Professional Documents

Culture Documents

Ebop Scada Manual

Uploaded by

Dawood TahirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ebop Scada Manual

Uploaded by

Dawood TahirCopyright:

Available Formats

Operation & Maintenance Manual

for

EBOP SCADA

(Schneider Eco SUI SCADA)

Prepared by: Sabir Hussain

Reviewed by: M. Nabeel & M. Abrar

Approved by: Peerzada Zain Ul Abidin Shah

SCADA

Table of Contents

1. Introduction & Objectives: ................................................................................................................... 3

1.1. Basic Definitions & Abbreviations:.............................................................................................. 3

1.2. Start Up:........................................................................................................................................ 6

2. SLD: ..................................................................................................................................................... 6

2.1. Introduction of SLD: .................................................................................................................... 6

2.1.1. 33kV: .................................................................................................................................... 6

2.1.2. Auxiliary Transformer .......................................................................................................... 6

2.1.3. SVC: ..................................................................................................................................... 6

2.1.4. WTG Loop:........................................................................................................................... 6

2.1.5. PT & Surge Arrestor for MV Busbar: .................................................................................. 7

2.1.6. Bus Section: .......................................................................................................................... 7

2.1.7. Main Transformer: ................................................................................................................ 7

2.1.8. Earthing Transformer: .......................................................................................................... 7

2.1.9. 132kV Bus Coupler: ............................................................................................................. 7

2.1.10. 132kV Busbar PTs: ............................................................................................................... 7

2.1.11. SF6 Circuit Breaker: ............................................................................................................. 7

2.1.12. Isolators: ............................................................................................................................... 7

2.1.13. Earth Switches: ..................................................................................................................... 7

2.1.14. VCB: ..................................................................................................................................... 7

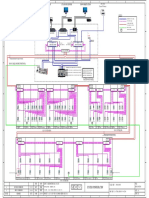

2.2. Complete Explanation of SLD: .................................................................................................... 8

2.2.1. Auxiliary Transformer: ......................................................................................................... 8

2.2.2. SVC (Static VAR Compensator): ......................................................................................... 8

2.2.3. WTG Loops: ......................................................................................................................... 8

2.2.4. PT & Surge Arrestor for MV Busbar: .................................................................................. 9

2.2.5. MV Bus Section: .................................................................................................................. 9

2.2.6. Main Transformers: .............................................................................................................. 9

2.2.7. Winding & Oil Temperature of MT: .................................................................................... 9

2.2.8. 132kV Busbar PTs: ............................................................................................................. 10

2.2.9. 132kV Transformer Bay: .................................................................................................... 10

2.2.10. 132kV Line Bay: ................................................................................................................ 10

2.2.11. 132kV Bus Coupler Bay: .................................................................................................... 10

3. Equipment Access: ............................................................................................................................. 11

3.1. WTG Loop Access: .................................................................................................................... 11

HDEC Engineering (PVT.) Limited 1

SCADA

3.2. Bay Access: ................................................................................................................................ 12

3.3. OLTC:......................................................................................................................................... 13

3.4. CB Opening & Closing: ............................................................................................................. 13

3.5. Transformer LV Side Parameters Measurement: ....................................................................... 14

3.6. Transformer HV Parameter Measurement: ................................................................................ 15

4. Tools: .................................................................................................................................................. 16

4.1. Alarms: ....................................................................................................................................... 16

4.2. States: ......................................................................................................................................... 16

4.3. Events: ........................................................................................................................................ 17

4.4. Trends: ........................................................................................................................................ 18

5. Views: ................................................................................................................................................. 21

5.1. DC1/DC2 System: ...................................................................................................................... 21

5.2. METER: ..................................................................................................................................... 22

5.3. RMU: .......................................................................................................................................... 23

5.4. SVC: ........................................................................................................................................... 24

5.5. Generator: ................................................................................................................................... 25

5.6. Alarms: ....................................................................................................................................... 26

5.7. Plant Summary: .......................................................................................................................... 27

5.8. System View:.............................................................................................................................. 28

5.9. Electrical Help View: ................................................................................................................. 29

5.10. System Help View: ................................................................................................................. 30

6. Interlocking:........................................................................................................................................ 31

6.1. 132kV Line Bay Earthing Switch & Isolator interlock Circuit: ................................................. 31

6.2. 132kV Transformer Bay Earthing Switch & Isolator interlock Circuit:..................................... 32

6.3. 132kV Bus Section Bay Earthing Switch & Isolator interlock Circuit: ..................................... 32

6.4. 33kV Bus Section Circuit Breaker J7Q1 interlock: .................................................................... 33

7. Standard Operating Procedures: ......................................................................................................... 34

7.1. Shutdown of Plant: ..................................................................................................................... 34

7.2. Energization of Plant: ................................................................................................................. 36

7.3. Load Shifting from MT1 to MT2: .............................................................................................. 38

7.4. Load Shifting from BusBar1 to BusBar2: .................................................................................. 38

8. Exporting Power & Importing Power: ................................................................................................ 39

HDEC Engineering (PVT.) Limited 2

SCADA

1. Introduction & Objectives:

SCADA stands for Supervisory Control and Data Acquisition. EBOP SCADA is an integral part

of control room operation of plant. Each BOP equipment at the complex is monitored & operated

remotely by EBOP SCADA. This manual would allow operation Engineers to get well versed with

EBOP SCADA and be able to operate it independently. Major objectives of this manual are listed

below.

➢ Control room Operation Engineer could monitor and control each EBOP equipment of the

plant remotely.

➢ Operation engineer could extract archived data in the form of table or graph.

➢ Operation Engineer could view and understand meaning of live parameters in EBOP Scada.

1.1. Basic Definitions & Abbreviations:

Terms Definitions

ACT Wind Farm Akhtar Candy land Tapal Wind Farm

HDEC Huadong Engineering Corporation Limited

EBOP Electrical Balance of Plant

SUI Substation User Interface

CCR Central Control Room

SLD Single Line Diagram

HMI Human Machine Interface

AIS Air Insulated Substation

OHL Overhead Line

SVC Static VAR Compensator

EDG Emergency Diesel Generator

WTG Wind Turbine Generator

CT Current Transformer

PT Potential Transformer

MT Main Transformer

OLTC ON Load Tap Changer

LV Low Voltage

HDEC Engineering (PVT.) Limited 3

SCADA

MV Medium Voltage

HV High Voltage

RMU Ring Main Unit

GSU Generator Step up Unit

BCU Bay Control Unit

RTU Remote Terminal Unit

CB Circuit Breaker

VCB Vacuum Circuit Breaker

ES Earth Switch

DS/Isolator Disconnector Switch

Remote Operation: Remote Operation

means operation from EBOP SCADA. Red

indication allows for remote operation.

Local Operation: Local Operation means

operation from AIS. Green indication means

that we can’t operate it remotely. We have to

operate from AIS locally.

Public: In Public mode we can’t give any

command for operation. By Clicking

“Schneider Electric” Icon and giving User

name and password we can change Public to

Operator mode.

Operator: In Operator mode we can give any

command for operation.

CB Circuit Breaker

VCB Vacuum Circuit Breaker

HDEC Engineering (PVT.) Limited 4

SCADA

ES Earth Switch

DS/Isolator Disconnector Switch

Rack in/ Rack out

P Active Power

Q Reactive Power

U Voltage

I Current

DEL ACT Delivered Active Power

DEL REA Delivered Reactive Power

REC ACT Received Active Power

REC REA Received Reactive Power

SNTP Simple Network Time Protocol

GPS Global Positioning System

IEC International Electro Technical Commission

IEC61850 International standard for communication in

substation.

PACIS Protection Automation Control Integrated

System

HDEC Engineering (PVT.) Limited 5

SCADA

1.2. Start Up:

Click on “EcoSUI HMI” on desktop to start the EBOP SCADA.

2. SLD:

2.1. Introduction of SLD:

2.1.1. 33kV: Incoming Line from WTG side.

2.1.2. Auxiliary Transformer: One auxiliary transformer installed in MV room.

2.1.3. SVC: There are two sets of SVCs installed at AIS.

2.1.4. WTG Loop: There are four loops of WTGs.

HDEC Engineering (PVT.) Limited 6

SCADA

2.1.5. PT & Surge Arrestor for MV Busbar: Two sets of PTs and surge arrestor for MV

Busbar.

2.1.6. Bus Section: Bus coupler between loop A, B and loop C, D connected by circuit

breaker J7Q1.

2.1.7. Main Transformer: There are two main transformers installed at AIS.

2.1.8. Earthing Transformer: Two earthing transformer used for earthing of main

transformer.

2.1.9. 132kV Bus Coupler: Circuit breaker E5Q1 is used for coupling of Busbar1 and

Busbar2

2.1.10. 132kV Busbar PTs: There are two sets of PTs One set for Busbar1 second for

Busbar2.

2.1.11. SF6 Circuit Breaker: There are seven SF6 Circuit Breakers. E1Q1, E2Q2

Installed at UEP Line and Artistic line respectively. E3Q1, E4Q1 installed at the HV

side of MT1 and MT2 respectively. E5Q1 installed at Bus Coupler of 132kV Busbar.

Two SF6 circuit breaker installed in MV room J2Q1, J12Q1 for SVC1 and SVC2.

2.1.12. Isolators: There are total sixteen isolator at AIS shown in SLD.

2.1.13. Earth Switches: There are total twenty earth switches at AIS and seven in MV

room as shown in SLD.

2.1.14. VCB: There are five vacuum circuit breakers installed in MV room, four VCB

for four loops of WTGs and one for Bus section between loop A, B and loop B, C.

HDEC Engineering (PVT.) Limited 7

SCADA

2.2. Complete Explanation of SLD:

2.2.1. Auxiliary Transformer:

An auxiliary transformer is a smaller transformer than

the main supply transformer. Auxiliary transformer

installed in MV room is Dry type power transformer.

Figure shows the auxiliary transformer in SLD which

is connected with 33kV Busbar. Figure shows the

values of all parameters of auxiliary transformer.

2.2.2. SVC (Static VAR Compensator):

A static VAR compensator is a set of electrical devices

for providing fast-acting reactive power on high-

voltage electricity transmission networks. We have

two sets of SVC in our substation. Figure shows the

SVC in SLD which is connected with 33kV Busbar.

Figure shows the values of all parameters of SVC.

2.2.3. WTG Loops:

There are four loops of wind turbine generators

Loop A have five WTGs

Loop B have six WTGs

Loop C have five WTGs

Loop D have four WTGS

All four loops are connected with 33kV Busbar. Figure

shows the values of all parameters of Loop.

HDEC Engineering (PVT.) Limited 8

SCADA

2.2.4. PT & Surge Arrestor for MV Busbar:

The PT is used for protection and measurement of MV

Busbar voltages and Surge Arrestor is used to protect

from the surges

2.2.5. MV Bus Section:

MV Bus section is used for coupling of Loops A, B &

Loop C, D. Circuit breaker J7Q1 is used for this

purpose. Normally J7Q1 is opened and WTG Loop A

& B transfer their load to Transformer 1 and WTG

Loop C & D transfer their load to Transformer 2

2.2.6. Main Transformers:

There are two main transformers in AIS which are used

to step up 33kV into 132kV. Figure shows the Main

Transformer is connected with 33kV Busbar. Figure

shows also a Grounding Transformer which provide a

ground path for main transformer in any abnormal

condition. Figure shows the Tap Position and values of

transformer parameters at LV side.

2.2.7. Winding & Oil Temperature of MT:

Figure shows the oil temperature and windings

temperature of transformer and also show the values of

transformer parameters at HV side.

HDEC Engineering (PVT.) Limited 9

SCADA

2.2.8. 132kV Busbar PTs:

Figure shows the Potential Transformer at Busbar. We

have two sets of PTs one set for Busbar1, second for

Busbar2. Figure also shows the voltages of Busbars.

2.2.9. 132kV Transformer Bay:

There are two 132kV transformer bay in AIS each bay

has one SF6 circuit breaker, three

Isolators/Disconnector switches, three earth switches.

Two Isolators connected with 132kV Busbar1 and

132kV Busbar2 and one Isolator connected between

main transformer and SF6 circuit breaker.

2.2.10. 132kV Line Bay:

There are two 132 kV line bay in AIS which have one

SF6 circuit breaker, three Isolators/Disconnector

switches, three earth switches. Two Isolators

connected with 132kV Busbar1 and 132kV Busbar2

and one is line Isolator.

2.2.11. 132kV Bus Coupler Bay:

One Bus Coupler in AIS which have one SF6 circuit

breaker, two Isolators/Disconnector switches. Isolators

are connected with 132kV Busbar1 and 132kV

Busbar2 respectively. This bus coupler is used for

coupling of Busbar1 and Busbar2

HDEC Engineering (PVT.) Limited 10

SCADA

3. Equipment Access:

3.1. WTG Loop Access:

WTG loops (33 kV) can be accessed by clicking on Loop A wind turbine group in SCADA

HMI as shown in figure.

After clicking on Loop A, it will show the below display

WTG Loop HMI gives the following information:

➢ Spot values of wind speed, active power, frequency.

➢ Status of circuit breakers and earth switches.

HDEC Engineering (PVT.) Limited 11

SCADA

3.2. Bay Access:

There are five bays 132kV transformer1 & 132 kV transformer2 bay. Line1 & Line2 bay and

bus coupler bay. All bay can be accessed by clicking on it. Which gives the following

information:

➢ Show the remote and local status of bay. In remote mode the operation can be done

from SCADA HMI. In local mode we can’t operate from SCADA HMI we have to

operate it from panel.

➢ Red indication means remote and green indication means local status of each device

like circuit breaker, isolator and earth switches. In remote mode operation can be done

from SCADA HMI. In local mode we can’t operate from SCADA HMI we have to

operate it from AIS.

➢ Spot values of phase current.

➢ Spot values of phase to phase voltage.

➢ Total active power.

➢ Total reactive power.

➢ Frequency.

HDEC Engineering (PVT.) Limited 12

SCADA

3.3. OLTC:

As shown in the figure the small arrow shows the tap position of the MT1. By Clicking the

MT1 LV side circuit breaker J10Q1 the HMI will show the tap position Icon from here we

can increase or decrease the tap position of OLTC.

3.4. CB Opening & Closing:

First of all, click on circuit breaker J12Q1 HMI will display four options OPEN, CLOSE,

Execute and Cancel, for closing we will click on the CLOSE so then HMI will display like

HDEC Engineering (PVT.) Limited 13

SCADA

this as shown in figure below; It means that the object which we want to close has been

selected.

After this we will click on Execute and CB will be closed.

Note: If after clicking on CLOSE we want to cancel the command then we have to click on

Cancel and the command will be cancelled.

3.5. Transformer LV Side Parameters Measurement:

Transformer LV side parameter menu can be accessed by clicking on transformer LV side

circuit breaker J10Q1. The HMI will display spot values of transformer parameters.

➢ Current of all phases.

➢ Phase to phase voltage.

HDEC Engineering (PVT.) Limited 14

SCADA

➢ Voltage of all phases.

➢ Total active power.

➢ Total reactive power.

➢ Power factor.

➢ Frequency.

➢ Tap position.

➢ Oil & Winding Temperature.

3.6. Transformer HV Parameter Measurement:

Transformer HV parameter menu can be accessed by clicking on transformer HV side circuit

E3Q1 for MT1 and E4Q1for MT2. The HMI will display spot values of transformer

parameters.

➢ Current of all phases.

➢ Phase to phase voltage.

➢ Voltage of all phases.

➢ Total active power.

➢ Total reactive power.

➢ Power factor.

➢ Frequency.

HDEC Engineering (PVT.) Limited 15

SCADA

4. Tools:

4.1. Alarms:

Alarm menu can be accessed by clicking on tools in top of the screen it will show menu list.

In that list click on the alarm or directly click on the alarm Icon in top of the screen then it will

display alarm list as shown in below figure.

This alarms list gives the following information:

➢ Date and time of the alarm appearance.

➢ Date and time of the alarm disappearance.

➢ Date and time of the alarm acknowledged.

➢ Origin of the alarm.

➢ Alarm description.

4.2. States:

States menu can be accessed by clicking on tools in top of the screen it will show menu list, in

that list click on the states Icon then it will display states list as shown in below figure.

HDEC Engineering (PVT.) Limited 16

SCADA

States menu gives the following information.

➢ It gives the information about all the equipment parameters connected with 132kV

Lines.

➢ It gives the information about all the equipment parameters connected with 33kV Line.

4.3. Events:

Event menu can be accessed by clicking on tools in top of the screen it will show menu list in

that list click on the Events it will display below figure;

HDEC Engineering (PVT.) Limited 17

SCADA

This Event list gives the following information:

➢ Date and time of the any Event like alarm, trip or operation of CB, DS and ES etc.

➢ Origin of the event.

➢ Description of the event.

4.4. Trends:

Trends menu can be accessed by clicking on tools in top of the screen it will show menu list

in that list click on the Trends it will display below figure;

After clicking on properties, it will display below figure

For selection of signal of voltage, current or power then click on the signal button. By

clicking on this button, it will display below figure:

HDEC Engineering (PVT.) Limited 18

SCADA

Now if we want to check the graph or signal of HV side then select 132kV. As shown in

below figure:

Now click on L1_BCU and then select HW_MV so it will show all the parameters of line 1.

Now we can select the required parameter for example select the Ubc by double click as

shown in below figure:

Note: If we want to extract the graph of more parameters same procedure will be follow.

HDEC Engineering (PVT.) Limited 19

SCADA

Now select the Minimum value, Maximum value and correct Unit and click on update. Then

Select date and time and extract, so the required graph will be generated, click on save to

save the required graph. Below figure is our required parameter graph.

HDEC Engineering (PVT.) Limited 20

SCADA

5. Views:

5.1. DC1/DC2 System:

DC1/DC2 system can be accessed by clicking on views which have different menu as shown

in figure then click by DC1 or DC2 menu.

We have two sets of DC system DC1 and DC2. Here we consider only DC1.

As shown in figure two 400V AC input coming to the converter which convert 400V AC to

110V DC. This DC further goes to DC1 Bus or DC2 Bus depends upon the condition that

which Bus we want to use. This 110V DC charge the batteries. There is a discharge load

connected with the batteries if we have to discharge the batteries then we use this discharge

load.

There is an alarm list of DC system in the figure where we can check the alarms.

HDEC Engineering (PVT.) Limited 21

SCADA

5.2. METER:

Meter menu can be accessed by clicking on views Icon in toolbars and then click by Meter

menu. Meter menu gives the following information.

➢ Spot values of parameters like Uab, I, P, Q, of auxiliary transformer, SVC1, SVC2, loop

A, loop B, loop C, loop D, 400V M1 and 400V M2 EDG.

➢ Delivered active power and delivered reactive power of auxiliary transformer, SVC1,

SVC2, loop A, loop B, loop C, loop D, 400V M1 and 400V M2 EDG.

➢ Received active power, Received reactive power of auxiliary transformer, SVC1, SVC2,

loop A,

➢ Loop B, loop C, loop D, 400V M1 and 400V M2 EDG.

HDEC Engineering (PVT.) Limited 22

SCADA

5.3. RMU:

RMU menu can be accessed by clicking on views Icon in toolbars and then click by RMU

menu. RMU menu gives the following information.

➢ Status of circuit breaker, Isolator and earth switches.

➢ Spot values of voltages, current, frequency, active power reactive power and power

factor.

➢ Status of Remote/Local mode of HV CB and LV CB

➢ Alarm list which show different alarms.

HDEC Engineering (PVT.) Limited 23

SCADA

5.4. SVC:

SVC menu can be accessed by clicking on views Icon in toolbars and then click by SVC menu.

SVC menu gives the following information.

➢ Spot values of voltages, current, frequency, active power and reactive power.

➢ Status of circuit breaker and Isolators.

➢ Status of 33kV bus coupler circuit breaker.

➢ Alarm list which show different alarms.

HDEC Engineering (PVT.) Limited 24

SCADA

5.5. Generator:

Generator menu can be accessed by clicking on views Icon in toolbars and then click by

Generator menu. There are three tables in the figure Measurment1, Measurment2 and Status

which gives the following information.

➢ Measurment1: Spot values of voltages, current, frequency, active power and reactive

power.

➢ Measurment2: Battery voltage, engine speed, oil pressure, oil temperature, fuel level etc.

➢ Status: It shows the auto and manual mode and also show the alarms.

HDEC Engineering (PVT.) Limited 25

SCADA

5.6. Alarms:

Alarms menu can be accessed by clicking on views Icon in toolbars and then click by Alarm

menu. Alarm menu gives the following information.

➢ Line1 Status: This column give information about any fault or any abnormal condition

on line1.

➢ Line2 Status: This column give information about any fault or any abnormal condition

on line2.

➢ T1 HV Status: This column give information about any fault or any abnormal condition

on T1 HV side.

➢ T2 HV Status: This column give information about any fault or any abnormal condition

on T2 HV side.

➢ T1 MV Status: This column give information about any fault or any abnormal condition

on T1 MV side.

➢ T2 MV Status: This column give information about any fault or any abnormal condition

on T2 MV side.

➢ 33kV: This column give information about any fault or any abnormal condition on 33kV

side.

HDEC Engineering (PVT.) Limited 26

SCADA

5.7. Plant Summary:

Plant Summary menu can be accessed by clicking on views Icon in toolbars and then click by

Plant Summary menu. Plant Summary menu gives the following information.

➢ Total active energy & reactive energy exported by MT1 & MT2.

➢ Total active energy & reactive energy imported by MT1 & MT2.

➢ Show the met mast data.

HDEC Engineering (PVT.) Limited 27

SCADA

5.8. System View:

System view menu can be accessed by clicking on views Icon in toolbars and then click by

system view menu. System view menu gives the following information.

➢ Figure shows the complete networking of the system.

➢ All the protection relays are connected with their respective BCU through Ethernet cable

RJ45.

➢ All the BCUs are interconnected with each other and also connected with COM_BCU,

Ethernet switches

➢ (H1 H352, H2 H352, H3 H352, H4 H352) through Multi Mode fiber optical cable. H1

H352 & H2 H352 in Remote communication cubicle in CCR, and H3 H352 & H4 H352

are installed in MV room.

➢ H1 H352 & H2 H352 are connected with OIS1/EBOP SCADA1 and OIS2/EBOP

SCADA2 through Ethernet cable RJ45. Ethernet switches receive the data from BCUs

and send it to the EBOP SCADA.

➢ H1 H352 further connected with SNTP and SNTP connected with GPS, for the purpose

to update the current time in all the BCUs and relays.

➢ H2 H352 further connected with printer and WEB HMI. And WEB HMI connected with

firewall and internet switch.

➢ H1 H352 & H2 H352 also connected with GTW1/RTU1 and GTW2/RTU2 respectively.

➢ Ethernet switch receives the command from EBOP SCADA and send it to the RTU for

operation of different devices.

HDEC Engineering (PVT.) Limited 28

SCADA

5.9. Electrical Help View:

Electrical Help View menu can be accessed by clicking on views Icon in toolbars and then

click by Electrical Help View menu. Electrical Help View menu gives the following

information.

➢ Red Line indicate 33kV bus bar and Green line indicate 132kV bus bar.

➢ Symbols of circuit breaker, isolator, and earth switch.

➢ Status of circuit breaker, isolator, and earth switch.

HDEC Engineering (PVT.) Limited 29

SCADA

5.10. System Help View:

HDEC Engineering (PVT.) Limited 30

SCADA

6. Interlocking:

An interlock is a feature that makes the state of two mechanisms or functions mutually dependent.

In most applications, an interlock is used to help prevent a machine from harming its operator or

damaging itself by preventing one element from changing state due to the state of another element.

6.1. 132kV Line Bay Earthing Switch & Isolator interlock Circuit:

Following Points are described in above figure.

E1E20 & E2E20 are interlocked with E1Q10 & E2Q10.

E1Q10& E2Q10 are interlocked with their respective earth switches and circuit breaker.

E1E10& E2E10 are interlocked with their respective Isolators.

E1E11 & E2E11 are interlocked with their respective Isolators.

E1Q11 & E2Q11 are interlocked with their respective earth switches and circuit breaker.

E1Q12 & E2Q12 are interlocked with their respective earth switches and circuit breaker.

HDEC Engineering (PVT.) Limited 31

SCADA

6.2. 132kV Transformer Bay Earthing Switch & Isolator interlock Circuit:

Following Points are described in above figure.

Isolator are interlocked with their respective earth switches and circuit breaker.

Earth switches are interlocked with their respective Isolators.

6.3. 132kV Bus Section Bay Earthing Switch & Isolator interlock Circuit:

Following Points are described in above figure.

Isolator are interlocked with their respective earth switches and circuit breaker.

Earth switches are interlocked with their respective Isolators.

HDEC Engineering (PVT.) Limited 32

SCADA

6.4. 33kV Bus Section Circuit Breaker J7Q1 interlock:

Figure shows that 33kV Bus section circuit breaker (J7Q1) is interlocked with main

transformer1 LV side circuit breaker (J4Q1) and main transformer2 LV side circuit breaker

(J10Q1)

HDEC Engineering (PVT.) Limited 33

SCADA

7. Standard Operating Procedures:

7.1. Shutdown of Plant:

S.No

Operation

1 From SCADA Stop WTG#1 to WTG#20 and wait 5-10 minutes

2 From SCADA Open the LOOP A J3Q1 circuit breaker

3 From SCADA Open the LOOP B J5Q1 circuit breaker

4 From SCADA Open the LOOP C J9Q1 circuit breaker

5 From SCADA Open the LOOP D J11Q1 circuit breaker

6 From SCADA Open the SVC#1 J2Q1 circuit breaker

7 From SCADA Open the SVC#2 J12Q1circuit breaker

8 From SCADA Open Auxiliary transformer J1Q1 circuit breaker

9 Start the Diesel generator & Close Diesel generator Breaker QF2.

10 Locally Open LV room Working power circuit breaker, Drag out the circuit breaker

from the "working" position to the "test" position;

11 LV room EDG power incoming line CB“test” position change to“work”position;

12 From SCADA Open 1# main transformer LV side circuit breaker J4Q1.

13 From SCADA Open 1# main transformer HV side circuit breaker E3Q1.

14 From SCADA Open 2# main transformer LV side J10Q1 circuit breaker;

15 From SCADA Open the 2# main transformer HV side E4Q1 circuit breaker;

16 From SCADA Open the Circuit Breaker of Bus coupler E5Q1

17 As per the Instruction of RCC From SCADA Open UEP Line circuit breaker of E1Q1

18 As per the Instruction of RCC From SCADA open UEP Line E1Q10 dis-connector

19 As per the Instruction of RCC From SCADA Close UEP Line E1E20 earthing switches.

20 As per the Instruction of RCC From SCADA Close UEP Line E1E10 earthing switch.

21 As per the Instruction of RCC From SCADA Open HAE Line circuit breaker of E2Q1.

22 As per the Instruction of RCC From SCADA open HAE Line E2Q10 dis-connector

23 As per the Instruction of RCC From SCADA Close HAE Line E2E20 earthing switches.

24 As per Instruction of RCC From SCADA Close HAE Line E2 E10 earthing switches

25 Drag out the trolleys from the "working" position to the "test" position of

J2Q1,J3Q1,J4Q1,J5Q1,J9Q1,J10Q1,J11Q1 and J12Q1

26 Manually Close the Earthing Switch of SVC # 01 J2E10 & SVC # 02 J12E10

27 From SCADA Open Disconnector of Transformer No 01 E3Q10

HDEC Engineering (PVT.) Limited 34

SCADA

28 From SCADA Close the Earthing switch of Transformer # 01 E3E20

29 From SCADA Open Disconnector of Transformer No 02 E4Q10

30 From SCADA Close the Earthing switch of Transformer # 02 E4E20

31 From SCADA Open Disconnector of Bus Bar-I E3Q11

32 From SCADA Open Disconnector of Bus Bar-II E4Q12

33 From SCADA Open the disconnector of Bus Coupler E5Q11

34 From SCADA Open the disconnector of Bus Coupler E5Q12

35 From SCADA Open the disconnector of Line 1 E1Q11

36 From SCADA Open the disconnector of Line 2 E2Q12

37 From SCADA Close the Earthing switch of BusBar-I BSE11

38 From SCADA Close the Earthing switch of BusBar-II BSE12

39 From SCADA Open the disconnector of PT1Q10

40 From SCADA Close the Earthing switch of Bus Bar I PT1E20

41 From SCADA Open the disconnector of PT2Q20

42 From SCADA Close the Earthing switch of Bus Bar II PT2E20

HDEC Engineering (PVT.) Limited 35

SCADA

7.2. Energization of Plant:

S.No Operation

1 Drag in the trolleys from the "test" position to the "working" position of

J2Q1,J3Q1,J4Q1,J5Q1,J9Q1,J10Q1,J11Q1 and J12Q1

2 From SCADA Close the Earthing switch of Bus Bar I PT1E20 & Bus Bar II PT2E20

3 From SCADA Close the Earthing switch of BusBar-I BSE11 & BusBar-II BSE12

4 From SCADA Close the Earthing switch of Transformer # 01 E3E20 & Transformer #

02 E4E20

5 From SCADA Close the Earthing Switch of SVC # 01 J2E10 & SVC # 02 J12E10

6 After receiving voltage from UEP and HAE line call to RCC with respect to supply

restoration and voltage stabilization status get go head to connect the system to

WAPDA.

7 OPEN Earthing Switch of UEP line E1E20/E1E10 with coordinating RCC.

8 OPEN Earthing Switch of HAE line E2E20/E2E10 with coordinating RCC.

9 CLOSE the Disconnector of HAE line E2Q10.

10 CLOSE HAE line breaker (E2Q1) with getting confirmation from RCC

11 CLOSE the Disconnector of UEP line E1Q10.

12 CLOSE breaker E1Q1 if voltage received from UEP line with coordinating RCC.

13 CLOSE the Disconnector of the Power Transformers for Transformer-I

(E3Q11/E3Q12).

14 CLOSE the Disconnector of the Power Transformers for Transformer-2

(E4Q11/E4Q12).

15 CLOSE the Disconnector of the Power Transformers for Transformer-1 E3Q10.

16 CLOSE the Disconnector of the Power Transformers for Transformer-2 E4Q10.

17 Close E3Q1 (Main Transformer No.1 132 KV CB)

18 Close E4Q1 (Main Transformer No.2 132KV CB)

19 Close J4Q1 (Main Transformer No.1 MV CB )

20 Close J10Q1 (Main Transformer No.2 MV CB )

21 Close J3Q1 (Loop A Wind Turbines Group)

22 Close J5Q1 (Loop B Wind Turbine Group)

23 Close J9Q1 (Loop C Wind Turbine Group)

24 Close J11Q1 (Loop D Wind Turbine Group)

25 CLOSE J1Q1 (Auxiliary Transformer MV CB)

26 CLOSE SVC#1, MV Breaker (J2Q1)

HDEC Engineering (PVT.) Limited 36

SCADA

27 CLOSE SVC#2 MV Breaker (J12Q1)

28 Go to LV room open Emergency Diesel Generator LV circuit breaker

29 Rack out Emergency Diesel Generator LV circuit breaker

30 Rack in Main’s LV circuit breaker

31 Switched on Main’s LV circuit breaker

32 Check either Emergency Diesel Generator stop or not

33 Check Emergency Diesel Generator oil level

34 Call to NPCC with respect to WAPDA supply restoration note down conversation

person name from NPCC

35 Send Fax with respect to WAPDA supply failure to NPCC and get acknowledgement

via Fax.

36 Start Command From Goldwind SCADA to All Loops.

HDEC Engineering (PVT.) Limited 37

SCADA

7.3. Load Shifting from MT1 to MT2:

S.No Operation

1 Make sure from Gold wind SCADA all the WTG of “Loop a” and “Loop B” have downtime

2 From SCADA Open the LOOP A J3Q1 circuit breaker

3 From SCADA Open the LOOP B J5Q1 circuit breaker

4 From SCADA Open the SVC#1 J2Q1 circuit breaker

5 From SCADA Open Auxiliary transformer J1Q1 circuit breaker

6 From SCADA Open 1# main transformer LV side circuit breaker J4Q1.

7 From SCADA Open 1# main transformer HV side circuit breaker E3Q1.

8 From SCADA Open Disconnector of Transformer No 01 E3Q10

9 From SCADA Open Disconnector of Bus Bar-I E3Q11

10 From SCADA Close the Bus-Section J7Q1 circuit breaker

11 From SCADA Close the LOOP B J5Q1 circuit breaker

12 From SCADA Close the LOOP A J3Q1 circuit breaker

13 From SCADA Close Auxiliary transformer J1Q1 circuit breaker

14 Start Command From Goldwind SCADA to Loop A & B

7.4. Load Shifting from BusBar1 to BusBar2:

S.No Operation

1 If Bus Coupler in closed. Position CLOSE the isolator E1Q12 of UEP line

2 CLOSE the isolator E3Q12

3 OPEN 132kV bus bar coupler circuit breaker E5Q1

4 OPEN Bus isolator E1Q11.

5 OPEN Bus isolator E3Q11

6 OPEN PT1Q10 Isolator

7 OPEN E5Q11 Isolator

8 Isolation of 132kV bus bar#1 is completed.

HDEC Engineering (PVT.) Limited 38

SCADA

8. Exporting Power & Importing Power:

Export Power

As shown in figure when we are generating power from WTGs and exporting to the grid, direction

of power flow is from WTG loops towards 132kV Bus bar to the grid. In this case power at the

transformer will be negative and power at the OHL will be positive.

Same can be seen in below diagram.

HDEC Engineering (PVT.) Limited 39

SCADA

Import Power

As shown in figure when we are importing power to the grid, direction of power flow from grid to

132kV Bus bar and from Bus bar to WTG Loops. In this case power at OHL will be negative and

power at Transformer will be positive.

Same can be seen in below diagram.

HDEC Engineering (PVT.) Limited 40

You might also like

- 400kV GIS Technical Data SheetDocument20 pages400kV GIS Technical Data SheetjigyeshNo ratings yet

- Dehn Catalogue Safety EquipmentDocument196 pagesDehn Catalogue Safety EquipmentIrfan AshrafNo ratings yet

- ACE - 66kV GIS 03.09.2022Document236 pagesACE - 66kV GIS 03.09.2022Chandan KumarNo ratings yet

- SS Consolidation ChennaiDocument532 pagesSS Consolidation ChennaiHariNo ratings yet

- Thermal PowerDocument66 pagesThermal PowerPrakhar Singh RawatNo ratings yet

- Substation - Project List: SR - No. Project Title Customer Consultant End Client Scope of WorkDocument7 pagesSubstation - Project List: SR - No. Project Title Customer Consultant End Client Scope of WorksunjeyNo ratings yet

- INPSNM-SA04 Substation Automation With IEC61850-Rev-BDocument1 pageINPSNM-SA04 Substation Automation With IEC61850-Rev-BMichael Parohinog GregasNo ratings yet

- Abb 61850 Sas GeneralDocument33 pagesAbb 61850 Sas GeneralantanaNo ratings yet

- Project:: Tra Vinh Wind Farm ProjectDocument19 pagesProject:: Tra Vinh Wind Farm ProjectcanNo ratings yet

- M.V. Anil Kumar Kumar: Summary: Work HistoryDocument3 pagesM.V. Anil Kumar Kumar: Summary: Work HistoryNarendra LakkojuNo ratings yet

- Abbreviations in Power Transmission SystemsDocument100 pagesAbbreviations in Power Transmission SystemsJayant Kumar Das100% (1)

- Ne02 Sas ArchitectureDocument5 pagesNe02 Sas ArchitectureApoorva BhushanNo ratings yet

- TDC & Specification of CSS&RMU - RevisedDocument31 pagesTDC & Specification of CSS&RMU - RevisedShatrughna SamalNo ratings yet

- 1KHW000890 en NSD570Document562 pages1KHW000890 en NSD570jckrishnah100% (1)

- 5.4 SCADA System Functional RequirementsDocument85 pages5.4 SCADA System Functional RequirementsYinwu ZhaoNo ratings yet

- 1376 Rekaguide To Usefor52 145kvDocument26 pages1376 Rekaguide To Usefor52 145kvparthaNo ratings yet

- Membrana - Pronal PDFDocument3 pagesMembrana - Pronal PDFWaldir GavelaNo ratings yet

- Marmaray TPS Project Contract CR1Document60 pagesMarmaray TPS Project Contract CR1Ismet Hizyolu100% (1)

- UntitledDocument53 pagesUntitledManosNo ratings yet

- Electrical & Automation Works For Raw Material Handling System at Tata Steel Limited - Kalinganagar ProjectDocument22 pagesElectrical & Automation Works For Raw Material Handling System at Tata Steel Limited - Kalinganagar ProjectkumarNo ratings yet

- Rtu - SasDocument19 pagesRtu - SasNitin KumarNo ratings yet

- PT Selection SchemeDocument1 pagePT Selection SchemeAnonymous UkDR2FBHTcNo ratings yet

- Technical Specification of Control CableDocument5 pagesTechnical Specification of Control CableBknboy PaliNo ratings yet

- Ae1172 Efa020 81mky01 116111 00Document1 pageAe1172 Efa020 81mky01 116111 00Mayur GuptaNo ratings yet

- SOR For Electrical Work - 9640Document16 pagesSOR For Electrical Work - 9640zarrar malikNo ratings yet

- I6s UPS Catalogue (Domestic)Document8 pagesI6s UPS Catalogue (Domestic)SagarNo ratings yet

- Discharge Detection using 'straight detectorsDocument10 pagesDischarge Detection using 'straight detectorsJoyson PereiraNo ratings yet

- KPTCL Pratap DTDocument34 pagesKPTCL Pratap DTGlyjojosephNo ratings yet

- Company Profile ARPSLDocument7 pagesCompany Profile ARPSLSharafat AliNo ratings yet

- Pix 2015Document44 pagesPix 2015Nuengruthai WeerawattanaNo ratings yet

- Matheran Rope-Way PDocument18 pagesMatheran Rope-Way Pnupur sanchetiNo ratings yet

- 33/22/11 KV GIS Switchgear SpecificationDocument52 pages33/22/11 KV GIS Switchgear SpecificationSOMU_61No ratings yet

- TransformersDocument43 pagesTransformersDavid LeviNo ratings yet

- Resume Sabir MoiduDocument9 pagesResume Sabir MoiduSABIRNo ratings yet

- Alstom BrochureDocument4 pagesAlstom BrochureRajeshBabuNo ratings yet

- 2021 May Intake Advert Revised 4Document2 pages2021 May Intake Advert Revised 4douglas0% (1)

- NEPCO Grid Code IRR-TIC 2015 - 07 - 16 v2 PDFDocument28 pagesNEPCO Grid Code IRR-TIC 2015 - 07 - 16 v2 PDFAta AtefNo ratings yet

- Test of 66 KV Incoming Line LA: 1) Insulation Resistance Test of LADocument2 pagesTest of 66 KV Incoming Line LA: 1) Insulation Resistance Test of LAArul KumarNo ratings yet

- Final GisDocument31 pagesFinal GiseliaseeeNo ratings yet

- ECP 11 0507 - Compact & Micro SS Comm ProcedureDocument6 pagesECP 11 0507 - Compact & Micro SS Comm ProcedureRahul Singania100% (1)

- Wide Area Measurement SystemDocument7 pagesWide Area Measurement SystemVIGNESH DHANASHEKHARNo ratings yet

- L1-CHE-SPE-034 Light & Power Isolation Transformers: Engineering Specification Electrical NetworksDocument12 pagesL1-CHE-SPE-034 Light & Power Isolation Transformers: Engineering Specification Electrical Networks4493464No ratings yet

- Schedule of Charges and Procedure PDFDocument58 pagesSchedule of Charges and Procedure PDFabhi...No ratings yet

- EPC bid document electrical equipment price summaryDocument64 pagesEPC bid document electrical equipment price summaryVimal Singh0% (1)

- S-TR-COM-LMS (Rev.0-2009)Document7 pagesS-TR-COM-LMS (Rev.0-2009)Ashutosh SharmaNo ratings yet

- Sascom1 Sse 2014 0034 02 1 A - 2 Kec Intl LTDDocument62 pagesSascom1 Sse 2014 0034 02 1 A - 2 Kec Intl LTDganesh_d2k6No ratings yet

- Meter Inspection and Maintenance: Distribution Maintenance Manual FORDocument10 pagesMeter Inspection and Maintenance: Distribution Maintenance Manual FORAmmar Lateef GakharNo ratings yet

- Hafincons 1yr PDFDocument1 pageHafincons 1yr PDFMuthazhagan SaravananNo ratings yet

- Easergy P3x3x - Instruction Manual - en - QS - D004 - Web - ANSIDocument40 pagesEasergy P3x3x - Instruction Manual - en - QS - D004 - Web - ANSIWalid DerradjiNo ratings yet

- Transformer Protection RET670: Exercise 1 - Differential Protection EngineeringDocument52 pagesTransformer Protection RET670: Exercise 1 - Differential Protection EngineeringRobert MihayoNo ratings yet

- Digital Flight Control Computer OFP Code TestingDocument155 pagesDigital Flight Control Computer OFP Code TestingAbha GuptaNo ratings yet

- Legend: 225Mw/337.5Mwp Ground Mounted Solar PV Project At, Vijayanagar KarnatakaDocument1 pageLegend: 225Mw/337.5Mwp Ground Mounted Solar PV Project At, Vijayanagar Karnatakaamit mitraNo ratings yet

- AMPP Construction, IncDocument44 pagesAMPP Construction, IncVishnu ShankerNo ratings yet

- FOX Solutions - Project Reference List PDFDocument16 pagesFOX Solutions - Project Reference List PDFOuseppachan AmbookenNo ratings yet

- Maintenenace Manual 23.01.17Document334 pagesMaintenenace Manual 23.01.17BD VERMANo ratings yet

- Mek6400 OmDocument345 pagesMek6400 OmduydonghtNo ratings yet

- 850 Professional IC: Anion - MCS - 2.850.2030Document122 pages850 Professional IC: Anion - MCS - 2.850.2030csmaues1No ratings yet

- S MVS Rmu33 - 00Document32 pagesS MVS Rmu33 - 00afsar.erNo ratings yet

- Sharingan ThesisDocument69 pagesSharingan Thesisprince asadNo ratings yet

- EE4T2 Electrical Measurements & InstrumentationDocument2 pagesEE4T2 Electrical Measurements & InstrumentationOluwamodupe EstherNo ratings yet

- Kenwood KVT 915Document98 pagesKenwood KVT 915Juan SolisNo ratings yet

- Price List: Cables With HTR (High Temperature Resistance)Document2 pagesPrice List: Cables With HTR (High Temperature Resistance)Amit MandalNo ratings yet

- CEG UPS Manul SharurahDocument242 pagesCEG UPS Manul SharurahQazi M Asim Wasim86% (7)

- SV4-8-3/3M - Solenoid ValveDocument2 pagesSV4-8-3/3M - Solenoid ValveJeremy JerezNo ratings yet

- Quiet Time GT-2 S User Guide V2 EnglishDocument24 pagesQuiet Time GT-2 S User Guide V2 EnglishDavid Levi BedenbaughNo ratings yet

- Delta Ia-Plc Ispsoft Um en 20150318Document657 pagesDelta Ia-Plc Ispsoft Um en 20150318Juliano SoaresNo ratings yet

- Crane Technical Data SheetDocument7 pagesCrane Technical Data Sheet98675No ratings yet

- Digital Signal Processing: EC303: September 22 2020Document35 pagesDigital Signal Processing: EC303: September 22 2020V Prakash SinghNo ratings yet

- Revisions Chapter 31Document5 pagesRevisions Chapter 31Agag HsgsNo ratings yet

- Esd Protection While Handling Leds: Application NoteDocument21 pagesEsd Protection While Handling Leds: Application NoteOrbán Norbert100% (1)

- DEA-640 CriticalPowerSolutionsBooklet EN Ed201708 PDFDocument100 pagesDEA-640 CriticalPowerSolutionsBooklet EN Ed201708 PDFcarlosmandopintoNo ratings yet

- CENTRAL WAREHOUSING CORPORATION ONLINE EXAMDocument15 pagesCENTRAL WAREHOUSING CORPORATION ONLINE EXAMRaja RamboNo ratings yet

- PIM Master MW82119A Sales Training - GoodDocument62 pagesPIM Master MW82119A Sales Training - GoodDo Ngoc AnhNo ratings yet

- MS 168B 1.0Document50 pagesMS 168B 1.0SinorneNo ratings yet

- Autonics Psan Series ManualDocument1 pageAutonics Psan Series ManualResaKandhyNo ratings yet

- Generator inspection checklistDocument2 pagesGenerator inspection checklistban-mrw CompaniesNo ratings yet

- LabVIEW Connect To HardwareDocument4 pagesLabVIEW Connect To HardwareAvneesh SinhaNo ratings yet

- D1052 DTS0040Document4 pagesD1052 DTS0040mojinjoNo ratings yet

- Fundamentals of HVDC and FACTS Devices Lecture NotesDocument48 pagesFundamentals of HVDC and FACTS Devices Lecture NotesIchigoNo ratings yet

- WDS Technology White Paper: Huawei Technologies Co., LTDDocument38 pagesWDS Technology White Paper: Huawei Technologies Co., LTDEric TsaiNo ratings yet

- User Guide SLF-H - 253255964-C - Ed.03Document178 pagesUser Guide SLF-H - 253255964-C - Ed.03jgsaliouNo ratings yet

- Service Manual: Downloaded From Manuals Search EngineDocument31 pagesService Manual: Downloaded From Manuals Search EnginerossiNo ratings yet

- Vibration Analysis of Motors in The Service Center: Part 7 Allows The Manufacturer ToDocument2 pagesVibration Analysis of Motors in The Service Center: Part 7 Allows The Manufacturer ToMuhammad Haris BaigNo ratings yet

- Ese ABB PDFDocument4 pagesEse ABB PDFJatinBatraNo ratings yet

- Config DolphinDocument3 pagesConfig DolphinFarhanNo ratings yet

- Lonworks in Brief PDFDocument21 pagesLonworks in Brief PDFRubens MartinsNo ratings yet

- The Secret of The Tesla Coils (Goran Marjanovic)Document17 pagesThe Secret of The Tesla Coils (Goran Marjanovic)THE NIKOLA TESLA INSTITUTE75% (12)

- TP SeriesDocument3 pagesTP SeriesPrasad KadamNo ratings yet

- 44 Cabin Systems PDFDocument40 pages44 Cabin Systems PDFAaron Harvey100% (3)