Professional Documents

Culture Documents

31 10 00 10-P6000CFP-000-PV - A

31 10 00 10-P6000CFP-000-PV - A

Uploaded by

Stephen RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

31 10 00 10-P6000CFP-000-PV - A

31 10 00 10-P6000CFP-000-PV - A

Uploaded by

Stephen RajCopyright:

Available Formats

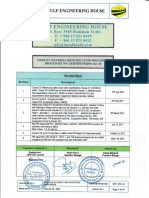

Kuwait National Petroleum Company (K.S.C.) 31.10.00.

10-P6000CFP-000-PV

Clean Fuels Project 2020 REV. A, 20-Mar.-13

Page 1 of 6

Project Variation

Project Variation to

Shell DEP 31.10.00.10

Positive Material Identification (PMI) Program

A 20-Mar 13 Approved for Design FW FW FW

CHKD Approved Client

Rev. Date Description Orig.

By By Approval

Kuwait National Petroleum Company (K.S.C.)

Clean Fuels Project 2020

Kuwait

Foster Wheeler Energy Limited

Reading

United Kingdom

CONTRACT NO. PROJECT VARIATION NO. REV. NO.

1-14-5230/9 31.10.00.10 -P6000CFP-000-PV A

file name Foster Wheeler

DSN:

Kuwait National Petroleum Company (K.S.C.) 31.10.00.10-P6000CFP-000-PV

Clean Fuels Project 2020 REV. A, 20-Mar.-13

Page 2 of 6

Project Variation

Record of Revisions

Rev. No. Date Description

A ’20-Mar-13 Approved for Design

file name Foster Wheeler

DSN:

Kuwait National Petroleum Company (K.S.C.) 31.10.00.10-P6000CFP-000-PV

Clean Fuels Project 2020 REV. A, 20-Mar.-13

Page 3 of 6

Project Variation

1.0 INTRODUCTION

DEP 31.10.00.10 - Gen, Positive Material Identification (PMI) Program dated September

2011, is adopted for the Clean Fuels Project (CFP) subject to the modification noted in this

project variation. This PV (Project Variation) shall be included, as a requirement, wherever

DEP 31.10.00.10 -Gen is referenced in any other project documents, including all DEPs.

In general, the requirements stated in this PV have precedence over, and supersede those

in the Shell DEPs. Any discrepancy between this PV and other Clean Fuels Project

documents shall be brought to the attention of the Company for review and direction.

References in DEP 31.10.00.10 -Gen to other Design and Engineering Practices

(specifications, guidelines, etc.) shall be amended, superseded, or otherwise revised by

the associated PV of a given DEP, where available.

2.0 DEP 31.10.00.10-GEN AMENDMENTS

2.1 Section 4.3 a)

Delete “section 4.6”

Replace “with section 4.7”

2.2 Section 4.5

Add following to fourth Paragraph

Where accessible after welding the root pass shall be subject to PMI

2.3 Section 4.5 i

Delete “If the function of the overlay is corrosion protection, a volumetric or surface

analysis shall be completeted at a minimum depth of 1.5 mm (0.060 inch) below the

process-contacted surface.”

Replace with “If the function of the overlay is corrosion protection, a volumetric or

surface analysis shall be completed at a minimum depth of 2.5 mm (0.1 inch) below

the process-contacted surface.”

2.4 Section 4.5 ii

Delete “If the function of the overlay is to assure product purity only, the sample shall

be taken at a minimum depth of 1 mm (0.040) inch”

Replace with “If the function of the overlay is to assure product purity only, the

sample shall be taken at a minimum depth of 1.5 mm (0.060) inch”

file name Foster Wheeler

DSN:

Kuwait National Petroleum Company (K.S.C.) 31.10.00.10-P6000CFP-000-PV

Clean Fuels Project 2020 REV. A, 20-Mar.-13

Page 4 of 6

Project Variation

2.5 Section 4.8

Add “To prevent damage to the gasket surface only the X-ray fluorescence method

of PMI may be used.”

2.6 Section 5

First paragraph

Delete “Refer to (4.6) ….”

Replace with “Refer to (4.7) ….”

Third paragraph

Delete “Shell Technical Authority”

Replace with “PMC/Principal”

2.7 Section 9 – References

Change Section number from “Section 9” to “Section 10”.

2.8 Add New Section 9

In addition the requirements listed above the minimum requirements shall apply

9.1 Receipt Inspection

A) Piping/Instrument piping

i) Sample PMI shall be carried out for 5% of each heat number for materials

(minimum 3) other than carbon steel during receiving inspection. If quantity is

less than 3, all items shall be PMI tested. PMI during receiving inspection is

applicable for all grades of stainless steels also.

ii) 100 % PMI shall be performed on completed piping systems (including welds),

after field installation of pipe spools but before release for testing as per

SHELL DEP 31.10.00.10-Gen. However for D category fluid service and SS

grade 304 in any service, only 10% PMI is required to be performed.

B) Equipment

i) Sample PMI shall be carried out of each purchase order line item during

receiving inspection at Site. 10% of components/parts of each item/equipment

file name Foster Wheeler

DSN:

Kuwait National Petroleum Company (K.S.C.) 31.10.00.10-P6000CFP-000-PV

Clean Fuels Project 2020 REV. A, 20-Mar.-13

Page 5 of 6

Project Variation

shall be subjected to spot PMI accordingly. Percentage shall be increased to

100% if non-conforming items are detected.

ii) PMI test shall be performed for 10% of the attachment welds for piping as well

as equipment.

9.2 Inspection at Suppliers Works

Equipment, Piping, Valves and Instrument piping

a) 100% PMI of materials & welds other than carbon steel at the material

fabricator / supplier’s works prior to delivery.

b) 100% PMI shall be carried out also for all internal parts other than carbon

steel.

c) 100 PMI check shall be performed for 10% of the attachment welds.

9.3 Acceptance Criteria

The material shall be considered acceptable if the analysis is within + or - 10% of

the range specified in the appropriate standard.

Where portable PMI indicates that the analysis is outside the range permitted

above a more accurate method may be used, e.g. wet analysis.

For dissimilar welds the acceptable range shall be agreed with PMC/Principle

2.9 Table 1 Note 8 a

Delete “If the function of the overlay is corrosion protection, a volumetric or surface

analysis shall be completeted at a minimum depth of 1.5 mm (0.060 inch) below the

process-contacted surface.“

Replace with “If the function of the overlay is corrosion protection, a volumetric or

surface analysis shall be completed at a minimum depth of 2.5 mm (0.1 inch) below

the process-contacted surface.”

file name Foster Wheeler

DSN:

Kuwait National Petroleum Company (K.S.C.) 31.10.00.10-P6000CFP-000-PV

Clean Fuels Project 2020 REV. A, 20-Mar.-13

Page 6 of 6

Project Variation

2.10 Table 1 Note 8 b

Delete “If the function of the overlay is to assure product purity only, the sample shall

be taken at a minimum depth of 1 mm (0.040) inch. “

Replace with “If the function of the overlay is to assure product purity only, the

sample shall be taken at a minimum depth of 1.5 mm (0.060) inch”

2.11 Table 3 Note 2

Delete

0.5 % to 0.75 % max Ni in base material and <1.1 % Ni for weld deposits.

0.1 % to 0.3 % Al.

0.2 % to 0.5 % Ti.

Add

Analysis for Al and Ti is not required

file name Foster Wheeler

DSN:

You might also like

- 34.14.20.31-P6000CFP-000-PV - C (Drainage System)Document76 pages34.14.20.31-P6000CFP-000-PV - C (Drainage System)Stephen RajNo ratings yet

- Mesc Spe 74 014 2016 PDFDocument15 pagesMesc Spe 74 014 2016 PDFSalahuddin FarooquiNo ratings yet

- LR EN 10204 Type 3Document2 pagesLR EN 10204 Type 3Jym GensonNo ratings yet

- Sfa 5.22 PDFDocument36 pagesSfa 5.22 PDFLuis Evangelista Moura PachecoNo ratings yet

- 76 - 200Document11 pages76 - 200rajaNo ratings yet

- SSM Su 5003 BDocument84 pagesSSM Su 5003 Bresp-ectNo ratings yet

- Asme Sec II Part B 2017Document1 pageAsme Sec II Part B 2017Lipika Gayen0% (1)

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- 34.51.01.33 P6000CFP 000 PV - A DEP Tanks VariationDocument22 pages34.51.01.33 P6000CFP 000 PV - A DEP Tanks VariationNaser Alshraim100% (1)

- 31 38 01 31-P6000CFP-000-PV - C PDFDocument5 pages31 38 01 31-P6000CFP-000-PV - C PDFmanojballaNo ratings yet

- Astm E736Document3 pagesAstm E736Diego NeiraNo ratings yet

- Asme Section 1 - Pmi PDFDocument3 pagesAsme Section 1 - Pmi PDFArul Edwin VijayNo ratings yet

- General Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt AlloysDocument4 pagesGeneral Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt Alloysanurag yadavNo ratings yet

- Es124 01Document90 pagesEs124 01Michael CovillNo ratings yet

- Mss sp-54 PDFDocument6 pagesMss sp-54 PDFPratik DesaiNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- ADCO Amendments 30-99-12-3207 Rev.1 To DEP 31.38.01.31 Steel Piping 2013...Document22 pagesADCO Amendments 30-99-12-3207 Rev.1 To DEP 31.38.01.31 Steel Piping 2013...aymanNo ratings yet

- 02 Samss 011Document36 pages02 Samss 011OMER ELFADILNo ratings yet

- Standard For AWS Certification of Welding InspectorsDocument24 pagesStandard For AWS Certification of Welding InspectorsFrancisco Eduardo SouzaNo ratings yet

- Carbon Steel Forgings (Amendments/Supplements To Astm A 105)Document7 pagesCarbon Steel Forgings (Amendments/Supplements To Astm A 105)manuneedhiNo ratings yet

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- Koc MP 018Document17 pagesKoc MP 018Subhajit BhattacharyaNo ratings yet

- 00 PR SP 00002 - 2 Positive Material Identification (PMI) of AlloysDocument14 pages00 PR SP 00002 - 2 Positive Material Identification (PMI) of AlloysStevanNikolicNo ratings yet

- E1936-97 Evaluating Digitization SystemsDocument4 pagesE1936-97 Evaluating Digitization SystemsNDT Div, MedequipNo ratings yet

- 4 5847992272976611240 PDFDocument8 pages4 5847992272976611240 PDFAyyappanSubramanianNo ratings yet

- Mss sp-121Document17 pagesMss sp-121Mhand AmsNo ratings yet

- Particular Material Appraisal (PMA) and The Pressure Equipment Regulations (PER)Document4 pagesParticular Material Appraisal (PMA) and The Pressure Equipment Regulations (PER)karanvkNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- 76-210 - 2012 Carbon Steel ForgingsDocument6 pages76-210 - 2012 Carbon Steel Forgingspradeep100% (1)

- Acoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011Document84 pagesAcoustic Emission Testing of Pressure Vessel - ASME Section V, ASNT - 24 Feb 2011concord1103No ratings yet

- MDR Form A-1Document2 pagesMDR Form A-1Yuvraj ThoratNo ratings yet

- Sa 450/sa 450MDocument13 pagesSa 450/sa 450MSaravana VelNo ratings yet

- MESC SPE 77-211 Nov 2012 PDFDocument6 pagesMESC SPE 77-211 Nov 2012 PDFaleeimeranNo ratings yet

- Sa 263Document8 pagesSa 263Wagner Renato AraújoNo ratings yet

- E1390-12 Standard Specification For Illuminators Used For Viewing Industrial RadiographsDocument3 pagesE1390-12 Standard Specification For Illuminators Used For Viewing Industrial RadiographsMuhammed Abo-FandoodNo ratings yet

- AWS A4.2M 2006 Standard Procedures For Calibrating Magnetic Instruments To Measure The Delta Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal PDFDocument58 pagesAWS A4.2M 2006 Standard Procedures For Calibrating Magnetic Instruments To Measure The Delta Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal PDFErik Jhonattan Jara YpanaqueNo ratings yet

- ASME - Brazing Procedures Qualification ReportDocument1 pageASME - Brazing Procedures Qualification ReportChowKC03100% (1)

- Spe 76-202 Sep 2012Document8 pagesSpe 76-202 Sep 2012akashdruva892100% (1)

- Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDocument4 pagesElectromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDamian Vega GNo ratings yet

- 6 77 0001 Rev - 4 PDFDocument40 pages6 77 0001 Rev - 4 PDFRam Kadam0% (1)

- ASME Nuclear - Brochure - FinalDocument29 pagesASME Nuclear - Brochure - FinalMircea Ovidiu BecheruNo ratings yet

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- HIC Test 22-Jul-19Document3 pagesHIC Test 22-Jul-19Panomsit SrirunpetchNo ratings yet

- D17.1 D17.1M 2017 Sample PQTR FormDocument1 pageD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaNo ratings yet

- Ultrasonic Examination Procedure (Issue 2)Document14 pagesUltrasonic Examination Procedure (Issue 2)Li Liu100% (1)

- ASME U StampDocument2 pagesASME U StampAJAY1381No ratings yet

- Ferrite Testing ProcedureDocument6 pagesFerrite Testing ProcedureReadersmo0% (1)

- Flanges ANSI16 5###Document48 pagesFlanges ANSI16 5###kunal shahNo ratings yet

- PMI Report May 2019Document19 pagesPMI Report May 2019RifanjshshNo ratings yet

- BS EN ISO 19232-1-2013 - 5b2018-05-19 - 12-51-18 PM5dDocument6 pagesBS EN ISO 19232-1-2013 - 5b2018-05-19 - 12-51-18 PM5darbabNo ratings yet

- Api 578 Positive Material Identification Pmi PDFDocument24 pagesApi 578 Positive Material Identification Pmi PDFSANKARAN.KNo ratings yet

- Spe 76-101 Sep 2012Document6 pagesSpe 76-101 Sep 2012akashdruva892No ratings yet

- RT ProcedureDocument44 pagesRT Procedureefmartin21100% (1)

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Asme Sec V-2013 3Document1 pageAsme Sec V-2013 3dhasdj100% (1)

- E 543 - 04 - Rtu0mw - PDFDocument11 pagesE 543 - 04 - Rtu0mw - PDFUpul Eranda AbeyrathnaNo ratings yet

- MSS-SP-112 (1999)Document9 pagesMSS-SP-112 (1999)mubs997100% (1)

- Procedure For Radiographic Profile Thickness MeasurementDocument7 pagesProcedure For Radiographic Profile Thickness MeasurementSergey KichenkoNo ratings yet

- Astm e 428 Rev A 2005 PDFDocument7 pagesAstm e 428 Rev A 2005 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Astm Se-273Document5 pagesAstm Se-273Deyci Yamile Peña SantosNo ratings yet

- Z73B I2 R0 EnglishDocument1 pageZ73B I2 R0 English阿康No ratings yet

- (PDF) Study On Application of Native Millet Starch For Cotton Warp Yarn SizingDocument8 pages(PDF) Study On Application of Native Millet Starch For Cotton Warp Yarn SizingAnkush JainNo ratings yet

- 1x40Mtr Foot BridgeDocument5 pages1x40Mtr Foot Bridgehakim imtiyazNo ratings yet

- ASTM A960-A960M-16aDocument11 pagesASTM A960-A960M-16aGabriel Perez CruzNo ratings yet

- TycoDocument10 pagesTycoTahseenNo ratings yet

- ANCAMINE® DETA Curing Agent: DescriptionDocument2 pagesANCAMINE® DETA Curing Agent: DescriptionMOHAMEDNo ratings yet

- Solvent Cements For Poly (Vinyl Chloride) (PVC) Plastic Piping SystemsDocument5 pagesSolvent Cements For Poly (Vinyl Chloride) (PVC) Plastic Piping SystemsDavid SolisNo ratings yet

- Case Study Extending The Life of Austin Energy Holman Hillje 345kV Transmission Line (Paper)Document7 pagesCase Study Extending The Life of Austin Energy Holman Hillje 345kV Transmission Line (Paper)Scott WaltonNo ratings yet

- Inspection Certificate: Zibo Wel-Fit Metal Products Co., LTD 255 NE 87 ST, EL PORTAL, FL 33138, USDocument1 pageInspection Certificate: Zibo Wel-Fit Metal Products Co., LTD 255 NE 87 ST, EL PORTAL, FL 33138, USSINDY TATIANA CLAVIJO BAYONANo ratings yet

- Construction and Demolition Waste Management PlanDocument6 pagesConstruction and Demolition Waste Management PlanNguyên Trịnh CaoNo ratings yet

- Module 8 Q2 Gen Chem I v.2Document11 pagesModule 8 Q2 Gen Chem I v.2Colb MLGNo ratings yet

- Effective Adsorption of Dyes On An Activated Carbon Prepared From Carboxy Metyl CelluloseDocument35 pagesEffective Adsorption of Dyes On An Activated Carbon Prepared From Carboxy Metyl CelluloseVũ Văn NguyênNo ratings yet

- Flex TM GP70Document2 pagesFlex TM GP70Shubhrajeet TiwariNo ratings yet

- 3.10 Foundry Sand PreparationDocument4 pages3.10 Foundry Sand PreparationKALEMA BEMME2025100% (1)

- 2-2 Ultrasonic WeldingDocument43 pages2-2 Ultrasonic WeldingnavneetrNo ratings yet

- Item No. Description Color RAL. No. 1 Combustion TurbineDocument4 pagesItem No. Description Color RAL. No. 1 Combustion TurbineSubrata DasNo ratings yet

- CBSE 8, Science, CBSE-Materials-metals and Non-Metals, NCERT SolutionsDocument3 pagesCBSE 8, Science, CBSE-Materials-metals and Non-Metals, NCERT SolutionsSoumitraBagNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- Qualifying Examination For Applicants For Japanese Government (Mext) Scholarship 2020Document7 pagesQualifying Examination For Applicants For Japanese Government (Mext) Scholarship 2020Abdulqahar M.SabirNo ratings yet

- Bs en 253 PDFDocument28 pagesBs en 253 PDFEko PriambodoNo ratings yet

- 4-Sealing Solution For Steel IndustryDocument20 pages4-Sealing Solution For Steel IndustryAnurag JainNo ratings yet

- What Are Valence Electrons?: Oxidation StateDocument3 pagesWhat Are Valence Electrons?: Oxidation StateexoisnineNo ratings yet

- Lecture 1Document7 pagesLecture 1Dr. Aung Ko LattNo ratings yet

- Experimental Investigation of Coasting On Piston by Thermal Torch MethodDocument31 pagesExperimental Investigation of Coasting On Piston by Thermal Torch MethodĐįñêśh ĎkNo ratings yet

- GFRP BrochureDocument4 pagesGFRP BrochureAnonymous RgjuCNLNo ratings yet

- Acacia GumDocument2 pagesAcacia GummohsinNo ratings yet

- One-Piece Instrumentation Ball Valves: 40G Series and 40 SeriesDocument29 pagesOne-Piece Instrumentation Ball Valves: 40G Series and 40 SeriesAlfonso BlancoNo ratings yet

- Solid Phenolic Overhead Braced Toilet Partitions: Technical Data SheetDocument1 pageSolid Phenolic Overhead Braced Toilet Partitions: Technical Data SheetheshamNo ratings yet

- Plastick WeldDocument35 pagesPlastick WeldsuronocaturatmojoNo ratings yet