Professional Documents

Culture Documents

BX Elevator Lock Tab Washer TO17311

Uploaded by

mohamed hamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BX Elevator Lock Tab Washer TO17311

Uploaded by

mohamed hamedCopyright:

Available Formats

Document No: HQS-OPS-TIB-ELEV-019

Author: HQS-Maintenance

TECHNICAL SERVICES Reviewed by: M. Darwiche

BULLETIN Approved by: V. Berthou

Bulletin Issue Date: 23-Aug-17

Bulletin Revision #: 00

The attached document has been reviewed to determine its validity and applicability within

Transocean.

RMS File Name: TO17311

NOV Elevator - Dropped Object Due To Incorrect Installation Of Lock

Subject:

Washer

Equipment: Elevator

Manufacturer: National Oilwell Varco (NOV)

Vendor Doc. No.: 1000012145-SA Rev02

Model(s): BX-3; BX4-50; BX4-75; BX-5; BX-7; BXS

Tag No.: PH-ELEV-XXX

ARC DDS DPS DWC ENR KG2 TBR

CAJ DEN DPT DWD EXS LDR TSB

CRL DGD DSL DWF HGR MAR

Applicable Rigs:

DAS DID DSP DWM JAB PBL

DCL DIN DTH DWN JRY PBS

DCQ DPN DVS DWP KG1 POL

Operations/Safety Critical? YES

Actions:

This Bulletin was reviewed by Technical Services and shall be implemented. A job has been

created in the CMMS, the job must remain open until all actions have been completed. Any

deviations to this Bulletin must be managed via the exemption process.

Job Target Completion Date 15-Oct-2017

Clarification can be obtained from the author.

Comments:

NOV has issued the attached safety alert as a follow up to bulletin BX-169-PIB-001 which

was previously issued in RMS as TO15387 Rev00. The required actions associated with

TO15387 were to visually inspect the bolt and lock washer on BX5 elevator. The PM

plans were also updated to include this inspection. The attached safety alert is now

recommending modifications to the elevators.

REV: 00 23-Aug-17 Document No. HQS-OPS-TIB-ELEV-019 Page 1 of 2

Document No: HQS-OPS-TIB-ELEV-019

Author: HQS-Maintenance

TECHNICAL SERVICES Reviewed by: M. Darwiche

BULLETIN Approved by: V. Berthou

Bulletin Issue Date: 23-Aug-17

Bulletin Revision #: 00

Required Actions:

NOTE: Transocean Technical Services agrees with NOV that the current washer

arrangement needs to be improved. However, the use of Nord-Lock washers combined with

the use of Loctite thread lock is Transocean’s preference rather than tab washers as

proposed by NOV

Remove existing tab washer and replace it with a Nord-Lock washer. Apply Loctite to the

threads of the bolt prior to reinstating it in place. Tighten bolt up to the recommended

torque as per the elevator’s operations manual.

Add lock wire as per step (3) in the NOV safety alert 1000012145-SA Rev02.

REV: 00 23-Aug-17 Document No. HQS-OPS-TIB-ELEV-019 Page 2 of 2

Product Safety Alert

Date: 23 July 2017

Bulletin Number: 1000012145-SA Revision: 02

Handling Tools

Subject: Dropped object, due to incorrect installation of lock washer.

Product Model: BX elevators

Effectivity: BX3, BX4-35, BX4-50, BX4-75, BX5, BX7, BX9, BX-S

Affected Assemblies: 203300*/ 10023967-001 BX3, 50005300*/ 10457625-001 BX4-35,

50000640*/ 10091627-001 BX4-50, 50000650*/ 10034284-001 BX4-75,

50004000*/ 10705608-001 BX5, 50000580*/ 10112883-001 BX7, 10776954

BX9, 50000202*/ 10140067-001 BX-S

Objective

Advise customers of dropped bolt and lock washer from a BX5 elevator and reinforcement of bulletin

“BX-169-PIB-001” covering a similar issue.

Issue

National Oilwell Varco (NOV) received a report describing a dropped object from the BX5 elevator.

While laying down a joint of drill pipe, a bolt and lock washer (weighing approx. 1lbs) fell down in the

red zone. There were no injuries reported as a result of the incident. The dropped bolt and lock washer

are located at the bottom plate of the BX elevator. (see pictures below)

1000012145-SA /Rev 02 Page 1 of 3

Product Safety Alert

Solution

Investigation revealed that the bolt was able to drop out due to incorrect installation of the lock washer.

Although NOV recommends customers to visually inspect the equipment for loose parts on a daily base

and pay special attention to the correct installation of the lock washers, it is difficult to see the condition

and correct installation of this particular lock washer, due to its location.

To avoid similar incidents, NOV has improved the design by:

1) Increasing the opening (1) , so that condition of the tab washer and correct installation can be

better visually checked.

2) Adding second hole for lock washer tab (2). This will give mechanic more options for installation

of the lock washer

3) Adding hole to lock wire bolt (3), this will create an additional retention, when lock washer tab

fails or when installed incorrectly.

(2) (3)

(1)

The above enhancements have been implemented for newbuilds. (Manufactured after June 2017). Units

in the field can be upgraded locally or at a National Oilwell Varco (NOV) Service Center. NOV will provide

upgrade drawing.

Ordering and Contact Information

Please contact your local National Oilwell Varco (NOV) Service Center, with reference to PB

1000012145-SA, for further assistance.

Economic Impact

This upgrade is at Customer cost.

1000012145-SA / Rev 02 Page 2 of 3

Product Safety Alert

Customers should also refer to previous NOV Product Bulletins for additional information regarding safe

operation, maintenance, and inspection criteria by signing in to your MYNOV account at

https://portal.mynov.com and then searching with the Product Bulletin Search available below the

heading ‘Application Groups’. For information on registering, please visit

https://www.nov.com/Search/register.aspx.

Failure to follow the recommendations and/or guidance in NOV Manuals and Product Bulletins may

result in death, bodily injury or property damage.

Please contact your local National Oilwell Varco (NOV) Service Center if you have any questions

regarding this bulletin.

Revision History

Revision Date Change Description

01 03-July-2017 First Release

02 23-July-2017 Changed Subject, Product Model, Effectivity, Affected assemblies and

Objective

1000012145-SA / Rev 02 Page 3 of 3

You might also like

- Harsh-Environment Semi-Submersible: General Description Storage CapacitiesDocument2 pagesHarsh-Environment Semi-Submersible: General Description Storage CapacitiesMuh. Saeful MHNo ratings yet

- West TucanaDocument3 pagesWest TucanaSarfaraz PatelNo ratings yet

- Ohsar PDFDocument40 pagesOhsar PDFMohammed Ali YoussefNo ratings yet

- RP 4.0 Edition 5 - 2019 FINALDocument14 pagesRP 4.0 Edition 5 - 2019 FINALKevin BryarNo ratings yet

- SAPCO EMD ProceduresDocument1 pageSAPCO EMD ProceduresMayur GuptaNo ratings yet

- SLP STD 28 CHIKSANDocument20 pagesSLP STD 28 CHIKSANmashanghNo ratings yet

- Derrick Escape Descender - Instruction ManualDocument12 pagesDerrick Escape Descender - Instruction ManualSteve WatsonNo ratings yet

- TDS 93 1 Pib PDFDocument6 pagesTDS 93 1 Pib PDFMohamed HashemNo ratings yet

- Pipe Handling EquipmentDocument4 pagesPipe Handling EquipmentJohn RongNo ratings yet

- CRT 350 Interlock Panel User ManualDocument74 pagesCRT 350 Interlock Panel User ManualAliHabesNo ratings yet

- Drill Pipe Handler Operating ManualDocument48 pagesDrill Pipe Handler Operating ManualJose Luis Rodriguez FernandezNo ratings yet

- HH 300 Rig InformationDocument2 pagesHH 300 Rig Informationsaysamajo100% (1)

- OTC-28011-MS - WSOG and Emergency DisconnectDocument19 pagesOTC-28011-MS - WSOG and Emergency Disconnectwpechie_66286825No ratings yet

- Cyber BaseDocument39 pagesCyber BaseayhamNo ratings yet

- 1 PDFDocument39 pages1 PDFAmirHossein SaberBaghabnNo ratings yet

- Drilling Automation Based On Rigs Equipped With THDocument11 pagesDrilling Automation Based On Rigs Equipped With THAbdallah AbdelrehimNo ratings yet

- Torkdrive Compact Internal Ts DNVDocument332 pagesTorkdrive Compact Internal Ts DNVcristian sanchezNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Rig Stacking StrategiesDocument14 pagesRig Stacking StrategiesJeril PhilipNo ratings yet

- Dokumen - Tips 7 FD 1600 Triplex Mud Pump User ManualDocument386 pagesDokumen - Tips 7 FD 1600 Triplex Mud Pump User ManualDiaa Mokhtar100% (1)

- WT3553 MsdsDocument17 pagesWT3553 Msdspitrer123100% (1)

- Ops HB 02 Iss02 Rev01 Sbop Sections 1 9Document58 pagesOps HB 02 Iss02 Rev01 Sbop Sections 1 9vikrant911No ratings yet

- Rules and Classification For Well Control EquipmentDocument22 pagesRules and Classification For Well Control EquipmentShaikh Sabir HussainNo ratings yet

- SFI Coding And Classification System A Complete Guide - 2021 EditionFrom EverandSFI Coding And Classification System A Complete Guide - 2021 EditionNo ratings yet

- Dual Activity Drill FloorDocument8 pagesDual Activity Drill FloorWILLIANS HERNANDEZNo ratings yet

- Safety Spinning Wrench SSW 40Document88 pagesSafety Spinning Wrench SSW 40Beitsaeed SinaNo ratings yet

- Bridon Service Procedure 1Document5 pagesBridon Service Procedure 1Ahmed ButtNo ratings yet

- McCoyDrillingCompletionsCatalog LowResDocument65 pagesMcCoyDrillingCompletionsCatalog LowResAlvin Garcia PalancaNo ratings yet

- SoftSpeed UMDocument94 pagesSoftSpeed UMIon100% (1)

- Drilling Rigs Built in The U.SDocument9 pagesDrilling Rigs Built in The U.SalmirNo ratings yet

- CDS - Operations Guide - 883003Document38 pagesCDS - Operations Guide - 883003mustafaNo ratings yet

- 250T EMI 400HP 50Hz - Install PDFDocument106 pages250T EMI 400HP 50Hz - Install PDFdaniel nunezNo ratings yet

- V5315 Z Ma 007 - 80346421Document192 pagesV5315 Z Ma 007 - 80346421peeps1980100% (1)

- Outline-Well Control Equipment Inspection & MaintenanceDocument2 pagesOutline-Well Control Equipment Inspection & MaintenanceSachin SahooNo ratings yet

- Operation and Maintenance Manual: Triplex Mud Pump - Skid MountedDocument118 pagesOperation and Maintenance Manual: Triplex Mud Pump - Skid MountedrolandNo ratings yet

- Advanced Subsea Engineer Program (ASSEP) : Lloyd's Register Energy - Drilling Training AcademyDocument2 pagesAdvanced Subsea Engineer Program (ASSEP) : Lloyd's Register Energy - Drilling Training AcademyShraddhanand More100% (1)

- Rig Handling and Installation Procedure DALIADocument269 pagesRig Handling and Installation Procedure DALIACarlos Gloogh100% (1)

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Document40 pagesDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUNo ratings yet

- Epl 1711Document161 pagesEpl 1711Alessandra Floresfar0% (1)

- Section 2Document134 pagesSection 2Fernanda Medeiros CarvalhoNo ratings yet

- Manual Bba Triplex BD-85 BopDocument47 pagesManual Bba Triplex BD-85 BopwiloNo ratings yet

- Offshore Jack UpsDocument5 pagesOffshore Jack Upsfle92100% (1)

- Ocean Rig OlympiaDocument6 pagesOcean Rig OlympiaFateNo ratings yet

- IADC/SPE 87102 Specialized Rig-Crew Training Produces Results For New Technology Drilling RigsDocument12 pagesIADC/SPE 87102 Specialized Rig-Crew Training Produces Results For New Technology Drilling RigsmsmsoftNo ratings yet

- PTW #: Location of work:RIG FLOOR Task Description: INSTALL T Piece Supervisor: TBRA #:D-111Document2 pagesPTW #: Location of work:RIG FLOOR Task Description: INSTALL T Piece Supervisor: TBRA #:D-111DrillerNo ratings yet

- D392004720 MKT 001 PDFDocument28 pagesD392004720 MKT 001 PDFsorangel_123No ratings yet

- Abb Jacking ControlDocument4 pagesAbb Jacking ControlAleksey Bondar100% (1)

- Electric Top Drive ETD 500Document76 pagesElectric Top Drive ETD 500SMEETNo ratings yet

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Document16 pagesKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashadNo ratings yet

- Drillship Intro Course Sept 2010Document216 pagesDrillship Intro Course Sept 2010Ernandes BeltrameNo ratings yet

- Next Generation Drilling and Subsea Systems PDFDocument8 pagesNext Generation Drilling and Subsea Systems PDFliu zhao liu zhaoNo ratings yet

- Driller Controller User ManualDocument12 pagesDriller Controller User ManualYahya BA100% (1)

- 00013976-Through Bore Subsea XTDocument15 pages00013976-Through Bore Subsea XTMartinus LuckyantoNo ratings yet

- Drawwork Lewco LDW1000KDocument4 pagesDrawwork Lewco LDW1000KCarlosSantamaria0% (1)

- Back PoshtDocument2 pagesBack Poshtmhn yNo ratings yet

- ABS Drops Guide E-Sept17Document85 pagesABS Drops Guide E-Sept17Max BeeksNo ratings yet

- 800 Dreco Diesel Electric Land Drilling RigDocument3 pages800 Dreco Diesel Electric Land Drilling RigGufron Amrony100% (2)

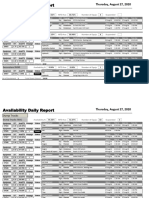

- Final Daily Report Availbility (30-8-2020)Document5 pagesFinal Daily Report Availbility (30-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (27-8-2020)Document5 pagesFinal Daily Report Availbility (27-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (26-8-2020)Document5 pagesFinal Daily Report Availbility (26-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (28-8-2020)Document5 pagesFinal Daily Report Availbility (28-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (29-8-2020)Document5 pagesFinal Daily Report Availbility (29-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (25-8-2020)Document5 pagesFinal Daily Report Availbility (25-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (24-8-2020)Document4 pagesFinal Daily Report Availbility (24-8-2020)mohamed hamedNo ratings yet

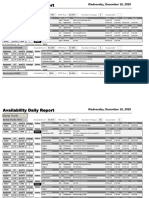

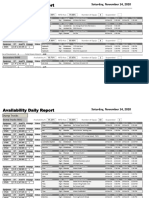

- Final Daily Report Availbility (17-11-2020)Document5 pagesFinal Daily Report Availbility (17-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility With Details 00Document5 pagesFinal Daily Report Availbility With Details 00mohamed hamedNo ratings yet

- Final Daily Report Availbility (28-8-2020)Document5 pagesFinal Daily Report Availbility (28-8-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (17-12-2020)Document5 pagesFinal Daily Report Availbility (17-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (18-12-2020)Document5 pagesFinal Daily Report Availbility (18-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (21-12-2020)Document5 pagesFinal Daily Report Availbility (21-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (16-12-2020)Document5 pagesFinal Daily Report Availbility (16-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (16-11-2020)Document5 pagesFinal Daily Report Availbility (16-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (13-12-2020)Document5 pagesFinal Daily Report Availbility (13-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (15-11-2020)Document5 pagesFinal Daily Report Availbility (15-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (11-12-2020)Document5 pagesFinal Daily Report Availbility (11-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (14-11-2020)Document5 pagesFinal Daily Report Availbility (14-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (15-12-2020)Document5 pagesFinal Daily Report Availbility (15-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (14-12-2020)Document5 pagesFinal Daily Report Availbility (14-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (13-11-2020)Document5 pagesFinal Daily Report Availbility (13-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (11-11-2020)Document5 pagesFinal Daily Report Availbility (11-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (12-10-2020)Document5 pagesFinal Daily Report Availbility (12-10-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (12-11-2020)Document5 pagesFinal Daily Report Availbility (12-11-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (12!12!2020)Document4 pagesFinal Daily Report Availbility (12!12!2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (9-12-2020)Document6 pagesFinal Daily Report Availbility (9-12-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (9-10-2020)Document5 pagesFinal Daily Report Availbility (9-10-2020)mohamed hamedNo ratings yet

- Final Daily Report Availbility (10-10-2020) ..Document5 pagesFinal Daily Report Availbility (10-10-2020) ..mohamed hamedNo ratings yet

- Final Daily Report Availbility (8-12-2020)Document6 pagesFinal Daily Report Availbility (8-12-2020)mohamed hamedNo ratings yet

- Liquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Document12 pagesLiquid Ring Vacuum Pump: LPH 55312, LPH 55316, LPH 55320Edu CordonNo ratings yet

- ACI 308R-16 - Guide o External Curing - PreviewDocument6 pagesACI 308R-16 - Guide o External Curing - PreviewHaniAmin0% (4)

- Q - Bae146 Inventory - SSS-Jan 2010Document6 pagesQ - Bae146 Inventory - SSS-Jan 2010sssavNo ratings yet

- Investor Presentation (Company Update)Document42 pagesInvestor Presentation (Company Update)Shyam SunderNo ratings yet

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleNo ratings yet

- Freno Motor ISMDocument6 pagesFreno Motor ISMFabiiam Kiimtero100% (2)

- VCS Commands Ease Coverage Efforts - Speed Simulation PDFDocument6 pagesVCS Commands Ease Coverage Efforts - Speed Simulation PDFAnonymous k2nUzQgO6HNo ratings yet

- Safety PrecautionsDocument14 pagesSafety Precautionspavanramana100% (2)

- Move Core Application: Fully Integrated 2D and 3D Model Building and AnalysisDocument2 pagesMove Core Application: Fully Integrated 2D and 3D Model Building and AnalysisAlfredo Iguaran AmayaNo ratings yet

- Embraco Standard Aftermarket Portfolio PDFDocument2 pagesEmbraco Standard Aftermarket Portfolio PDFJOR4CHNo ratings yet

- How To Make AspirinDocument5 pagesHow To Make Aspirincb67No ratings yet

- MC 10115610 9999Document5 pagesMC 10115610 9999Eddie Kelvin Isidro LauraNo ratings yet

- Internal Arc IEC 61641 - EN - V07Document24 pagesInternal Arc IEC 61641 - EN - V07arkupi100% (1)

- Zahvalnica Bla BlaDocument2 pagesZahvalnica Bla BlaBiljanaJanjušević100% (1)

- 3D Printing Research Paper - Various Aspects PDFDocument6 pages3D Printing Research Paper - Various Aspects PDFhipovemicNo ratings yet

- Wabco GuideDocument16 pagesWabco GuideMohd FairusNo ratings yet

- Security For VPNs With IPsec Configuration Guide - 15.2MTDocument166 pagesSecurity For VPNs With IPsec Configuration Guide - 15.2MTAnonymous fIXhrYSmNo ratings yet

- Delphi Heavy Duty Emissions Brochure 2011 2012Document100 pagesDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamNo ratings yet

- NexstarcommprotDocument8 pagesNexstarcommprotskirmixNo ratings yet

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006No ratings yet

- (Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Document8 pages(Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Fazsroul100% (9)

- NAPCA TrainingDocument149 pagesNAPCA TrainingalejandroNo ratings yet

- Harsh SukhramaniDocument6 pagesHarsh SukhramaniHarsh SukhramaniNo ratings yet

- Users Manual For Oslo, Bremen and Turboaire.: Installation, Operation and Maintenance InstructionsDocument40 pagesUsers Manual For Oslo, Bremen and Turboaire.: Installation, Operation and Maintenance Instructionsbuttler25No ratings yet

- Structured Text CheatsheetDocument1 pageStructured Text CheatsheetMauricio Rodriguez0% (1)

- Sin EncoderDocument6 pagesSin Encoderboynew87No ratings yet

- Settling Tank DecantDocument23 pagesSettling Tank Decantjvan migvelNo ratings yet

- SEPG and Consulting ProcessDocument20 pagesSEPG and Consulting ProcesszafzNo ratings yet

- UNNPX206R3Document4 pagesUNNPX206R3David OlayaNo ratings yet