Professional Documents

Culture Documents

Liebherr R984C Litronic Fault Codes DTC

Liebherr R984C Litronic Fault Codes DTC

Uploaded by

Saeid Sharifi0 ratings0% found this document useful (0 votes)

7 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views6 pagesLiebherr R984C Litronic Fault Codes DTC

Liebherr R984C Litronic Fault Codes DTC

Uploaded by

Saeid SharifiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

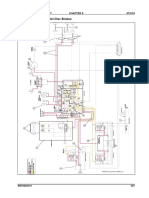

Malfunctions Operating instructions

Error code charts

4.1 Error code charts

Danger!

When switching over to emergency operation, the speed can no longer be changed

using the arrow keys on the monitoring screen. The servo control, parking brake

and swing gear brake can no longer be activated.

Please also note the subheading Emergency operations in the chapter Oper-

ating the machine in this regard.

Error code Effect Cause Measure / remedy

E 004 Engine coolant level Short circuit to earth Check engine coolant level.

E 005 Short circuit + 24 V

E 006 Cable break

E 010 Hydraulic oil level not being Short circuit to earth Check hydraulic oil level.

E 011 monitored. Short circuit + 24 V

E 012 Cable break

E 013 Hydraulic oil temperature not Short circuit to earth Check that the radiator is not dirty.

E 014 being monitored. Short circuit + 24 V

E 015 Cable break

E 016 Gear oil temperature Short circuit to earth Check gear oil temperature.

E 017 Short circuit + 24 V

E 018 Cable break

E 022 Diesel engine RPM Short circuit to earth

E 023 Short circuit + 24 V

E 024 Cable break

E 027 Solenoid valve for power con- Cable break

trol (LR)

E 033 Solenoid valve for cooler fan Cable break

regulation (EV5)

E 036 Solenoid valve for flow con- Cable break

trol (hydraulic pump 1) EV1

E 039 Solenoid valve for flow con- Cable break

trol (hydraulic pump 1) EV2

E 042 Solenoid valve - Reserve Cable break

(EV3)

E 045 Solenoid valve - Pressure op- Cable break

erate (EV6)

E 068 Fan RPM Fan RPM defective

E 302 Keyboard No coding plug

E 303 Keyboard No CAN bus connection to

BST

E 305 Keyboard No CAN bus connection to

ESP01 board

E 308 Display No connection between

keyboard and display

4-2 R 984 C - Litronic / 10069859

https://www.truck-manuals.net/

MJFCIFSS

Operating instructions Malfunctions

Faults and remedies

Error code Effect Cause Measure / remedy

E 309 Display No Software compatibility

between keyboard and

display

E 319 BST No compatibility between

hardware coding and soft-

ware coding

E 321 BST No reception of recog-

nised machine typ by BBT

E 322 BST Unknown Hardware cod-

ing

E 442 Joystick left Short circuit + 24 V

E 443 Short circuit to earth or

Cable break

E 445 Joystick right Short circuit + 24 V

E 446 Short circuit to earth or

Cable break

E 450 The pressure for pressure- Cable break

less boom down movement

not being monitored.

E 454 Rotation gear speed Short circuit + 24 V

E 455 Short circuit to earth or

Cable break

E 456 Fuel tank sensor Short circuit + 24 V

E 458 Short circuit to earth or

Cable break

4.2 Faults and remedies

4.2.1 Diesel engine and fuel system

Fault / error Cause Solution

Diesel engine does not start Fuel tank almost or completely emp- Fill tank and vent fuel system

ty

Low pressure in tank Remove fuel filler cap

Fuel filter dirty Clean or change filter and vent fuel

system, drain fuel / clean tank

Outside temperature below 0°C For operation under specific climatic

conditions, see operating instruc-

tions

Starter motor not drawing through Check line connections, overhaul

starter motor

Batteries have no power Charge / replace

R 984 C - Litronic / 10069859 4-3

https://www.truck-manuals.net/

MJFCIFSS

Malfunctions Operating instructions

Faults and remedies

Fault / error Cause Solution

Engine starts but stops immediately Fuel tank empty (low pressure in Fill tank and vent fuel system

after or runs irregularly tank)

Fuel filter dirty Clean or change filter and vent fuel

system (tank)

Particularly in winter: too viscous Use engine oil suitable for the out-

engine oil used side temperature

Dry-air filter dirty Clean or change main filter element

Air in fuel system Vent fuel system

Ventilation in fuel tank obstructed Clean

Fuel line bent Check line and repair if required

Diesel engine emitting grey or black Dry-air filter dirty Clean or change filter

smoke

Diesel engine continually emitting Water in combustion chamber Consult customer service

while smoke (steam)

Diesel engine does not reach full Speed adjustment not set to maxi- Set speed adjustment to maximum

speed mum value value

Injection system is set incorrectly Consult customer service

Dry-air filter dirty Clean or replace filter

Bad fuel supply Clean or change fuel filter, check

lines, drain water from tank

Diesel engine becomes too hot Too little coolant Fill coolant, check for leaks

Water pump defective Repair

Thermostats do not work Change thermostats

Coolant contaminated Clean coolant

Diesel engine has insufficient oil Oil level too low Correct oil level

pressure Oil pressure display faulty Change oil pressure switch

Note!

Switch off diesel engine immediate-

ly

Diesel engine consumes too much External leak on diesel engine Retighten screws, replace seals if

oil required

Oil in coolant or coolant in oil Consult customer service

Unusual noise / sounddevelopment Exhaust system leaking Check exhaust system / repair

on exhaust side

4.2.2 Hydraulic system

Fault / error Cause Solution

Unusual noise / sounddevelopment Shutoff valve on hydraulic tank Open stop cock

at hydraulic pumps closed

Note! Hydraulic pumps taking in air Check oil level in hydraulic tank,

Switch off diesel engine immediate- check intake lines for leaks

ly

Modes E and P showing lack of No power adjustment via propor- Unplug cable of Y50 connection, re-

power tional solenoid valve Y50 move safety cotter pin, move lever

to emergency setting

4-4 R 984 C - Litronic / 10069859

https://www.truck-manuals.net/

MJFCIFSS

Operating instructions Malfunctions

Faults and remedies

Fault / error Cause Solution

Hydraulic oil temperature too high Coolant contaminated Clean coolant

Fan or fan control defective Rectify error / consult customer

service

Hydraulic oil level too low Oil loss Repair leaks, exchange hoses, refill

oil via return-line filter

Cannot drive Push the safety lever up Push the safety lever down

No direction of travel preselected Use drive selection switch in right

joystick to determine direction of

travel

Parking brake pressure switch de- Consult customer service

fective

Parking brake not released Release parking brake using switch

Parking brake will not release de- Servo pressure present:

spite switch being operated Operate emergency function Y6

Servo pressure not present:

Consult customer service

Service brake engaged Release service brake

Slewing gear not functioning No servo control Push the safety lever down

Switch on servo control

Slewing gear brake activated Push the safety lever down

Release slewing gear brake

No working movement No servo control Push the safety lever down

Switch on servo control

No servo pressure present Consult customer service

No pump high pressure present Consult customer service

4.2.3 Transmission

Fault / error Cause Solution

Oil flowing out on track rollers, sup- Seal defective Replace seal

port rollers or leading wheel

Insufficient crawler tracking on lead- Leading wheel tracking on track roll- Adjust the leading wheel tracking

ing wheel er mounting has too much play play

Crawler jumps off or over Crawler tension too low / crawler Adjust crawler tension

wheel worn

Correctly tensioned crawler losing Crawler tensioning cylinder defec- Check crawler tensioning cylinder,

tension quickly during use tive change if required or seal (only au-

thorized specialist personnel)

Track roller or support roller sticking Running gear extremely dirty Clean running gear

R 984 C - Litronic / 10069859 4-5

https://www.truck-manuals.net/

MJFCIFSS

Malfunctions Operating instructions

Faults and remedies

4.2.4 Electrical system

Fault / error Cause Solution

Battery charge telltale light does not Drive belt for alternator loose or torn Tension or replace drive belt

goes out Alternator defective Replace alternator

Batteries do not charge or charge Batteries defective Replace batteries

poorly Battery connections dirty / oxidised Clean battery connections

Cable loose or damaged Connect or replace cable

Telltale light or display instrument Bulb burnt out, display instrument Replace defective part

not functioning or functioning incor- defective

rectly

Some or all functions on instrument Plug connector separated or dam- Mount plug connector correctly or

panel drop out aged, earth lead interrupted, short change, rectify short circuit, replace

circuit fuse defective fuse or activate overload cut-outs

Diesel speed adjustment via operat- Automatic idling switch S20 is acti- Touch the joystick or deactivate au-

ing keypad (mode and arrow keys) vated tomatic idling switch S20.

not functioning Excavator speed adjustment elec- Switch the emergency function over

tronics do not function from AUTO to MANU using

No signal emits from speed sensor switch S71 in the right control panel.

B12 Set speed using switch S72. Emer-

gency function display appears on

monitoring screen. Consult custom-

er service.

Automatic idling not functioning, Permanent sensor signal Consult customer service

speed does not reduce Switch S20 is deactivated Activate switch S20

Servo control cannot be activated Excavator electrics faulty Switch on emergency function using

using switch switch S73 in the right control panel

Parking brake cannot be released Caution: Servo circuit and brake cir-

using switch cuit can only be switched off using

the safety lever. Keypad not func-

Slewing gear brake cannot be re- tioning. Consult customer service.

leased using switch

4.2.5 Heating/air-conditioning system

Fault / error Cause Solution

Heating not giving out warm air Shutoff valves for coolant line on Open shutoff valve

diesel engine closed

Engine not at operating temperature Bring engine to operating tempera-

ture

Heating fan does not operate No power supply Check fuse and wiring / repair

Fan motor defective Change fan motor

Only low air flow in cab Outside air filter / recirculated air fil- Clean air intake opening, replace

ter dirty outside air filter

Air vent closed Open air vent

4-6 R 984 C - Litronic / 10069859

https://www.truck-manuals.net/

MJFCIFSS

Operating instructions Malfunctions

Faults and remedies

4.2.6 Work equipment

Fault / error Cause Solution

Cylinder stretches when loaded Piston seal in cylinder defective Overhaul cylinder

Bearing clearance too high on Bearing points worn out Replace bearing parts

equipment

Grab / bucket does not move Valve block on tilting cylinder incor- Switch over valve block

rectly switched

Add-on unit cannot be turned / rotat- Auxiliary function has not been re- Release auxiliary function using

ed / operated leased switch S19

Lines are not connected Connect lines

R 984 C - Litronic / 10069859 4-7

https://www.truck-manuals.net/

MJFCIFSS

You might also like

- Fault Code List LIEBHERRDocument6 pagesFault Code List LIEBHERRexodus exc71% (17)

- Liebherr A-900-1031 Service Manuel-Part 8 - Electricity PDFDocument486 pagesLiebherr A-900-1031 Service Manuel-Part 8 - Electricity PDFSami Enis Arıoğlu92% (12)

- Tier 4i Error Code ListDocument15 pagesTier 4i Error Code ListRicardo Costa100% (3)

- B25D B30D MKIII ElectricalDocument208 pagesB25D B30D MKIII ElectricalErmias88% (8)

- Fault Code TEREXDocument11 pagesFault Code TEREXMarco Guachun88% (8)

- Liebherr r934 r984 Excavator ManualDocument265 pagesLiebherr r934 r984 Excavator ManualPHÁT NGUYỄN THẾ88% (26)

- Sm-Liebherr Pr724 Pr734 Pr744 Pr754 Pr764 Series 4 Litronic Crawler Dozer Service RepairDocument131 pagesSm-Liebherr Pr724 Pr734 Pr744 Pr754 Pr764 Series 4 Litronic Crawler Dozer Service RepairJozef40% (10)

- Manual Troubleshotting Hitachi ZW 310Document506 pagesManual Troubleshotting Hitachi ZW 310Tomas HP67% (3)

- Service Manual L550 L580 2plus2 PDFDocument714 pagesService Manual L550 L580 2plus2 PDFRached Douahchua92% (13)

- 08 Isuzu 4le2 GBDocument121 pages08 Isuzu 4le2 GBWere Wolf100% (14)

- EW160 AlarmsDocument12 pagesEW160 AlarmsIgor MaricNo ratings yet

- Volvo A25d Articulated Dump Truck Service Repair ManualDocument26 pagesVolvo A25d Articulated Dump Truck Service Repair Manualchawkigenie100% (12)

- ECOS Error Codes - 5220Document24 pagesECOS Error Codes - 5220Benjamín Sancho Contreras100% (3)

- Service LiebbherDocument828 pagesService Liebbherxuan100% (12)

- Transmission Error Codes - CargadorasDocument36 pagesTransmission Error Codes - CargadorasTeresa Marina Peralta80% (5)

- Terex Engine Fault CodesDocument9 pagesTerex Engine Fault CodesFlorin Stoica100% (1)

- BOBCAT S175 SKID STEER LOADER Service Repair Manual SN 517625001 & Above PDFDocument52 pagesBOBCAT S175 SKID STEER LOADER Service Repair Manual SN 517625001 & Above PDFfujsjejfksekmem50% (4)

- Heui Fuel System c9 EngineDocument25 pagesHeui Fuel System c9 Enginebabaisandip91% (53)

- B40D Bell Truck Hydraulic SystemDocument19 pagesB40D Bell Truck Hydraulic SystemMaimun maimun100% (1)

- Error CodeDocument411 pagesError CodeTRIQUERE100% (2)

- B30C ADT ElectricsDocument59 pagesB30C ADT Electricswtn2013100% (2)

- GENERAL - All Controllers: Bell Equipment Co. S.A. (Pty) LTDDocument19 pagesGENERAL - All Controllers: Bell Equipment Co. S.A. (Pty) LTDkandukiss100% (4)

- Volvo A30d Articulated Dump PDFDocument15 pagesVolvo A30d Articulated Dump PDFHamid Essarbouti100% (1)

- Service Manual - E215B-E245B - 5 - ENDocument118 pagesService Manual - E215B-E245B - 5 - ENaritmetics100% (5)

- R934C 1439 33766 02-2015 en PDFDocument303 pagesR934C 1439 33766 02-2015 en PDFRiza DS100% (2)

- Wiring Schematic (Manual Machine) S770 (S/N AT5A11001 - AT5A11533) S770 (S/N B3BV11001 - B3BV11242) Sheet 1 of 18Document18 pagesWiring Schematic (Manual Machine) S770 (S/N AT5A11001 - AT5A11533) S770 (S/N B3BV11001 - B3BV11242) Sheet 1 of 18Teknik MakinaNo ratings yet

- B25C Omm EnglishDocument167 pagesB25C Omm EnglishTeknik MakinaNo ratings yet

- M.O 80Z5Document203 pagesM.O 80Z5David arango.100% (2)

- b25d b30d Mkiii HydraulicsDocument28 pagesb25d b30d Mkiii HydraulicsErmias100% (3)

- B30C TransmissionDocument65 pagesB30C Transmissionwtn2013100% (9)

- Liebher R900B-R944B - enDocument1,233 pagesLiebher R900B-R944B - enviktor94% (16)

- Cab Overview: New Operating ConceptDocument34 pagesCab Overview: New Operating ConceptBoran Carmona100% (1)

- TELEHANDER TH336 337 406 407 414 514 417C - CAT - ServiceDocument296 pagesTELEHANDER TH336 337 406 407 414 514 417C - CAT - ServiceMARIOLARA1980100% (3)

- 10.3.01 Service Code List - Lindiag Software V2.62A: 1 Overview of Service Codes Cep14 Travel ElectronicDocument12 pages10.3.01 Service Code List - Lindiag Software V2.62A: 1 Overview of Service Codes Cep14 Travel Electronicjabrik bobelNo ratings yet

- Liebherr L544-443 Wheel Loader Service Repair Manual SN 6190 To 7476 PDFDocument35 pagesLiebherr L544-443 Wheel Loader Service Repair Manual SN 6190 To 7476 PDFjfjksekdmeik0% (1)

- MLT625 XPRT Service TrainingDocument158 pagesMLT625 XPRT Service TrainingLuiz Souza Souza100% (2)

- Frigidaire Affinity Front Load Washer Error CodesDocument2 pagesFrigidaire Affinity Front Load Washer Error CodesSamurai Appliance Repair Man100% (5)

- FCL Tracking 2019Document698 pagesFCL Tracking 2019NQTNo ratings yet

- Manual Motor WC30D Tier-3 SM PDFDocument105 pagesManual Motor WC30D Tier-3 SM PDFAndres Abril100% (1)

- Silkolene Catalogue For WebDocument16 pagesSilkolene Catalogue For Webapi-295271471No ratings yet

- F20a, F25a (E)Document210 pagesF20a, F25a (E)Xristos GrFree100% (2)

- PC20 - PC27R-8 Shop ManualDocument296 pagesPC20 - PC27R-8 Shop Manualsfe100% (1)

- NORSOK Z-001-Dcoument Content GuideDocument42 pagesNORSOK Z-001-Dcoument Content GuideneracaliNo ratings yet

- Manual AV110XDocument190 pagesManual AV110XEl Aleman100% (5)

- 926 Error CodesDocument20 pages926 Error CodesKyaw Lin Naing OfficialNo ratings yet

- Error Code Symbol Description Log CommentDocument8 pagesError Code Symbol Description Log CommentFuad Jahić100% (2)

- CASE 821F TIER 4 WHEEL LOADER Operator's Manual PDFDocument15 pagesCASE 821F TIER 4 WHEEL LOADER Operator's Manual PDFfjskedmmsme100% (4)

- 003 Electrical R934BDocument33 pages003 Electrical R934BSamuel Sanchez50% (2)

- Esquema Eletr Liebherr - R 934C Á R 954CDocument81 pagesEsquema Eletr Liebherr - R 934C Á R 954CSeib100% (1)

- L150G Transmission Oil PressureDocument5 pagesL150G Transmission Oil PressureHendry PardedeNo ratings yet

- Service Manual BW 219 - D5Document1,062 pagesService Manual BW 219 - D5Manuel ParreñoNo ratings yet

- SHB LTM 1030-2 Uw-09 899500808 enDocument36 pagesSHB LTM 1030-2 Uw-09 899500808 enHoracio Berni100% (2)

- SM ADT +large Mk+7 Rev BDocument449 pagesSM ADT +large Mk+7 Rev BBiswajit DasNo ratings yet

- Volvo BL 71 4 Power TransmissionDocument62 pagesVolvo BL 71 4 Power TransmissionVygintas Balcius50% (2)

- Lec 002527108 EngDocument248 pagesLec 002527108 EngIvailo Zapryanov100% (1)

- Bell B40DDocument15 pagesBell B40DAndy LiputoNo ratings yet

- ART e SeriesDocument54 pagesART e Seriesdavi100% (3)

- LiebherrDocument3 pagesLiebherrСлавік ЦобаNo ratings yet

- Fault Code List 9350Document2 pagesFault Code List 9350Eza IR100% (1)

- Fault Code ListDocument9 pagesFault Code ListPT. GLOBAL MULTI TRAKTORNo ratings yet

- PC78US-8 SEN04555-01 TroubleshootingDocument332 pagesPC78US-8 SEN04555-01 TroubleshootingdatphuongNo ratings yet

- Diagnostic Trouble Code (DTC) (Flash DTC 41) Ignition Coil Driver "B" Short To BatteryDocument4 pagesDiagnostic Trouble Code (DTC) (Flash DTC 41) Ignition Coil Driver "B" Short To BatteryDavid MendezNo ratings yet

- BT Forklift Fault Codes List - Truck PDFDocument22 pagesBT Forklift Fault Codes List - Truck PDFSina ShirdelNo ratings yet

- Directional High Response Valve 4wrte With Obe Re29083Document24 pagesDirectional High Response Valve 4wrte With Obe Re29083Kiagus Abdul HadiNo ratings yet

- Drive01 ErrorDocument1 pageDrive01 ErrorMohammad NazirulNo ratings yet

- Service Manual: 1 2 3 C E F G H KDocument71 pagesService Manual: 1 2 3 C E F G H KredNo ratings yet

- PC200 (LC) - 8E0 SEN05245-02 Hybrid TroubleshootingDocument548 pagesPC200 (LC) - 8E0 SEN05245-02 Hybrid Troubleshootingdatphuong100% (2)

- Ec140lc - Codigos de ErrosDocument2 pagesEc140lc - Codigos de ErrosJheckson BalbinotNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- BCKS Tra Vinh - Quach Van Duc EngDocument4 pagesBCKS Tra Vinh - Quach Van Duc EngNQTNo ratings yet

- Annex 04 - EDocument11 pagesAnnex 04 - ENQTNo ratings yet

- PV Drilling'S: PV Drilling I PV DRILLING VI Respectively Achieved 10 Years 2 Years of Safe OperationDocument6 pagesPV Drilling'S: PV Drilling I PV DRILLING VI Respectively Achieved 10 Years 2 Years of Safe OperationNQTNo ratings yet

- BCKS Tra Vinh - Anh Dau EngDocument4 pagesBCKS Tra Vinh - Anh Dau EngNQTNo ratings yet

- Technical Description: FEEDER SERVER® StandardDocument21 pagesTechnical Description: FEEDER SERVER® StandardNQTNo ratings yet

- CangHP 2017Document29 pagesCangHP 2017NQTNo ratings yet

- SFT Iom Us English 2017Document32 pagesSFT Iom Us English 2017NQTNo ratings yet

- Gu Container Model TCO - TCUDocument2 pagesGu Container Model TCO - TCUNQTNo ratings yet

- Container Gantry Crane: MaintenanceDocument46 pagesContainer Gantry Crane: MaintenanceNQTNo ratings yet

- New Doc 2018-08-19 10.01.00 - 20180819103419833Document82 pagesNew Doc 2018-08-19 10.01.00 - 20180819103419833NQTNo ratings yet

- Engine Range VolvoTADDocument2 pagesEngine Range VolvoTADNQTNo ratings yet

- C27 and C32 Generator Sets-Maintenance IntervalsDocument57 pagesC27 and C32 Generator Sets-Maintenance IntervalsRktBatamNo ratings yet

- Pt. Corelab Indonesia: Oil Analysis ResultDocument1 pagePt. Corelab Indonesia: Oil Analysis ResultBahtiar Yudhistira100% (1)

- Engines For Fire PumpDocument39 pagesEngines For Fire PumpMOHNISHKUMARJHANo ratings yet

- Maintenance For Generators and Motors - Training CourseDocument117 pagesMaintenance For Generators and Motors - Training CourseWaleed TahawyNo ratings yet

- Science: Grade 9 Achievement TestDocument42 pagesScience: Grade 9 Achievement TestRoxanne Bernadette LacadenNo ratings yet

- Hino Parts Torque Summer 2012 PDFDocument8 pagesHino Parts Torque Summer 2012 PDFWahyu Bayu Aji100% (2)

- MAN Marine Diesel Engine D 2876 LE 401Document200 pagesMAN Marine Diesel Engine D 2876 LE 401Arturo AltamiranoNo ratings yet

- Q8 Supertruck FE 5W-30: DescriptionDocument1 pageQ8 Supertruck FE 5W-30: DescriptionPinggir KaliNo ratings yet

- Classic 500 Owners Manual - Feb 2012Document114 pagesClassic 500 Owners Manual - Feb 2012prassu1No ratings yet

- 6cyl English PDFDocument16 pages6cyl English PDFking852No ratings yet

- Report On Oil Types and Applications: 3 YearDocument5 pagesReport On Oil Types and Applications: 3 YearMahmoud KassabNo ratings yet

- Radial Inflow Turboexpander Redesign Steamboat Geothermal Power Plants I/IA - Reno, Nevada Brad Platt, Project ManagerDocument4 pagesRadial Inflow Turboexpander Redesign Steamboat Geothermal Power Plants I/IA - Reno, Nevada Brad Platt, Project Managerrcarpioo100% (1)

- Cummins Om ManualDocument2 pagesCummins Om ManualVellai Pandi PNo ratings yet

- Isuzu Engine 4J Series Workshop Manual LG4J WE 9491Document406 pagesIsuzu Engine 4J Series Workshop Manual LG4J WE 9491Yudy M Reyes TejedaNo ratings yet

- SD 77daDocument315 pagesSD 77dajulianmataNo ratings yet

- Mobil Delvac 1 ESP 5W-40Document3 pagesMobil Delvac 1 ESP 5W-40RachitNo ratings yet

- Operating Fluids.11 5.17Document10 pagesOperating Fluids.11 5.17CelsoBrantesNo ratings yet

- UNIT # 1 Final Report of WDADocument38 pagesUNIT # 1 Final Report of WDArashmi006kiit8417No ratings yet

- Hydro Fluid EngDocument6 pagesHydro Fluid EngИлья РадзивиновичNo ratings yet

- BOSIL Product CatalogDocument7 pagesBOSIL Product Catalogsunhell1611No ratings yet