Professional Documents

Culture Documents

6440 SIPKYD ALUMINIUM 440 June-12

Uploaded by

محمد عزتCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6440 SIPKYD ALUMINIUM 440 June-12

Uploaded by

محمد عزتCopyright:

Available Formats

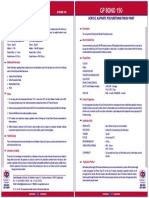

SIPKYD ALUMINIUM 440 Product No.

6440

Aluminium Finish Based on a Synthetic Resin/Oil Combination

Features Recommended Use

Bright metallic finish As a superior quality aluminium finish for use

in a wide range of marine and industrial

Excellent hiding and easy application. applications such as steel structures and

pipeline complexes.

Moderate heat resistance.

Not suitable for permanent immersion.

One-pack and economical.

Approved under APCS-4 & 7.

Physical Data

Density : 1.0 kg/ltr.

Finish : Bright Metallic

Drying and Recoating Times at 40 microns

Colour : Aluminium (25°C/65% RH):

Dry to Recoat : 12 Hours

Volume Solids : 44% Hard Dry : 16 Hours

Maximum Recoating Time : No Limit

Recommended Film Thickness:

25 microns dry = 61 microns wet Heat Resistant : 150°C Dry

Theoretical Coverage: Flash Point : 42°C

17.6 m²/ltr. at 25 microns

Specification Data

Preparation

All surfaces should be thoroughly degreased in accordance with SSPC-SP1. All dust and other foreign matter

should be removed from substrate prior to painting.

Paint System

Finish on intact conventionally primed steel or wooden surfaces.

Issued: June 2012

Issued: June 2012

Product No. 6440

Application Data

Thinning The paint is supplied ready for brush or airless spray application.

If the paint is too thick, in cold weather for example, then add a small amount

Thinner 710 / Thinner 0104 to obtain the suitable viscosity. The amount of

thinner that may be added is dependent on the application conditions and

methods. Overthinning will lead to poor results.

Application Conditions Application temperature: 5 - 50°C.

The minimum temperature required for satisfactory drying is 5°C. The surface

temperature must be at least 3°C above the dew point to prevent condensation.

Never apply paint under adverse weather conditions.

Application directions Prior to application, mix paint thoroughly to obtain an homogeneous product. Use

a mixer for this which is powered by air or a flameproof electric motor.

Application Methods Airless Spray Conventional Spray

and Details Recommended thinner Thinner 710/Thinner 0104 Thinner710/Thinner

0104

Thinner Addition Max. 5 vol.%. Max. 5 vol.%

Nozzle Orifice 0.015” - 0.017” 1.5 - 2 mm

Working Pressure 140 - 160 bar 3 - 4 bar

Brush/Roller

Recommended Thinner Thinner 710 / Thinner 0104

Thinner Addition Max. 3 vol.%

The recommended method of application is by airless spray. However, brush,

roller or conventional spray may also be used.

The spray fan should be adjusted depending on the nature and shape of the

substrate to be painted in order that overspray can be restricted to a minimum.

Cleaning of Equipment Use Thinner 710 / Thinner 0104

Storage Information

Pack Size 5 and 20 ltr. (Single component material)

Storage Store generally in original sealed container, indoors, at a temperature between 5

and 40C and relative humidity below 70%.

Shelf Life 1 Year

Safety Information

See the material safety data sheet and product label for complete safety and precaution requirements.

Disclaimer

The information in this data sheet represent test results or experience under well defined conditions. Its accuracy or suitability under the actual conditions of any intended use is not

guaranteed and must be determined by the user. All advice given about this product is given in good faith. Since as we have no control over conditions of substrate and application,

manufacturer and seller can not accept any liability in connection with the use of the product relative to coverage, performance, injury or damage, unless we specifically agree in

writing to do so. The information in this data sheet is subject to change without notice and it is the user’s responsibility to ensure it is current. For further information and advice

contact SIPCO Technical Services Department on Tel. (03) 847 2299, Fax (03) 847 3780.

Issued: June 2012

Issued: June 2012

You might also like

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- 6430 SIPKYD FINISH 430 June-12Document2 pages6430 SIPKYD FINISH 430 June-12محمد عزتNo ratings yet

- 6424 Redoxide Primer 424 June-12Document2 pages6424 Redoxide Primer 424 June-12محمد عزتNo ratings yet

- 6640 SIP-SPLASH 640 June-12Document2 pages6640 SIP-SPLASH 640 June-12ShaikhRizwanNo ratings yet

- Apcodur 220Document3 pagesApcodur 220JOSEPH GRAHAMSENGGNo ratings yet

- Sipkyd Aluminium 440: Aluminium Finish Based On A Synthetic Resin/Oil CombinationDocument1 pageSipkyd Aluminium 440: Aluminium Finish Based On A Synthetic Resin/Oil Combinationمحمد عزتNo ratings yet

- Epoxy Primer216Document2 pagesEpoxy Primer216kishortilekarNo ratings yet

- Asian Ezrp: Organic Zinc Rich EpoxyDocument3 pagesAsian Ezrp: Organic Zinc Rich EpoxyrohitNo ratings yet

- PC 7091 - Apcothane CF 675 FinishDocument3 pagesPC 7091 - Apcothane CF 675 Finishonshore purchaseNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- Epoxy primer protects steel and concrete surfacesDocument3 pagesEpoxy primer protects steel and concrete surfacesPRERAKNo ratings yet

- GP Bond PU-141Document2 pagesGP Bond PU-141replyrajanNo ratings yet

- 1402-00 Simazinc EP PrimerDocument2 pages1402-00 Simazinc EP PrimerMuhammad Mulya JatiNo ratings yet

- PC 1262 - Asian Epoxy HB CoatingDocument3 pagesPC 1262 - Asian Epoxy HB CoatingHithayathulla KhanNo ratings yet

- PC 4050 - Apcofine 910Document3 pagesPC 4050 - Apcofine 910rohitNo ratings yet

- Asian Apcodur Epoxy Mio PaintDocument3 pagesAsian Apcodur Epoxy Mio PaintPrinceRaghavNo ratings yet

- 2 - PC 7058 - Asian Epoxy HB ZR PrimerDocument3 pages2 - PC 7058 - Asian Epoxy HB ZR Primersujay AvatiNo ratings yet

- Nippon Paint 8048 protects steelDocument3 pagesNippon Paint 8048 protects steelArmanda SiryogiawanNo ratings yet

- SteelkobeDocument3 pagesSteelkobealexamaigutNo ratings yet

- GP Primeguard 235Document1 pageGP Primeguard 235Krunal RudaniNo ratings yet

- PC 4033 - Epoxy Mio CoatingDocument3 pagesPC 4033 - Epoxy Mio CoatingUmesh ShengalNo ratings yet

- PC 0443 - Apcothane CF 675Document3 pagesPC 0443 - Apcothane CF 675Gunjan GaganNo ratings yet

- Apcothane CF 678: PolyurethaneDocument3 pagesApcothane CF 678: Polyurethanerumi_2kNo ratings yet

- Asian Epoxy Zinc Phosphate PrimerDocument3 pagesAsian Epoxy Zinc Phosphate PrimerAabhas UpadhyayaNo ratings yet

- DS - 752-Rev01 - Epilux 485 HB IntermediateDocument2 pagesDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainNo ratings yet

- Thermaline 4700 PDSDocument4 pagesThermaline 4700 PDSArmani FernandesNo ratings yet

- Apcoguard SF 725Document3 pagesApcoguard SF 725kiran vargheseNo ratings yet

- Grand Polycoat PolyurethaneDocument1 pageGrand Polycoat PolyurethaneAniket GaikwadNo ratings yet

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDocument3 pagesSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- PC 0246 - Asian Epoxy Finish PaintDocument3 pagesPC 0246 - Asian Epoxy Finish PaintHithayathulla KhanNo ratings yet

- PC 7048 - Asian Epoxy Dual CoatDocument3 pagesPC 7048 - Asian Epoxy Dual CoatGunjan GaganNo ratings yet

- Carbothane 134 HPDocument4 pagesCarbothane 134 HPsrinath vNo ratings yet

- PC 1787 - Apcotherm HR 600 PDFDocument3 pagesPC 1787 - Apcotherm HR 600 PDF41464147No ratings yet

- Thermaline 400 Primer PDSDocument3 pagesThermaline 400 Primer PDSQuy RomNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- Epoxy Zinc Phosphate Primer for Steel ProtectionDocument3 pagesEpoxy Zinc Phosphate Primer for Steel Protectionfransiska_ogaNo ratings yet

- Thermaline 4700 PDSDocument4 pagesThermaline 4700 PDSLâm Trần BáNo ratings yet

- PC 7051 - Apcomin Industrial EnamelDocument3 pagesPC 7051 - Apcomin Industrial EnamelHithayathulla KhanNo ratings yet

- PC 0443 - Apcothane CF 675 - Apcothane 675 Latest PDSDocument3 pagesPC 0443 - Apcothane CF 675 - Apcothane 675 Latest PDSonshore purchaseNo ratings yet

- Pentatherm CUI - F16Document4 pagesPentatherm CUI - F16Vineet KhanduriNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- Pds Simathane Gloss 9-1Document2 pagesPds Simathane Gloss 9-1Aulia RahmahNo ratings yet

- Apcodur 207Document3 pagesApcodur 207Md Irshad AhmadNo ratings yet

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- H. V. NC: High Gloss - WhiteDocument1 pageH. V. NC: High Gloss - Whiteمحمد عزتNo ratings yet

- Neromastic_4000Document2 pagesNeromastic_4000m pallonjiNo ratings yet

- Plasite 7159 HAR abrasion resistant epoxyDocument4 pagesPlasite 7159 HAR abrasion resistant epoxyRobertoNo ratings yet

- Apcosil - PC 2119Document3 pagesApcosil - PC 2119Naren SudarsanNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Epilux 44 Enamel: Product Data Resistance GuideDocument2 pagesEpilux 44 Enamel: Product Data Resistance GuideKishore Nayak kNo ratings yet

- Nippon HB Epoxy LinerDocument3 pagesNippon HB Epoxy LinerRai Hasnain Ahmad DahaNo ratings yet

- Thor ZcepDocument2 pagesThor Zcepazam RazzaqNo ratings yet

- Protective Epoxy Coating for TanksDocument4 pagesProtective Epoxy Coating for TanksShravana PrasadNo ratings yet

- Interchar 1190: Water Borne Intumescent CoatingDocument4 pagesInterchar 1190: Water Borne Intumescent Coatingsubham sahuNo ratings yet

- Paralux 4HGDocument2 pagesParalux 4HGDuong DuongdangNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- Durable Semi-Gloss Polyurethane PaintDocument3 pagesDurable Semi-Gloss Polyurethane PaintMarcin HryciukNo ratings yet

- DS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Document2 pagesDS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Ranjan Kumar SahuNo ratings yet

- Bergerthane PU Glossy Finish: Product Data Resistance GuideDocument2 pagesBergerthane PU Glossy Finish: Product Data Resistance Guidesangram keshari pattanaikNo ratings yet

- ER351 A BC FormDocument1 pageER351 A BC Formمحمد عزتNo ratings yet

- Quality Control SpecificationsDocument1 pageQuality Control Specificationsمحمد عزتNo ratings yet

- Quality Control SpecificationsDocument1 pageQuality Control Specificationsمحمد عزتNo ratings yet

- Ec495 AformDocument1 pageEc495 Aformمحمد عزتNo ratings yet

- Quality Control Specifications: Last Update: 12/01/2004Document1 pageQuality Control Specifications: Last Update: 12/01/2004محمد عزتNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Documentمحمد عزتNo ratings yet

- Jotashield Colourxtreme MattDocument4 pagesJotashield Colourxtreme Mattمحمد عزتNo ratings yet

- Jotashield Exterior Paint Technical DataDocument3 pagesJotashield Exterior Paint Technical Dataمحمد عزتNo ratings yet

- Quality Control Specifications: Last Update: 12/01/2004Document1 pageQuality Control Specifications: Last Update: 12/01/2004محمد عزتNo ratings yet

- Jotashield ColourLast Matt (I)Document3 pagesJotashield ColourLast Matt (I)محمد عزتNo ratings yet

- Jotashield Colourlast MattDocument3 pagesJotashield Colourlast Mattمحمد عزتNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Documentمحمد عزتNo ratings yet

- Jotashield Alkali Resistant Primer Technical Data SheetDocument3 pagesJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyNo ratings yet

- Jotashield ColourXtreme Silk (In)Document3 pagesJotashield ColourXtreme Silk (In)محمد عزتNo ratings yet

- Jotashield ColourXtreme Matt (In)Document3 pagesJotashield ColourXtreme Matt (In)محمد عزتNo ratings yet

- Jotashield Colourxtreme SilkDocument3 pagesJotashield Colourxtreme Silkمحمد عزتNo ratings yet

- Jotashield ColourXtreme Silk (I)Document3 pagesJotashield ColourXtreme Silk (I)محمد عزتNo ratings yet

- Jotashield ColourXtreme Matt (I)Document3 pagesJotashield ColourXtreme Matt (I)محمد عزتNo ratings yet

- Jotashield Colourlast MattDocument3 pagesJotashield Colourlast Mattمحمد عزتNo ratings yet

- Jotashield Colourlast SilkDocument3 pagesJotashield Colourlast Silkمحمد عزتNo ratings yet

- Jotashield Colourlast GlossDocument3 pagesJotashield Colourlast Glossمحمد عزتNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Jotashield ColourXtreme Silk (In)Document3 pagesJotashield ColourXtreme Silk (In)محمد عزتNo ratings yet

- Fenomastic My Home Smooth SilkDocument4 pagesFenomastic My Home Smooth Silkمحمد عزتNo ratings yet

- Jotashield Alkali Resistant Primer Technical Data SheetDocument3 pagesJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyNo ratings yet

- Jotashield Colourlast SemiglossDocument3 pagesJotashield Colourlast Semiglossمحمد عزتNo ratings yet

- Durosan Interior Eggshell SilkDocument3 pagesDurosan Interior Eggshell Silkمحمد عزت0% (1)

- Fenomastic Stain Resistant EmulsionDocument3 pagesFenomastic Stain Resistant Emulsionمحمد عزتNo ratings yet

- Interior Emulsion Paint Technical DataDocument3 pagesInterior Emulsion Paint Technical Dataمحمد عزتNo ratings yet

- Durosan Interior Eggshell SilkDocument3 pagesDurosan Interior Eggshell Silkمحمد عزت0% (1)

- Cronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearDocument24 pagesCronidur 30: Maximum Demand by Maximum Demand by Corrosive Stress WearVlad PopescuNo ratings yet

- Oet Listening 1Document9 pagesOet Listening 1English Around The WorldNo ratings yet

- Master FormDocument62 pagesMaster FormsamsulNo ratings yet

- STD Comparison ChartDocument4 pagesSTD Comparison Chartabu ubaidahNo ratings yet

- Caffeine Natural Coffee BeanDocument1 pageCaffeine Natural Coffee BeanMayang TariNo ratings yet

- DCM601A51 - Technical DataDocument405 pagesDCM601A51 - Technical Datathanhthuan100% (1)

- Riel Comun Fstguide2Document2 pagesRiel Comun Fstguide2Rosita TejedaNo ratings yet

- IIAP Mock 1 Answer KeyDocument6 pagesIIAP Mock 1 Answer KeyTGiF Travel0% (1)

- Predicting Natural Hazards PowerPointDocument29 pagesPredicting Natural Hazards PowerPointZarlene SierraNo ratings yet

- Simplex 4100ES 5 Days Customer TrainingDocument1 pageSimplex 4100ES 5 Days Customer TrainingBrahmantyo HadiprasetyoNo ratings yet

- Arthur Kleinman The Illness Narratives Suffering Healing and The Human ConditionDocument46 pagesArthur Kleinman The Illness Narratives Suffering Healing and The Human Conditionperdidalma62% (13)

- M 200Document3 pagesM 200Rafael Capunpon VallejosNo ratings yet

- Stanley - Your Voice (1957) PDFDocument396 pagesStanley - Your Voice (1957) PDFŠašavi Sam MajmunNo ratings yet

- Jurnal Dermatitis AtopikDocument20 pagesJurnal Dermatitis AtopikchintyaNo ratings yet

- CS Risk and Crisis Management FinalDocument62 pagesCS Risk and Crisis Management FinaldangermanNo ratings yet

- Concrete Pump Hose TDSDocument2 pagesConcrete Pump Hose TDSAlaa Abu KhurjNo ratings yet

- ETR - Part C - Course SyllabusDocument26 pagesETR - Part C - Course SyllabusDon JubacNo ratings yet

- Drug study on TegretolDocument2 pagesDrug study on TegretolSophia Kaye AguinaldoNo ratings yet

- Aircraft Instruments and Avionics PDFDocument211 pagesAircraft Instruments and Avionics PDFairbuk doeing88% (8)

- Rakovic Dejan - Arandjelovic Slavica - Micovic Mirjana - Quantum-Informational Medicine QIM 2011 PDFDocument150 pagesRakovic Dejan - Arandjelovic Slavica - Micovic Mirjana - Quantum-Informational Medicine QIM 2011 PDFPrahovoNo ratings yet

- Personal LetterDocument4 pagesPersonal LetterAskme AzmyNo ratings yet

- Kshitija's ResumeDocument1 pageKshitija's ResumeNavinNo ratings yet

- Life Wealth Mastery EnglishDocument12 pagesLife Wealth Mastery EnglishD.j. Ralmm100% (1)

- D1553.140U1 German Braun Speed - Braun Card-Xi'an Yuanhua Instrument Co., LTDDocument2 pagesD1553.140U1 German Braun Speed - Braun Card-Xi'an Yuanhua Instrument Co., LTDTrong Hung NguyenNo ratings yet

- Nitrogen BlanketingDocument21 pagesNitrogen Blanketingrvkumar61No ratings yet

- ASME B16.5 Flange Rating CalculatorDocument10 pagesASME B16.5 Flange Rating Calculatorfaizal100% (2)

- A Study On Satisfaction Level of Employees With Special Reference Textile IndustryDocument12 pagesA Study On Satisfaction Level of Employees With Special Reference Textile Industrysai kiran bade100% (1)

- The Secret of Eternal Youth PDFDocument36 pagesThe Secret of Eternal Youth PDFArunesh A Chand100% (4)

- How Yeast Growth is AffectedDocument9 pagesHow Yeast Growth is AffectedMisika AlamNo ratings yet

- Cambridge O Level: English Language 1123/22Document4 pagesCambridge O Level: English Language 1123/22Shania SeneviratneNo ratings yet