Professional Documents

Culture Documents

Welding Procedure Specification (WPS)

Uploaded by

Mohamad Marwan HamwiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS)

Uploaded by

Mohamad Marwan HamwiCopyright:

Available Formats

Welding Procedure Specification (WPS)

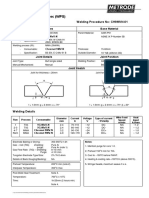

Welding Procedure No: CH9MVN-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P91

- Consumable: 9CrMoV-N ASME IX P-Number 5B

BS EN: W CrMo 91

- Specification:

AWS: ER90S-B9

Welding process (fill): MMA (SMAW)

- Consumable: Chromet 9MV-N Thickness: 15-60mm

- Specification: BS EN, E CrMo 91 B Outside Diameter: 16″ NB (406mm OD)

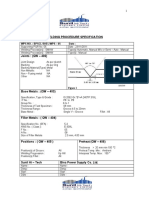

Joint Details Joint Position

Joint Type: Butt single sided Welding Position: ASME: 5G

Manual/Mechanised: Manual BS EN: PF

Joint Sketch

Joint for thickness < 20mm Joint for thickness > 20mm

α β

f g f g

f = 1-3mm; g = 2-4mm; α = 70° f = 1-3mm; g = 2-4mm; α = 70°; β = 20°

Welding Details

Diameter Current Voltage Type of current Wire Feed Heat

Run Process Consumable Speed Input

mm A V / Polarity

m/min kJ/mm

1 TIG 9CrMoV-N 2.4 70-110 ~12 DC- NA ~1.2

2-3 TIG 9CrMoV-N 2.4 80-140 ~12 DC- NA ~ 1.2

4-7 MMA Chromet 9MV-N 3.2 90-130 ~24 DC+ NA ~ 1.0

Rem MMA Chromet 9MV-N 4.0 120-170 ~25 DC+ NA ~ 1.2

o

Electrode Baking or Drying: 300-350 C/1-2h Notes:

Gas – root (TIG) shielding: Pure Ar

1. Maintain purge for runs 1-3.

purge: Pure Ar (note 1)

Gas Flow Rate (TIG) – Shielding: 8-15 l/min o

2. Preheat 150 C min for TIG.

Purge: 4-10 l/min

o

Tungsten Electrode Type/Size: 2% Th/2.4mm 3. Cool to ~100 C before PWHT.

o

Details of Back Gouging/Backing: NA 4. Heating & cooling rate <100 C/h (above 300°C).

o

Preheat Temperature: 200 C min (note 2) 5. Stringer beads, maximum weave 3 x ø.

o

Interpass Temperature: 300 C max

Post-Weld Heat Treatment: Note 3.

o o

Temperature: 760 C ± 10 C

Time: 1h/25mm (2 hours min)

Note 4.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

Welding Procedure Specification (WPS)

Welding Procedure No: CH9MVN-02

Consumables Base Material

Welding process (root): NA Parent Material: A335 A217 C12A ((cast)

- Consumable: - ASME IX P-Number 5B

- Specification: -

Welding process (fill): MMA (SMAW)

- Consumable: Chromet 9MV-N Thickness: 15-60mm

- Specification: BS EN, E CrMo 91 B Outside Diameter: -

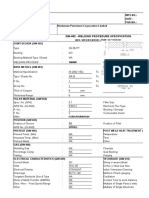

Joint Details Joint Position

Joint Type: Butt/groove Welding Position: ASME, 1G

Manual/Mechanised: Manual BS EN, PA

Joint Sketch

R =8-12mm; α = 20-30°

Welding Details

Diameter Current Voltage Type of current Wire Feed Heat

Run Process Consumable Speed Input

mm A V / Polarity

m/min kJ/mm

MMA Chromet 9MV-N 3.2 90-135 ~23 DC+ NA ~ 1.2

MMA Chromet 9MV-N 4.0 130-180 ~24 DC+ NA ~ 1.4

MMA Chromet 9MV-N 5.0 160-240 ~25 DC+ NA ~ 1.8

o

Electrode Baking or Drying: 300-350 C/1-2h Notes:

Gas – root (TIG) shielding: NA o

1. Cool to ~100 C before PWHT.

purge: NA

Gas Flow Rate (TIG) – Shielding: NA o

2. Heating & cooling rate <100 C/h (above 300°C).

Purge: NA

Tungsten Electrode Type/Size: NA

Details of Back Gouging/Backing: NA

o

Preheat Temperature: 200 C min

o

Interpass Temperature: 300 C max

Post-Weld Heat Treatment: Note 1.

o o

Temperature: 745 C ± 10 C

Time: 8 hours

Note 2.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

Welding Procedure Specification (WPS)

Welding Procedure No: CH9B9-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P91

- Consumable: 9CrMoV-N ASME IX P-Number 5B

- Specification: AWS ER90S-B9 (note 1).

Welding process (fill): MMA (SMAW)

- Consumable: Chromet 9-B9 Thickness: 15-60mm

- Specification: AWS E9015-B9 (note 2). Outside Diameter: 16″ NB (406mm OD)

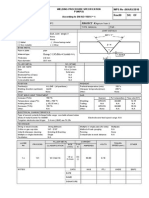

Joint Details Joint Position

Joint Type: Butt single sided Welding Position: ASME, 5G

Manual/Mechanised: Manual BS EN, PF

Joint Sketch

Joint for thickness < 20mm Joint for thickness > 20mm

α β

f g f g

f = 1-3mm; g = 2-4mm; α = 70° f = 1-3mm; g = 2-4mm; α = 70°; β = 20°

Welding Details

Diameter Current Voltage Type of current Wire Feed Heat

Run Process Consumable Speed Input

mm A V / Polarity

m/min kJ/mm

1 TIG 9CrMoV-N 2.4 70-110 ~12 DC- NA ~ 1.2

2-3 TIG 9CrMoV-N 2.4 80-140 ~12 DC- NA ~ 1.2

4-7 MMA Chromet 9-B9 3.2 90-130 ~24 DC+ NA ~ 1.0

Rem MMA Chromet 9-B9 4.0 120-170 ~25 DC+ NA ~ 1.2

o

Electrode Baking or Drying: 300-350 C/1-2h Notes:

Gas – root (TIG) shielding: Pure Ar

1. ASME IX, QW-432 F-number 4.

purge: Pure Ar (note 3)

Gas Flow Rate (TIG) – Shielding: 8-15 l/min

2. ASME IX, QW-442 A-number 5.

Purge: 4-10 l/min

Tungsten Electrode Type/Size: 2% Th/2.4mm 3. Maintain purge for runs 1-3.

o

Details of Back Gouging/Backing: NA 4. Preheat 150 C min for TIG.

o o

Preheat Temperature: 200 C min (note 4) 5. Cool to ~100 C before PWHT.

o o

Interpass Temperature: 300 C max 6. Heating & cooling rate <100 C/h (above 300°C).

Post-Weld Heat Treatment: Note 5.

o o

Temperature: 760 C ± 10 C

Time: 1h/25mm (2 hours min)

Note 6.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

Welding Procedure Specification (WPS)

Welding Procedure No: CMM91-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P91

- Consumable: 9CrMoV-N ASME IX P-Number 5B

- Specification: BS EN: W CrMo 91

Welding process (fill): MIG (GMAW)

- Consumable: Cormet M91 (MCW) Thickness: 15-60mm

- Specification: AWS: ER90C-G Outside Diameter: -

Joint Details Joint Position

Joint Type: Butt single sided Welding Position: ASME, 1G

Manual/Mechanised: Manual BS EN, PA

Joint Sketch

Joint for thickness < 20mm Joint for thickness > 20mm

α β

f g f g

f = 1-3mm; g = 2-4mm; α = 70° f = 1-3mm; g = 2-4mm; α = 70°; β = 20°

Welding Details

Diameter Current Voltage Type of current Wire Feed Heat

Run Process Consumable Speed Input

mm A V / Polarity

m/min kJ/mm

1–5 TIG 9CrMoV-N 2.4 70-110 ~12 DC- NA ~1.2

- MCW Cormet M91 1.2 240-280 ~28 DC+ (note 1) ~10 ~ 1.6

- MCW Cormet M91 1.6 270-330 ~29 DC+ (note 2) ~7 ~ 2.0

Electrode Baking or Drying: NA Notes:

Gas – (Cormet M91) shielding: Ar-2.5%CO2

1. Electrode stickout 10-20mm.

purge: Ar

Gas Flow Rate – Shielding: 15-25 l/min

2. Electrode stickout 15-25mm.

Purge: 4-10 l/min

o

Tungsten Electrode Type/Size: 2% Th/2.4mm 3. Preheat 150 C min for TIG.

o

Details of Back Gouging/Backing: NA 4. Cool to ~100 C before PWHT.

o o

Preheat Temperature: 200 C min (note 3) 5. Heating & cooling rate <100 C/h (above 300°C).

o

Interpass Temperature: 300 C max

Post-Weld Heat Treatment: Note 4.

o o

Temperature: 760 C ± 10 C

Time: 1h/25mm (2 hours min)

Note 5.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

Welding Procedure Specification (WPS)

Welding Procedure No: SCF91-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P91

- Consumable: 9CrMoV-N ASME IX P-Number 5B

- Specification: AWS: ER90S-B9 Thickness: 15-60mm

Welding process (fill): MMA Joint Details

- Consumable: Chromet 9MV-N Joint Type: Single side butt weld

- Specification: AWS: E9015-B9 Manual/Mechanised: Manual

Welding process (fill): FCAW Joint Position

- Consumable: Supercore F91 (Note 1) Welding Position: ASME: 6G

- Specification: _ BS EN: HL045

Joint Sketch Welding Sequences

f g

f = 1-2mm; g = 3-4mm; α = 75°; β = 10-20°

Welding Details

Diameter Current Voltage Type of Wire Feed Heat

Run Process Consumable current / Speed Input

mm A V

Polarity m/min kJ/mm

1 TIG 9CrMoV-N 2.4 80-120 ~12 DC- NA ~1.4

2-6 MMA Chromet 9MV-N 3.2 90-110 ~22 DC+ NA ~1.0

Fill FCW Supercore F91 1.2 160-190 25-27 DC+ (Note 2) ~6-8 ~1.2

Electrode Baking or Drying: 300-350°C/1-2h Notes:

Gas – root (TIG) shielding: Argon

1. Shielding gas Ar-20%CO2 at 15-25 l/min.

purge: Argon (Note 3)

Gas Flow Rate (TIG) – Shielding: 8-12 l/min

2. Electrode stickout 15-25mm.

Purge: 4-10 l/min

Tungsten Electrode Type/Size: 2% Th / 2.4mm 3. Maintain purge for at least first two runs.

Details of Back Gouging/Backing: NA 4. Preheat 150°C min for TIG.

Preheat Temperature: 200°C min (note 4) 5. Cool to ~100°C before PWHT.

Interpass Temperature: 300°C 6. Heating & cooling rate <100°C/h (above 300°C).

Post-Weld Heat Treatment: Note 5.

Temperature: 760°C ± 10°C

Time: 1 h/25mm (min 3 hours)

Note 6.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

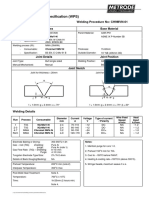

Welding Procedure Specification (WPS)

Welding Procedure No: SAW-P91-01

Consumables Base Material

Welding process (root): TIG (GTAW) Parent Material: A335 P91 ASME IX P-No. 5B

- Consumable: 9CrMoV-N Thickness: 25-75mm

- Specification: BS EN, W CrMo 91 Outside diameter:

Welding process (hot pass): MMA (SMAW) Joint Details

- Consumable: Chromet 9MV-N Joint Type: Butt single sided

- Specification: BS EN E CrMo 91 B Manual/Mechanised: Manual & mechanised

Welding process (fill): SAW Joint Position

- Consumable: 9CrMoV-N + LA491 (flux) Welding Position: ASME, 1G (1GR; note 6).

- Specification: BS EN S CrMo 91 (wire). BS EN, PA (note 6).

Joint Sketch

f g

f = 1–3mm; g = 2-4mm; α = 70°; β = 20°

Welding Details

Diameter Current Voltage Type of Travel Heat

Run Process Consumable current / Speed Input

mm A V

Polarity mm/min kJ/mm

1 TIG 9CrMoV-N 2.4 70-110 ~12 DC- NA ~ 1.0

2-3 TIG 9CrMoV-N 2.4 80-140 ~12 DC- NA ~ 1.2

4-7 MMA Chromet 9MV-N 3.2 90-130 ~24 DC+ NA ~ 1.2

Rem SAW (note 1) 9CrMoV-N 2.4 350-450 ~30 DC+ 400-500 ~ 2.0

o

Electrode & Flux Drying: 300-350 C/1-2h Notes:

Gas – root (TIG) shielding: Pure Ar

1. SAW flux LA491.

purge: Pure Ar (note 2)

Gas Flow Rate (TIG) – Shielding: 8-15 l/min

~20mm wire extension, ~30mm flux depth.

Purge: 4-10 l/min

Tungsten Electrode Type/Size: 2% Th/2.4mm 2. Maintain purge for runs 1-3.

o

Details of Back Gouging/Backing: NA 3. Preheat 150 C min for TIG.

o o

Preheat Temperature: 200 C min (note 3) 4. Cool to <100 C before PWHT.

o o

Interpass Temperature: 300 C max 5. Heating & cooling rate <100 C/h (above 300°C).

Post-Weld Heat Treatment: Note 4. 6. For rotated pipe, head to be 10° before TDC

o o

Temperature: 760 C ± 10 C perpendicular to pipe.

Time: 1h/25mm (2 hours min)

Note 5.

c:\my documents\technical\welding procedure specifications\tr884 wps.doc

You might also like

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Welding SA210 GR CDocument2 pagesWelding SA210 GR Cabet_singkong8930No ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 pageEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNo ratings yet

- Pbx100xa-Mm eDocument2 pagesPbx100xa-Mm ewegaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- Is-4696-1 2004Document7 pagesIs-4696-1 2004ofajNo ratings yet

- BCH Electric Ltd-Limit Switch-CatalogueDocument6 pagesBCH Electric Ltd-Limit Switch-CataloguesachmayaNo ratings yet

- ST 37Document7 pagesST 37rendra.farisrNo ratings yet

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533No ratings yet

- Esab Buddy TIG400iDocument2 pagesEsab Buddy TIG400iJeganeswaranNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- NPCIL Tube Fitting SpecificationsDocument22 pagesNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Data Table For Grades Tool Die Steels SKD-11Document3 pagesData Table For Grades Tool Die Steels SKD-11Adhi candra irawanNo ratings yet

- OCS Prel WPS 007Document2 pagesOCS Prel WPS 007vinothNo ratings yet

- Paint Specification SheetDocument1 pagePaint Specification Sheetheru firmansyah100% (1)

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerDocument118 pagesTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenNo ratings yet

- Helium leak test procedureDocument7 pagesHelium leak test procedureChandrasekhar mishraNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Fire Test Certificate SummaryDocument1 pageFire Test Certificate SummaryjajakaNo ratings yet

- Standard 2 5 5 8: Object IndexDocument9 pagesStandard 2 5 5 8: Object IndexanhthoNo ratings yet

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- SOLENOID VALVE ASCO LowPower - Gseries - R8 PDFDocument14 pagesSOLENOID VALVE ASCO LowPower - Gseries - R8 PDFNUR AFIFAHNo ratings yet

- WPS - 2Document3 pagesWPS - 2aleventNo ratings yet

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- Overallstructure PDFDocument11 pagesOverallstructure PDFChhoan NhunNo ratings yet

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- API 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryDocument3 pagesAPI 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryBilel NajjarNo ratings yet

- PFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFDocument8 pagesPFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFfatapia74No ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Pwps 06Document1 pagePwps 06eldobie3No ratings yet

- Weld History SheetDocument2 pagesWeld History SheetAjin S100% (1)

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- LE B-255 H4R: ClassificationDocument2 pagesLE B-255 H4R: ClassificationVivien EmeraldoNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaNo ratings yet

- QAP CondenserDocument3 pagesQAP CondenserisaacNo ratings yet

- 07 SMAW 332 18 532 332 E7018 Prequalified WPSsDocument82 pages07 SMAW 332 18 532 332 E7018 Prequalified WPSsErick VazquezNo ratings yet

- American Light Screw Socket Thread Specification SheetDocument19 pagesAmerican Light Screw Socket Thread Specification SheetJuan C Poza100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Poster DIN EN 1090-1 ENG Final PDFDocument1 pagePoster DIN EN 1090-1 ENG Final PDFlth770310No ratings yet

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- 6 MM TCDocument1 page6 MM TCpranesh kadamNo ratings yet

- WPS - Api 5L X52 - Codigo Api1104Document1 pageWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNo ratings yet

- Design and Analysis of Disc Plate in Hot Blast Valve #DN1800Document8 pagesDesign and Analysis of Disc Plate in Hot Blast Valve #DN1800MounicaRasagyaPallaNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Welding Procedure Specifications for P91 Butt WeldsDocument6 pagesWelding Procedure Specifications for P91 Butt WeldssrinivasanNo ratings yet

- السلسلة 1 & 8 خصائص وتركيب كيميائيDocument4 pagesالسلسلة 1 & 8 خصائص وتركيب كيميائيMohamad Marwan HamwiNo ratings yet

- Research Article: Laser Beam Welding of AA5052, AA5083, and AA6061 Aluminum AlloysDocument10 pagesResearch Article: Laser Beam Welding of AA5052, AA5083, and AA6061 Aluminum AlloysMohamad Marwan HamwiNo ratings yet

- Callister - Fundamentals of Materials Science and Engineering 5e HQDocument2 pagesCallister - Fundamentals of Materials Science and Engineering 5e HQsathwikNo ratings yet

- b 557m - 02 عينة الشد المستطيلةDocument19 pagesb 557m - 02 عينة الشد المستطيلةMohamad Marwan HamwiNo ratings yet

- b 557m - 02 عينة الشد المستطيلةDocument19 pagesb 557m - 02 عينة الشد المستطيلةMohamad Marwan HamwiNo ratings yet

- Aluminum Welding PDFDocument9 pagesAluminum Welding PDFAnilNo ratings yet

- Inspection of Unfired Pressure VesselsDocument35 pagesInspection of Unfired Pressure Vesselstbmari100% (7)

- Aws A5.3Document28 pagesAws A5.3ahmedNo ratings yet

- Stainless Steel International StandardsDocument3 pagesStainless Steel International StandardsAmir MusaibNo ratings yet

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- Carbon Equivalent (Ce) Composition Parameter (PCM)Document9 pagesCarbon Equivalent (Ce) Composition Parameter (PCM)Arif Budi JatmikoNo ratings yet

- ASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFDocument2 pagesASM Handbook, Vol 01 - Properties and Selection - Irons, Steels, and High Performance Alloys PDFCésar Santana50% (4)

- Steel and Pipes For Africa Price ListDocument1 pageSteel and Pipes For Africa Price ListG A U G E100% (3)

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Document36 pages'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Vinoth KannanNo ratings yet

- Types of Welding ElectrodesDocument2 pagesTypes of Welding ElectrodeschittineniNo ratings yet

- 4 Selectarc Tig 308l 309l Et 316l FT Web AnglaisDocument1 page4 Selectarc Tig 308l 309l Et 316l FT Web Anglaisamir moniriNo ratings yet

- 90deg Elbow (Long, Short)Document40 pages90deg Elbow (Long, Short)IvyNo ratings yet

- Selection of Welding RodDocument5 pagesSelection of Welding RodbalaeNo ratings yet

- Equivalent Materials ChartDocument3 pagesEquivalent Materials Chartarianaseri100% (1)

- Stick ElectrodeDocument1 pageStick Electroderizviabbas2012No ratings yet

- Staircase Design: For Landings Span at Right Angles To The Stairs, Ie. Landings Become The Supporting MembersDocument45 pagesStaircase Design: For Landings Span at Right Angles To The Stairs, Ie. Landings Become The Supporting MembersvivekNo ratings yet

- Equivalences - Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKDocument3 pagesEquivalences - Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKIsaac IglesiasNo ratings yet

- Italian Submersible Pumps and Motors Manufacturer Since 1906Document286 pagesItalian Submersible Pumps and Motors Manufacturer Since 1906Diana NietoNo ratings yet

- Steel Making Process RoutesDocument7 pagesSteel Making Process Routespkn_pnt9950No ratings yet

- T-PUT Voestalpine Roll-Bonded Clad PlatesDocument8 pagesT-PUT Voestalpine Roll-Bonded Clad PlatesVăn Trường LêNo ratings yet

- Astm - JisDocument7 pagesAstm - Jisvalli rajuNo ratings yet

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Page 0014Document1 pagePage 0014has sasNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- Welding Electrode CalculationDocument2 pagesWelding Electrode CalculationSarwarNo ratings yet

- Design of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Document100 pagesDesign of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Cesar MigoNo ratings yet

- RTFI For WeldingDocument60 pagesRTFI For WeldingMAXX ENGINEERSNo ratings yet

- Melal Courq and odih RAM MUTHYALA Welding Processes ComparisonDocument9 pagesMelal Courq and odih RAM MUTHYALA Welding Processes Comparisonanurag danielNo ratings yet

- WELD REPAIR PROCEDURES FOR BOILER COMPONENTSDocument165 pagesWELD REPAIR PROCEDURES FOR BOILER COMPONENTSLakshmi Narayan100% (2)

- ABS Approved Still Mill PDFDocument84 pagesABS Approved Still Mill PDFJanuar Target Willyam0% (1)

- 1Document4 pages1Anonymous 6MI1wMNo ratings yet