Professional Documents

Culture Documents

Welding Cable Ampacities

Uploaded by

Daudkandi Laboratory High SchoolOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Cable Ampacities

Uploaded by

Daudkandi Laboratory High SchoolCopyright:

Available Formats

Welding Cable Ampacities

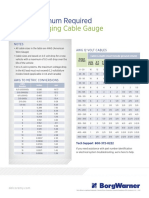

Required Cable Sizes:

• For Arc Welding Cable Applications

• Length in feet for total circuit* for secondary voltage ONLY

(Do not use this table for 600 volt applications)

Amps 100’ 150’ 200’ 250’ 300’ 350’ 400’

100 4 4 2 2 1 1/0 1/0

150 4 2 1 1/0 2/0 3/0 3/0

200 2 1 1/0 2/0 3/0 4/0 4/0

250 1 1/0 2/0 3/0 4/0 - -

300 1/0 2/0 3/0 4/0 - - -

350 1/0 3/0 4/0 - - - -

400 2/0 3/0 - - - - -

450 2/0 4/0 - - - - -

500 3/0 4/0 - - - - -

550 3/0 4/0 - - - - -

600 4/0 - - - - - -

* The total circuit length includes both welding and ground leads (based on 4-volt drop) 60% duty cycle

These values for current-carrying capacity are based on a copper temperature of 60C (140F), an ambient temperature of 40C (104F), and yield load factor of approximately 32% from the 2 AWG

cable, approximately 23% for the 3/0 AWG cable and higher for the smaller sizes.

The sizes of cables generally used ranged from 2 AWG to 3/0 AWG. In actually service, the load factor may be much higher than indicated without overheating the cable as the ambient

temperature will generally be substantially lower than 40C.

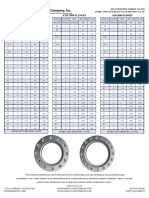

Suggested Ampacities for 600 volt in-line applications:

AWG AMPERES AWG AMPERES

4/0 315 1 170

3/0 275 2 150

2/0 235 3 130

1/0 200 4 110

- - 6 85

Per standards: ICEA S-19-81

NEMA WC-3 Part 8, Appendix J

Ampacities for portable cable, continuous duty (Ambient Temperature of 40C)

IEWC • 5001 S. Towne Drive, New Berlin, WI 53151 | Toll-Free: 800-344-2323 | Web: www.iewc.com

IEWC assumes no responsibility for the use of, or reliance on the information provided herein and disclaims all liability for any and all damages arising out of the use of, or reliance on, this information.

You might also like

- Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Document1 pageTorque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Shijumon Kp100% (2)

- WWW Altestore Com Howto Recommended Inverter Cables Sizing and Breakers or Fuses A62Document2 pagesWWW Altestore Com Howto Recommended Inverter Cables Sizing and Breakers or Fuses A62Suhas PatilNo ratings yet

- Delco Charging Cable Flyer 9 18Document1 pageDelco Charging Cable Flyer 9 18dima65No ratings yet

- Welding Wire Spec SheetDocument3 pagesWelding Wire Spec SheetVada SeamNo ratings yet

- Notice Tarif Jaune (020250)Document7 pagesNotice Tarif Jaune (020250)plkouadioNo ratings yet

- Ramco Recommended Torque ChartDocument2 pagesRamco Recommended Torque ChartMohamed ElmoghazyNo ratings yet

- Typical Edge Section E-E: 4Ø12 Stø8C/C250 L-740 400 2Ø14 +2Ø12 2Ø14 +2 Ø12Document1 pageTypical Edge Section E-E: 4Ø12 Stø8C/C250 L-740 400 2Ø14 +2Ø12 2Ø14 +2 Ø12metsihafeNo ratings yet

- Iron Pump QVDocument2 pagesIron Pump QVAmit ChourasiaNo ratings yet

- Bolting Chart For Industrial FlangesDocument6 pagesBolting Chart For Industrial FlangesPritam JadhavNo ratings yet

- d4 ts2 2011 AclimDocument5 pagesd4 ts2 2011 Aclimgc1501293No ratings yet

- Studbolt Size ChartDocument3 pagesStudbolt Size ChartRenalyn TorioNo ratings yet

- SSS GuidelineDocument13 pagesSSS GuidelineAditya NarayanNo ratings yet

- IP Pump DataSheet CNLDocument2 pagesIP Pump DataSheet CNLAmit ChourasiaNo ratings yet

- Bonding Jumper-Cable Tray)Document2 pagesBonding Jumper-Cable Tray)nadeem UddinNo ratings yet

- BS 6779 - Highways Parapets For Bridges... Part 4Document56 pagesBS 6779 - Highways Parapets For Bridges... Part 4Vicky Munien100% (3)

- Type 1279, 1377, 1379 & 2462 Receiver GaugesDocument4 pagesType 1279, 1377, 1379 & 2462 Receiver GaugesHectorNo ratings yet

- Type 1279, 1377, 1379 & 2462 Receiver GaugesDocument4 pagesType 1279, 1377, 1379 & 2462 Receiver Gaugesshaggy0078No ratings yet

- 4BLOCKDocument4 pages4BLOCKlinsupNo ratings yet

- Socket Weld Reducing Insert: Type 1Document2 pagesSocket Weld Reducing Insert: Type 1jaimeorozNo ratings yet

- Pipe Flange Torque Summary (Modified by Joan Franco)Document21 pagesPipe Flange Torque Summary (Modified by Joan Franco)Wilmer FigueraNo ratings yet

- ABA-Constant-Torque Standard-DatasheetDocument1 pageABA-Constant-Torque Standard-DatasheetgauravNo ratings yet

- Conduit Size (MM To Inches) IMC PVC: Thickness Width X Section Wt./Lin Ft. Carrying Inch Inch Sq. In. Pounds CapacityDocument1 pageConduit Size (MM To Inches) IMC PVC: Thickness Width X Section Wt./Lin Ft. Carrying Inch Inch Sq. In. Pounds CapacityRon Carlo HernandezNo ratings yet

- Strut Pipe Clamps TechDataDocument1 pageStrut Pipe Clamps TechDatar4kinNo ratings yet

- Belt and Bucket Elevator - LBEB - Data Sheet - ENDocument2 pagesBelt and Bucket Elevator - LBEB - Data Sheet - ENsalih khattabNo ratings yet

- IP Pump DataSheet DHBDocument2 pagesIP Pump DataSheet DHBAmit ChourasiaNo ratings yet

- Flange Bolt Chart and Flange Stud Size in MMDocument1 pageFlange Bolt Chart and Flange Stud Size in MMRodrigo Celes100% (1)

- Bleed Ring ReportDocument1 pageBleed Ring ReportRatna Giridhar KavaliNo ratings yet

- 4block - enDocument4 pages4block - enDaniel ZahraNo ratings yet

- Flage Bolting PDFDocument3 pagesFlage Bolting PDFDHAVAL PANCHALNo ratings yet

- C:/Tricomponente 08-05-2019/acetaminofen - Dat, DAD-280 NM: Retention Time Name Area (Group) Name AreaDocument1 pageC:/Tricomponente 08-05-2019/acetaminofen - Dat, DAD-280 NM: Retention Time Name Area (Group) Name AreaMaria Del Pilar Hurtado SanchezNo ratings yet

- Prysmian EU 11kV 1core ArmourDocument5 pagesPrysmian EU 11kV 1core ArmourBhagoo HatheyNo ratings yet

- Welding Soldadura Amperes AmperiosDocument1 pageWelding Soldadura Amperes AmperiosHectorNo ratings yet

- Stud Bolt Length For UploadDocument1 pageStud Bolt Length For UploadDan PastorNo ratings yet

- Stud Bolt LengthDocument1 pageStud Bolt LengthSanthosh100% (1)

- Stud Bolt Length For UploadDocument1 pageStud Bolt Length For UploadPat AuffretNo ratings yet

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFvishnu300022No ratings yet

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFDiego Martínez FernándezNo ratings yet

- Welding CableDocument4 pagesWelding CablegsbkrishnanNo ratings yet

- Stud Bolt LengthDocument1 pageStud Bolt LengthRyan Goh Chuang HongNo ratings yet

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFTharindu JeewanaNo ratings yet

- Wire Ampacity ChartDocument1 pageWire Ampacity ChartAxelrose04No ratings yet

- Outlet Pipe FittingsDocument13 pagesOutlet Pipe FittingspetromatcompanyNo ratings yet

- Torque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsDocument2 pagesTorque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsPranpath NarupantawartNo ratings yet

- Cable Porta Electrodo CapacidadDocument1 pageCable Porta Electrodo CapacidadAbraham GalvánNo ratings yet

- Littelfuse Fuse LLNRK LLSRK DatasheetDocument3 pagesLittelfuse Fuse LLNRK LLSRK DatasheetLuis RomeroNo ratings yet

- CU AL Ampacity Chart FinalDocument1 pageCU AL Ampacity Chart FinalRobertoHerediaJacoboNo ratings yet

- Valve RatesDocument34 pagesValve RatesDeepthy VasavanNo ratings yet

- IP Pump DataSheet CNLBDocument2 pagesIP Pump DataSheet CNLBVikk Suriya100% (1)

- Pipe SizeDocument2 pagesPipe SizeKrishna PATELNo ratings yet

- Where UsedDocument1 pageWhere Used9588400913No ratings yet

- Anilla Simple CM UsaDocument1 pageAnilla Simple CM Usajm467191No ratings yet

- Tüketim Toplumu Ve Dünyanın Geeceği - Alan DurningDocument80 pagesTüketim Toplumu Ve Dünyanın Geeceği - Alan DurningorkinoksNo ratings yet

- End Mill Speed FeedDocument12 pagesEnd Mill Speed FeedkxeNo ratings yet

- SCI Stainless ForgedDocument12 pagesSCI Stainless ForgedBrandon TrocNo ratings yet

- Torque SummaryDocument1 pageTorque Summarycesar gallardoNo ratings yet

- Selectalloy 307cDocument1 pageSelectalloy 307cJuan Carlos RodriguezNo ratings yet

- Turbocharger TurbochargerDocument38 pagesTurbocharger TurbochargerFrank ChukwujiNo ratings yet

- Standard Series Chain: Chain Descriptions and DimensionsDocument2 pagesStandard Series Chain: Chain Descriptions and DimensionspasswordNo ratings yet

- Ashcroft ThermometerDocument2 pagesAshcroft ThermometerjlcegarraNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Master Schedule For Hotel BuildingDocument15 pagesMaster Schedule For Hotel BuildingDaudkandi Laboratory High School100% (1)

- Substation Design - ManualDocument127 pagesSubstation Design - Manualmujeeb.alam489% (9)

- Busbar Scheme (Siemens)Document78 pagesBusbar Scheme (Siemens)Hanis Halim100% (1)

- Top Pages - Inception ReportDocument205 pagesTop Pages - Inception ReportOnik Plabon100% (1)

- SerieAK-2020 GBDocument120 pagesSerieAK-2020 GBAndré SilvaNo ratings yet

- Development of Sodium Leak Detectors For PFBRDocument13 pagesDevelopment of Sodium Leak Detectors For PFBRWilliam MunnyNo ratings yet

- 844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideDocument3 pages844K 4WD Loader PIN 1DW844K D642008 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- CAT4-2 Complete ENDocument264 pagesCAT4-2 Complete ENalltheloveintheworldNo ratings yet

- Pio Joe Sleiman 11D Science Capstone ProjectDocument18 pagesPio Joe Sleiman 11D Science Capstone ProjectpiojoesleimanNo ratings yet

- Quantitative Determination OF AND: Vitamin A Vitamin EDocument20 pagesQuantitative Determination OF AND: Vitamin A Vitamin EAras RafiqNo ratings yet

- 2012 A6 Self Study Program Part 1Document44 pages2012 A6 Self Study Program Part 1Soriteu Sorin100% (2)

- End of Well ReportDocument6 pagesEnd of Well Reportvengurion100% (1)

- Manual - BigMuff - Green RussianDocument10 pagesManual - BigMuff - Green RussianBen KussauerNo ratings yet

- Omnik - Let Mankind Share and Enjoy Blue Sky and White Clouds Professional Inverter ManufacturerDocument18 pagesOmnik - Let Mankind Share and Enjoy Blue Sky and White Clouds Professional Inverter ManufactureromnikshanNo ratings yet

- SSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFDocument586 pagesSSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFBhavani Gujjari0% (1)

- Siemons - Cello Bowing TechniqueDocument15 pagesSiemons - Cello Bowing TechniqueMassa Awaj100% (2)

- 35-3000RKA-LEL Sample Draw Combustible Gas Detector: SpecificationsDocument18 pages35-3000RKA-LEL Sample Draw Combustible Gas Detector: SpecificationspcatruongNo ratings yet

- Wave and Sond MCQ QuestionsDocument5 pagesWave and Sond MCQ Questionsmairaj24800100% (2)

- Dwelling PresentationDocument1 pageDwelling PresentationAliciaB2No ratings yet

- Spare Parts List STORM 15 20180000 XDocument4 pagesSpare Parts List STORM 15 20180000 XFati ZoraNo ratings yet

- Maching Learning Methods Used in Data MiningDocument11 pagesMaching Learning Methods Used in Data MiningYunir Causil NoyaNo ratings yet

- Biodegradation of Agricultural Wastes (Rice Straw and Sorghum Stalk) Into Substrates of Utilizable Products Using White Rot FungusDocument7 pagesBiodegradation of Agricultural Wastes (Rice Straw and Sorghum Stalk) Into Substrates of Utilizable Products Using White Rot FungusInes HrastinskiNo ratings yet

- Advanced Power System-I (Department Elective-I)Document4 pagesAdvanced Power System-I (Department Elective-I)Palak AriwalaNo ratings yet

- Catalogue Bzi GBDocument15 pagesCatalogue Bzi GBdenis_alexNo ratings yet

- ALUPEX BrochureDocument5 pagesALUPEX BrochureTamas PapikNo ratings yet

- Design of Flywheel: Prepared By:-Mourya Sachin BabulalDocument16 pagesDesign of Flywheel: Prepared By:-Mourya Sachin BabulalSachin MouryaNo ratings yet

- EIR 221 Prac 3 Guide 2017Document5 pagesEIR 221 Prac 3 Guide 2017mpaka felliNo ratings yet

- Hydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntoDocument22 pagesHydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntosaitejaNo ratings yet

- Rex Analog Time SwitchesDocument9 pagesRex Analog Time SwitchesKatarina GomezNo ratings yet

- Chemcad FeaturesDocument39 pagesChemcad FeaturesMOHAMED ESSALHINo ratings yet

- Passive Noise Control in BuildingsDocument12 pagesPassive Noise Control in BuildingsANJUSREE B.S. MBT18CE025No ratings yet

- Lab Report On Climate ChangeDocument3 pagesLab Report On Climate ChangecmsbballNo ratings yet

- Wind Power ProjectDocument96 pagesWind Power ProjectBina Das MazumdarNo ratings yet

- 14.03 - General Design - Design of Steel Bridges BD 13-90Document27 pages14.03 - General Design - Design of Steel Bridges BD 13-90Oscar MendozaNo ratings yet