Professional Documents

Culture Documents

Sipkyd Aluminium 440: Aluminium Finish Based On A Synthetic Resin/Oil Combination

Uploaded by

محمد عزتOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sipkyd Aluminium 440: Aluminium Finish Based On A Synthetic Resin/Oil Combination

Uploaded by

محمد عزتCopyright:

Available Formats

SIPKYD ALUMINIUM 440 Product No.

6440

Aluminium Finish Based on a Synthetic Resin/Oil Combination

Tomorrow’s Technology on the Surface

FEATURES SPECIFICATION

Bright metallic finish

Preparation

All surfaces should be thoroughly degreased in accordance with

Excellent hiding and easy application.

SSPC-SP1. All dust and other foreign matter should be removed

from substrate prior to painting.

Moderate heat resistance.

Paint System

One-pack and economical. Finish on intact conventionally primed steel or wooden surfaces.

RECOMMENDED USE APPLICATION DATA

As a superior quality aluminium finish for use in a wide range of

marine and industrial applications such as steel structures and Thinning

pipeline complexes. The paint is supplied ready for brush or airless spray application.

If the paint is too thick, in cold weather for example, then add a

Not suitable for permanent immersion. small amount Thinner 710 to obtain the suitable viscosity. The

amount of thinner that may be added is dependent on the

PROPERTIES application conditions and methods. Overthinning will lead to poor

results.

Finish

Bright Metallic Application Conditions

Application temperature: 5 - 500 C.

Color The minimum temperature required for satisfactory drying is 50 C.

Aluminium The surface temperature must be at least 30 C above the dew

point to prevent condensation. Never apply paint under adverse

Pack Size weather conditions.

5 and 20 ltr. (Single component material)

Application directions

Volume Solids Prior to application, mix paint thoroughly to obtain an homogeneous

Approx. 44% product. Use a mixer for this which is powered by air or a

flameproof electric motor.

Recommended Film Thickness

25 microns dry = 61 microns wet Application Methods and Details

Airless Spray Conventional

Theoretical Coverage Spray

16.40 m²/ltr. at 25 microns Recommended thinner Type 710 Thinner 710

Thinner Addition Max. 5 vol. % Max. 5 vol. %

Density Nozzle Orifice 0.015" - 0.017" 1.5 - 2 mm

1.0 kg./ltr. Working Pressure 140 - 160 bar 3 - 4 bar

Drying and Recoating Times at 40 microns Brush/Roller

(200 C/65% RH) Recommended Thinner Type 710

Dry to Recoat : 12 Hours Thinner Addition Max. 3 vol. %

Hard Dry : 16 Hours

Maximum Recoating Time : No Limit The recommended method of application is by airless spray.

However, brush, roller or conventional spray may also be used.

Heat Resistant The spray fan should be adjusted depending on the nature and

1500 C Dry shape of the substrate to be painted in order that overspray can

be restricted to a minimum.

Flash Point (closed cup method)

Over 240 C Cleaning of Equipment

Thinner 710 : 420 C Use Thinner 710.

Storage Information SAFETY INFORMATION

Store generally in original sealed container, indoors, at a See the material safety data sheet and product label for complete

temperature between 50 C and 400 C and relative humidity below safety and precaution requirements.

70%.

Shelf Life

1 Year

The information in this data sheet represent test results or experience under well defined conditions. Its accuracy or suitability under the actual conditions of any intended use is not guaranteed and

must be determined by the user. All advice given about this product is given in good faith. Since as we have no control over conditions of substrate and application, manufacturer and seller can not

accept any liability in connection with the use of the product relative to coverage, performance, injury or damage, unless we specifically agree in writing to do so. The information in this data sheet is

subject to change without notice and it is the user’s responsibility to ensure it is current. For further information and advice contact SIPCO Technical Services Department on Tel. (03) 847 2299, Fax

(03) 847 3780. Issue Date: June 2003

You might also like

- Jotashield Colourlast MattDocument3 pagesJotashield Colourlast Mattمحمد عزتNo ratings yet

- Jotashield Colourlast MattDocument3 pagesJotashield Colourlast Mattمحمد عزتNo ratings yet

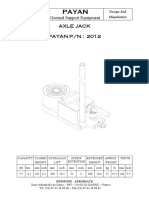

- Payan: Axle Jack PAYAN P/N: 2012Document38 pagesPayan: Axle Jack PAYAN P/N: 2012gmailNo ratings yet

- Qns Bank For Final Exam FilteredDocument104 pagesQns Bank For Final Exam FilteredPhuong PhamNo ratings yet

- 6440 SIPKYD ALUMINIUM 440 June-12Document2 pages6440 SIPKYD ALUMINIUM 440 June-12محمد عزتNo ratings yet

- GP Primeguard 235Document1 pageGP Primeguard 235Krunal RudaniNo ratings yet

- Thor ZcepDocument2 pagesThor Zcepazam RazzaqNo ratings yet

- Carbozinc 858Document2 pagesCarbozinc 858Muhammad RizwanNo ratings yet

- Road Marking Paint SB AcrylicDocument4 pagesRoad Marking Paint SB AcrylicAngga PratamaNo ratings yet

- Thermaline 4900Document2 pagesThermaline 4900Khemaraj PathNo ratings yet

- Japan’s No.1 Durable Road Marking CoatingDocument2 pagesJapan’s No.1 Durable Road Marking Coatingazam RazzaqNo ratings yet

- Selection & Specification Data Substrates & Surface PreparationDocument2 pagesSelection & Specification Data Substrates & Surface PreparationJuanNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- KAN-TAURUS High Build Epoxy Finish: CharacteristicsDocument2 pagesKAN-TAURUS High Build Epoxy Finish: Characteristicsazam RazzaqNo ratings yet

- Nippon ArocoatDocument3 pagesNippon ArocoatHANIF IZANI ISHAKNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Nippon Arocoat Protective Coating for Aggressive EnvironmentsDocument3 pagesNippon Arocoat Protective Coating for Aggressive EnvironmentsHamza GhaniNo ratings yet

- Therma HRCDocument2 pagesTherma HRCazam RazzaqNo ratings yet

- Starox 2100 (P) : Selection & Specification Data Substrates & Surface PreparationDocument2 pagesStarox 2100 (P) : Selection & Specification Data Substrates & Surface PreparationtrinhminhkhoaNo ratings yet

- Carboguard 60: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard 60: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Thermaline 4700 Aluminum: Selection & Specification DataDocument4 pagesThermaline 4700 Aluminum: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Grand Polycoat PolyurethaneDocument1 pageGrand Polycoat PolyurethaneAniket GaikwadNo ratings yet

- 6430 SIPKYD FINISH 430 June-12Document2 pages6430 SIPKYD FINISH 430 June-12محمد عزتNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Thermaline 4700 Aluminum PDSDocument4 pagesThermaline 4700 Aluminum PDSEsakki muthuNo ratings yet

- Al-Jazeera Firedamp 263Document2 pagesAl-Jazeera Firedamp 263EngTamer100% (1)

- Zinc Rich 1p pc102Document2 pagesZinc Rich 1p pc102livefreakNo ratings yet

- Thor EfccDocument2 pagesThor Efccazam RazzaqNo ratings yet

- Thermaline 4900 PDSDocument4 pagesThermaline 4900 PDSDuongthithuydungNo ratings yet

- Zincanode 304: Solvent Borne Inorganic Zinc SilicateDocument3 pagesZincanode 304: Solvent Borne Inorganic Zinc SilicatelivefreakNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Acothane Spray Grade 0117Document2 pagesAcothane Spray Grade 0117gregNo ratings yet

- Characteristics: Japan's No.1Document2 pagesCharacteristics: Japan's No.1azam RazzaqNo ratings yet

- Thermaline 4700 PDSDocument4 pagesThermaline 4700 PDSLâm Trần BáNo ratings yet

- H.V. NC SANDING SEALER PRODUCT OVERVIEWDocument1 pageH.V. NC SANDING SEALER PRODUCT OVERVIEWمحمد عزتNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- Carboguard 893 SG PDFDocument2 pagesCarboguard 893 SG PDFQA QCNo ratings yet

- EA4 Finish MetalDocument3 pagesEA4 Finish MetalAzmeer YusufNo ratings yet

- 1402-00 Simazinc EP PrimerDocument2 pages1402-00 Simazinc EP PrimerMuhammad Mulya JatiNo ratings yet

- NP ArocoatDocument4 pagesNP ArocoatJohn HaNo ratings yet

- Carbomastic 615E: Selection & Specification DataDocument6 pagesCarbomastic 615E: Selection & Specification DataAnhera enterpriseNo ratings yet

- Apexior-No 1 Aug 2018Document2 pagesApexior-No 1 Aug 2018emadsafy20002239No ratings yet

- Carbothane 134: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbothane 134: Selection & Specification Data Substrates & Surface PreparationMarcos MacaiaNo ratings yet

- Pentatherm CUI - F16Document4 pagesPentatherm CUI - F16Vineet KhanduriNo ratings yet

- Thermaline 4700 PDSDocument4 pagesThermaline 4700 PDSArmani FernandesNo ratings yet

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Carboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationImran AhmadNo ratings yet

- 467 MPDocument3 pages467 MPjgNo ratings yet

- Neromastic 800: Scope Application DetailsDocument1 pageNeromastic 800: Scope Application DetailsTanvir Ahmed Khan100% (1)

- Carboguard 703Document2 pagesCarboguard 703Achraf BoudayaNo ratings yet

- 6424 Redoxide Primer 424 June-12Document2 pages6424 Redoxide Primer 424 June-12محمد عزتNo ratings yet

- Carbothane 134 HPDocument4 pagesCarbothane 134 HPsrinath vNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Product Data: Carboguard 190 HDocument2 pagesProduct Data: Carboguard 190 HClarkFedele27100% (1)

- Arocoat - Repair Paint Data SheetDocument3 pagesArocoat - Repair Paint Data SheetIsboNo ratings yet

- Durebild HSE: High Build Two Pack Epoxy CoatingDocument3 pagesDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNo ratings yet

- EA9 Red Oxide PrimerDocument3 pagesEA9 Red Oxide PrimernkhhhNo ratings yet

- Abecote 384Document2 pagesAbecote 384engramir07No ratings yet

- Neromastic_4000Document2 pagesNeromastic_4000m pallonjiNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Quality Control SpecificationsDocument1 pageQuality Control Specificationsمحمد عزتNo ratings yet

- Ec495 AformDocument1 pageEc495 Aformمحمد عزتNo ratings yet

- ER351 A BC FormDocument1 pageER351 A BC Formمحمد عزتNo ratings yet

- Quality Control SpecificationsDocument1 pageQuality Control Specificationsمحمد عزتNo ratings yet

- Jotashield ColourXtreme Silk (In)Document3 pagesJotashield ColourXtreme Silk (In)محمد عزتNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Documentمحمد عزتNo ratings yet

- Quality Control Specifications: Last Update: 12/01/2004Document1 pageQuality Control Specifications: Last Update: 12/01/2004محمد عزتNo ratings yet

- Jotashield Colourxtreme MattDocument4 pagesJotashield Colourxtreme Mattمحمد عزتNo ratings yet

- Quality Control Specifications: Last Update: 12/01/2004Document1 pageQuality Control Specifications: Last Update: 12/01/2004محمد عزتNo ratings yet

- Jotashield Exterior Paint Technical DataDocument3 pagesJotashield Exterior Paint Technical Dataمحمد عزتNo ratings yet

- Jotashield ColourXtreme Matt (I)Document3 pagesJotashield ColourXtreme Matt (I)محمد عزتNo ratings yet

- Jotashield ColourXtreme Silk (I)Document3 pagesJotashield ColourXtreme Silk (I)محمد عزتNo ratings yet

- New Microsoft Word DocumentDocument2 pagesNew Microsoft Word Documentمحمد عزتNo ratings yet

- Jotashield Colourxtreme SilkDocument3 pagesJotashield Colourxtreme Silkمحمد عزتNo ratings yet

- Jotashield ColourLast Matt (I)Document3 pagesJotashield ColourLast Matt (I)محمد عزتNo ratings yet

- Jotashield ColourXtreme Matt (In)Document3 pagesJotashield ColourXtreme Matt (In)محمد عزتNo ratings yet

- Jotashield Colourlast SilkDocument3 pagesJotashield Colourlast Silkمحمد عزتNo ratings yet

- Jotashield ColourXtreme Silk (In)Document3 pagesJotashield ColourXtreme Silk (In)محمد عزتNo ratings yet

- Interior Emulsion Paint Technical DataDocument3 pagesInterior Emulsion Paint Technical Dataمحمد عزتNo ratings yet

- Jotashield Alkali Resistant Primer Technical Data SheetDocument3 pagesJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyNo ratings yet

- Jotashield Alkali Resistant Primer Technical Data SheetDocument3 pagesJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyNo ratings yet

- Jotashield Colourlast GlossDocument3 pagesJotashield Colourlast Glossمحمد عزتNo ratings yet

- Jotashield Colourlast SemiglossDocument3 pagesJotashield Colourlast Semiglossمحمد عزتNo ratings yet

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتNo ratings yet

- Durosan Interior Eggshell SilkDocument3 pagesDurosan Interior Eggshell Silkمحمد عزت0% (1)

- Durosan Interior Eggshell SilkDocument3 pagesDurosan Interior Eggshell Silkمحمد عزت0% (1)

- Fenomastic Stain Resistant EmulsionDocument3 pagesFenomastic Stain Resistant Emulsionمحمد عزتNo ratings yet

- Fenomastic My Home Smooth SilkDocument4 pagesFenomastic My Home Smooth Silkمحمد عزتNo ratings yet

- Models - Heat.conical Dielectric ProbeDocument28 pagesModels - Heat.conical Dielectric ProbeDenis JaissonNo ratings yet

- AutoLaser UM enDocument151 pagesAutoLaser UM enCristian LopezNo ratings yet

- Windows Desktop Interview Questions and AnswersDocument5 pagesWindows Desktop Interview Questions and AnswersVikas KumarNo ratings yet

- Day 3 Multiplying Polynomials Homework Assignment OnlyDocument2 pagesDay 3 Multiplying Polynomials Homework Assignment Onlyapi-316619857No ratings yet

- Covid 19 ImpactDocument38 pagesCovid 19 ImpactNavneet NandaNo ratings yet

- UCS310-Lec-11 230213 141523Document40 pagesUCS310-Lec-11 230213 141523ARYAN TYAGINo ratings yet

- MFPS-JHD-P-SIE9-096: Product ClassificationDocument3 pagesMFPS-JHD-P-SIE9-096: Product Classificationhotrokythuat SNTekNo ratings yet

- Mitsui Cranes & SystemsDocument12 pagesMitsui Cranes & SystemsKhang ElvisNo ratings yet

- Smart Farming System Irrigation Using Iot For EfficientDocument13 pagesSmart Farming System Irrigation Using Iot For EfficientMahesh DevarintiNo ratings yet

- SCULPFUN S30 Series User ManualDocument72 pagesSCULPFUN S30 Series User Manualriello12No ratings yet

- Digital Force Gauge: User GuideDocument5 pagesDigital Force Gauge: User GuideJorge Cardona GilNo ratings yet

- Amulet FeliciaDocument103 pagesAmulet FeliciaDaniele PioNo ratings yet

- 06.01.2021.warehouse ManagementDocument29 pages06.01.2021.warehouse ManagementArham OrbNo ratings yet

- NURS FPX 6612 Assessment 2 Quality Improvement ProposalDocument6 pagesNURS FPX 6612 Assessment 2 Quality Improvement Proposalzadem5266No ratings yet

- PRPL - Assignment 2 - Software Analysis DocumentDocument4 pagesPRPL - Assignment 2 - Software Analysis DocumentDzaki HNo ratings yet

- 40-BGP Regular ExpressionDocument5 pages40-BGP Regular ExpressionprakashrjsekarNo ratings yet

- PJ1000C-LCD PJ1300C-LCD PJ2000LCD: User ManualDocument44 pagesPJ1000C-LCD PJ1300C-LCD PJ2000LCD: User ManualВладимир100% (1)

- SSV 2019 - Wiring Diagram - 219100978 - WD91Y019S10 - enDocument9 pagesSSV 2019 - Wiring Diagram - 219100978 - WD91Y019S10 - enAlex CachuNo ratings yet

- Snort LoggerDocument5 pagesSnort Loggerzacktoby74No ratings yet

- Snake Game Blackbook PROJECTDocument40 pagesSnake Game Blackbook PROJECTjoe bidenNo ratings yet

- Performance Report SummaryDocument13 pagesPerformance Report SummaryHariprasad Reddy GNo ratings yet

- Lubricator L26 Economist™ L27 Atomist™: Specifi CationsDocument2 pagesLubricator L26 Economist™ L27 Atomist™: Specifi CationsJacobo SuarezNo ratings yet

- 4 Special Fire Hazards and PreventionDocument22 pages4 Special Fire Hazards and Preventiondroffilcz27100% (1)

- GIGABYTE GA-H81M-DS2 Mainboard ManualDocument32 pagesGIGABYTE GA-H81M-DS2 Mainboard Manualcr33pz1llaNo ratings yet

- Share PricesDocument186 pagesShare PricesHarshul BhatiaNo ratings yet

- 4 Job Interviews and Career Part 2Document2 pages4 Job Interviews and Career Part 2lala inriyaniNo ratings yet

- Justmoh Procter Test So-13Document11 pagesJustmoh Procter Test So-13Abu FalasiNo ratings yet

- A Report On Industrial VisitDocument15 pagesA Report On Industrial VisitChandni Bhagchandani100% (1)