Professional Documents

Culture Documents

Loco Test

Uploaded by

Saptarshi Pal0 ratings0% found this document useful (0 votes)

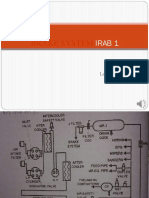

669 views1 pageThe document outlines test procedures for diesel electric locomotives equipped with IRAB-1 twin pipe pure air brake systems. It describes procedures for testing the compressor capacity and checking for brake pipe and auxiliary pipe leakage. The compressor capacity test ensures the main reservoir pressure is maintained above 8 kg/cm2 under emergency braking conditions. The brake pipe leakage test checks for no more than 0.7 kg/cm2 pressure drop over 5 minutes with the control valve in the "trail" position. The auxiliary pipe leakage test similarly checks for no more than 0.7 kg/cm2 pressure drop over 5 minutes with the cut-out cock closed before the feed valve.

Original Description:

Original Title

Loco test

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines test procedures for diesel electric locomotives equipped with IRAB-1 twin pipe pure air brake systems. It describes procedures for testing the compressor capacity and checking for brake pipe and auxiliary pipe leakage. The compressor capacity test ensures the main reservoir pressure is maintained above 8 kg/cm2 under emergency braking conditions. The brake pipe leakage test checks for no more than 0.7 kg/cm2 pressure drop over 5 minutes with the control valve in the "trail" position. The auxiliary pipe leakage test similarly checks for no more than 0.7 kg/cm2 pressure drop over 5 minutes with the cut-out cock closed before the feed valve.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

669 views1 pageLoco Test

Uploaded by

Saptarshi PalThe document outlines test procedures for diesel electric locomotives equipped with IRAB-1 twin pipe pure air brake systems. It describes procedures for testing the compressor capacity and checking for brake pipe and auxiliary pipe leakage. The compressor capacity test ensures the main reservoir pressure is maintained above 8 kg/cm2 under emergency braking conditions. The brake pipe leakage test checks for no more than 0.7 kg/cm2 pressure drop over 5 minutes with the control valve in the "trail" position. The auxiliary pipe leakage test similarly checks for no more than 0.7 kg/cm2 pressure drop over 5 minutes with the cut-out cock closed before the feed valve.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

TEST PROGRAMME FOR DIESEL ELECTRIC LOCOMOTIVES

EQUIPPED WITH IRAB-1 TWIN PIPE PURE AIR BRAKE SYSTEM

TEST PROGRAMME NO.MPTP-029/87 REV. 02

OCTOBER -2008

RESEARCH DESIGNS AND STANDARDS ORGANISATION

LUCKNOW - 226011.

Compressor capability Test

5.13 Capacity of A – 9 Automatic Brake Valve

Place the automatic driver’s brake valve handle in emergency position. Allow the main

reservoir pressure to build up to 10 ± 0.1 Kg / cm² Provide 7.5 mm dia leak hole plate at the

brake pipe hose at one end of locomotive keeping the other end hose pipe on dummy. Place

the automatic brake valve handle in release position. Open angle cock of the brake pipe

where leak hole plate has been provided. Note the pressure in the brake pipe gauge in the cab

which should be more than 4.4 Kg/cm² in ‘Release’ position of ‘Release-Run’ magnet valve

and between 2.5 to 3.5 Kg/cm² in ‘Run’ position of ‘Release-Run’ magnet valve. It should be

ensured that main reservoir pressure does not fall below 8 Kg/cm². If it falls below 8 Kg/cm²

the engine speed should be raised. Remove the 7.5 mm dia leak hole plate after applying

emergency brake by A-9 automatic brake valve. Now close the angle cock and move A-9

automatic brake valve handle to release position to charge the system.

Loco Leakage Test

3.7 Brake pipe leakage

Charge the system fully. Make 0.6 Kg / cm² reduction in brake pipe pressure by partially

applying automatic brake. Close cut out cock (52) and then move “MU-2B” control valve

(49) to “trail” position. Observe pressure on the brake pipe gauge (21). Pressure drop should

not exceed 0.7 Kg / cm² in 5 minutes. Move MU-2B control valve to “lead” position, A-9

valve handle to release position and then open the brake pipe cut out cock to charge the

system fully.

3.8 1 – 1 / 4” Auxiliary pipe (Feed pipe) Leakage

Charge the system fully and ensure that the duplex pressure gauge (23) indicates 6 Kg / cm²

pressure in Auxiliary air (feed) pipe. Close cut out cock (52) provided before feed valve.

Observe pressure on the auxiliary (feed) pipe gauge (23). Pressure drop should not exceed 0.7

Kg / cm² in 5 minutes. After completion of test, open cut out cock (52) provided before feed

valve.

You might also like

- RWP Worker Protection Manual PDFDocument262 pagesRWP Worker Protection Manual PDFPaul BardoffNo ratings yet

- US Navy Course NAVEDTRA 14256 - Tools and Their UsesDocument368 pagesUS Navy Course NAVEDTRA 14256 - Tools and Their UsesGeorges100% (8)

- Cathal Bowe - PHD - Dynamic Interaction of Trains and Railway Bridges (ANSYS Code Included)Document555 pagesCathal Bowe - PHD - Dynamic Interaction of Trains and Railway Bridges (ANSYS Code Included)cathalbowe100% (1)

- LHB AIR BRAKE SYSTEM COURSE BOOK Rev 01Document92 pagesLHB AIR BRAKE SYSTEM COURSE BOOK Rev 01abhishekNo ratings yet

- ICF Bogie 10.3.08Document101 pagesICF Bogie 10.3.08kr_abhijeet72356587100% (6)

- Codal Life-Assets 18.08.2016Document14 pagesCodal Life-Assets 18.08.2016Saptarshi PalNo ratings yet

- Handbook On Air Brake System For Freight StockDocument77 pagesHandbook On Air Brake System For Freight StockSourav PaulNo ratings yet

- Sketches and Diagrams: Water Cooling System of Diesel LocoDocument9 pagesSketches and Diagrams: Water Cooling System of Diesel LocoAmit Ojha100% (2)

- Centre Buffer CouplerDocument51 pagesCentre Buffer Couplersaurabh kumar100% (1)

- Air SuspentionDocument42 pagesAir Suspentionbhaskar098100% (1)

- Brake2 PDFDocument59 pagesBrake2 PDFPushpendra RawatNo ratings yet

- PM (Dr. S.N.Saxena)Document45 pagesPM (Dr. S.N.Saxena)Rk SkNo ratings yet

- LHB April 20Document83 pagesLHB April 20nwdsumanfacebookcomNo ratings yet

- Linke Hofmann Busch Coaches (LHB) : ADARSH (14113004) AJAY SINGHAL (14113007)Document15 pagesLinke Hofmann Busch Coaches (LHB) : ADARSH (14113004) AJAY SINGHAL (14113007)Deepak MahawarNo ratings yet

- Southern Railway, Tiruchchirappalli: RC Guards Batch No: 1819045 Paper PresentationDocument12 pagesSouthern Railway, Tiruchchirappalli: RC Guards Batch No: 1819045 Paper PresentationSathya VNo ratings yet

- Bogie Mounted Brake System, Indian Railways.Document18 pagesBogie Mounted Brake System, Indian Railways.Srinivas Avutapalli50% (2)

- BMBS-APM Working SystemDocument5 pagesBMBS-APM Working SystemSrinivas AvutapalliNo ratings yet

- Mandatory Question and Answers For Running StaffDocument57 pagesMandatory Question and Answers For Running StaffKhajahussain Syed100% (1)

- Dom Bobr Wagon PDFDocument42 pagesDom Bobr Wagon PDFShantanu DuttaNo ratings yet

- Troubleshooting Directory For 25 KV AC EMU-MEMUDocument80 pagesTroubleshooting Directory For 25 KV AC EMU-MEMUGopal Dixit100% (1)

- Brake SystemDocument33 pagesBrake SystemriznknkNo ratings yet

- Lead and Trail SwitchDocument19 pagesLead and Trail SwitchP. S. VENUGOPALNo ratings yet

- FIBA TestsDocument33 pagesFIBA TestsRishika RNo ratings yet

- Industrial training at Electrical Loco Shed, GhaziabadDocument34 pagesIndustrial training at Electrical Loco Shed, GhaziabadShubham GuptaNo ratings yet

- BCNHL DoorsDocument12 pagesBCNHL DoorsRakesh JainwalNo ratings yet

- Train Driving Techniques PDFDocument99 pagesTrain Driving Techniques PDFआनंद कुमार विश्वकर्माNo ratings yet

- Delhi Metro Working ReportDocument30 pagesDelhi Metro Working ReportShubham Tyagi0% (1)

- Air Suspension System IntroductionDocument4 pagesAir Suspension System IntroductionArijitNandiNo ratings yet

- Multiple Unit Loco OperationDocument5 pagesMultiple Unit Loco OperationmajjisatNo ratings yet

- LVPH BPC ValidityDocument4 pagesLVPH BPC ValidityJeetendra Singh ChauhanNo ratings yet

- LHB WorkDocument26 pagesLHB WorkŠäçhín KâmbléNo ratings yet

- TROM1.3.5-Loco & Crew LinksDocument45 pagesTROM1.3.5-Loco & Crew LinksSandeep Joseph100% (2)

- LHB Maintenance PraticesDocument28 pagesLHB Maintenance Praticesnaveenkumarvasili100% (1)

- Bogie Mounted Brake CylinderDocument8 pagesBogie Mounted Brake CylinderSharad Kumar Agarwal100% (1)

- Loco Model Booklet 2003Document27 pagesLoco Model Booklet 2003Sankati Srinivas100% (6)

- HHP Locomotive Compartments and Parts Location: DTTC/GTLDocument233 pagesHHP Locomotive Compartments and Parts Location: DTTC/GTLarjunsai100% (1)

- My EMU BASIC, Power & Aux CKTDocument102 pagesMy EMU BASIC, Power & Aux CKTGame RajNo ratings yet

- Air Brake System of LHBDocument86 pagesAir Brake System of LHBAbhishek patelNo ratings yet

- Disk BrakeDocument42 pagesDisk Brakekr_abhijeet7235658783% (6)

- Locomotive Fault Codes and DescriptionsDocument18 pagesLocomotive Fault Codes and DescriptionsMahesh Dewani50% (2)

- CBC PresentationDocument29 pagesCBC PresentationSoumava SamantaNo ratings yet

- IP COCK (Old WAG-5, WAG-7 & WAP-4 LocoDocument17 pagesIP COCK (Old WAG-5, WAG-7 & WAP-4 LocoJITENDRA KUMAR SHARMA0% (1)

- Mainenace Guidelines For LHB Cocahes.Document7 pagesMainenace Guidelines For LHB Cocahes.Parthaprotim Nath0% (1)

- C&W Obj Que Bank With AnsDocument23 pagesC&W Obj Que Bank With Ans1553No ratings yet

- LHB Coach GuideDocument21 pagesLHB Coach Guide4179309100% (1)

- LHB Coach Maintenance - 1Document61 pagesLHB Coach Maintenance - 1Dhanraj chavan100% (1)

- 1483772168068-C&W STC SC Hand BookDocument472 pages1483772168068-C&W STC SC Hand BookMani YuviNo ratings yet

- Revised Codal LifeDocument11 pagesRevised Codal Lifebvdas0% (1)

- E-70 GuideDocument103 pagesE-70 Guideanshul100% (2)

- RDSO Air Brake Spec for 3-Phase Electric LocosDocument26 pagesRDSO Air Brake Spec for 3-Phase Electric LocosaksNo ratings yet

- Southern Railway 3 Phase Loco Study GuideDocument96 pagesSouthern Railway 3 Phase Loco Study Guideprasoon tiwariNo ratings yet

- HHP Locomotive's BogiesDocument47 pagesHHP Locomotive's BogiesSAI KRISHNAN LNo ratings yet

- CBCDocument15 pagesCBCabheypriyaNo ratings yet

- MCBG MaintenanceDocument48 pagesMCBG MaintenancePunit DhullNo ratings yet

- Maintaining Railway CoachesDocument429 pagesMaintaining Railway CoachesSachin V D50% (2)

- 1434534006809-Air Brake Irab-1 PDFDocument17 pages1434534006809-Air Brake Irab-1 PDFSatyam singhNo ratings yet

- 006 Air Brake System On LHBDocument57 pages006 Air Brake System On LHBDivyanshu SrivastavaNo ratings yet

- Final-Draft Spec of AC-AC System For HHP LocosDocument101 pagesFinal-Draft Spec of AC-AC System For HHP LocosRahul KumarNo ratings yet

- Pocket Book On CCB Fitted On Diesel LocomotiveDocument49 pagesPocket Book On CCB Fitted On Diesel LocomotiveHanuma ReddyNo ratings yet

- On Vocational Training Loco WorkshopDocument21 pagesOn Vocational Training Loco WorkshopAnand ShekharNo ratings yet

- RTR PosterDocument1 pageRTR PosterGauravSinghNo ratings yet

- 1514285051142-Rehresher Course Book PDFDocument99 pages1514285051142-Rehresher Course Book PDFSaptarshi Pal100% (1)

- IRAB Brake System FeaturesDocument15 pagesIRAB Brake System FeaturesSk IrshadNo ratings yet

- Testing of Loco and Rake - 0Document21 pagesTesting of Loco and Rake - 0SSE.C&W TIGNo ratings yet

- Safety During WeldingDocument49 pagesSafety During WeldingSaptarshi PalNo ratings yet

- Notes On Welding & Metal CuttingDocument69 pagesNotes On Welding & Metal CuttingSaptarshi PalNo ratings yet

- Testing of MaterialsDocument102 pagesTesting of MaterialsSaptarshi PalNo ratings yet

- TIG Welding GuideDocument39 pagesTIG Welding GuideSaptarshi PalNo ratings yet

- Non Destructive TestDocument37 pagesNon Destructive TestSaptarshi PalNo ratings yet

- Incentive Scheme 21 JET 1Document39 pagesIncentive Scheme 21 JET 1Saptarshi PalNo ratings yet

- Introduction to Indian Railway ZonesDocument113 pagesIntroduction to Indian Railway ZonesKapilNo ratings yet

- Gmaw Rwti KGPDocument108 pagesGmaw Rwti KGPSaptarshi PalNo ratings yet

- Recruitment & TrainingDocument7 pagesRecruitment & TrainingSaptarshi PalNo ratings yet

- Chapter-2 Operation of 140T CraneDocument114 pagesChapter-2 Operation of 140T CraneSaptarshi PalNo ratings yet

- Handbook On Standardization of Infrastructural Facilities For Maintenance of ART ARME 140T CraneDocument12 pagesHandbook On Standardization of Infrastructural Facilities For Maintenance of ART ARME 140T CraneSaptarshi PalNo ratings yet

- Post acceptance contract managementDocument54 pagesPost acceptance contract managementSaptarshi PalNo ratings yet

- Attached & Subordinate Offices Under RBDocument7 pagesAttached & Subordinate Offices Under RBSaptarshi PalNo ratings yet

- RS (D&a) Rules, 1968Document47 pagesRS (D&a) Rules, 1968Saptarshi PalNo ratings yet

- Retirement BenefitsDocument9 pagesRetirement BenefitsSaptarshi PalNo ratings yet

- Works Programme and Working on RSP, M&P, & IRPSM PortalDocument40 pagesWorks Programme and Working on RSP, M&P, & IRPSM PortalSaptarshi Pal100% (1)

- Presentation On GCC For Works ServicesDocument42 pagesPresentation On GCC For Works ServicesSaptarshi PalNo ratings yet

- Rule NO Sub-Rule: Every Railway Servant Shall at All TimesDocument8 pagesRule NO Sub-Rule: Every Railway Servant Shall at All TimesSaptarshi PalNo ratings yet

- Model SOP 2018Document421 pagesModel SOP 2018B KRISHNA RAONo ratings yet

- Pass Rules, 1986Document8 pagesPass Rules, 1986Saptarshi PalNo ratings yet

- Coaching CBC: Nowadays Locos Are Also Fitted With Type"h" CouplersDocument5 pagesCoaching CBC: Nowadays Locos Are Also Fitted With Type"h" CouplersSaptarshi PalNo ratings yet

- Leave Rules SummaryDocument58 pagesLeave Rules SummarySaptarshi PalNo ratings yet

- Type of Wagon and Their Identification 12Document105 pagesType of Wagon and Their Identification 12Saptarshi Pal100% (1)

- Tender ContractsDocument91 pagesTender ContractsSaptarshi PalNo ratings yet

- Finance of Indian RailwaysDocument32 pagesFinance of Indian RailwaysDasari RamamohanaNo ratings yet

- Elect Aspect Coaches ICFDocument69 pagesElect Aspect Coaches ICFSaptarshi PalNo ratings yet

- ICF Bogie OverhaulingDocument10 pagesICF Bogie OverhaulingSaptarshi PalNo ratings yet

- M Kumar Ci (Em) /Irimee/JmpDocument51 pagesM Kumar Ci (Em) /Irimee/JmpSaptarshi PalNo ratings yet

- Corporate Restructuring of Indian RailwaysDocument10 pagesCorporate Restructuring of Indian RailwaysSnehil MishraNo ratings yet

- Play Trashbusters Online and on Mobile to Collect Litter and Release PrincessDocument2 pagesPlay Trashbusters Online and on Mobile to Collect Litter and Release PrincessSiddhartha BrahmaNo ratings yet

- Hotels in Shimla: Reservation - Clarkes@clarkesDocument6 pagesHotels in Shimla: Reservation - Clarkes@clarkesAnwesha SenNo ratings yet

- CMB Metropolitan Region Transport 2015-08-11 Final v7Document120 pagesCMB Metropolitan Region Transport 2015-08-11 Final v7hima_bindu_89No ratings yet

- Brochure CPR ENDocument8 pagesBrochure CPR ENMakiberNo ratings yet

- ARGE Guideline Part 2Document37 pagesARGE Guideline Part 2Oz WizardNo ratings yet

- Envoirmental Mughalsarai BhaupurDocument254 pagesEnvoirmental Mughalsarai Bhaupursunil_rathore20073921No ratings yet

- S11Control Table & Selection Circuits PDFDocument66 pagesS11Control Table & Selection Circuits PDFvoru89No ratings yet

- Traffic Jam in Dhaka City: Causes and ImpactsDocument10 pagesTraffic Jam in Dhaka City: Causes and ImpactsJahed KhanNo ratings yet

- Urban Transpo CombinedDocument62 pagesUrban Transpo CombinedJoyce Anne FulgarNo ratings yet

- Aws and Tpws Handbook: RS/522 Issue 3 December 2015Document28 pagesAws and Tpws Handbook: RS/522 Issue 3 December 2015Shiva PrasadNo ratings yet

- MRIN Autumn20 P001.indd PDFDocument56 pagesMRIN Autumn20 P001.indd PDFN SayNo ratings yet

- Indian Railways Signalling and Telecommunication ReportDocument56 pagesIndian Railways Signalling and Telecommunication ReportShubhamJain100% (1)

- Maglev Train: Abhishek Saini Ee 3Rd Year ID-180302Document10 pagesMaglev Train: Abhishek Saini Ee 3Rd Year ID-180302Abhishek SainiNo ratings yet

- History of TransportationDocument3 pagesHistory of TransportationNishat KhanNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- More Information, A Discussion Forum & To Read Up On The Small Print..Document2 pagesMore Information, A Discussion Forum & To Read Up On The Small Print..zarko radojevicNo ratings yet

- Different modes of transportation discussedDocument2 pagesDifferent modes of transportation discussedJessie Jade DurojaNo ratings yet

- P.M. - Bolo'bolo PDFDocument54 pagesP.M. - Bolo'bolo PDFlucasdostNo ratings yet

- WCTR2010 - Sessions - at - A - GlanceDocument63 pagesWCTR2010 - Sessions - at - A - GlanceqwertycrewNo ratings yet

- Network CatalogueDocument247 pagesNetwork CatalogueconcretetechgroupNo ratings yet

- Curba de Etalonare Spectrul Mercurului He X (Div) X (Div) L (NM) L (NM)Document16 pagesCurba de Etalonare Spectrul Mercurului He X (Div) X (Div) L (NM) L (NM)georgianaeleve1No ratings yet

- Guideline For Railbound FDocument26 pagesGuideline For Railbound FŚwistakeroNo ratings yet

- Koloosi Katalog - ENG 1.2 7Document6 pagesKoloosi Katalog - ENG 1.2 7fernanguedes2071No ratings yet

- Egis Rail Identité ENGDocument2 pagesEgis Rail Identité ENGChris MarkerNo ratings yet

- Indian Railway DivisionDocument3 pagesIndian Railway Divisionsujit kumar poddarNo ratings yet

- Tambaram To Chennai Beach MRTS Train Timings On Weekdays - Chennai Local Suburban Train Time Tabel ScheduleDocument6 pagesTambaram To Chennai Beach MRTS Train Timings On Weekdays - Chennai Local Suburban Train Time Tabel ScheduleRaul ThomasNo ratings yet

- Reis - Roger White DC PresentationDocument67 pagesReis - Roger White DC Presentationdcf67my75% (4)