TougheningRonald GeorgeNo ratings yet

- MetallizationDocument51 pagesMetallizationjust4u2cjoshy67% (3)

- "Channel Sampling": Forms & ChecklistDocument1 page"Channel Sampling": Forms & ChecklistevonNo ratings yet

- SITHPAT006 Student LogbookDocument46 pagesSITHPAT006 Student LogbookÇrox Rmg PunkNo ratings yet

- Quality Operating Process: Manual of Operations Care of PatientsDocument4 pagesQuality Operating Process: Manual of Operations Care of PatientsPrabhat KumarNo ratings yet