Professional Documents

Culture Documents

Hydraulic Forklift Project Report

Uploaded by

manoj phadtareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Forklift Project Report

Uploaded by

manoj phadtareCopyright:

Available Formats

Mechanical projects : Learnmech.

com

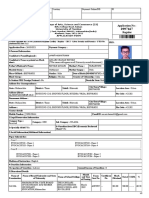

DIPLOMA IN MECHANICAL ENGINEERING

SUBJECT: PROJECT-I (Course code: 3351908)

PROJECT TITLE HYDRAULIC FORK LIFT

GROUP NO. 06

DOSHI SANKET D. - 146170319026

KANSARA NIL M. -146170319040

MACWAN SWAPNIL N. - 146170319045

MAKWANA JAYDIP B. - 146170319046

PAL NILESH K. - 146170319055

S.H. SUNDARANI C. M. PATEL

L.M.E MECH ENGG DEPT. H.O.D

PROJECT GUIDE MECH. ENGG. DEPT.

Government Polytechnic Ahmedabad Page 1

Mechanical projects : Learnmech.com

GOVERNMENT POLYTECHNIC AHMEDABAD

CERTIFICATE

This is to certify that following students as below has

satisfactorily completed their term work for subject

PROJECT-1 (3351908) and submitted the report on

HYDRAULIC FORKLIFT for year 2016-17

GROUP NO. 06

DOSHI SANKET D. - 146170319026

KANSARA NIL M. - 146170319040

MACWAN SWAPNIL N. - 146170319045

MAKWANA JAYDIP B. - 146170319046

PAL NILESH K. - 146170319055

DATE: DATE:

S.H. SUNDARANI C. M. PATEL

L.M.E MECH ENGG DEPT. H.O.D

PROJECT GUIDE MECH. ENGG. DEPT.

Government Polytechnic Ahmedabad Page 2

Mechanical projects : Learnmech.com

INDEX

SR.NO TITLE PAGE

1. ACKNOWLEDGEMENT 4

2. AIM OF PROJECT 5

3. PROJECT SELECTION 6

4. PROJECT PLANNING 8

5. INTRODUCTION OF FORKLIFT 9

6. HISTORY OF FORKLIFT 11

7. TYPES OF FORKLIFT 12

8. HYDRAULIC FORKLIFT 19

9. CONSTRUCTION & DESCRIPTION OF 23

HYDRAULIC FORKLIFT

10. DETAIL AND ASSEMBLY DRWINGS 31

11. SPECIFICATION OF FORKLIFT 33

12. MAKE OR BY DECISION 35

13. COST ESTIMATION 36

14. PLANNING FOR THE NEXT 41

SEMESTER

15. REFERENCES 42

16. WORK LOG BOOK 43

Government Polytechnic Ahmedabad Page 3

Mechanical projects : Learnmech.com

ACKNOWLEDGEMENT

The completion of this project would not have been possible

without the expert guidance and support of our respected project

guide and the Head of our department for his continuous support

and also valuable suggestions when required by our respected

Professors at the college.

We would be leaving a great dent in the work if we don’t thank

the following persons. We are very much thankful to,

Shri S.H. Sundarani for his valuable guidance and support for

work and also the encouragement.

Shri C. M. Patel for his support and suggestion when required.

At last but not the least I am also thankful to my team members

for their effort, participation, enthusiasm, helping to build and

bring out great team work to bring success of the project.

Government Polytechnic Ahmedabad Page 4

Mechanical projects : Learnmech.com

AIM OF PROJECT

We as students of Diploma in Mechanical Engineering have

studied in detail about fundamentals of engineering,

manufacturing processes, machine design, strength of material,

metallurgy, maintenance, costing, management, etc. In this

semester we have been given opportunity to exhibit our learning

abilities through project work.

During the project work most aspects of engineering fields are

covered. In Diploma in Mechanical Engineering the purpose of

introduction of project is to develop

Attitude of Inquiry.

Ability of exploring Ideas

Ability of selection

Market Surveying Skill

Ability of process/product planning

Decision making ability

Team Work and etc

In short PROJECT summarizes the course of Diploma in

Mechanical Engineering.

Government Polytechnic Ahmedabad Page 5

Mechanical projects : Learnmech.com

SELECTION OF PROJECT

Selection of project is an important aspect of this course. Project

must be appealing in learning aspects and should provide a scope

of developing the qualities – technical and managerial both. The

group had a thorough discussion and analysis of various ideas.

This discussion included talks on new trends in the fields,

learning aspects provided by them, cost consideration, SWOT

analysis of them, weightage of work provided to have inclusive

participation and many other factors.

After the discussion and literature study the team had come down

to a shortlist of few ideas that would serve the purpose to its

whole content. The projects considered were

Solar Operated Bicycle

Wind Operated Bicycle

Hydraulic Forklift

Electricity Generation by Speed Beaker

Multi Hacksaw Cutter

Mechanical Segway

Government Polytechnic Ahmedabad Page 6

Mechanical projects : Learnmech.com

The team after discussion on certain factors came to the selection

of Hydraulic forklift. This decision was an inclusive one where

all the team members brought in their views of advantages and

backdrops. The discussion helped to develop the quality of

considering factor, evaluation, and also to bring out ideas and also

how to conduct them.

The team selected The Project of Hydraulic Forklift because of

these aspects:

The Forklift Project includes a well enough use of

manufacturing processes and thus will develop a practical

knowledge of carrying them out and apparatus used.

The project has good scope of testing the skill and

knowledge of estimating and costing.

The project has a various parts that would be required to

purchase thus exposing us to market survey and develop skill

of compare and purchase.

There is a wide scope of Hydraulic forklift in every Industry

where Material Handling is required.

Without the forklifts no warehouse industry will work

efficiently.

Hydraulic Forklifts uses hydraulic principle for lifting Heavy

loads so there is no fuel required hence no environment

pollution will occur.

Forklifts are very compact in size and can be used in very

small passages so material handling can be carried out

success fully for indoor uses.

Government Polytechnic Ahmedabad Page 7

Mechanical projects : Learnmech.com

PROJECT PLANNING

Before starting any project its planning is to be done. Planning of

project is a very important task and should be taken up with great

care as the effective implementation of the whole project largely

depends upon unit planning.

Project planning consisted of following steps:

Selection of project

Production Capacity

Investment Decision

Design and Drawings

Selection of Material

Selection of Machine tools and equipment required.

Resource labor, transportation and loss in manufacturing.

Inventory planning

Process planning

Preparation of F.P.C and O.P.C

Costing and Estimating

Testing of project

Market response of project

Project planning is thus helpful to totally prepare an action plan

that would lead to success of the project. As it is said “A work

well begun is half done.” The same sense is applied here “A

project well planned is half done.”

Government Polytechnic Ahmedabad Page 8

Mechanical projects : Learnmech.com

INTRODUCTION OF FORKLIFT

In general the forklift can be defined as a tool capable of lifting

hundreds of kilograms. A forklift is a vehicle similar to a small

truck that has two metal forks on the front used to lift the load.

The forklift operator drives the forklift forward until the forks

push under the cargo, and can then lift the cargo several feet in

the air by operating the forks. The forks, also known as blades or

tines, are usually made out of steel and can lift up to a few tons.

Forklifts are either powered by gasoline, or electricity. Electric

forklifts relay on batteries to operate. Gasoline or propane

forklifts are sometimes stronger or faster than electric forklifts,

but they are more difficult to maintain, and fuel can be costly.

Government Polytechnic Ahmedabad Page 9

Mechanical projects : Learnmech.com

Electric forklifts are great for warehouse use because they do not

give off noxious fumes like gas powered machines do. Forklifts

are most often used in warehouses, but some are meant to be used

outdoors. The vast majority of rough terrain forklifts operate on

gasoline, but some use diesel or natural gas. Rough terrain

forklifts have the highest lifting capacity of all forklifts and heavy

duty tires (like those found on trucks), making it possible to drive

them on uneven surfaces.

Forklifts have revolutionized warehouse work. They made it

possible for one person to move thousands of pounds at once.

Well-maintained and safely operated forklifts make lifting and

transporting cargo infinitely easier. This is the general description

of a normal forklift.

Government Polytechnic Ahmedabad Page 10

Mechanical projects : Learnmech.com

HISTORY OF FORKLIFT

Just like many other inventions, the forklift was born out of

necessity. The two-wheel hand operated forklift first appeared

over one hundred years ago. These original units were wrought-

iron axle and cast iron wheels which enabled loads to be lifted

and transported without manual labor. In the early 1900s the

evolution to combine horizontal and vertical motion resulted in

the first hand operated forklift capable of lifting a few inches of

the ground. And with this the development of the forklift are on

fastrack till today.

In 1917 the Clark Company, manufacturers of axles, created a

truck called the Tructractor to move materials around their factory.

As people visited the factory and saw the Tructractor at work they

placed orders from Clark to build Tructractors for their companies.

A few years later the first hydraulic powered lift was added to

some trucks to give them lifting power. In 1923, Yale was the

first company to use forks that lifted loads off the ground and an

elevated mast that could extend beyond the height of the truck.

The Yale truck is considered to be the first forklift.

A few developments helped the forklift to increase in production

including the introduction of the standardized pallet in 1930 and

World War II. Both of these developments increased production

of forklifts and allowed distributors the means to efficiently move

heavy loads.

Government Polytechnic Ahmedabad Page 11

Mechanical projects : Learnmech.com

TYPES OF FORKLIFT

1. 3 or 4 wheel forklift truck

Three wheel forklift trucks are used for indoor and warehouses

were space requirement is very important.

While four-wheel forklift trucks are used for lifting heavy

loads in outdoor uses and transportation at long distances.

Used for loading trucks and moving pallets and other loads.

It may be electric, diesel or gasoline operated.

Diesel and gasoline powered forklifts will generate more

power than electric lifts and move faster over long distances.

Capacity ranging from 3 ton- 40 ton.

Government Polytechnic Ahmedabad Page 12

Mechanical projects : Learnmech.com

2. Reach trucks/ Narrow-Aisle forklift

Perfect for optimizing storage space use.

Use to rack pallets on smooth surfaces.

Are generally electric powered.

Very much useful at small passages in warehouses and small

industries.

Can lift heights upto 10 meters.

Ranging from 1-3 tons load lifting capacity.

Government Polytechnic Ahmedabad Page 13

Mechanical projects : Learnmech.com

3. Order-pickers/ Stock-pickers

Use for rider to stand on an elevating platform along with forks

so rider may rise to select the materials.

Very much useful for packaging industries and warehouses

were they are constantly required to pick and put heavy

packages at certain level.

Used in very narrow paths.

Generally electric powered.

Capacity ranging from 1-3 ton.

Government Polytechnic Ahmedabad Page 14

Mechanical projects : Learnmech.com

4. Turret trucks type forklift

In this type of forklift, Forks are mounted on a mast and

carriage that operates on a turret able to rotate at 90 degrees in

either direction for picking the loads without turning the base

of the forklift.

Use in very narrow aisles and employ a rotating mast.

Generally electric powered.

Capacity of lifting load is from 1.5- 4 ton.

Government Polytechnic Ahmedabad Page 15

Mechanical projects : Learnmech.com

5. Rough Terrain Forklifts

Rough terrain forklifts are used for outdoor works where

uneven surface conditions needs to be faced.

It is an one type of heavy capacity forklift widely used for

engineering and construction purposes.

It is generally gasoline, diesel or CNG operated.

Load capacity is 15 ton or more according to size and

operations.

Ideal for lumberyards, construction projects, landscaping and

other outdoor uses.

Government Polytechnic Ahmedabad Page 16

Mechanical projects : Learnmech.com

6. Hydraulic Fork Lift or Pallet truck

Hydraulic forklift is the most compact design from the overall

forklift family.

It is widely use in all types of industry where indoor material

transportation are essential.

It is the most economical solution for small scale industry as

well as big ones for transporting loads at short distances.

It is generally hydraulic operated which utilizes the pascal’s

principle for lifting heavy loads at negligible efforts applied.

According to the type of hydraulic cylinder use the forklift can

lift the load from 1- 3 ton.

Government Polytechnic Ahmedabad Page 17

Mechanical projects : Learnmech.com

7. Side Loader Forklift

In this type of forklifts the load lifting pallets are fitted by the side

of the truck, so that while traveling at long distances operator

doesn’t get any kind of trouble.

Use for narrow aisle work where space between racks are

limited.

This type of forklifts may be electric or gasoline powered.

Loading or unloading can be done by the sides.

Lifting capacity are high for this type of forklifts.

Government Polytechnic Ahmedabad Page 18

Mechanical projects : Learnmech.com

HYDRAULIC FORKLIFT

Hydraulic forklift also know as hydraulic hand pallets is a tool

used to lift and transport heavy load for sort distances with the

help of pallets.

Pallet jacks are the most compact and modern form of forklifts

and are intended to move heavy and light weight materials within

a warehouses.

Like other forms of fork lift hydraulic forklift doesn’t require any

kind of electric power source or diesel and gasoline. Because

hydraulic forklifts works on the principle of hydraulic force

transmission.

Lifting of heavy loads are accomplished with the help of

hydraulic cylinder in the forklift. Cylinder are generally fited at

upperparts of the pallet.

Working principle of hydraulic forklift

The hydraulic forklift works on the principle of hydro static force

transmission which utilizes a non-compressible fluid for

transmission of pressure from fluid to lifting heavy loads. The

principle of hydraulic forklift can be easily understand by the

Pascal’s law.

Government Polytechnic Ahmedabad Page 19

Mechanical projects : Learnmech.com

Pascal’s law

Pascal’s law is very popular in every equipment where heavy

loads needs to be lifted by applying negligible amount of forces.

“ Pascal’s law simply states that when there is an increase in

pressure at any point in confined fluid, there is an equal

increase in pressure at every other point in the container.”

Pressure is equal to the force divided by the area on which it acts.

According to the Pascal’s law, in a hydraulic system a pressure

exerted on a piston produces an equal increase in another piston in

the system. If the second piston has an area 10 times that of the

first piston, the force produced on second piston will be 10 times

more than the force applied on the first piston.

Government Polytechnic Ahmedabad Page 20

Mechanical projects : Learnmech.com

OPERATION OF HYDRAULIC FORKLIFT

The jack is steered by a ‘tiller’ like lever that also acts as the

handle for raising the forklift pallets on which load are resting. A

small lever provided on handle will releases the hydraulic fluid,

causing the forks to lower.

The front wheel inside the end of the forks are mounted on levers

attached to the hydraulic cylinder. As the hydraulic jack at the

‘tiller’ end is raised, the links forces the wheel down, raising the

forks vertically above the front wheels, raising the load upward

until it clears the floor space. The pallet is only lifted enough to

clear the floor for subsequent travel.

Often, hydraulic pallet jacks are used to move and organize

pallets inside a trailer, especially when there is no forklift truck

available.

Government Polytechnic Ahmedabad Page 21

Mechanical projects : Learnmech.com

OPERATING MECHANISM

Pallet jack in lowered position, allowing it to be inserted under a load on a

pallet.

Forklift showing how wheels drop, lifting forks and load. The steering

tiller and raised hydraulic cylinder are clearly visible on the right side.

Under side of forklift showing Push rod under the forks.

Government Polytechnic Ahmedabad Page 22

Mechanical projects : Learnmech.com

CONSTRUCTION OF HYDRAULIC FORKLIFT

MAIN PART

1. Body or frame 5. Load Roller

2. Hydraulic pump unit 6. Handle

3. Steer wheels 7. Handle Trigger

4. Push rod

Government Polytechnic Ahmedabad Page 23

Mechanical projects : Learnmech.com

1. Body or Main frame:

Body is the most important part of forklift. It supports all other

parts of the forklift. The main frame of the forklift is made from

Mild steel plates.

2. Hydraulic pump unit:

Pump is the main element of the hydraulic forklift and mainly

responsible for lifting heavy load at minimum efforts.

It utilizes an non-compressible liquid mainly oil for transferring

pressure of piston and lifting the load resting on the pallet.

Hydraulic pump unit comprises of so many parts like Piston and

Cylinder, Fluid release valve, push springs and other welding

joints for connecting all the parts rigidly.

3. Steer wheels:

Steer wheel are the primary wheels of the forklift for the rotation

of forklift from one direction to another.

The steering wheels are generally made from Nylon, rubber, or

from any other metal or non metal material. The only must have

requirement is that wheel should work efficiently on rough

surfaces and must sustain the load lifted by the pallets.

4. Push rod:

The push rod is a round long rod which connects the load roller

and hydraulic cylinder for transmitting the pressure to lift the load

wheels above the surface.The push rod is mounted below the two

forks of the forklift. And are generally made from mild steel bars.

Government Polytechnic Ahmedabad Page 24

Mechanical projects : Learnmech.com

5. Load roller:

Load rollers are the front wheels of the forklifts. And Is intended

for the lifting of load and traveling of forklift at short distances.

The front wheels are generally made from nylon, high grade

plastic or from any other metal or non metal. The main

requirement for the material is that it must work on rough surfaces

and lift the load according to its capacity without bending and

cracks.

6. Handle:

Handle is also very important part of the fork lift. It is used for

mainly three purposes.

1. For creating pressure in the cylinder by tilting or pushing the

handle frequently.

2. For the proper direction alignment of the forklift by hand.

3. For the traveling of forklift by pushing the handle in forward

direction.

The fork lift handle works as a lever for lifting the load. And is

generally made from a round bar of mild steel. Proper gripping is

to be given at the handle for efficient traveling.

Government Polytechnic Ahmedabad Page 25

Mechanical projects : Learnmech.com

7. Handle trigger:

Handle trigger is lever or clutch type small element provided at

upper part of the forklift handle. The main function of the Trigger

is to release the fluid pressure and lower the forks and front wheel

for loading the pallets on the fork.

Government Polytechnic Ahmedabad Page 26

Mechanical projects : Learnmech.com

ADVANTAGES AND DISADVANTAGES

Advantages

1) Hydraulic forklift utilizes the non-compressible fluid like oil

for lifting the heavy loads with the help of hydraulic cylinder

arrangement, so there is no fuel required like other power

operated forklifts.

2) No environment pollution and health hazards occurs while

using hydraulic forklifts.

3) Hydraulic forklifts are the most economical solution for indoor

and warehouse uses because it requires very small space to

operate.

4) The best thing is that you can choose a forklift with the right

configuration and capacity depending on your need.

5) One advantage of forklifts is that they can reach at higher

altitude for loading and unloading of the materials.

6) Without these machines, the warehouses would not be able to

operate efficiently and with easiness.

7) They perform eco-friendly operation and have very long

working life span.

Government Polytechnic Ahmedabad Page 27

Mechanical projects : Learnmech.com

Disadvantages

1) According to the capacity and size of the forklift limited weight

is lifted.

2) The capacity of the hydraulic hand operated forklift is limited

to some 1.5- 3 ton.

3) Manually operated so long distance can not be traveled.

4) One person is required for the operation.

5) More time consuming than the other types of powered forklifts.

Government Polytechnic Ahmedabad Page 28

Mechanical projects : Learnmech.com

APPLICATION OF FORKLIFT

1) There is hardly any industry where material handling is not

require. The Hydraulics and other type of forklifts are the most

economical solution for all the industries and warehouses where

material handling as well as transportation of it at short distances

is required.

2) Fork lifts are used for lifting and transporting all kind of

materials like packaged products, raw material and other

equipment.

3) Warehousing is the most popular area where forklifts have

proven their worth. In a warehouse, materials are constantly being

move around. Most of the activity is focused around the loading

and unloading of trucks. The warehousing operation can

sometimes take on the appearance of a hive as forklifts of every

size and description scurry about, ferrying boxes and crates from

one place to another. A forklift’s design also makes them

excellent machines for stacking and unstacking boxes and crates.

Forklifts extreme maneuverability means that they also fit into

small spaces to retrieve cargo. It is hard to imagine such an

operation getting alone without forklifts.

Government Polytechnic Ahmedabad Page 29

Mechanical projects : Learnmech.com

4) Another popular place where forklifts are used is transportation

industry. It may be ship ports, railways or an air line

transportation. Everywhere forklifts are used. The principle and

application are same MATERIAL HANDLING, the only thing

differs is the the size and power source of the forklift according to

the application for which it is used.

5) Forklifts are also proven very useful for ship crushing, metal

scraps etc. Industry where heavy materials are required to be

lifted and transported.

Government Polytechnic Ahmedabad Page 30

Mechanical projects : Learnmech.com

DETAIL AND ASSEMBLY DRAWING

Government Polytechnic Ahmedabad Page 31

Mechanical projects : Learnmech.com

Government Polytechnic Ahmedabad Page 32

Mechanical projects : Learnmech.com

SPECIFICATION OF HYDRAULIC FORKLIFT

Load lifting capacity 1500-2000 kg

Fork length 82 cm

Distance between two forks 43 cm

Fork width 10.5 cm

Max. Lift height 10 cm

Handle length 90 cm

Gripping handle width 25 cm

Government Polytechnic Ahmedabad Page 33

Mechanical projects : Learnmech.com

MATERIALS AND EQUIPMENTS REQUIRED

Equipment Required:

1. Hacksaw Cutter or Machine

2. Welding Machine

3. Hand Drilling Machine

4. Color sprayer

Tools Required:

1. Cutting tools (for above stated machines)

2. Hacksaw

3. Hammers

4. Measure tape

5. Spanner set

6. Screwdriver

Materials Required:

1. M.S. Plate( 7 mm thick)

2. M.S. Hollow round bars

3. Arc welding electrodes

4. Spraying color

5. Coolants and oil

6. Fasteners

7. Safety wears

Government Polytechnic Ahmedabad Page 34

Mechanical projects : Learnmech.com

MAKE OR BUY DECISION CHART

SR.NO NAME OF QUANTITY MAKE

COMPONENT /BUY

1 Base Frame 1 Make

2 Hydraulic cylinder 1 Buy

3 Double Steering wheels 1 Buy

4 Forklift handle 1 Make

5 Load wheels 2 Buy

6 Push lever 1 Make

7 Nut-bolts As required Buy

Government Polytechnic Ahmedabad Page 35

Mechanical projects : Learnmech.com

COST ESTIMATION

Cost estimating is an art of finding the cost which is likely to be

incurred on manufacturing of an article before it is actually

manufactured. This calculates material cost. It prepares the

estimate for labor cost based on production time and wages of

worker. Based on these estimated cost data decides the cost of

production, selling prize and profit estimates.

Estimating prepares the records showing all the above details,

which can be used in material and product. It requires a highly

technical knowledge hence an estimator is basically an engineer.

Elements of Cost:

1. Material Cost

2. Labor Cost

3. Other expenses or overhead

Material Cost

Object Weight Price(per kg) Cost

M.S. plate 36 kg(body) Rs 45/kg Rs 1620

(7mm thick)

M.S. hollow pipe 2 kg (handle) Rs 40/kg Rs 80

(7 mm thick,

30 mm dia.)

Cylinder and other 1 kg Rs 40/kg Rs 40

joining links

Government Polytechnic Ahmedabad Page 36

Mechanical projects : Learnmech.com

Standard calculation ( all dimension in cm)

1)volume

A) 2 Forks = 2 (l×b×t)

= 2 (82×10.5×0.7)

= 2 ( 602.5 )

= 1205 cm3

Fork also have a side plates at its base. volume of which will be

1200 cm3 . So total volume of base will be 2400 cm3.

B) Upper body

The upper body of the forklift have total 4 plates welded together.

i. Front plate = ( L×H×t )

= ( 64×27×0.7 )

= 1200 cm3

ii. Upper plate = ( 35×18×0.7)

= 440 cm3

iii.2 side plates= 2 ( 27×18×0.7)

= 340 cm3

Total volume of body above the fork= 1200+440+340

= 1980 cm3.

Government Polytechnic Ahmedabad Page 37

Mechanical projects : Learnmech.com

C) Fork lift handle:

I. Long hollow handle = P÷4 (DO2 _ Di2 ) × L

= p/4 ( 32 - 2.32 ) × 90

= 260 cm3

II. Gripping handle = 70 cm3.

Total volume of Whole body and handle= A+B+C

= 2400+2000+250

= 4650 cm3.

2) Weight of body

Mass = Volume × Density

Density of mild steel = 7.8 gm/cm3

Mass = 4650 × 7.8

= 36270 gm

= 36.2 kg

Government Polytechnic Ahmedabad Page 38

Mechanical projects : Learnmech.com

3) Material cost:

Material cost = Mass × Price/ kg

According to our survey market price of the mild steel is 45/kg.

Material cost = 36 × 45

= Rs. 1620

Welding Cost

The total length of plates which needs to be joined by welding is

around 600 cm. Or around 20 feet.

Considering market cost of welding Rs 40 per feet. The estimated

welding length will be around 20 feet. Hence

Welding cost= 20 × 40

= Rs. 800

Total Cost of Manufacturing Components

Material cost+ Welding Cost+ Overheads

1600+800+500 = Rs.2900

Government Polytechnic Ahmedabad Page 39

Mechanical projects : Learnmech.com

Cost chart of Bought Elements

Sr. No Product Quantity Cost

1. Hydraulic cylinder 1 1200

unit

2. Fasteners As required 300

3. Steering wheel 1 250

4. Load wheel 2 150

5. Paint Color Spray 2 300

Total 2200

Total Cost of Project

Total Cost = Manufacturing cost + Cost of Bought Element +

other overheads

= 2900 + 2200 + 1000

= 6100

Total project cost = 6100

Government Polytechnic Ahmedabad Page 40

Mechanical projects : Learnmech.com

PLANNING FOR THE NEXT SEMESTER

In our next semester we are going to do a Retrofitting of our

Hydraulic Forklift in which we are Determine to do the

Following Practical work.

1) Cleaning work of the Hydraulic forklift.

2) Dis mental all the parts of Hydraulic forklift.

3) Identify which parts are working properly and which needs to

manufactured and replacement.

4) Retrofitting of the Hydraulic Cylinder.

5) Welding of the supporting link of Hydraulic cylinder.

6) Changing the steering wheels.

7) Changing the Load wheels.

8) Adding some innovative and creative Elements in the forklift

which are absent in the Traditional hydraulic forklift.

9) Painting of whole Forklift by spray paint.

10) Testing the successful operation of Forklift.

Government Polytechnic Ahmedabad Page 41

Mechanical projects : Learnmech.com

REFERENCE

To complete our project HYDRAULIC FORKLIFT, help is taken

from various resources. In which Internet has been the most

essential tool for any kind of information we needed for our

project. If we don’t mention the resources from which we have

gathered all the information about our project, our project will be

incomplete. So here we would like to thank all of the websites and

books which have been proven the most essential tool for the

successful completion of our project.

1) www.Atlantaforklift.com

2) www.Wikipedia.com

3) www.academia.edu

4) www.mechengg.net

5) www.Toyotaforklift.com

6) www.Grabcad.com

Government Polytechnic Ahmedabad Page 42

Mechanical projects : Learnmech.com

Work Log Book

Date Details of work carried out Sign.

2-7-16 Searching for the project ideas

16-7-16 Study of selected project

30-7-16 Gathering all the information

required for the project

6-8-16 Preparing the Drawings

6-8-16 Make or Buy Decisions

20-8-16 Market survey

3-9-16 Identifying the required resources,

materials, machine tools and

workshop tools required.

17-9-16 Cost Estimation

17-9-16 Preparation of notes individually

on:

1. Extent to which he has

achieved learning outcomes

2. Own experience in executing

project.

3. Technical problem faced and

solutions found

1-10-16 Preparation of list of references

Preparation of project report

15-10-16 Presentation

Government Polytechnic Ahmedabad Page 43

You might also like

- Project Management Casebook: Instructor's ManualFrom EverandProject Management Casebook: Instructor's ManualNo ratings yet

- Forklift Project Report - 1Document43 pagesForklift Project Report - 1Anonymous bAj233Fs1e86% (49)

- Hydraulic ForkliftDocument21 pagesHydraulic ForkliftHector Sepulveda OrellanaNo ratings yet

- MA4001 15 16sem1Document14 pagesMA4001 15 16sem1Pearlyn Tiko Teo0% (2)

- TDC FINAL EXAM 2 DriveSafe PDFDocument76 pagesTDC FINAL EXAM 2 DriveSafe PDFlynzel Marie LozaresNo ratings yet

- Design and Fabrication of Pneumatic Scissor Lift ErDocument11 pagesDesign and Fabrication of Pneumatic Scissor Lift ErParuthi Ilam VazhuthiNo ratings yet

- Final ProjectDocument35 pagesFinal ProjectAnsh SharmaNo ratings yet

- Hydraulic ForkliftDocument52 pagesHydraulic Forkliftsiddharth100% (3)

- Crane Lifting MCD ProjectDocument43 pagesCrane Lifting MCD ProjectMahes WarNo ratings yet

- Design and Development of Forkliftfinal PROJECT REPORTDocument66 pagesDesign and Development of Forkliftfinal PROJECT REPORTSiddhant Malvade0% (1)

- Gujarat Technological University: "3 Wheel Drive Forklift For Industry Warehouse "Document27 pagesGujarat Technological University: "3 Wheel Drive Forklift For Industry Warehouse "VIKAS PatelNo ratings yet

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6Juan RiveraNo ratings yet

- Workshop, Repair and Service Manuals, Wiring Diagrams, Fault Codes PDF - More Than 1000+ Truck Manuals Are Available For Free Download!Document12 pagesWorkshop, Repair and Service Manuals, Wiring Diagrams, Fault Codes PDF - More Than 1000+ Truck Manuals Are Available For Free Download!Anbarasan0% (1)

- Forklift Project Report 1 PDFDocument43 pagesForklift Project Report 1 PDFfahamith ahamed67% (3)

- Fabrication of Hydraulic Scissor Lift: February 2020Document10 pagesFabrication of Hydraulic Scissor Lift: February 2020atashi baran mohantyNo ratings yet

- Hydraulic Floor Crane 360 Degree RotationDocument12 pagesHydraulic Floor Crane 360 Degree RotationPawan mehtaNo ratings yet

- Fabrication of Hydraulic Fork LiftDocument41 pagesFabrication of Hydraulic Fork LiftElakkiya Karthic50% (2)

- Stress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894Document7 pagesStress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894anil sajjanarNo ratings yet

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDocument8 pagesDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataNo ratings yet

- Design and Fabrication of a Hydraulic Floor CraneDocument29 pagesDesign and Fabrication of a Hydraulic Floor CraneVignesh DeepNo ratings yet

- Two Wheel Drive Forklift For Indusrial WarehousesDocument31 pagesTwo Wheel Drive Forklift For Indusrial WarehousesKalai SelvanNo ratings yet

- Fyp Hydraulic CraneDocument29 pagesFyp Hydraulic CraneGaganMaan71% (17)

- Pneumatic Scissor Lift ManualDocument14 pagesPneumatic Scissor Lift ManualGptc ChekkanuraniNo ratings yet

- Material Handling EquipmentsDocument28 pagesMaterial Handling EquipmentsAngshumanNo ratings yet

- Design and Fabrication of Mechanical Lift For TransportationDocument5 pagesDesign and Fabrication of Mechanical Lift For TransportationGRD JournalsNo ratings yet

- Report - Hydraulic Pipe Bending MachineDocument2 pagesReport - Hydraulic Pipe Bending MachinedhirajNo ratings yet

- Railway ProjectDocument51 pagesRailway Projectsanojjose75No ratings yet

- Automatic Side Stand Retreiving SystemDocument49 pagesAutomatic Side Stand Retreiving SystemEtgsNo ratings yet

- Chhuon Aasman Ko, Zameen Se Judhkar.: Presenting The World TractorDocument2 pagesChhuon Aasman Ko, Zameen Se Judhkar.: Presenting The World TractorgitamamNo ratings yet

- Junttan PMx27 DatasheetDocument4 pagesJunttan PMx27 DatasheetIkhsan SetiawanNo ratings yet

- JCB 4Dx - Backhoe Loader: Powered To SucceedDocument15 pagesJCB 4Dx - Backhoe Loader: Powered To SucceedAjans VictorNo ratings yet

- Linkage in Farm MachineryDocument4 pagesLinkage in Farm MachineryRehan RashidNo ratings yet

- Structural Optimization of Mini Hydraulic Backhoe ExcavatorDocument14 pagesStructural Optimization of Mini Hydraulic Backhoe Excavatormanjunath k sNo ratings yet

- Design and Construction of Hydraulic Scissor Lift: Research ArticleDocument4 pagesDesign and Construction of Hydraulic Scissor Lift: Research Articleyousuf79No ratings yet

- Hydrauliccranes Project ReportDocument14 pagesHydrauliccranes Project ReportRavikant0% (1)

- Volvo 8400 City Bus Brochure For Sales KitDocument8 pagesVolvo 8400 City Bus Brochure For Sales KitER Balram YadavNo ratings yet

- Earth Moving EquipmentDocument5 pagesEarth Moving EquipmentEmmett YoungNo ratings yet

- Hydraulic Gear Pumps Market 2016 Global Industry SizeDocument8 pagesHydraulic Gear Pumps Market 2016 Global Industry SizefullkuleNo ratings yet

- Scissor Lift DocumentDocument14 pagesScissor Lift DocumentTamil SelvanNo ratings yet

- Fabrication of Hydraulic Pipie Bending MachineDocument50 pagesFabrication of Hydraulic Pipie Bending MachineElakkiya Karthic100% (4)

- Group No. 2 Project Report Review 2Document35 pagesGroup No. 2 Project Report Review 2Devansh SharmaNo ratings yet

- Automatic Road Curve Finder: SynopsisDocument4 pagesAutomatic Road Curve Finder: SynopsissathishNo ratings yet

- 9.optimisation in Design of Mechanical Scissor LiftDocument5 pages9.optimisation in Design of Mechanical Scissor LiftAmit GhadeNo ratings yet

- DAR ES SALAAM INSTITUTE OF TECHNOLOGY MECHANICAL ENGINEERING DEPARTMENT BACHELOR OF MECHANICAL ENGINEERING SENIOR PROJECT - II MODIFICATION AND MANUFACTURE OF MANUALLY COCONUT DE HUSKING MACHINEDocument70 pagesDAR ES SALAAM INSTITUTE OF TECHNOLOGY MECHANICAL ENGINEERING DEPARTMENT BACHELOR OF MECHANICAL ENGINEERING SENIOR PROJECT - II MODIFICATION AND MANUFACTURE OF MANUALLY COCONUT DE HUSKING MACHINEdavidNo ratings yet

- 3 PTL MBD SimulationDocument8 pages3 PTL MBD SimulationSumit SheoranNo ratings yet

- Chapter 1 Introduction To Fluid PowerDocument33 pagesChapter 1 Introduction To Fluid PowerSiraj Busse100% (4)

- Designing a Hydraulic Bottle JackDocument45 pagesDesigning a Hydraulic Bottle JackBirhanu AsfawNo ratings yet

- Design Project RepoprtDocument34 pagesDesign Project Repoprtuda2y2100% (2)

- Everything You Need to Know About Fluid Power PumpsDocument10 pagesEverything You Need to Know About Fluid Power PumpspowertrainlNo ratings yet

- Manual - Ace CraneDocument60 pagesManual - Ace CraneManoj SinghNo ratings yet

- Design of Post Hole Digger Machine IJERTV3IS030320Document5 pagesDesign of Post Hole Digger Machine IJERTV3IS030320Ajit KalasaitNo ratings yet

- Design and Optimation of Arm ExcavatorDocument6 pagesDesign and Optimation of Arm Excavatoranon_664850107No ratings yet

- GMD 16 20 Operators ManualDocument80 pagesGMD 16 20 Operators ManualVladimir ArsicNo ratings yet

- Gearless TransmissionDocument48 pagesGearless TransmissionIpaseta Dhara88% (8)

- Analysis of Hoisting Gearbox of EOT CraneDocument20 pagesAnalysis of Hoisting Gearbox of EOT CraneAnkit PatelNo ratings yet

- Everything You Need to Know About Engine ConfigurationsDocument25 pagesEverything You Need to Know About Engine ConfigurationsPrajwal JaiswalNo ratings yet

- JCB's Commitment to Quality, Sustainability and Employee WelfareDocument7 pagesJCB's Commitment to Quality, Sustainability and Employee WelfareSalman ShafiqueNo ratings yet

- Automatic pneumatic jack lifts vehicles with rack and pinionDocument4 pagesAutomatic pneumatic jack lifts vehicles with rack and pinionMectrosoft Creative technologyNo ratings yet

- Design and Fabrication of Motorized Hydraulic Jack SystemDocument8 pagesDesign and Fabrication of Motorized Hydraulic Jack SystemIJRASETPublicationsNo ratings yet

- ClutchesDocument9 pagesClutchessonabrar10No ratings yet

- Diploma in Mechanical Engineering: Hydraulic Fork LiftDocument43 pagesDiploma in Mechanical Engineering: Hydraulic Fork LiftEngland OYINMIEBINo ratings yet

- Hydrulic Lift PDFDocument43 pagesHydrulic Lift PDFShaswat ranjan KundaNo ratings yet

- Design and Fabrication of Pneumatic Sheet Metal Cutting MachineDocument34 pagesDesign and Fabrication of Pneumatic Sheet Metal Cutting Machine4008- Manoj KumarNo ratings yet

- All Types Painting Work Done Here Add: Milindnagar Near Vitthal Mandir Kalyan West 421301Document1 pageAll Types Painting Work Done Here Add: Milindnagar Near Vitthal Mandir Kalyan West 421301manoj phadtareNo ratings yet

- Research Protocol: Department of Molecular BiologyDocument2 pagesResearch Protocol: Department of Molecular Biologymanoj phadtareNo ratings yet

- Bill Back SideDocument1 pageBill Back Sidemanoj phadtareNo ratings yet

- AbcbDocument3 pagesAbcbmanoj phadtareNo ratings yet

- Experience CertificateDocument1 pageExperience Certificatemanoj phadtareNo ratings yet

- Vaibhav CLG Form Part 1Document1 pageVaibhav CLG Form Part 1manoj phadtareNo ratings yet

- Application No: RegularDocument2 pagesApplication No: Regularmanoj phadtareNo ratings yet

- Lead School: Class 6Document2 pagesLead School: Class 6manoj phadtare100% (2)

- IERC Application Form GuideDocument2 pagesIERC Application Form Guidemanoj phadtareNo ratings yet

- Class 8 Biology Unit 1: ASM 1 Science: InstructionsDocument1 pageClass 8 Biology Unit 1: ASM 1 Science: Instructionsmanoj phadtare67% (3)

- Logout Fees Receipt FormDocument2 pagesLogout Fees Receipt Formmanoj phadtare0% (1)

- Éé®Úié Êxé Éb÷Héúeò +É ÉéäméDocument7 pagesÉé®Úié Êxé Éb÷Héúeò +É Ééämémanoj phadtareNo ratings yet

- Class 6: When End Quiz ClickDocument2 pagesClass 6: When End Quiz Clickmanoj phadtareNo ratings yet

- Sub - Application For The Post of Asst. Professor For PoliticsDocument1 pageSub - Application For The Post of Asst. Professor For Politicsmanoj phadtareNo ratings yet

- Class 6: Unit 4: Asm 1 CcsDocument1 pageClass 6: Unit 4: Asm 1 Ccsmanoj phadtareNo ratings yet

- Mumbai University Project on EuthanasiaDocument28 pagesMumbai University Project on Euthanasiamanoj phadtareNo ratings yet

- M Tech ProjectDocument98 pagesM Tech Projectmanoj phadtareNo ratings yet

- A121 7CCS01Document2 pagesA121 7CCS01manoj phadtare100% (1)

- Seminar Presentation On Pocso Act 2012Document26 pagesSeminar Presentation On Pocso Act 2012manoj phadtare0% (1)

- PoscoDocument34 pagesPoscomanoj phadtareNo ratings yet

- Wireless Power TransferDocument18 pagesWireless Power Transfermanoj phadtareNo ratings yet

- M Tech Projects - Engineering Project REPORTDocument55 pagesM Tech Projects - Engineering Project REPORTmanoj phadtareNo ratings yet

- Euthanasia Research DataDocument15 pagesEuthanasia Research Datamanoj phadtareNo ratings yet

- M Tech ProjectDocument98 pagesM Tech Projectmanoj phadtareNo ratings yet

- Cadbury's Sales Promotion Strategy for ChildrenDocument72 pagesCadbury's Sales Promotion Strategy for ChildrenShivam KapoorNo ratings yet

- Cadbury's Sales Promotion Strategy for ChildrenDocument72 pagesCadbury's Sales Promotion Strategy for ChildrenShivam KapoorNo ratings yet

- Real Passive Express Solution LLPDocument1 pageReal Passive Express Solution LLPmanoj phadtareNo ratings yet

- Cadbury's Sales Promotion Strategy for ChildrenDocument72 pagesCadbury's Sales Promotion Strategy for ChildrenShivam KapoorNo ratings yet

- M Tech Projects - Engineering Project REPORTDocument55 pagesM Tech Projects - Engineering Project REPORTmanoj phadtareNo ratings yet

- Plaza Code, Type, Name and LocationDocument10 pagesPlaza Code, Type, Name and LocationSivaraj D0% (1)

- Minutes of the 7th Regular Session of the 20th City CouncilDocument28 pagesMinutes of the 7th Regular Session of the 20th City CouncilJournal SP DabawNo ratings yet

- 2023 Beta Xtrainer Service ManualDocument120 pages2023 Beta Xtrainer Service ManualPASCONo ratings yet

- 318D, 319D, 320D and 323D Skid Steer Loader Repair (Manual Controls)Document23 pages318D, 319D, 320D and 323D Skid Steer Loader Repair (Manual Controls)Ronald VelascoNo ratings yet

- DFG/TFG 16 - 50 A/B/C-K: Operating InstructionsDocument142 pagesDFG/TFG 16 - 50 A/B/C-K: Operating InstructionsbenjaminNo ratings yet

- Sixth Fast JS Series GearboxDocument23 pagesSixth Fast JS Series Gearboxrumen80100% (1)

- Mitsubishi Motors Service & Maintenance Schedule: New Triton VGT atDocument2 pagesMitsubishi Motors Service & Maintenance Schedule: New Triton VGT atFaizul AzmanNo ratings yet

- Activity Sheet in Science 9 For CODocument8 pagesActivity Sheet in Science 9 For COjmym0902No ratings yet

- ASME-A17.1-CSA-B44 (2013, 2016 and 2019)Document169 pagesASME-A17.1-CSA-B44 (2013, 2016 and 2019)HR DCCON100% (1)

- Track Your Fleet of School Buses. Anytime, AnywhereDocument4 pagesTrack Your Fleet of School Buses. Anytime, AnywhereMohammed NizamNo ratings yet

- Mid XRXpartsDocument22 pagesMid XRXpartsReal DealNo ratings yet

- MPR Package - 6 AprilDocument28 pagesMPR Package - 6 AprilRayNo ratings yet

- Hilux GR Sport 2023 BrochureDocument15 pagesHilux GR Sport 2023 BrochureKiki LalaNo ratings yet

- CBE 25 30 30L 35: Service ManualDocument62 pagesCBE 25 30 30L 35: Service Manualmoviteknika100% (1)

- Design of a Permanent Magnet Synchronous Motor for Electric VehiclesDocument131 pagesDesign of a Permanent Magnet Synchronous Motor for Electric VehiclesMounir Aoutti EttajliNo ratings yet

- Functional & Innovative ProductsDocument9 pagesFunctional & Innovative ProductsShubham RathiNo ratings yet

- Earthwork Report WikitDocument9 pagesEarthwork Report WikitAfif AzharNo ratings yet

- 10a AuditDocument47 pages10a AuditMohammed MinhajNo ratings yet

- Fatigue Analysis Techniques for Vehicle Truck FramesDocument5 pagesFatigue Analysis Techniques for Vehicle Truck FramesPrateek GadagiNo ratings yet

- Mercedes Benz Sprinter 2004 Parts ManualDocument20 pagesMercedes Benz Sprinter 2004 Parts Manualjoyce100% (48)

- Cost-effective material handling with conveyorsDocument79 pagesCost-effective material handling with conveyorsmichaelNo ratings yet

- Lamelle KYB Fork Oem 2011Document10 pagesLamelle KYB Fork Oem 2011manualmaniaitalyNo ratings yet

- 06 Bituminous Material PDFDocument16 pages06 Bituminous Material PDFidlemineNo ratings yet

- Dynapac Pneumatic Tire Roller Cp1200 Operation and MaintenanceDocument8 pagesDynapac Pneumatic Tire Roller Cp1200 Operation and Maintenancemanuel100% (44)

- PPR Edifice - 17-Jahind Encave-Madhapur-For LeaseDocument10 pagesPPR Edifice - 17-Jahind Encave-Madhapur-For LeaseRishi KhuranaNo ratings yet

- Technical Service Information: GM 4T65EDocument5 pagesTechnical Service Information: GM 4T65EVIDAL ALEJANDRO GARCIAVARGASNo ratings yet

- Sgrwa Rule Book: Team Work Makes The Dream WorkDocument18 pagesSgrwa Rule Book: Team Work Makes The Dream WorkPrashant SharmaNo ratings yet