Professional Documents

Culture Documents

Section Views Objectives: 8.1.1 Section Views Are Used For Three Main Purposes

Uploaded by

Aldrin VillanuevaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section Views Objectives: 8.1.1 Section Views Are Used For Three Main Purposes

Uploaded by

Aldrin VillanuevaCopyright:

Available Formats

Section View Engineering Drawing and Plans

CHAPTER VIII

SECTION VIEWS

Objectives

After studying the material in this chapter, you should be able to:

Understand sections and cutting-plane lines.

Apply correct section-lining practices.

Recognize and draw section lining for 10 different materials.

Identify some types of sections.

Interpret drawings that include section views.

8.1 Section Views

8.1.1 Section views are used for three main purposes:

To document the design and manufacture of single parts that is manufactured as one piece.

To document how multiple parts are to be assembled or built.

To aid in visualizing the internal workings of a design.

8.1.2 Full Sections

When the part is cut fully in half, the resulting view is called a full section, as shown in Figure 8.1.

Fig 8.1. Slicing a Single Part.

8.1.3 The Cutting Plane

A line called the cutting-plane line provides the information necessary for understanding

where the part was cut.

The arrows at the ends of the cutting-plane line indicate the direction of sight for the section

view, as shown in Figure 8.2.

The arrows point toward the section being viewed as shown in Figures 8.2 and 8.3, not away

from it, as in Figure 8.4.

Tarlac State University | B111L Aldrin Joar. Taduran 1

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

Fig 8.2 Front and Right-Side View in Full Section. Using a section view makes it easier to see

interior details.

Fig 8.3 Cutting-plane Line Indicates Direction of Sight

8.4 Arrows should not point to removed portion.

Tarlac State University | B111L Aldrin Joar. Taduran 2

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

8.2 Rules for Lines in Section Views

When creating section views follow these general rules:

Show edges and contours that are now visible behind the cutting plane; otherwise a section will

appear to be made up of disconnected and unrelated parts.

Omit hidden lines in section views. Section views are used to show interior detail without a

confusion of hidden lines, so add them only if necessary to understand the part.

Sometimes hidden lines are necessary for clarity and should be used in such cases, especially if

their use will make it possible to omit a view (Figure 8.5d).

A sectioned area is always completely bounded by a visible outline—never by a hidden line,

because in every case the cut surfaces will be the closest surface in the section view and

therefore their boundary lines will be visible (Figure 8.5e).

In a section view of an object, the section lines in all hatched areas for that object must be

parallel, not as shown in Figure 8.5f. The use of section lining in opposite directions is an

indication of different parts, as when two or more parts are adjacent in an assembly drawing.

A visible line can never cross a sectioned area in a view of a single part. This would be

impossible on the full section of a single part because the section lines are all in the same plane.

A line across it would indicate a change of plane (Figure 8.5g). In an assembly section, this

would be possible. You will learn about assemblies later in the chapter.

Fig 8.5 Right and Wrong Lines in Section Views

Tarlac State University | B111L Aldrin Joar. Taduran 3

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

8.3 Section-Lining Technique

The correct method of drawing section lines is shown in Figure 8.6a.

When drawing by hand, use a sharp, medium grade pencil (H or 2H) to draw uniformly thin

section lines, or hatching (a term meaning closely spaced parallel lines).

There should be a marked contrast between the thin section lines and the thick visible outlines of

the part.

Draw section lines at 45° from horizontal unless they would be parallel or perpendicular to major

edges of the part, in which case use a different angle.

Figure 8.6b shows an example of section lines drawn at a different angle to prevent them from

being parallel or perpendicular to visible outlines.

Space the lines as evenly as possible by eye (for most drawings, about 2.5 mm (110″) apart).

The spacing interval depends on the size of the drawing or of the sectioned area, with larger

drawings having wider spacing.

In a smaller drawing the spacing interval may be as small as 1.5 mm (116″); in a large drawing,

it may be 3 mm (18″) or more.

As a rule, space the lines as generously as possible; yet close enough to clearly distinguish the

sectioned areas.

Keep extension lines and dimension values off sectioned areas. If there is no alternative, omit the

section lines behind the dimensions (Figure 8.6c).

Tarlac State University | B111L Aldrin Joar. Taduran 4

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

Fig 8.6 Correct and Incorrect Section-Lining Technique

8.4 Section-Lining Symbols

Section-lining symbols (Figure 8.7) may be used to indicate specific materials.

A detailed specification listing the material must be lettered in the form of a note or in the title

strip.

The general-purpose section lining (which is the same as that for cast iron) may be used to

represent any material on the detail drawing for a single part.

Using different section-lining patterns helps you distinguish different materials, especially on

assembly drawings, but it is acceptable to use the general-purpose symbol shown at different

angles for different parts.

Tarlac State University | B111L Aldrin Joar. Taduran 5

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

Fig 8.7 Symbols for Section Lining

8.5 Broken out Sections

It often happens that only a partial section of a view is all that is needed to expose interior

shapes. Such a section, limited by a break line, is called a broken out section.

In Figure 8.8, a full or half section is not necessary, and a small broken out section is sufficient to

explain the construction.

Fig 8.8 Broken Out Section

Tarlac State University | B111L Aldrin Joar. Taduran 6

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

8.6 Aligned Sections

Figure 8.9 shows an aligned section.

The cutting plane was bent to pass through the angled arm and then revolved to a vertical

position (aligned), from where it was projected across to the section view.

The angle of revolution should always be less than 90° for an aligned section.

Do not revolve features when the clarity of your drawing is not improved.

Fig 8.9 Aligned Section

8.7 Assembly Sections

Section views are often used to create assembly drawings.

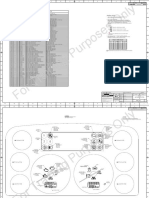

Figure 8.10 shows an orthographic drawing for an assembly.

Notice that the hatching on different parts varies; it has a different hatch pattern or is hatched at a

different angle.

On the same part, the hatching is always at the same angle to help you recognize the parts easily.

Solid features that do not have interior structure are not hatched.

Tarlac State University | B111L Aldrin Joar. Taduran 7

College of Engineering and Technology Aldrin M. Villanueva

Section View Engineering Drawing and Plans

Fig 8.10 Assembly Section (Courtesy of Wood’s Power-Grip Co., Inc.)

Reference:

F. E. Giesecke, et. al., 2016, Technical Drawing with Engineering Graphics, 5th Ed. Pearson Education,

Inc., Publishing as Prentice Hall.

Tarlac State University | B111L Aldrin Joar. Taduran 8

College of Engineering and Technology Aldrin M. Villanueva

You might also like

- p94-1738 Instrumentation t2000Document6 pagesp94-1738 Instrumentation t2000AaronNo ratings yet

- MITSUBISHI Elevator PDFDocument12 pagesMITSUBISHI Elevator PDFBirhami AkhirNo ratings yet

- Working Drawing GuideDocument63 pagesWorking Drawing GuideLhen Mediante AsuncionNo ratings yet

- Introduction To Electricity 1.1Document23 pagesIntroduction To Electricity 1.1August DuqueNo ratings yet

- Section ViewsDocument43 pagesSection ViewsTechnical UETiansNo ratings yet

- Graphic Expression and Communication: in This Unit You Will Learn The Answers To These QuestionsDocument24 pagesGraphic Expression and Communication: in This Unit You Will Learn The Answers To These QuestionsEduardo u100% (2)

- Engineering Drawing Module 3Document8 pagesEngineering Drawing Module 3Aldrin VillanuevaNo ratings yet

- Engineering DrawingDocument25 pagesEngineering DrawingElena Edna100% (1)

- Design an App or Website Using Figma for UI/UXDocument68 pagesDesign an App or Website Using Figma for UI/UXAldrin VillanuevaNo ratings yet

- Design an App or Website Using Figma for UI/UXDocument68 pagesDesign an App or Website Using Figma for UI/UXAldrin VillanuevaNo ratings yet

- Technical Drawing Manual IntroductionDocument138 pagesTechnical Drawing Manual IntroductionSamson ManyanyeNo ratings yet

- 3 View Orthographic DrawingDocument3 pages3 View Orthographic DrawingMuhammad FitriNo ratings yet

- Engineering Drawing by Jhole, Chapter 01Document32 pagesEngineering Drawing by Jhole, Chapter 01Abhishek KumarNo ratings yet

- Alphabet of Lines: The Backbone of DraftingDocument9 pagesAlphabet of Lines: The Backbone of DraftingCedrick DyNo ratings yet

- Engineering Drawing ModuleDocument8 pagesEngineering Drawing ModuleAldrin Villanueva100% (3)

- Engineering Drawing FundamentalsDocument9 pagesEngineering Drawing FundamentalsAldrin Villanueva100% (2)

- Lecture 1 Part OneDocument78 pagesLecture 1 Part Onewubied100% (1)

- Collateral Asset DefinitionsDocument116 pagesCollateral Asset Definitionsapi-3748391100% (2)

- ISOMETRICDocument39 pagesISOMETRICKaustubh MallikNo ratings yet

- Basic Engineering DrawingDocument38 pagesBasic Engineering DrawingVignesh SelvarajNo ratings yet

- Codex AlexandrinusDocument294 pagesCodex AlexandrinusHevel Cava100% (2)

- Instructional Module ComponentsDocument5 pagesInstructional Module ComponentsHenry ContemplacionNo ratings yet

- Charcoal Briquet Ting Technology in The Province of Aurora, PhilippinesDocument18 pagesCharcoal Briquet Ting Technology in The Province of Aurora, PhilippinesEutiquio Rotaquio100% (8)

- RR 2016 VolIV E A5Document546 pagesRR 2016 VolIV E A5Aldrin VillanuevaNo ratings yet

- Engineering Graphics Chapter 6Document63 pagesEngineering Graphics Chapter 6aemychangminNo ratings yet

- "Disaster Readiness and Risk Reduction": Test 2 True or FalseDocument2 pages"Disaster Readiness and Risk Reduction": Test 2 True or FalseMiki AntonNo ratings yet

- Exercise 1 Orthographic Projection Isometric Views UNiMDocument6 pagesExercise 1 Orthographic Projection Isometric Views UNiMljtldidiNo ratings yet

- Engineering Drawing Line Types and SymbolsDocument7 pagesEngineering Drawing Line Types and SymbolsAldrin Villanueva100% (1)

- Rr2016 Vol II Ea5Document814 pagesRr2016 Vol II Ea5Aldrin VillanuevaNo ratings yet

- Department of Transport Engineering and Technology Engineering Drawing MEU 07102Document64 pagesDepartment of Transport Engineering and Technology Engineering Drawing MEU 07102Fahad Khalef Al Barwan100% (1)

- Engineering Dimensioning GuideDocument22 pagesEngineering Dimensioning GuideAldrin VillanuevaNo ratings yet

- Engineering Drawing Course OutlineDocument2 pagesEngineering Drawing Course OutlineAbiyu Alemayehu100% (1)

- Technical Drawing PDFDocument71 pagesTechnical Drawing PDFrsalvasanNo ratings yet

- Technical Sketching WorksheetsDocument17 pagesTechnical Sketching WorksheetsnezutronNo ratings yet

- Tutorial 3 PDFDocument2 pagesTutorial 3 PDFsantoNo ratings yet

- Draw Die Design by SivapapachariDocument11 pagesDraw Die Design by SivapapachariSiva ChariNo ratings yet

- List of Mechanical Components for Engineering DrawingDocument2 pagesList of Mechanical Components for Engineering DrawingMuhammad KhalilNo ratings yet

- Engineering Drawing Course OverviewDocument27 pagesEngineering Drawing Course OverviewAhmad JuttNo ratings yet

- ME-109 Engineering DrawingDocument40 pagesME-109 Engineering DrawingHaadin ZamanNo ratings yet

- Drawing LayoutDocument6 pagesDrawing LayoutwelwelNo ratings yet

- Engineering Drawing & WorkshopDocument126 pagesEngineering Drawing & WorkshopAtthapol YuyaNo ratings yet

- Engineering Drawing Question - pdf-21Document14 pagesEngineering Drawing Question - pdf-21gidlavinayNo ratings yet

- 1.2.2 Types of Lines and Letters Part 2Document25 pages1.2.2 Types of Lines and Letters Part 2ethan philasia100% (1)

- Sakthi 1 Tancet - Engineering Mathematics-2011Document8 pagesSakthi 1 Tancet - Engineering Mathematics-2011Asp CoolNo ratings yet

- 1 Engineering DrawingDocument4 pages1 Engineering DrawingRovil BeridoNo ratings yet

- Intro To Technical DrawingDocument15 pagesIntro To Technical DrawingIman SatriaNo ratings yet

- Workbook Eng Draw PDFDocument69 pagesWorkbook Eng Draw PDFHarry Voltaire MorteraNo ratings yet

- Mod 3 BDocument19 pagesMod 3 BVinay H ShivannaNo ratings yet

- Engineering Drawing Form 4 (Quadrilaterals)Document14 pagesEngineering Drawing Form 4 (Quadrilaterals)farah sakinah100% (1)

- ES 114ea Engineering DrawingsDocument3 pagesES 114ea Engineering DrawingsMelchor Jaramilla OronosNo ratings yet

- Concise for Research Paper TemplateDocument3 pagesConcise for Research Paper TemplateCharlyne Mari FloresNo ratings yet

- Orthographic Projection With Scaling and Dimensions Engineering DrawingDocument33 pagesOrthographic Projection With Scaling and Dimensions Engineering DrawingKent Lewis GornezNo ratings yet

- Auto CAD Lab Practice Set 1Document4 pagesAuto CAD Lab Practice Set 1Techno India UniversityNo ratings yet

- Drafting Tools GuideDocument4 pagesDrafting Tools GuideAJNo ratings yet

- MME 1211 Engineering Drawing Course Outline-StudentsDocument3 pagesMME 1211 Engineering Drawing Course Outline-StudentsSarang Hae IslamNo ratings yet

- 1.drawing Instruments and AccessoriesDocument5 pages1.drawing Instruments and AccessoriesAbdul JabbarNo ratings yet

- JE Pictorial Drawing NoteDocument14 pagesJE Pictorial Drawing NoteGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Engineering Drawing Chapter 5 Auxiliary ViewsDocument25 pagesEngineering Drawing Chapter 5 Auxiliary ViewsTeshome Bekele100% (1)

- Auxiliary View LessonDocument23 pagesAuxiliary View LessonYonas YGNo ratings yet

- Sample Midterm Problems - Engineering Graphics in DesignDocument5 pagesSample Midterm Problems - Engineering Graphics in Designmaterial manNo ratings yet

- Engineering Drawing-II Book for Diploma StudentsDocument9 pagesEngineering Drawing-II Book for Diploma StudentsJithesh.k.sNo ratings yet

- GENG 111 - Lecture 05 - Orthographic ProjectionDocument38 pagesGENG 111 - Lecture 05 - Orthographic ProjectionNaeem NasserNo ratings yet

- 005.00 Multiview DrawingDocument42 pages005.00 Multiview DrawinghaniebalmNo ratings yet

- Notes For Projection of Points and LinesDocument14 pagesNotes For Projection of Points and LinesShantam Sinha100% (1)

- Engineering Drawing Form 4 (Circles)Document12 pagesEngineering Drawing Form 4 (Circles)farah sakinahNo ratings yet

- SectioningDocument7 pagesSectioningIamINNo ratings yet

- Advantages of CAD Over Conventional Drawing Techniques (Assignnet 1)Document9 pagesAdvantages of CAD Over Conventional Drawing Techniques (Assignnet 1)Firdaus Khan100% (1)

- Engineering DrawingDocument1 pageEngineering DrawingDreamtech PressNo ratings yet

- Workshop Manual 15wsl24 PDFDocument94 pagesWorkshop Manual 15wsl24 PDFZiyauddin SeikhNo ratings yet

- Machine Design Lab SyllabusDocument24 pagesMachine Design Lab SyllabusMohammed KhaleelNo ratings yet

- Lect 14 HO #1 - SectionsDocument19 pagesLect 14 HO #1 - SectionsAram IbrahimNo ratings yet

- Job planning and process preparationDocument11 pagesJob planning and process preparationNiza JamilNo ratings yet

- Activity No 1Document1 pageActivity No 1Aldrin VillanuevaNo ratings yet

- Tarlac State University Electronics Engineering Program ObjectivesDocument3 pagesTarlac State University Electronics Engineering Program ObjectivesAldrin VillanuevaNo ratings yet

- 43 Ecep331l Digital Electronics 1 Logic Circuits and Switching Theory LaboratoryDocument3 pages43 Ecep331l Digital Electronics 1 Logic Circuits and Switching Theory LaboratoryAldrin VillanuevaNo ratings yet

- Rr2016vol IeDocument440 pagesRr2016vol IePuput Adi SaputroNo ratings yet

- B313Document2 pagesB313Aldrin VillanuevaNo ratings yet

- RR2016 Vol IIIEDocument568 pagesRR2016 Vol IIIEPuput Adi SaputroNo ratings yet

- 43 Ecep331l Digital Electronics 1 Logic Circuits and Switching Theory LaboratoryDocument3 pages43 Ecep331l Digital Electronics 1 Logic Circuits and Switching Theory LaboratoryAldrin VillanuevaNo ratings yet

- Engineering Drawing Module 7Document8 pagesEngineering Drawing Module 7Aldrin VillanuevaNo ratings yet

- Course Code Course Title Date Effective: Date Revised: Prepared By: Approved By: Page No.Document4 pagesCourse Code Course Title Date Effective: Date Revised: Prepared By: Approved By: Page No.Aldrin VillanuevaNo ratings yet

- Course Code Course Title Date Effective: Date Revised: Prepared By: Approved By: Page No.Document2 pagesCourse Code Course Title Date Effective: Date Revised: Prepared By: Approved By: Page No.Aldrin VillanuevaNo ratings yet

- Engineering Drawing Module 6Document6 pagesEngineering Drawing Module 6Aldrin VillanuevaNo ratings yet

- Kinematics in One DimensionDocument4 pagesKinematics in One DimensionAldrin VillanuevaNo ratings yet

- OIDA ImprovedcarbonizerDocument15 pagesOIDA ImprovedcarbonizerAldrin VillanuevaNo ratings yet

- 66 - 10285 - EC341 - 2011 - 1 - 2 - 1 - CH.3 Electric FluxDocument21 pages66 - 10285 - EC341 - 2011 - 1 - 2 - 1 - CH.3 Electric Fluxjoticamario123No ratings yet

- Smart Gold Fish Eggs Nursery With MicrocontrollerDocument6 pagesSmart Gold Fish Eggs Nursery With MicrocontrollerAldrin VillanuevaNo ratings yet

- Smart Gold Fish Eggs Nursery With MicrocontrollerDocument6 pagesSmart Gold Fish Eggs Nursery With MicrocontrollerAldrin VillanuevaNo ratings yet

- Smart Fish Pond For Economic Growing in Catfish FarmingDocument5 pagesSmart Fish Pond For Economic Growing in Catfish FarmingAldrin VillanuevaNo ratings yet

- Impulse and MomentumDocument4 pagesImpulse and MomentumAldrin VillanuevaNo ratings yet

- E-Learning - Learning For Smart GenerationZ-Dr.U.S.pandey, Sangita RawalDocument2 pagesE-Learning - Learning For Smart GenerationZ-Dr.U.S.pandey, Sangita RawaleletsonlineNo ratings yet

- bài tập ôn MA1Document34 pagesbài tập ôn MA1Thái DươngNo ratings yet

- Digital Marketing - Scope Opportunities and Challenges - IntechOpen PDFDocument31 pagesDigital Marketing - Scope Opportunities and Challenges - IntechOpen PDFPratsNo ratings yet

- 9A01709 Advanced Structural Analysis PDFDocument8 pages9A01709 Advanced Structural Analysis PDFReddy Kiran KDNo ratings yet

- Energy Loss in Pipe and Fitting 1.0 ObjectiveDocument5 pagesEnergy Loss in Pipe and Fitting 1.0 Objectivefaku lolipopNo ratings yet

- Understanding Social Problems - PPTDocument21 pagesUnderstanding Social Problems - PPTaneri patel100% (1)

- BE InstallGuide RooftopSeries12R ZXDocument80 pagesBE InstallGuide RooftopSeries12R ZXAlexandreau del FierroNo ratings yet

- Behaviour of Rectangular Travelling Wave (Unit Step Function at Transition Points-Typical CasesDocument1 pageBehaviour of Rectangular Travelling Wave (Unit Step Function at Transition Points-Typical CasesAngela VaughnNo ratings yet

- Tests On Educational Interest and Its ImpactDocument2 pagesTests On Educational Interest and Its ImpactSusan BenedictNo ratings yet

- Cisco UCS 5108 Server Chassis Hardware Installation GuideDocument78 pagesCisco UCS 5108 Server Chassis Hardware Installation GuidemicjosisaNo ratings yet

- ARIA JumpChainDocument52 pagesARIA JumpChainDorothy FeelyNo ratings yet

- Detailed Lesson PlanDocument7 pagesDetailed Lesson PlanPrecious BuenafeNo ratings yet

- Answer Sheet ToeicDocument2 pagesAnswer Sheet ToeicNgọc PhanNo ratings yet

- User's Manual: 2.5" External Hard DriveDocument26 pagesUser's Manual: 2.5" External Hard DriveMathew PhilipNo ratings yet

- Range Brochure Wardrobes 2012Document23 pagesRange Brochure Wardrobes 2012Uci DutzuNo ratings yet

- KETRACO Clarifies Technical Queries for 400kV Transmission ProjectDocument5 pagesKETRACO Clarifies Technical Queries for 400kV Transmission Projectahmadove1No ratings yet

- How Computer Viruses Work and How to Prevent InfectionDocument4 pagesHow Computer Viruses Work and How to Prevent InfectionVishal guptaNo ratings yet

- Adrenergic SystemDocument6 pagesAdrenergic SystemdocsNo ratings yet

- Strategic Cost ManagementDocument3 pagesStrategic Cost ManagementShubakar ReddyNo ratings yet

- Tamil Nadu Govt Form for Testing Lab EMDocument4 pagesTamil Nadu Govt Form for Testing Lab EMPraveenNo ratings yet

- Designing An LLC ResonantDocument30 pagesDesigning An LLC Resonant劉品賢No ratings yet

- Nanosafety Exam QuestionsDocument4 pagesNanosafety Exam QuestionsMulugetaNo ratings yet

- CH 6 SandwichesDocument10 pagesCH 6 SandwichesKrishna ChaudharyNo ratings yet

- Dual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch GebruikershandleidingDocument21 pagesDual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch Gebruikershandleidingminerva_manNo ratings yet

- Antioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. LeavesDocument7 pagesAntioxidant Activity by DPPH Radical Scavenging Method of Ageratum Conyzoides Linn. Leavespasid harlisaNo ratings yet