Professional Documents

Culture Documents

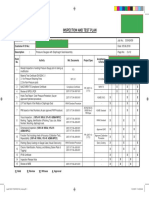

Field Joint Coating Installation Procedure

Uploaded by

unix manCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Joint Coating Installation Procedure

Uploaded by

unix manCopyright:

Available Formats

GTS-PE

Factory Grade 3LPE Field Applied Coating System

Product Description Equipment List Flame Intensity & Torch Size

1 2 3 Pipe O.D. Pipe O.D. 4 25

mm

Epoxy BP ≤ 450mm > 450mm h+

(18”) (18”) idt

W

ve

lee

Cure +S

mm

25

Base

SIS Sa 2½

near white metal

SSPC SP 10

GTS-PE Sleeve Use moderate

flame intensity or

Use moderate to high

flame intensity or

induction heating for induction heating for

GTS-PE Global Transmission Sleeves are Propane tank, hose, torch & regulator; Power metal cutback pre- metal cutback pre- Ensure that the pipe is dry before cleaning.

shipped pre-cut with a preattached closure. grinder with grind wheel of a Grade 40 grit heating and shrinking. heating and shrinking. Thoroughly clean the weld area with a sand or

Bulk quantities are also available. The joint rating; Canusa heat shields, Induction coil & grit blaster to “near white metal” SIS Sa 2½ or

completion system uses liquid epoxy on generator; Digital thermometer with suitable Minimum Torch Size: Minimum Torch Size: equivalent. Using a grinder with a grind disk

bare steel cutback. The GTS-PE sleeves are probe; Knife, J roller, rags & approved solvent 150,000 BTU/hr. 300,000 BTU/hr. with roughness rating of 40-60, ensure that

packaged in PE bags that are only to be opened cleanser; Standard safety equipment; gloves, the PP mainline coating edges are beveled to

prior to the application of the product. goggles, hard hat, etc. 15° from the horizontal and that the adjacent

Canusa recommends the use of induction PP pipe coating is cleaned, exposing fresh

or infrared heating equipment for pipe sizes PP, to a distance of 25mm beyond the sleeve

greater than 760mm(30”) O.D. width.

Positional Markings Pre-Warm Liquid Epoxy

5 6 7 8 Epoxy BP

Epoxy CB

Cure

Base

50°C-65°C

C

(122°F-149°F))

Base Cure

Wipe clean or air blast the steel and pipe Measure and mark the width of the GTS-PE Using the appropriate sized induction coil or Follow the preparation, mixing and applications

coating to remove foreign contaminants. sleeve across the joint. Also, adjust the induc- propane torch, pre-warm the steel area to instructions provided with the supplied Canusa

tion coil’s heating area to the width of the 50-65°C. Using a temperature measuring Liquid Epoxy Pack. For bulk quantities, mix

GTS-PE sleeve. The induction coil heating device, ensure that the correct temperature is the epoxy cure with epoxy base (see Liquid

width shall be approximately 25 to 75 mm reached on the steel. Epoxy Product data sheet for mixing ratio). Stir

wider than the supplied GTS-PE sleeve width. for a minimum of 1 minute to assure uniform

mixture.

Liquid Epoxy Application Pre-Heat Sleeve Installation

9 10 11 12

> 130°C

(> 266°F)

Apply mixed epoxy to a minimum uniform Preheat the epoxy to a minimum of 130°C Check the temperature to ensure the preheat Place the underlap of the sleeve onto the joint,

thickness of 6 mils (150 microns) on all using the appropriate sized induction coil. While has been obtained on the entire pipe circum- centering the sleeve such that the sleeve

exposed bare metal plus FBE toe only, using induction heating is highly recommended, in ference. This preheat will substantially cure the overlap is positioned at either the 10 or 2

the applicator pads as supplied or an approved certain cases, propane torches may be used if epoxy and ensure proper flow and bonding of o’clock position. Press the underlap firmly into

tool. proven to provide acceptable results in project the sleeve adhesive. Ensure that the epoxy is place and use a roller to work out any trapped

specific conditions. Preheat temperature dry to the touch prior to sleeve installation. air. Feed the remaining length of sleeve under

and profile is dependant on project specific the pipe.

conditions, and must be determined prior to

the start of the project. Optional Heat Shields can be used during the

sleeve application. After wrapping the sleeve

around the pipe, the heat shields can be

wrapped adjacent to the sleeve to protect the

mainline coating during shrink down.

INSTALLATION GUIDE canusacps.com

13 14 15 C E Storage & Safety Guidelines

To ensure maximum performance, store

Canusa products in a dry, ventilated area. Keep

1 products sealed in original cartons and avoid

exposure to direct sunlight, rain, snow, dust or

other adverse environmental elements. Avoid

prolonged storage at temperatures above 35°C

B D F (95°F) or below -20°C (-4°F). Product installa-

tion should be done in accordance with local

2 health and safety regulations.

These installation instructions are intended as

a guide for standard products. Consult your

Canusa representative for specific projects or

unique applications.

Wrap the sleeve loosely around the pipe, With the green-yellow coloured adhesive side Gently heat the closure and pat it down with

ensuring the appropriate overlap. facing down, firmly press the entire closure a gloved hand. Repeating this procedure,

seal into place. Ensure that the closure is move from one side to the other. Smooth any

Before finishing wrapping the sleeve: centred evenly over the underlap-overlap wrinkles by gently working them outward from Canusa-CPS

1. heat the backing side of the underlap until sleeve seam. If necessary, add additional heat the centre of the closure with a roller. A division of Shawcor Ltd.

the backing starts to recover. Then use a roller to the closure underside in cold conditions,

to secure the underlap to the pipe. using a low flame intensity. Head Office

2. gently heat the green-yellow coloured adhe- 25 Bethridge Road

sive side of the closure seal until it appears Toronto, ON, Canada M9W 1M7

glossy. Tel: +1 416 743 7111

Fax: +1 416 743 5927

16 17 18 Canada

Dome Tower St. 2200,

333-7th Avenue SW

Calgary, AB, Canada T2P 2Z1

Tel: +1 403 218 8207

Fax: +1 403 264 3649

Pipe O.D. Americas

≤450mm (18”)

1 torch 5875 N. Sam Houston Pkwy W.,

>450mm (18”) Suite 200

2 torches Houston, TX, USA 77086

Tel: +1 281 886 2350

Using the appropriate sized torch, begin at the Continue heating from the centre toward one Shrinking has been completed when the Fax: +1 281 886 2353

centre of the sleeve and heat circumferentially end of the sleeve until recovery is complete. In adhesive begins to ooze at the sleeve edges

around the pipe. Use broad strokes. If utilizing a similar manner, heat and shrink the remaining all around the circumference. Finish shrinking Middle East

two torches, operators should work on side. the sleeve with long horizontal strokes over

opposite sides of pipe. the entire surface to ensure a uniform bond. ADPC - Mussafah Port,

P.O. Box 2621

Abu Dhabi, UAE

Tel: +971 2 496 3500

Fax: +971 2 496 3501

Europe, Africa & Russia

Quality Check - Adhesion Test Inspection Dellaertweg 9-E, Gebouw

“Le Carrefour”

19 20 21 2316 WZ Leiden,

The Netherlands (NL)

Tel: +31 71 80 802 70

Fax: +31 71 80 802 71

Asia-Pacific

101 Thomson Road,

#11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Fax: +65 6749 8919

While the sleeve is still hot and soft, use a hand Test sleeve adhesion by gently pulling the Visually inspect the installed sleeve for the

roller to gently roll the sleeve surface and push edge of the backing back to ensure that the following: Quality Management system

any trapped air up and out of the sleeve, as adhesive remains in place and is fully bonded registered to ISO 9001

shown above. Continue the procedure by also to the factory coating. The sleeve is well • Sleeve is in full contact with the steel joint.

firmly rolling the closure with long horizontal bonded when the adhesive and coating remain • Adhesive flows beyond both sleeve edges.

strokes from the weld outwards. intimately contacted. If required to improve • No cracks or holes in sleeve backing. Canusa warrants that the product conforms

bonding, additional heat should be applied to to its chemical and physical description

the sleeve. and is appropriate for the use stated on the

installation guide when used in compliance

with Canusa’s written instructions. Since

many installation factors are beyond

our control, the user shall determine the

suitability of the products for the intended

use and assume all risks and liabilities in

connection therewith. Canusa’s liability is

stated in the standard terms and conditions

of sale. Canusa makes no other warranty

either expressed or implied. All information

contained in this installation guide is to be

used as a guide and is subject to change

without notice. This installation guide

Onshore and Offshore Guidelines supersedes all previous installation guides

on this product. E&OE

After shrinking is complete, allow the sleeve to cool to less than 90°C prior to laying (for offshore applications, product

can be water quenched).

Part No. 99060-204

IG_GTS-PE_rev019

You might also like

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- Ug-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08Document2 pagesUg-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08AHMED LASSOUEDNo ratings yet

- Wps Model 2 PDFDocument17 pagesWps Model 2 PDFbeyNo ratings yet

- Torque Value DelmonDocument8 pagesTorque Value DelmonKhalid HaiderNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Specification For 3 Layer Polyethylene CoatingDocument34 pagesSpecification For 3 Layer Polyethylene CoatingYogesh BaraskarNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Electrode Brand Name and Class MirfaDocument13 pagesElectrode Brand Name and Class MirfaAnonymous rYZyQQot55No ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Wps PQR p918908091328904 PDFDocument7 pagesWps PQR p918908091328904 PDF채종언No ratings yet

- 3LPE Repair ProcedureDocument3 pages3LPE Repair Procedurelhanx2No ratings yet

- Reliance Industries Limited Line History Sheet For Low Alloy Steel PipingDocument2 pagesReliance Industries Limited Line History Sheet For Low Alloy Steel PipingRavi ShankarNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- StyreneDocument2 pagesStyreneBiju_PottayilNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- Shop ItpDocument4 pagesShop ItpRanu JanuarNo ratings yet

- Painting Inspection Report - 539 UVDocument1 pagePainting Inspection Report - 539 UVRahul MoottolikandyNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Flange Insulation Kits - WebDocument1 pageFlange Insulation Kits - WebabhishekNo ratings yet

- Test Pack Flow / Control Log: Punch List / Inspection Prior For Hydro TestDocument2 pagesTest Pack Flow / Control Log: Punch List / Inspection Prior For Hydro Testsyedahmad39No ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- ITP Heat ExchangerDocument1 pageITP Heat Exchangersarmad009No ratings yet

- Piping - Mapress Installation GuidelinesDocument144 pagesPiping - Mapress Installation GuidelinesPetru VladeanuNo ratings yet

- SOP Pipe WeldingDocument1 pageSOP Pipe WeldingAndre Mars100% (1)

- Bar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationDocument22 pagesBar / Wire Wrapped Steel Cylinder Pipes With Mortar Lining and Coating (Including Specials) - SpecificationPratik KharmateNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocument15 pages4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Oil Pantriting ProcedureDocument5 pagesOil Pantriting ProcedureSERT-QA/QC- BUZNo ratings yet

- SFPS For HDPE 90 MMDocument1 pageSFPS For HDPE 90 MMraajc2No ratings yet

- ITPDocument1 pageITPVenkatesh PethurajNo ratings yet

- PQR (Hdpe)Document3 pagesPQR (Hdpe)abdo elmokademNo ratings yet

- CIT Procedure - 14.02.2020 - Rev.01 PDFDocument9 pagesCIT Procedure - 14.02.2020 - Rev.01 PDFAashish MoyalNo ratings yet

- STEEL Structures in GeneralDocument11 pagesSTEEL Structures in GeneralsbunNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Tool Fab - WorkshopDocument347 pagesTool Fab - Workshophrdsby100% (1)

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Welder and Welder Operator Qualification Record FormDocument1 pageWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohNo ratings yet

- Weld Repair ProcedureDocument51 pagesWeld Repair Proceduremohd as shahiddin jafriNo ratings yet

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriNo ratings yet

- Materials System SpecificationDocument15 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- 3-Layer Global Transmission Sleeve: Equipment List Product Description Storage & Safety GuidelinesDocument2 pages3-Layer Global Transmission Sleeve: Equipment List Product Description Storage & Safety GuidelinesPorfirio Ruiz GascaNo ratings yet

- Nason Industrial Brochure 2015 Singles PDFDocument4 pagesNason Industrial Brochure 2015 Singles PDFsidneidecarvalhoNo ratings yet

- Monitor, Style 649: Compact Monitor DN80 / 3", For Water and Foam (AFFF), FM ApprovedDocument2 pagesMonitor, Style 649: Compact Monitor DN80 / 3", For Water and Foam (AFFF), FM Approvedunix manNo ratings yet

- 1.3.2 Elkhart Nozzle 2,5 InchDocument4 pages1.3.2 Elkhart Nozzle 2,5 Inchunix manNo ratings yet

- Field Joint Coating CatalogeDocument2 pagesField Joint Coating Catalogeunix manNo ratings yet

- Type D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionDocument6 pagesType D3 Protectospray Directional Spray Nozzles, Open, Medium Velocity General DescriptionJackNo ratings yet

- Meditran S SAE 10W, 30,40,50Document1 pageMeditran S SAE 10W, 30,40,50Norman YazidNo ratings yet

- Meditran S SAE 10W, 30,40,50Document1 pageMeditran S SAE 10W, 30,40,50Norman YazidNo ratings yet

- Inspection Housing, Polyolefin - IH2600EDocument1 pageInspection Housing, Polyolefin - IH2600Eunix manNo ratings yet

- Checklist For Mechanical CompletionDocument8 pagesChecklist For Mechanical CompletionAnand PatelNo ratings yet

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocument27 pagesNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocument27 pagesNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- NORSOK Z-CR-007 Mechanical Completion and CommissioningDocument27 pagesNORSOK Z-CR-007 Mechanical Completion and CommissioningWilkin Llanca Blas100% (1)

- Desing of Municipal WWTPDocument260 pagesDesing of Municipal WWTPGREGORIO MOCTEZUMA100% (1)

- Weapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)Document1 pageWeapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)John SmithNo ratings yet

- SC3 User Manual - V1.06 PDFDocument196 pagesSC3 User Manual - V1.06 PDFJoeNo ratings yet

- Chapter 22-The Pre Cam Brian EarthDocument38 pagesChapter 22-The Pre Cam Brian Earthncl12142No ratings yet

- Identifing Legends and CultureDocument2 pagesIdentifing Legends and CultureHezekaiah AstraeaNo ratings yet

- P.B.B.SC Nsg. Syllabus Original PDFDocument57 pagesP.B.B.SC Nsg. Syllabus Original PDFRajalakshmi SrinivasanNo ratings yet

- Principle of Virtual Work and Its ApplicationDocument7 pagesPrinciple of Virtual Work and Its Applicationprem adhikari100% (1)

- 06 Story StiffnessDocument2 pages06 Story StiffnessDigvijay GiraseNo ratings yet

- Journal of Experimental Biology and Agricultural Sciences: Anitha KC, Rajeshwari YB, Prasanna SB and Shilpa Shree JDocument5 pagesJournal of Experimental Biology and Agricultural Sciences: Anitha KC, Rajeshwari YB, Prasanna SB and Shilpa Shree Jkristel amadaNo ratings yet

- OLIVE VIEW HOSPITAL-San Fernando Earthquake 1971 PDFDocument5 pagesOLIVE VIEW HOSPITAL-San Fernando Earthquake 1971 PDFZakir UllahNo ratings yet

- Clippers and ClampersDocument8 pagesClippers and Clamperspuneeth kumarNo ratings yet

- Unit 14 Workbook BussinessDocument45 pagesUnit 14 Workbook BussinessAna Victoria DíazNo ratings yet

- Amended Consent Decree and Draft Interim Action Work Plan For The Hansville General R Men Store Site - Available Fo Public Review and Com TDocument4 pagesAmended Consent Decree and Draft Interim Action Work Plan For The Hansville General R Men Store Site - Available Fo Public Review and Com TCommunityNewsNo ratings yet

- Shear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsDocument2 pagesShear Strength Prediction of Crushed Stone Reinforced Concrete Deep Beams Without StirrupsSulaiman Mohsin AbdulAziz100% (1)

- Soundarya Lahari Translation in EnglishDocument50 pagesSoundarya Lahari Translation in EnglishRanganatha Gowda100% (1)

- GDPDocument6 pagesGDPBenedetta NardiNo ratings yet

- Lecture 1-5 EEEN323 March2022Document139 pagesLecture 1-5 EEEN323 March2022Lekono KagoNo ratings yet

- Flex-10 Virtual ConnectDocument2 pagesFlex-10 Virtual ConnectArif HusainNo ratings yet

- Vray MaterialsDocument206 pagesVray MaterialsDodeptrai BkNo ratings yet

- Fundamentals of Ship Maintenance and Repair For Future Marine Engineers PDFDocument11 pagesFundamentals of Ship Maintenance and Repair For Future Marine Engineers PDFShawn Wairisal100% (2)

- Gerus Air Driven Hydraulic PumpDocument7 pagesGerus Air Driven Hydraulic Pumpmahmoudayoub173No ratings yet

- (Ronald Weed, John Von Heyking (Eds.) ) Civil ReligiDocument375 pages(Ronald Weed, John Von Heyking (Eds.) ) Civil ReligiskaspeNo ratings yet

- Okuma GENOS M560R-V TECHNICAL SHEET (4th Edition)Document79 pagesOkuma GENOS M560R-V TECHNICAL SHEET (4th Edition)Ferenc Ungvári100% (1)

- Laboratory Department Tracking Sheet OriginalCHARM2Document128 pagesLaboratory Department Tracking Sheet OriginalCHARM2Charmaine CorpuzNo ratings yet

- Ant WorldDocument17 pagesAnt WorldGerardo TorresNo ratings yet

- Front Axle, Tie Rod and Drag Link (A21) - 20: Parts ListDocument4 pagesFront Axle, Tie Rod and Drag Link (A21) - 20: Parts ListdgloshenNo ratings yet

- DIO 20. ZAŠTITA PRI RADU I SMJEŠTAJ POSADE Jan 2015Document44 pagesDIO 20. ZAŠTITA PRI RADU I SMJEŠTAJ POSADE Jan 2015Samo SpontanostNo ratings yet

- BS 5655-14Document16 pagesBS 5655-14Arun Jacob Cherian100% (1)

- Computer Graphics Chapter-1Document61 pagesComputer Graphics Chapter-1abdi geremewNo ratings yet

- EarlyDocument59 pagesEarlyjrtlimNo ratings yet