Professional Documents

Culture Documents

Question

Uploaded by

Subha RajaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Question

Uploaded by

Subha RajaCopyright:

Available Formats

Operations Strategy

Dabur caters to large Indian market through its 9 plants spread across North and West India (exhibit 1). To

achieve operational efficiency it has also out-sourced its Personal care products to 8 contract manufacturers.

Dabur has been giving considerable emphasis on improving manufacturing and operational efficiencies by

enhancing productivity of capital and existing assets through its Total Production Maintenance program. It

emphasis on improving plant efficiencies in the existing manufacturing facilities and following more stringent

quality control and supervision norms at outsourcing locations through its Total Quality Control program. It

aims at reducing raw material wastage, time saving and makes the procurement process more efficient.

Dabur strongly believes that financial performance and sustainability go hand in hand and can never be

separated1. To achieve sustainability Dabur is committed to reduce its carbon footprints, maximize production

paralleled by minimizing consumption of natural resources. It leads various initiatives towards achieving the goal:

y

New boiler technology to generate attractive savings in energy costs, and reduce

discharge of solid waste to the environment

y

Substitute furnace oil with pet cake a by-product of crude refining-as fuel, a move that

has led to considerable every savings

y

Using rice husk as fuel to save energy costs

y

Convert herbal waste onto bio-briquettes that can be used as fuel in boilers

y

Rain water harvesting and water recycling

Operations at Dabur continuously strives to improve its performance and its standing in the society by focusing all

efforts towards making the most meaningful difference in both environment and social sustainability2.

Suppliers and purchase process

Dabur has a huge network of suppliers and vendors to cater to the raw material requirements

for its 300 diverse products in FMCG, Healthcare and Ayurveda segments. TheCentral Planning

and Procurement Division (CPPD) is responsible for purchase operations at Dabur, acting in

coordination with the Production and Marketing Divisions3.

1 Annual Report 2009-2010, Dabur

2 Sustainability Report 2009-2010, Dabur

3 h tt p: / / www.d abu r. co m/ S u p pl i ers

IT Initiatives at Dabur

At Dabur, Knowledge and technology are the key resources which have helped the Company achieve higher

levels of operational excellence and efficiency. To would also help in integrating its vast distribution system spread

across the world. Some of its major IT initiatives to achieve operational efficiency include4:

y

Migration from Baan and Mfg ERP Systems to centralized SAP ERP system from 1st Apr il

2006 for all business units

y

Implementation of a country wide new WAN Infrastructure for running centralized ERP

system

y

Extension ofReach System to distributors for capturing Secondary Sales Data.

y

Roll out of IT services to new plants and CFAs.

Research and Development

Research at Dabur focuses on its core values5 of consumer focus and innovation. There are over

ten diverse areas in which DaburResearch Foundation carries out research besides conducting tests and trials.

They are AyurvedicResearch, Pharmaceutical research, Phyto-pharmaceuticals, Biotechnology, Agronomy,

Personal care products, analytical, synthetic chemistry, oncology research, peptide research, food research and

clinical research.

4 h tt p: / / www.d abu r. co m/ A b ou t %2 0 Da bu r -IT% 2 0 In i t i at i ves

5 h tt p: / / www.d abu r. co m/ A b ou t %2 0 Da bu r -Cor e%2 0 V al u es

You might also like

- Dabur Operations StrategyDocument3 pagesDabur Operations Strategydevkaran_nehraNo ratings yet

- Project of Global BusinessDocument6 pagesProject of Global BusinessArpit BohreNo ratings yet

- Dabur StrategiesDocument4 pagesDabur StrategiesNeha GillNo ratings yet

- CiplaDocument9 pagesCiplaVarsha GuptaNo ratings yet

- WiproDocument6 pagesWiprovatsala mishraNo ratings yet

- SUPPLY CHAIN MANAGEMENT OF COLGATE PALMOLIVEDocument12 pagesSUPPLY CHAIN MANAGEMENT OF COLGATE PALMOLIVESai Vasudevan88% (8)

- Sun Pharma Ind Annuals Report (Final) 707Document151 pagesSun Pharma Ind Annuals Report (Final) 707ÄbhíñävJäíñNo ratings yet

- KDPC All PostersDocument30 pagesKDPC All PostersPratikshaNo ratings yet

- Introduction of The StudyDocument72 pagesIntroduction of The StudyAbdul MalikNo ratings yet

- Company Analysis-Dabur LTDDocument25 pagesCompany Analysis-Dabur LTDSusheel MenonNo ratings yet

- HARNOOR 2230 ESG Framework of Coromandel International LimitedDocument9 pagesHARNOOR 2230 ESG Framework of Coromandel International LimitedharnoorhorajbNo ratings yet

- DR ReddyDocument8 pagesDR ReddyBiswajit SarmaNo ratings yet

- C CCCCCCCCCCCCCCCC C: O CC C C ODocument9 pagesC CCCCCCCCCCCCCCCC C: O CC C C ONancy BhandariNo ratings yet

- CP MotivatorDocument27 pagesCP MotivatorKhushi PatelNo ratings yet

- Opportunity: A. Refining & MarketingDocument19 pagesOpportunity: A. Refining & MarketingsagarNo ratings yet

- A Study On Inventory Management With Reff To Kallishwari CompanyDocument52 pagesA Study On Inventory Management With Reff To Kallishwari CompanyMuthu MarshNo ratings yet

- DETAILS PROJECT REPORT JanmanjayaDocument38 pagesDETAILS PROJECT REPORT JanmanjayaJan Man JayaNo ratings yet

- Focus Issue7Document20 pagesFocus Issue7seajoemathewNo ratings yet

- Product of DaburDocument3 pagesProduct of DaburBhanu PrakashNo ratings yet

- 2014 Industry ProfilesDocument9 pages2014 Industry ProfilesMilling and Grain magazineNo ratings yet

- ICICI Prudential's ESG Report Highlights Sustainability EffortsDocument26 pagesICICI Prudential's ESG Report Highlights Sustainability EffortsSiddharth P100% (3)

- Write UpDocument12 pagesWrite UpTahseen ArshadNo ratings yet

- Corporate Report 2020Document40 pagesCorporate Report 2020Arpit CooldudeNo ratings yet

- Shoppers StopDocument23 pagesShoppers Stoptarannum0887No ratings yet

- Nestle Case Study AccountingDocument10 pagesNestle Case Study AccountingAbeyjjNo ratings yet

- P&GDocument11 pagesP&GSabir RahimNo ratings yet

- Guidebook On Waste Minimisation For IndustriesDocument27 pagesGuidebook On Waste Minimisation For Industriesnarasimhamurthy414No ratings yet

- Sustainability at Jubilant Life Sciences LimitedDocument13 pagesSustainability at Jubilant Life Sciences Limitedsourav84No ratings yet

- Assessment 3 OmDocument5 pagesAssessment 3 OmHarpreet KaurNo ratings yet

- Driving Global Adoption of Procurement Technology, A Cargill ApproachDocument27 pagesDriving Global Adoption of Procurement Technology, A Cargill ApproachZycusInc100% (2)

- Inventory-Management - Theory & DIDocument102 pagesInventory-Management - Theory & DIAnil Kumar SinghNo ratings yet

- Mother Dairy DelhiDocument10 pagesMother Dairy Delhibugoff700No ratings yet

- Project Blue Nile Industry and Financial OverviewDocument9 pagesProject Blue Nile Industry and Financial OverviewKristin BryanNo ratings yet

- Sime Darby Plantation Sustainability Report 2014Document48 pagesSime Darby Plantation Sustainability Report 2014harizhamidon100% (1)

- OPM ProjectDocument65 pagesOPM ProjectMohammad FaheemNo ratings yet

- OEE Guidelines 2017Document21 pagesOEE Guidelines 2017Sabahudin JašarevićNo ratings yet

- 10 Dec 2015 171411190GDI51SI2ProjectreportforpollutionDocument28 pages10 Dec 2015 171411190GDI51SI2ProjectreportforpollutionNajeeb HasanNo ratings yet

- MCC5412 - Lecture 2sDocument38 pagesMCC5412 - Lecture 2sDickson ChanNo ratings yet

- Inte 2 E20152 E0802Document19 pagesInte 2 E20152 E0802Matías OchoaNo ratings yet

- UnileverDocument49 pagesUnileverSana JavedNo ratings yet

- Dr. Reddy'sDocument28 pagesDr. Reddy'sdener81930No ratings yet

- SLM1Document3 pagesSLM1SHYAM LAL MITTALNo ratings yet

- Assessment of Cleaner Production in Agro Processing Industries: A Data Envelopment Analysis ApproachDocument7 pagesAssessment of Cleaner Production in Agro Processing Industries: A Data Envelopment Analysis ApproachInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- NestleDocument93 pagesNestleAparna KhannaNo ratings yet

- ERRC Grid and Blue Ocean StrategyDocument2 pagesERRC Grid and Blue Ocean StrategyfereNo ratings yet

- Healthcare Pharmaceuticals LTDDocument26 pagesHealthcare Pharmaceuticals LTDNafiz NiazNo ratings yet

- SIP-1Document29 pagesSIP-1Arijit SahaNo ratings yet

- Sample Business ProposalDocument10 pagesSample Business Proposalvladimir_kolessov100% (8)

- Final Report SM HavellsDocument44 pagesFinal Report SM HavellsPuneet MurarkaNo ratings yet

- Eet Case StudyDocument6 pagesEet Case StudySpyBro GamingYTNo ratings yet

- Sustainability Report of DR ReddysDocument23 pagesSustainability Report of DR ReddysOmkar JadhavNo ratings yet

- Summer training report appraisalDocument46 pagesSummer training report appraisalGauravNo ratings yet

- Samridhi Sparsh SIIBDocument4 pagesSamridhi Sparsh SIIBBandish PatelNo ratings yet

- Case Study EPLADocument2 pagesCase Study EPLASajid Ali MaariNo ratings yet

- Business PlanDocument11 pagesBusiness Planrrahul209467% (3)

- Dabur India LimitedDocument31 pagesDabur India LimitedNikita GheradeNo ratings yet

- OMICRON Magazine Volume2 2011 Issue1 ENUDocument41 pagesOMICRON Magazine Volume2 2011 Issue1 ENUkessir taouilNo ratings yet

- Alternative 1Document8 pagesAlternative 1JeanNo ratings yet

- DCR 2004 and 2026Document103 pagesDCR 2004 and 2026karthikaNo ratings yet

- República Federativa Do Brasil Agência Nacional de Aviação Civil - AnacDocument10 pagesRepública Federativa Do Brasil Agência Nacional de Aviação Civil - AnacRicardo zafraNo ratings yet

- Electrical Systems Transfer Function ModelsDocument58 pagesElectrical Systems Transfer Function ModelsNoor Ahmed86% (7)

- Chem Principles 7e ISM Focus 04 Even FINALDocument62 pagesChem Principles 7e ISM Focus 04 Even FINALSelma MeloNo ratings yet

- Ch-2 Demand Side Management ReviewDocument128 pagesCh-2 Demand Side Management Reviewmariam williamNo ratings yet

- 04 - Thiết Bị Đưa Vải VàoDocument2 pages04 - Thiết Bị Đưa Vải VàoPhan Quốc ThịnhNo ratings yet

- Pm6501 Mass Transfer I SyllabusDocument2 pagesPm6501 Mass Transfer I SyllabusSampathkumar MtechNo ratings yet

- Tpo50 3Document2 pagesTpo50 3Whiz YTNo ratings yet

- Nipcib 000033Document209 pagesNipcib 000033AlfoFSNo ratings yet

- Narrative Report on Disaster Risk Reduction Training ActivitiesDocument6 pagesNarrative Report on Disaster Risk Reduction Training ActivitiesPersia BangeroNo ratings yet

- Isensor ManualDocument2 pagesIsensor ManualRickz2k8No ratings yet

- Heat Transfer Mechanisms and EquationsDocument12 pagesHeat Transfer Mechanisms and EquationsabeeNo ratings yet

- Final Thesis PDFDocument77 pagesFinal Thesis PDFSureil GupteNo ratings yet

- LONGWAY GENERAL BATTERY SERIES SPECSDocument2 pagesLONGWAY GENERAL BATTERY SERIES SPECSRosendo Vidal100% (1)

- 25 - B - SC - , Home Sciene Syllabus (2017-18)Document28 pages25 - B - SC - , Home Sciene Syllabus (2017-18)quickdannyNo ratings yet

- XIM Lert: (Amended Upto 002/2022-Customs Dated 1 February, 2022 and W.E.F. 2nd February, 2022)Document139 pagesXIM Lert: (Amended Upto 002/2022-Customs Dated 1 February, 2022 and W.E.F. 2nd February, 2022)raviNo ratings yet

- TILES Green Building Catalogue 2013 NewDocument52 pagesTILES Green Building Catalogue 2013 NewPrasanthNo ratings yet

- Review of The Adam and Eve Story by Chan ThomasDocument17 pagesReview of The Adam and Eve Story by Chan ThomasJeffrey Russell100% (6)

- Unit3 - Electrical SystemDocument57 pagesUnit3 - Electrical SystemNethaji BKNo ratings yet

- Energy Fuel Report Avalara Tax Changes 2023Document15 pagesEnergy Fuel Report Avalara Tax Changes 2023aramsaranNo ratings yet

- Kaya - 2007 - Mathematical Modeling of Multiple Effect Evaporators and Energy EconomyhDocument7 pagesKaya - 2007 - Mathematical Modeling of Multiple Effect Evaporators and Energy EconomyhGabriel NguyenNo ratings yet

- AccessoriesDocument2 pagesAccessoriesPankaj JadhavNo ratings yet

- Active and Passive Fire FightingDocument16 pagesActive and Passive Fire FightingAnirudh BabbarNo ratings yet

- Flow Accelerated Corrosion (FAC)Document21 pagesFlow Accelerated Corrosion (FAC)DSGNo ratings yet

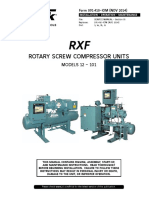

- Compressor ManualDocument68 pagesCompressor ManualyosafatedenNo ratings yet

- J Jpowsour 2006 02 003Document4 pagesJ Jpowsour 2006 02 003Customer Tech Support / Product Development Sales/CCT Dept. AECPLNo ratings yet

- Sunfire-Hylink: Clean Hydrogen For Sector IntegrationDocument2 pagesSunfire-Hylink: Clean Hydrogen For Sector IntegrationМар'яна ПелипенкоNo ratings yet

- Compressor Technical Data: NJ9232GK 220-240 V 50 HZ 943NA01 A - Application / Limit Working ConditionsDocument3 pagesCompressor Technical Data: NJ9232GK 220-240 V 50 HZ 943NA01 A - Application / Limit Working ConditionsGeri SulanjakuNo ratings yet