Professional Documents

Culture Documents

4226 Life Cycle Analysis Load Bearing Structures of High Rise Buildings in Western Europe

Uploaded by

Alisson CabreraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4226 Life Cycle Analysis Load Bearing Structures of High Rise Buildings in Western Europe

Uploaded by

Alisson CabreraCopyright:

Available Formats

ctbuh.

org/papers

Title: Life Cycle Analysis: Load-Bearing Structures Of High-Rise Buildings in

Western Europe

Authors:

Subjects: Architectural/Design

Conservation/Restoration/Maintenance

Publication Date: 2019

Original Publication: CTBUH Journal Issue III

Paper Type: 1. Book chapter/Part chapter

2. Journal paper

3. Conference proceeding

4. Unpublished conference paper

5. Magazine article

6. Unpublished

© Council on Tall Buildings and Urban Habitat /

Materials

Life Cycle Analysis: Load-Bearing Structures

Of High-Rise Buildings in Western Europe

Abstract

Authors

Gerran J. Lankhorst, Structural Engineer, Industry

The choice of structural system has a big influence on the environmental impact

& Buildings of structural materials in tall building design. This paper provides a comparison

Janko Arts, Associate Director and Consulting

Engineer, Industry & Buildings of the environmental impact of several structural systems for high-rise buildings.

Royal HaskoningDHV

George Hintzenweg 85 The environmental performance for relatively slender buildings in the range of

Rotterdam 3068 AX, the Netherlands

t: +31 88 348 22 23

150 to 250 meters in Western Europe is analyzed for five different types of

e: gerran.lankhorst@rhdhv.com structural systems in cast-in-situ concrete, precast concrete, and steel. The

royalhaskoningdhv.com

cradle-to-gate environmental impact was determined by using environmental

Karel C. Terwel, Assistant Professor, Structural

Design and Safety cost, an assessment method including 10 impact categories. Compared to tube

Henk M. Jonkers, Associate Professor, Sustainability

Group, Materials & Environment, Civil Engineering

structures, diagrid structures reduced the impact by 17-33% for the concrete

and Geosciences models and 28-41% for the steel models, due to reduction of material use.

Delft University of Technology

Delft, the Netherlands By using non-conventional structural systems such as diagrids, reductions in

t: +31 15 27 81 512

t: +31 15 27 86157 environmental impact can be achieved relatively easily.

e: communication-CiTG@tudelft.nl

tudelft.nl/en Keywords: Sustainability, Materials, Life Cycle, Carbon

Gerran Lankhorst is a Structural Engineer at

Royal HaskoningDHV and former DUT student in Introduction 2012). Figure 1 shows an overview of the life

Building Engineering, Structural Design. During his

studies and internship at Nikken Sekkei in Tokyo, he cycle stages of a building with definitions

developed skills and interests in tall building design, The built environment is a key contributor to per European standard EN 15804.

parametric modeling and sustainable structural

design. Lankhorst aims to tackle structural design global greenhouse gas emissions (Oldfield,

challenges with new computational technologies 2012), and buildings account for 30-40% of

and a multi-disciplinary approach.

all primary energy used worldwide (UNEP, Research Objective and Scope

Janko Arts is Associate Director and Consulting 2007). Therefore, the industry is researching

Engineer at Royal HaskoningDHV. He has performed

design activities for a broad range of buildings possible ways to reduce its environmental Research into the environmental impact of a

including high-rise buildings in Rotterdam (the Red impact. High-rise buildings have proven to wide range of stability systems for high-rise

Apple and First Rotterdam), Feyenoord City, large

naval projects in India and metro stations in Qatar. be a potential solution for reducing the building structures is limited. It is uncertain

As Associate Director, he manages a structural design environmental impact of construction whether the research by Trabucco et al.

and engineering team of 25-35 people. Arts carries

the qualification of registered structural engineer (Trabucco & Wood, 2016). (2016) is applicable in Western Europe. First,

(RO) in the Netherlands. the average height of high-rise buildings in

Karel Terwel is Assistant Professor Structural Design Most of the research conducted to date on Europe is typically lower than in North

and Safety at DUT and Consulting Engineer/Project improving sustainability of buildings has America and Asia. Second, regulations and

Leader at IMd Raadgevende Ingenieurs and has

performed design activities for various types of been focused on reducing operational local conditions are different. For example, a

buildings, including two governmental towers of 146 energy (OE), used for heating, cooling, hot rule regarding daylight penetration in the

meters in The Hague. His PhD thesis (2014) focused

on human and organizational factors influencing water, ventilation, etc. (Oldfield, 2012; Netherlands restricts the depth of office

structural safety. Terwel is vice-chair of TG5.1 Sarkisian, 2016; Trabucco & Wood, 2016). As floors to approximately 9 meters, resulting in

“Forensic Structural Engineering” of IABSE.

future buildings will be designed to net-zero slender buildings. Also, poor soil conditions

Henk Jonkers is Associate Professor of the energy standards, the impact of embodied in many parts of Western Europe result in

Sustainability Group within the Materials &

Environment section of the faculty of Civil energy (EE), used for production, building deflections caused by rotation of

Engineering and Geosciences at DUT. Jonkers construction, maintenance and demolition the foundation structure. Additionally,

obtained his PhD in Marine Microbiology at

Groningen University and currently researches of materials, will represent a significantly material production industries differ from

the development of innovative-, bio-based- and increasing part of the total impact (Trabucco those in North America, resulting in different

sustainable construction materials, such as self-

healing concrete. Furthermore, he is scientific advisor & Wood, 2016; Webster, 2004; Yohanis & environmental impacts due to the ratio of

of the DUT spinoff company Basilisk Concrete. Norton, 2002), possibly increasing up to fly-ash in cement or the ratio of blast to

100% (Sarkisian, 2016). The biggest part of electric-arc furnaces in steel production.

EE is caused by the predominant structural

materials used in tall buildings: concrete and The goal of this paper is to provide a

steel (Kaethner & Burridge, 2012; Oldfield, comparison of the environmental impact of

28 | Materials CTBUH Journal | 2019 Issue III

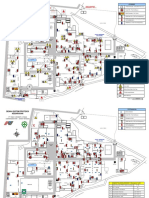

CRADLE GATE SITE GRAVE

PRODUCTION CONSTRUCTION USER PHASE DEMOLITION &

PHASE PHASE PROCESSING PHASE

A1–A3 A4–A5 B1–B7 C1–C4

Building & Installation Process

Extraction of Resources

Final Waste Treatment

Waste Treatment

Replacements

Maintenance

Renovations

Demolition

Production

Transport

Transport

Transport

Repair

Use

A1 A2 A3 A4 A5 B1 B2 B3 B4 B5 C1 C2 C3 C4

Operational Energy Use

B6

Operational Water Use

B7

Reuse

Recycle

Recovery

Landfill

BENEFITS/LOADS

D

Figure 1. Life cycle stages of a building, including the life cycle phases, represented by A1-D, according to EN 15804.

several structural systems for high-rise

“

buildings in the range of 150-250 meters

located in Western Europe. Five different Differences in daylight penetration

stability systems and three floor systems

were designed in cast-in-situ concrete, standards, soil conditions, material production

techniques, and generally lower heights

precast concrete and steel for three fictitious

office buildings in Rotterdam. All models

contained a concrete core, and the

foundation structure was excluded from the

suggest the importance of independently

study. The environmental impact was

calculated and analyzed according to the

studying European skyscrapers’ environmental

cradle-to-gate principle (production phase impact, beyond prior research conducted on

”

only, A1-A3) for 10 different impact

categories, using environmental cost (EC) as North American and Asian buildings.

the common indicator.

CTBUH Journal | 2019 Issue III Materials | 29

General Geometry

Structural Materials Height Zones

Cast-in-situ Concrete (C) Column dimensions and core wall thickness are tapered down over the

Precast Concrete (P) height by using the height Zones A to E.

Steel (S)

243.2 m Methodology

64 stories

Floor Systems Structural Design

Zone E

Flat Slab Floor (F) 197.6 m Three different building geometries were

52 stories

Hollow Core Slab Floor (H) considered with heights of 150, 200 and 250

Composite Floor (C) meters. The depth of the floors, 9 meters, was

Zone D

152.0 m based on daylight-entry regulations in the

40 stories

Material & Floor Combinations Netherlands. For these three building

Cast-in-situ Concrete + Zone C geometries, five different stability systems

Precast Concrete + were designed, based on the classifications

Steel + by Ali & Moon (2007): 1, rigid frame structure;

2, outrigger structure; 3, tube structure; 4,

Zone B

Model ID

braced-tube structure and 5, diagrid

#XY structure (see Figure 2). The stability systems

#= Nr. stability system (1 to 5) contained up to five sub-variations in

Zone A

X=Material (C, P or S) column spacing or diagrid configuration,

Y = Floor system (F, H or C) resulting in 15 different building structure

cases per height. All the modeled building

12.0 m 13.5 m 15.0 m

cases contained a structural concrete core,

since it also provides significant advantages

Width 30.0 m 31.5 m 33.0 m

for multiple functionalities.

Slenderness 5.1 6.3 7.4

GFA 36,000 m2 51,597 m2 65,340 m2

Three floor types (flat-slab floor, prestressed

hollow-core slab floor and composite floor),

Stability Systems and three different materials (cast-in-situ

concrete, precast concrete and steel) were

used, resulting in five possible material cases

for each possible building structure case.

1. Frame 2. Outrigger 3. Tube 4. Braced Tube 5. Diagrid Structures were designed according to the

Eurocode. Only wind loads were considered,

as there is no meaningful seismic activity in

the area. The influence of the foundation

structure on the global stiffness was

included by assuming that the foundation

structure was responsible for half of the total

building deflection at the top.

A total of 146 models were assessed. Due to

the high number of repetitive models, a

Connections Connections Connections Connections Connections

parametric and automated workflow was

Rigid Hinged Rigid Hinged Rigid developed and implemented. The workflow

consisted of linked models in Grasshopper,

Materials Materials Materials Materials Materials

Cast-in-situ Concrete Cast-in-situ Concrete Cast-in-situ Concrete Cast-in-situ Concrete Cast-in-situ Concrete Karamba and Excel for generating the

Precast Concrete Precast Concrete Precast Concrete Precast Concrete Precast Concrete geometry, performing the structural

Steel Steel Steel Steel Steel

analysis, optimizing the geometry, cross-

Variations Variations Variations Variations Variations sections and reinforcement, and performing

the life cycle analysis (LCA) respectively.

Structural optimization of the geometry was

achieved by generating and comparing

several sub-variations (such as varying

column spacing or selecting a diagrid

Figure 2. Overview of the used building geometry, floor systems, structural materials, stability systems, variations

and considered cases. configuration) on their environmental

30 | Materials CTBUH Journal | 2019 Issue III

Impact Categories & Corresponding Shadow Prices Impact Categories & Corresponding Shadow Prices

impact. Outrigger locations were optimized Example: Steel (S355)

for minimum global deflection using Shadow Price /

kg Equivalents / Shadow Price / Impact

algorithms. Cross-section dimensions and Impact Category Unit kg Equivalents

Impact Category (kg/kg) Category (€/kg)

(€/kg)

reinforcement quantities were optimized for

Abiotic Depletion kg Sb eq € 0.1600 x 5.21E-03 = € 0.0008

both local and global strength, and for

stiffness, aiming for unity checks of 0.8-0.9 in Global Warming (GWP100) kg CO2 eq € 0.0500 x 9.08E-01 = € 0.0454

the ultimate limit state. Ozone Layer Depletion (OCP) kg CFC-11 eq € 30.0000 x 1.55E-08 = € 0.0000

Human Toxicity kg 1,4-DB eq € 0.0900 x 3.33E-02 = € 0.0030

Life Cycle Analysis Fresh Water Aquatic Ecotox kg 1,4-DB eq € 0.0300 x 3.02E-03 = € 0.0001

The Fast Track LCA method was used in Marine Aquatic Ecotoxicity kg 1,4-DB eq € 0.0001 x 6.34E+00 = € 0.0006

this study, as it is considered advantageous

Terrestrial Ecotoxicity kg 1,4-DB eq € 0.0600 x 4.68E-04 = € 0.0000

for comparing design alternatives. It uses

Photochemical Oxidation kg C2H4 eq € 2.0000 x 3.30E-04 = € 0.0007

the data that is produced by a classical LCA

Acidification kg SO2 eq € 4.0000 x 3.38E-03 = € 0.0135

(the environmental impact of different

materials) as an input. The impact of the Eutrophication kg PO43- eq € 9.0000 x 3.74E-04 = € 0.0034 +

final product can then be determined Shadow Price S355 = € 0.0675

by quantifying the used materials in the

product, and scaling upward to determine Materials & Corresponding Example

their individual impacts. Environmental Impacts 200 m building using steel outrigger and hollow-core slab

Shadow Price Environmental Cost per

Material Mass Material (T)

Material (€/kg) Material (€)

The environmental impact in this research

C20/25 € 0.0073 x 7,028 = € 51,457

was quantified using EC, which is a Dutch

assessment method containing 10 C35/45 € 0.0075 x 12,798 = € 95,987

environmental impact categories (see Table C45/55 € 0.0082 x 15,892 = € 130,912

€ 20.00

1) and the following formulas. Each impact C55/67 € 0.0090 x0 =€0

category is assigned a factor, in euros, FEB500 € 0.2471 x 742 = € 183,276

which represents the fictional cost (shadow PT Steel € 0.6568 x 194 = € 127,148 € 15.00

price) required to bring its impact to a S355 € 0.0675 x 4,155 = € 280,446

sustainable level.

Steel Sheet € 0.1675 x0 =€0

€ 10.00

Fire Safety Material € 0.0692 x 428 = € 29,668 +

ECtotal = ∑(mmaterial;i ∙ SPmaterial;i )

Total Environmental Cost = € 898,894

SPmaterial;i = ∑(mimpact;i ∙ SPimpact;i ) € 5.00

Total Gross Floor Area (GFA) = 51,597 m2

ECtotal : total environmental cost of Total Environmental Cost

= 17.42 €/m2

per Square Meter GFA € 0.00

considered structure [€]

Table 1. Explanation of the shadow price concept, showing the different environmental impact categories, an

mmaterial;i : mass of material i in considered example calculation of the shadow price for steel, the used shadow prices for each material, and an example

calculation for the environmental impact of one model.

structure [kg]

SPmaterial;i : shadow price of material i per kg Eurocode criteria regarding strength and of the other life cycle phases. Further

material [€/kg] stiffness, which make them comparable with research is required to identify the

each other. The single indicator used was environmental impact of these phases for all

mimpact;i : mass of equivalent of impact environmental cost per square meter of 10 impact categories. End-of-life phase is

category i per kg material [kg/kg] gross floor area (EC/m2 GFA). This enables excluded because high-rise buildings are

comparison of the impacts of the different rarely demolished.

SPimpact;i : shadow price of equivalent of building height cases.

impact category i per kg equivalent [€/kg] Data about the environmental impact of the

The system boundaries are represented by materials was mainly obtained from the

The functional unit of this research is the the cradle-to-gate principle (production Dutch National Environmental Database

main load-bearing structure of the building. phase only, A1-A3). This is mainly due to the (NMD) (Stichting Bouwkwaliteit, 2014). An

The structures have the same function and choice of using EC as indicator, since there is exception was made for steel sections and

are designed according to the same no suitable or sufficient data of the impact sheets, which were retrieved from Bouwen

CTBUH Journal | 2019 Issue III Materials | 31

Total Environmental Cost/Area (€/m2) per Material Average Environmental Cost

of Floor Types/Area (€/m2)

€ 30,000

€ 12,00

€ 25,000

€ 20,000 € 10,00

150 Meters

€ 15,000

€ 10,000 € 8,00

€ 5,000

€ 6,00

€0

1CF 1CH 1PH 1SC 1SH 2CF 2CH 2PH 2SC 2SH 3CF 3CH 3PH 3SC 3SH 4SC 4SH 5PH 5SC 5SH

€ 4,00

€ 30,000

€ 25,000

€ 2,00

€ 20,000

200 Meters

€ 15,000 € 0,00

€ 10,000

€ 5,000

€0

1CF 1CH 1PH 1SC 1SH 2CF 2CH 2PH 2SC 2SH 3CF 3CH 3PH 3SC 3SH 4SC 4SH 5PH 5SC 5SH

€ 30,000

€ 25,000

€ 20,000

250 Meters

€ 15,000

€ 10,000

€ 5,000

€0

1CF 1CH 1PH 1SC 1SH 2CF 2CH 2PH 2SC 2SH 3CF 3CH 3PH 3SC 3SH 4SC 4SH 5PH 5SC 5SH

1. Frame 2. Outrigger 3. Tube 4. Braced 5. Diagrid

Tube

Key

Fire Safety Material Steel Plate S355 PT Steel FEB500 C55/67 C45/55 C35/45 C20/25

Figure 3. Results of the life cycle analysis for each case, broken down by impact per material, in environmental cost per square meter GFA, including the average environmental

impact of the three floor systems. Model IDs are explained in Figure 2.

met Staal (BmS), a Dutch steel branch Figure 4 and Table 2 show the results only a lower weight than the concrete models, but

organization (MRPI 2013a and 2013b). In for the models containing hollow-core slab the higher shadow price of steel yields a

fact, any European database can principally floors, and indicates the share of each higher total EC. The impacts of the cast-in-situ

be used for recalculation of the element type in the environmental impact concrete and precast concrete models are

environmental impact. The material of the model. Evaluating the results of the relatively similar.

quantities were automatically determined models with the same floor system enables

within the parametric workflow. comparison of the environmental Floor systems comprise the biggest share in

performance of the different stability the total environmental impact of the

systems and structural materials. building structure. Depending on the

Results and Discussion efficiency of the stability system, floors are

Steel models generally score 6-35% higher in responsible for 32-73% of the total

Figure 3 shows the results and indicates environmental impact than the environmental impact. Flat-slab floors show

the share of each material in the corresponding concrete models with the the highest environmental impact,

environmental impact of each model. same stability system. The steel models have composite floors are situated in the middle,

32 | Materials CTBUH Journal | 2019 Issue III

Total Environmental Cost/Area (€/m2) per Element Type

€ 30,000

€ 25,000

€ 20,000

150 Meters

€ 15,000 The braced-tube structure only reduces the

environmental impact of the models of 200 and

€ 10,000

250 meters by 7-12%, compared to the tube

€ 5,000 structures. This is due to the use of heavy belt

trusses to transfer vertical loads horizontally to

€0

1CH 1PH 1SH 2CH 2PH 2SH 3CH 3PH 3SH 4SH 5PH 5SH the corner columns. Changing the design

regarding vertical load distribution, e.g.,

€ 30,000 increasing the floor areas supported by the

corner columns by increasing column spacing,

€ 25,000

might lead to a higher material efficiency, and

€ 20,000 therefore a lower environmental impact.

200 Meters

€ 15,000

The two best-performing stability systems are

€ 10,000 the outrigger and diagrid structures. The

environmental impact of the concrete outrigger

€ 5,000 structures is 5-16% lower than that of the tube

€0

structures. For steel outrigger structures, the

1CH 1PH 1SH 2CH 2PH 2SH 3CH 3PH 3SH 4SH 5PH 5SH reduction is 20-26%. The diagrid structures

show the lowest environmental impact in both

€ 30,000

concrete and steel for each height. The

€ 25,000 reduction for the concrete models is 17-33%,

and for the steel models is 28-41%, compared

€ 20,000 to the tube structures in the same material.

250 Meters

€ 15,000

The better environmental performance of the

€ 10,000 outrigger and diagrid structures can be

€ 5,000

explained by mechanics. When subjected to

wind forces, structural elements in the rigid

€0 frame and tube structure are loaded in bending

1CH 1PH 1SH 2CH 2PH 2SH 3CH 3PH 3SH 4SH 5PH 5SH

to provide lateral stiffness. However, within the

outrigger and diagrid structure, the elements

are predominantly axially loaded. The axial

1. Frame 2. Outrigger 3. Tube 4. Braced Tube 5. Diagrid stiffness of a structural element is significantly

higher than the bending stiffness, which

Key

therefore results in a lower amount of required

Floors Core Beams Columns Outriggers/Belt-trusses/Braces

material and a lower environmental impact.

Figure 4. Results of the life cycle analysis, limited to cases with hollow-core slab floors, broken down for their impact

by element type, in EC/m2 GFA. Model IDs are explained in Figure 2.

Moreover, the results show increasing

differences in environmental impact between

and hollow-core slab floors have the lowest Using a tube structure resulted in a the different stability systems when building

impact. This indicates that using a lighter reduction of impact for the concrete height and slenderness increase. This indicates

floor system does not necessarily lead to a models of 5-11%, compared to the frame that the choice of stability system has an

lower environmental impact, which was also structures. This is due to better material increasing influence on the environmental

a finding by Foraboschi, Mercanzin & distribution for global stiffness. Long performance of the building structure as the

Trabucco (2014). rectangular cross-sections are used for building’s structural behavior becomes less stiff.

columns in the tube structures, instead of Consequently, a decreased foundation stiffness

When comparing the different stability the square sections used in frame due to poor soil conditions might have a

systems, the frame structures have the highest structures. For the steel tube structures, the magnifying effect on the differences in

environmental impacts. At 250 meters, it was environmental impact remains the same environmental impact between the different

impossible to design a frame structure that compared to frame structures. The tube stability systems. This is caused by more strict

would fulfill the strength, stiffness and design structures are taken as a reference for deflection criteria, because the foundation is

criteria for the determined building geometry further comparisons between different already responsible for a significant part of the

and soil conditions. stability systems, as shown in Table 2. permissible deflections.

CTBUH Journal | 2019 Issue III Materials | 33

Relative Results per Structural Material

1. Frame 2. Outrigger 3. Tube 4. Braced Tube 5. Diagrid

C 110% 95% 100%

150 Meters P 110% 95% 100% 83%

S 101% 80% 100% 99% 72% have a positive influence on the

C 109% 89% 100% environmental impact. According to

200 Meters P 113% 89% 100% 72% Sarkisian, on average, the impact of the

construction phase is twice as high for

S 99% 74% 100% 88% 60%

reinforced-concrete buildings as for steel

C 84% 100%

buildings (10% vs 20% of the total impact)

250 Meters P 86% 100% 67%

(Sarkisian & Shook, 2014). The construction

S 79% 100% 93% 59% phase has a significant influence on the total

Table 2. Relative performances of structural systems, showing the (in)efficiency of each, on the basis of its structural environmental impact of the structure. It is

material, compared to tube structures using the same material.

likely that the differences in environmental

impact between the steel and concrete

Factors of Influence environmental impact of the structure. models will be reduced by inclusion of the

Oldfield (2012) estimated this to be 28% for construction phase into the LCA.

A brief sensitivity analysis was performed on 30 St. Mary Axe, London. The weight of the

the shadow prices of concrete, reinforcement building generally plays a major role in the

steel and structural steel for the 200-meter foundation design: heavier buildings require Comparison with Literature

models. Fluctuations in shadow prices can heavier foundation structures. This could be

occur due to several circumstances, e.g., using beneficial for steel buildings, since these are A comparison is made with the 60-story

different material suppliers, different concrete lighter than concrete buildings, but rotation models of the research by Trabucco et al.

mix designs, etc. An increase/decrease of 25% stiffness of the foundation is a major factor (2016). These models have a gross floor area of

of the shadow prices of these materials leads and can govern strength in design. 141,600 square meters and are 246 meters in

to an increase/decrease of the gap between Therefore, it is unknown to what extent the height. Due to the large differences in

concrete and steel models, but does not lead gap between steel and concrete models geometry (significantly lower slenderness), it

to a scenario where the environmental impact could be reduced by inclusion of the was chosen to only compare the all-steel

of the steel models becomes the lowest. foundation structure. diagrid from Trabucco with the 250-meter

steel diagrid models with composite floors

Using older steel shadow prices originating The construction phase (A4-A5) is from this research. Global warming potential

from the NMD instead of BmS resulted in an accountable for approximately 10% to 25% of (GWP) was used as the only indicator, as EE is

enormous increase of 52-124% in the the total EC (Sarkisian & Shook, 2014). not listed in the NmD.

environmental impact of the steel models. One of the aspects within the construction

This shows that the Fast Track LCA method is a phase is transportation to the building site The total impact (A1-A5) of the all-steel

relatively simple, yet sensitive way to (A4). A sub-study was performed for the diagrid model of Trabucco is 243 kg CO₂/m²,

determine the environmental impact of 200-meter outrigger model, where the whereas the impact (A1-A3) of the 250-meter

building structures. More transparency is impact of transportation was determined. steel diagrid models of this research range

required from material suppliers and Default distances of 150 kilometers were from 185 to 212 kg CO₂/m2, which is 13-24%

databases to make fairer comparisons. used, except for cast-in-situ concrete and lower. This difference in impact has several

reinforcement steel, where 30 kilometers was explanations. Trabucco’s results include the

Reusing structural elements after building used. The results showed that for the construction phase, which is accountable for

demolition for construction of new buildings cast-in-situ concrete and steel models, 10-25% (Sarkisian & Shook, 2014). Also, the

has a high potential of reducing the transportation was accountable for 3.5% and model in this research contains a concrete

environmental impact of building structures. 2.4% of the total environmental impact core, which reduces the amount of required

Steel has a significant advantage over (A1-A4), respectively. For the precast concrete steel for lateral stiffness. Finally, the GWP

concrete in this regard, since it has a great model, transportation was accountable for values for steel used by Trabucco are 33%

potential for reuse. Considering reuse of steel 9.0%, due to the heavy weight and large higher in this research.

elements could lead to scenarios where the transportation distance.

steel models would become more favorable Trabucco et al. concluded that for the 60-story

over the concrete models in terms of The impact of the construction phase (A5) scenario the concrete models had the highest

environmental impact. This would require depends on several project-specific factors scores regarding GWP, while all-steel scenarios

developing demountable high-rise building (Cole, 1999). These factors also relate to had the highest EE. When only considering

structures and special demolition techniques. building erection speed. Construction of a GWP as indicator in this research, similar

building with prefabricated concrete or steel observations can be made as described

The foundation (or substructure) is elements is generally faster than constructing above: the steel models have a higher GWP

responsible for a large part of the a cast-in-situ concrete structure, which might than the concrete models. This contradicts the

34 | Materials CTBUH Journal | 2019 Issue III

FORABOSCHI, P.; MERCANZIN, M. & TRABUCCO, D. 2014.

conclusion by Trabucco that concrete In terms of stability systems, the frame and “Sustainable structural design of tall buildings based on

embodied energy.” Energy and Buildings. 68:254–269. doi:

models have the highest GWP values. tube structures lead to the highest cradle-to-

10.1016/j.enbuild.2013.09.003.

gate environmental impacts (A1-A3) for all

One possible reason for this contradiction is heights. The outrigger and diagrid structure KAETHNER, S. C. & BURRIDGE, J. A. 2012. “Embodied CO2 of

structural frames.” The Structural Engineer. May (5):33–40.

that the models in this research are result in the lowest environmental impacts for

ISSN 14665123.

significantly slenderer than those in all heights. Using an outrigger structure

Trabucco’s study. This means that structural decreases the impact by 5-16% for concrete MRPI. 2013a. “MRPI® sheet for heavy steel construction

products.” SGS INTRON-rapport R20110677, MRPI® van

elements are often designed for global and 20-26% for steel models, compared to the

constructiestaal. January 2012.

stiffness instead of strength capacity, tube structure. The diagrid structure has the

emphasizing the differences in stiffness of lowest impact for all examined heights and MRPI. 2013b. “MRPI® sheet for light steel construction

products.” SGS INTRON-rapport R20110677, MRPI® van

the stability systems. Poorer soil conditions reduces the impact by 17-28% for concrete

constructiestaal. January 2012.

have a similar effect, causing additional and 28-41% for steel models, compared to the

lateral deflection due to decreased rotational tube structure. OLDFIELD, P. 2012. “Embodied Carbon and High-Rise.” In

CTBUH 2012 9th World Congress, Shanghai. pages

stiffness of the foundation. Another reason

614–622.

can be found in the mix design of the Structural designers and engineers already

concrete. The average GWP values for have options for making a difference in SARKISIAN, M. 2016. “Designing Tall Buildings, Structure as

Architecture.” Routledge. New York, 2nd edition.

concrete used by Trabucco are 50-90% reducing the environmental impact of

higher than values used here. The concrete high-rise buildings. This research showed that SARKISIAN, M. & SHOOK, D. 2014. “Embodied Carbon in

mix designs used in the Netherlands are the choice of a structural system plays a major Structures and Cities.” 37th IABSE Symposium Madrid.

Volume 102, pages 3166–3173.

generally based on low-clinker-content role compared to the choice of a structural

cements (typically 30-50% clinker and more material when seeking to reduce the STICHTING BOUWKWALITEIT. 2017. Nationale

fly-ash, plus 50-70% ground granulated environmental impact of tall building Milieudatabase. Version 3.3, 2017

blast-furnace slag), which reduces the GWP structures in Western Europe. More

TRABUCCO, D. & WOOD, A. 2016. “LCA of tall buildings: Still

significantly. Another discrepancy might lie in importantly, by using less-obvious but already a long way to go.” Journal of Building Engineering.

Trabucco’s inclusion of transportation, existing design solutions for the considered 7:379–381. doi: 10.1016/j.jobe.2016.07.009.

construction and demolition, which could height range of 150-250 meters, like the

TRABUCCO, D. et al. 2016. “A Whole LCA of the Sustainable

have an equalizing effect between the diagrid structure, reductions in impact can be Aspects of Structural Systems in Tall Buildings Paper Type.”

impacts of the steel and concrete models. achieved relatively easily. International Journal of High-Rise Buildings. 5(2):71–86.

UNITED NATIONS. 2001. “Future World Population Growth

Unless otherwise noted, all image credits in this to be Concentrated in Urban Areas.” United Nations

Conclusions paper belong to the authors. Some images have Population Division Report, March.

been redrawn by CTBUH.

YOHANIS, Y. G. & NORTON, B. 2002. “Life-cycle operational

Steel models have a 6-35% higher cradle-to- and embodied energy for a generic single-storey office

gate impact (A1-A3) than the corresponding building in the UK.” Energy. 27:77–92. doi: 10.1016/

S0360-5442(01)00061-5.

concrete models. It is likely that inclusion of References

the construction phase and foundation ALI, M. & MOON, K. S. 2007. “Structural Developments in WEBSTER, M. D. 2004. “Relevance of structural engineers to

structure in the LCA leads to a decrease in Tall Buildings: Current Trends and Future Prospects.” sustainable design of buildings.” Structural Engineering

Architectural Science Review. 50(3):205–223. doi: International: Journal of the International Association for

the gap between the environmental impacts doi:10.3763/asre.2007.5027. Bridge and Structural Engineering (IABSE). 3:181–185. doi:

of the concrete and steel models. Regarding 10.2749/101686604777963874.

cast-in-situ versus precast concrete, no clear COLE, R. J. 1999. “Construction of Alternative Structural

Systems.” Building and Environment. 34:335-348.

winner can be appointed yet, as the

environmental impact scores are close.

Floor systems are responsible for the largest

“

part, 32-73%, of the total environmental

impact of high-rise building structures. For the cast-in-situ concrete and steel

Decreasing the impact of the stability system

increases the significance of reducing the models, transportation was accountable for

impact of floors. Using a lighter floor system

leads to a decreasing demand of material but

3.5% and 2.4% of the total environmental

does not necessarily lead to a lower total impact, respectively. For the precast concrete

”

environmental impact, due to the floor itself

having a big share of the total impact. model, that figure was 9.0%.

CTBUH Journal | 2019 Issue III Materials | 35

You might also like

- Asme A112.6.7-2001 PDFDocument16 pagesAsme A112.6.7-2001 PDFAmer AmeryNo ratings yet

- Astm C-270 PDFDocument13 pagesAstm C-270 PDFGita Tawankz100% (2)

- Carbon Footprint of Concrete Buildings Seen in The Life Cycle Perspective PDFDocument14 pagesCarbon Footprint of Concrete Buildings Seen in The Life Cycle Perspective PDFGoodson ChitsaNo ratings yet

- A Life Cycle Assessment Model For Evaluating The Environmental Impacts of Building Construction in Hong KongDocument9 pagesA Life Cycle Assessment Model For Evaluating The Environmental Impacts of Building Construction in Hong KongsamarafrancaNo ratings yet

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- High Temp Shearing Blind Rams Exceed API SpecsDocument2 pagesHigh Temp Shearing Blind Rams Exceed API Specscrni rokoNo ratings yet

- Heat Exchanger DesignDocument21 pagesHeat Exchanger DesignSaniha Aysha Ajith100% (1)

- 3D Printing in The Construction Industry - A Systematic Review of The Thermal Performance in BuildingsDocument13 pages3D Printing in The Construction Industry - A Systematic Review of The Thermal Performance in BuildingsAlfonzo SamudioNo ratings yet

- Journal of Cleaner Production: Yun Zhong, Peng WuDocument9 pagesJournal of Cleaner Production: Yun Zhong, Peng WuJohn Kayle BorjaNo ratings yet

- Relevance of Simplifications in LCA of Building ComponentsDocument8 pagesRelevance of Simplifications in LCA of Building ComponentsMônica CiríacoNo ratings yet

- Building and Environment: Rajib Sinha, Maria Lennartsson, BJ Orn FrostellDocument10 pagesBuilding and Environment: Rajib Sinha, Maria Lennartsson, BJ Orn FrostelllebronNo ratings yet

- Reliable Concrete Repair - A Critical ReviewDocument13 pagesReliable Concrete Repair - A Critical ReviewSheri DiĺlNo ratings yet

- Future Use of Life-Cycle Assessment in C PDFDocument9 pagesFuture Use of Life-Cycle Assessment in C PDFIndradi WijatmikoNo ratings yet

- 10.1007 - s11625 015 0342 4Document23 pages10.1007 - s11625 015 0342 4jrolfonNo ratings yet

- Roldán-Fontana2017 Article OptimizationOfCO2EmissionsInThDocument21 pagesRoldán-Fontana2017 Article OptimizationOfCO2EmissionsInThDrkumar SwamyNo ratings yet

- Nature-Inspired Optimization of Tubular Joints For Metal 3D PrintingDocument5 pagesNature-Inspired Optimization of Tubular Joints For Metal 3D PrintingAlper KzNo ratings yet

- 1 s2.0 S235271021830247X Main PDFDocument13 pages1 s2.0 S235271021830247X Main PDFAbrar Sameer M BaamerNo ratings yet

- Environmental Life Cycle Assessment of A PDFDocument14 pagesEnvironmental Life Cycle Assessment of A PDFIndradi WijatmikoNo ratings yet

- Innovations-2023!1!3 Sustainability and Application of Life Cycle Assessment in Welded StructuresDocument3 pagesInnovations-2023!1!3 Sustainability and Application of Life Cycle Assessment in Welded StructuresElisaveta DoncevaNo ratings yet

- Applying LCA to Improve Sustainability in Welded StructuresDocument3 pagesApplying LCA to Improve Sustainability in Welded StructuresElisaveta DoncevaNo ratings yet

- Assessment of The Environmental Impacts of Bridge Designs Involving UHPFRCDocument19 pagesAssessment of The Environmental Impacts of Bridge Designs Involving UHPFRCHarry KinyanjuiNo ratings yet

- Road ConstructionDocument10 pagesRoad ConstructionducioxNo ratings yet

- Comparative Material-Based Life Cycle Analysis of StructuralDocument15 pagesComparative Material-Based Life Cycle Analysis of StructuralSamantha KriegNo ratings yet

- Strategic Progress in Foam Stabilisation Towards High-Performance Foam Concrete For Building Sustainability - A State-Of-The-Art ReviewDocument27 pagesStrategic Progress in Foam Stabilisation Towards High-Performance Foam Concrete For Building Sustainability - A State-Of-The-Art ReviewDm EerzaNo ratings yet

- A_Review_of_the_Performance_and_Benefits_of_Mass_TDocument24 pagesA_Review_of_the_Performance_and_Benefits_of_Mass_TRehema KabareNo ratings yet

- IJCRT2012094Document3 pagesIJCRT2012094Engr. Abu Mohammad SamsuddinNo ratings yet

- Life Cycle Design and Prefabrication in Buildings A Review and Case Studies in PDFDocument8 pagesLife Cycle Design and Prefabrication in Buildings A Review and Case Studies in PDFMASILAMANI TNo ratings yet

- Building Information Modeling-Based Model For Calculating Direct and Indirect Emissions in Construction ProjectsDocument13 pagesBuilding Information Modeling-Based Model For Calculating Direct and Indirect Emissions in Construction ProjectsRong BernardNo ratings yet

- LCA Oftallbuildings:stillalongwaytogoDocument3 pagesLCA Oftallbuildings:stillalongwaytogoNicolas Pardo AlvarezNo ratings yet

- 2023 - Yi Liu - Carbon Emission Based Life Cycle Assessment of Rural ResidentialDocument19 pages2023 - Yi Liu - Carbon Emission Based Life Cycle Assessment of Rural Residentialdoni erlanggaNo ratings yet

- Impact of prefabrication technology on the cradle‑to‑site CO2Document16 pagesImpact of prefabrication technology on the cradle‑to‑site CO2ramtin hajirezaeiNo ratings yet

- SBM (Life Cycle, EoL)Document9 pagesSBM (Life Cycle, EoL)Priom ZarrahNo ratings yet

- 1 s2.0 S1877705815010826 MainDocument8 pages1 s2.0 S1877705815010826 MainRockstar AnilNo ratings yet

- 1 s2.0 S2352710219313415 MainDocument10 pages1 s2.0 S2352710219313415 MainvalberNo ratings yet

- Buildings 12 00404 v2Document42 pagesBuildings 12 00404 v2Maira Rafaela PenazzoNo ratings yet

- Building and Environment: Carine Lausselet, Vilde Borgnes, Helge Brattebø TDocument11 pagesBuilding and Environment: Carine Lausselet, Vilde Borgnes, Helge Brattebø THarneet KaurNo ratings yet

- 1 s2.0 S2352710223021630 MainDocument16 pages1 s2.0 S2352710223021630 Mainferlya98angNo ratings yet

- High Strength Concrete For Sustainable Construction: D.wu11@ugrad - Unimelb.edu - AuDocument9 pagesHigh Strength Concrete For Sustainable Construction: D.wu11@ugrad - Unimelb.edu - AuĐinh Tiến ĐạtNo ratings yet

- 1 s2.0 S2210670714000055 MainDocument6 pages1 s2.0 S2210670714000055 MainjrolfonNo ratings yet

- Rtcebe: Wong Jing Xian, Mohammad Soffi MD NohDocument9 pagesRtcebe: Wong Jing Xian, Mohammad Soffi MD NohSrinivas TanigantiNo ratings yet

- Balasbaneh Et Al., 2018Document13 pagesBalasbaneh Et Al., 2018Fernanda LagoNo ratings yet

- A Review of Direct and Indirect Emission PAPERDocument15 pagesA Review of Direct and Indirect Emission PAPERIntern at TechnogreenNo ratings yet

- Opher 2021Document16 pagesOpher 2021Aline Caiado MachadoNo ratings yet

- Sensors: Cement-Based Piezoelectric Ceramic Composites For Sensing Elements: A Comprehensive State-of-the-Art ReviewDocument29 pagesSensors: Cement-Based Piezoelectric Ceramic Composites For Sensing Elements: A Comprehensive State-of-the-Art ReviewtasaddaqYounasNo ratings yet

- Bioclimatic Architecture As The Main Part of Green BuildingDocument8 pagesBioclimatic Architecture As The Main Part of Green BuildingSOFIA PRISCILLA TORRES LOPEZNo ratings yet

- Examining The Role of Structural Enginee PDFDocument13 pagesExamining The Role of Structural Enginee PDFabudabeejajaNo ratings yet

- Irjet V7i248Document2 pagesIrjet V7i248Manjuladevi PNo ratings yet

- Innovative Technologies For Recycling End of Life - 2020 - Resources ConservatDocument12 pagesInnovative Technologies For Recycling End of Life - 2020 - Resources Conservatluis fernandoNo ratings yet

- Demountable Construction For Sustainable BuildingsDocument9 pagesDemountable Construction For Sustainable BuildingsimroicohNo ratings yet

- PPR 4Document10 pagesPPR 4Shreya KulkarniNo ratings yet

- Building Lifespan Effect On The Environmental Impact of Building Components in A Danish PerspectiveDocument22 pagesBuilding Lifespan Effect On The Environmental Impact of Building Components in A Danish PerspectiveIced Orca-FinNo ratings yet

- An Investigation of Physico-Mechanical Properties of Some Chosen Concrete Mixtures by Ultrasonic Pulse Velocity (UPV) TechniquesDocument4 pagesAn Investigation of Physico-Mechanical Properties of Some Chosen Concrete Mixtures by Ultrasonic Pulse Velocity (UPV) TechniquesCIVIL ENGINEERINGNo ratings yet

- Circular Economy Potential Within The Building StockDocument11 pagesCircular Economy Potential Within The Building StockTudor Ioan PopescuNo ratings yet

- Inventory Analysis of LCA On Steel - and Concrete-Construction Office BuildingsDocument6 pagesInventory Analysis of LCA On Steel - and Concrete-Construction Office BuildingsXavierEstrellaNo ratings yet

- Reduccion de Huella de CarbonDocument14 pagesReduccion de Huella de CarbonAndrey Gamboa RuedaNo ratings yet

- The Role of Building Construction Materials On Global Warming Lessons For ArchitectsDocument4 pagesThe Role of Building Construction Materials On Global Warming Lessons For ArchitectsSáñthôsh KúmãrNo ratings yet

- 7 Lee2019 PDFDocument11 pages7 Lee2019 PDFAnders AguilarNo ratings yet

- 1 s2.0 S2352710218310994 MainDocument19 pages1 s2.0 S2352710218310994 MainJulian Leonardo AcevedoNo ratings yet

- Optimization of Reinforced Concrete Columns According To Different Environmental Impact Assessment ParametersDocument10 pagesOptimization of Reinforced Concrete Columns According To Different Environmental Impact Assessment ParametersParth TrivediNo ratings yet

- IJTech CVE 1104 Improving Project Performance and Waste ReductionDocument11 pagesIJTech CVE 1104 Improving Project Performance and Waste ReductionLuthfi Wahyu PratamaNo ratings yet

- Research On Sustainability of Building MaterialsDocument6 pagesResearch On Sustainability of Building MaterialsVaishnavi J RamNo ratings yet

- 328829581Document12 pages328829581Archibold KganyagoNo ratings yet

- 9 482 Couto 14Document13 pages9 482 Couto 14张文卓No ratings yet

- Journal of Building Engineering: SciencedirectDocument17 pagesJournal of Building Engineering: SciencedirectShimizu KokuruNo ratings yet

- Geohazards and Pipelines: State-of-the-Art Design Using Experimental, Numerical and Analytical MethodologiesFrom EverandGeohazards and Pipelines: State-of-the-Art Design Using Experimental, Numerical and Analytical MethodologiesNo ratings yet

- 3079 An Overview of Structural Aesthetic Developments in Tall Buildings Using Exterior Bracing Diagrid SystemsDocument22 pages3079 An Overview of Structural Aesthetic Developments in Tall Buildings Using Exterior Bracing Diagrid SystemsalokNo ratings yet

- 3079 An Overview of Structural Aesthetic Developments in Tall Buildings Using Exterior Bracing Diagrid SystemsDocument22 pages3079 An Overview of Structural Aesthetic Developments in Tall Buildings Using Exterior Bracing Diagrid SystemsalokNo ratings yet

- 3079 An Overview of Structural Aesthetic Developments in Tall Buildings Using Exterior Bracing Diagrid SystemsDocument22 pages3079 An Overview of Structural Aesthetic Developments in Tall Buildings Using Exterior Bracing Diagrid SystemsalokNo ratings yet

- The Emergence of The Diagrid - It's All About The NodeDocument13 pagesThe Emergence of The Diagrid - It's All About The NodeVilas BhuwadNo ratings yet

- Surface Symmetries The Smith House Revis PDFDocument22 pagesSurface Symmetries The Smith House Revis PDFAlisson CabreraNo ratings yet

- CIVE 1160 IndeterminateTorsion ExamplesDocument17 pagesCIVE 1160 IndeterminateTorsion ExamplesAnonymous ee5dOjNo ratings yet

- Hydrostatic Extrusion, Theory and ApplicationsDocument6 pagesHydrostatic Extrusion, Theory and ApplicationsKarthik SholayNo ratings yet

- Carrier 50TCM SeriesDocument44 pagesCarrier 50TCM SeriesJojo FernandezNo ratings yet

- IDENTIFIKASI SUMBER BAHAYA DI TEMPAT KERJA PT INDO VENEER UTAMADocument19 pagesIDENTIFIKASI SUMBER BAHAYA DI TEMPAT KERJA PT INDO VENEER UTAMAAjiWidyartaNo ratings yet

- 2 - Stress, Strain - Axial LoadDocument58 pages2 - Stress, Strain - Axial LoadPhước Trần NguyênNo ratings yet

- 3D plate bending example: sheet pile wallDocument2 pages3D plate bending example: sheet pile wallJim Jakson MboeNo ratings yet

- 1.EPV NORTH SEA Exploded PartviewDocument45 pages1.EPV NORTH SEA Exploded PartviewPSC RFQNo ratings yet

- !indx DWG IDocument23 pages!indx DWG IAmolNo ratings yet

- Investigatory Project On Prep of CementDocument9 pagesInvestigatory Project On Prep of CementKrish JaiswalNo ratings yet

- InstructiuniDocument72 pagesInstructiuniRobert ColțaNo ratings yet

- ChillersDocument7 pagesChillersBRANDONNo ratings yet

- Bridge Design To Eurocodes - UK ImplementationDocument11 pagesBridge Design To Eurocodes - UK ImplementationMarekNo ratings yet

- Sub Engineer Civil MCQDocument14 pagesSub Engineer Civil MCQGowrishankarNo ratings yet

- GTT Mark III PlaquetteDocument4 pagesGTT Mark III PlaquetteAlexandros HatzisNo ratings yet

- Special Specification 4604 Stay CablesDocument15 pagesSpecial Specification 4604 Stay CablesAbok Cai NginumNo ratings yet

- 12 09 SdsteelDocument3 pages12 09 SdsteelBogdan BuzaianuNo ratings yet

- Fosroc Expandafoam Closed Cell TDSDocument2 pagesFosroc Expandafoam Closed Cell TDSsattar12345No ratings yet

- LM25 Aluminium Casting Alloy PropertiesDocument3 pagesLM25 Aluminium Casting Alloy Propertiesdaniel_sasikumarNo ratings yet

- Optimal Performance-Based Design of FRP Jackets For Seismic Retrofit of Reinforced Concrete FramesDocument14 pagesOptimal Performance-Based Design of FRP Jackets For Seismic Retrofit of Reinforced Concrete FramesPhilip Amsal Apriano GintingNo ratings yet

- 6-Graficos Correccion DTML IntercambiadoresDocument13 pages6-Graficos Correccion DTML IntercambiadoresLeandroNo ratings yet

- S75 Catalog Eng PDFDocument8 pagesS75 Catalog Eng PDFsixtoNo ratings yet

- STRENGTH OF BASE BLOCK DURING ERECTIONDocument3 pagesSTRENGTH OF BASE BLOCK DURING ERECTIONShubham BhamareNo ratings yet

- Learn Steel 2007 Limit State Design of Structural Steel MembersDocument31 pagesLearn Steel 2007 Limit State Design of Structural Steel MembersshaikcivilNo ratings yet

- Biaxial cyclic deformation behaviour of steelsDocument14 pagesBiaxial cyclic deformation behaviour of steelsDavid C Houser100% (1)