Professional Documents

Culture Documents

04 - Case Study 672

Uploaded by

smallik3Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 - Case Study 672

Uploaded by

smallik3Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/339498831

FMEA AIAG-VDA - Commentary and Case Study

Preprint · February 2020

DOI: 10.13140/RG.2.2.26358.55363

CITATIONS READS

0 5,358

2 authors:

Edly Ramly Hood Atan

EFR Certification, Malaysia Exergy management training plt

17 PUBLICATIONS 16 CITATIONS 3 PUBLICATIONS 2 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Operational IR4.0 Readiness Assessment View project

Operational Risk Management and FMEA View project

All content following this page was uploaded by Edly Ramly on 23 April 2020.

The user has requested enhancement of the downloaded file.

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

FMEA AIAG-VDA - Commentary and Case Study

Edly F. Ramly

Certification Director

EFR Certification Sdn Bhd, Malaysia

e.ramly@efrcertification

Hood Atan

IATF Auditor

Exergy Management Consultant Malaysia

hood.atan@yahoo.com

Abstract

Automotive Industry Action Group (AIAG) and Verband der Automobilindustrie (VDA) jointly published

a FMEA handbook to be used by automotive suppliers to assist them in development of FMEA. Since the

handbook newly published in June 2019, there are several issues in adopting the reference manual. This

paper explores the common issues and benefits in developing the Process FMEA by using the the AIAG-

VDA handbook through two case study. The output of this paper provide the commentary of strength,

benefit and issues in developing PFMEA through AIAG-VDA FMEA handbook.

Keywords:

Risk Assessment, Risk Management, FMEA, Operation Management, IATF.

1. Introduction

The reference manual that outline the guideline for Failure Mode Effect Analysis (FMEA) published by Automotive

Industry Action Group (AIAG) 4th edition in year 2008, has been updated with new handbook. The new handbook

was published jointly by AIAG which is based in United States of America and Verband der Automobilindustrie

(VDA) which is based in Germany in June 2019. In 2017-2018, we conducted case study in implementation of FMEA

and determined that there are seven issues in implementation of FMEA and concluded as followed (Ramly and Atan,

2018):

PFMEA is proven risk assessment methodology to prevent defects. However, there are seven issues that face by the

organization and the team that develop the PFMEA for their manufacturing process. The issues include determining

whether to develop the design FMEA or process FMEA, setting up the objectives of PFMEA, determining the

processes, determining the severity score, listing the causes, determining occurrence score, determining control and

prioritizing the improvement. Each of the issue have the proposed solution as discussed in previous paper. The future

research should focus on linking the PFMEA and other quality improvement tools such as cause and effect diagram,

control plan and application of PFMEA in quality improvement initiatives such as six sigma and lean manufacturing.

Hence this paper conducted additional case study with two organization in order to study and provide commentary:

- The main difference between the AIAG 4th Edition FMEA handbook vs AIAG-VDA 1st edition handbook;

- The benefit of implementing the PFMEA according to AIAG-VDA FMEA handbook;

- The issues and limitation of the AIAG-VDA FMEA handbook;

© IEOM Society International

2957

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

- Recommended solution to minimise the issues and limitation in implementing the PFMEA according to

AIAG-VDA FMEA handbook.

AIAG-VDA FMEA handbook provide guideline for Design FMEA (DFMEA), Process FMEA (PFMEA), and

Monitoring system response (MSR FMEA). However, since both organizations in the case study are not design

responsible, hence the study and commentary are limited to Process FMEA (PFMEA) as prescribed in section III of

the AIAG-VDA FMEA handbook.

2.0 Improvement of AIAG/VDA PFMEA framework

From the 2017-2018 study of FMEA develop by Ramly and Atan (2018), the AIAG/ VDA FMEA framework

complement and improve 6 out of seven issues recommended in the from the papers as followed:

1. Product or process – Addressed

2. Defect Prevention – Partially Addressed

3. Process Flow – Not addressed

4. Effects to determine severity score - Addressed

5. Top three causes – Partially Addressed

6. Determining occurrence score - Addressed

7. Continual Improvement Prioritization - Addressed

2.1 Product or Process

The previous reference manual (AIAG, 2008) not clearly addressed the context of organization in developing the

FMEA. Hence, the recommended solution is to include the clear context in risk management as recommended in

ISO31000 Risk Management guideline (Ramly and Atan, 2018). The 2019 AIAG/ VDA FMEA handbook have clearly

addressed the context in section 1.1. The section 1.1 stated that the context of the FMEA framework is cover only

technical risk and exclude the financial risk, time risk and strategy risk.

2.2 Defect Prevention

For FMEA, mandate and commitment as required by ISO31000 should be “Defect Prevention” as proposed by the

previous case study. The 2019 AIAG/ VDA FMEA handbook provide more lengthy explanation and example of

objective of FMEA such as defect free launch in section 1.2. However, the defect prevention should be highlighted as

main goal of FMEA that will lead to achievement of other objectives such as reducing warranty and goodwill costs,

increasing of customer satisfaction and building knowledge base in the company.

At the meantime, the seven steps in FMEA development as outline in 2019 AIAG/ VDA FMEA handbook provide

clear framework in defect prevention. The first part of “step 2 structure analysis”, “step 3 functional analysis” and

“step 4 failure analysis”, provide structured methodology to define the requirements as show in table 1 that can be

focused on defect prevention. From previous version of FMEA, there are column on “Requirement”. Requirements

can be refer to specification or characteristic of the product such as dimension, colour, functionality and appearance.

The requirements column is recommended since it can help the team to determine the potential failure mode in term

of defects or opposite to the requirements such as Bent, Burred, Hole off-location, Cracked, Hole too shallow, Hole

missing, Dirty, Surface too rough, Deformed, Open circuited, Short circuited and Mis-labelled. The 2019 AIAG/ VDA

FMEA handbook provide the step to determine the requirement effectively under the step 3 as shown in both table 1

and table 2. The step 3 determine the function of the process item, or function of system or subsystem, or part element

or process step. Hence the step 3, effectively assisted to determine the failure mode, failure effect and failure cause in

step 4 of 2019 AIAG/ VDA FMEA framework.

© IEOM Society International

2958

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

Table 1: Sequence in analysis of parts/ components

. STRUCTURE ANALYSIS . FUNCTION ANALYSIS . FAILURE ANALYSIS

(STEP 2) (STEP 3) (STEP 4)

.1. Function of the Process Item

1. Process Item, System, .1. Failure Effect (FE) to the Next Higher-

Function of System, Subsystem,

Subsystem, Part Element Level Element and/or End User

Part Element or Process

Electrical Motor Assembly Your Plant: Your Plant:

Assembly of shaft into pole Clearance too small to assemble shaft without

housing assembly potential damage

Ship to Plant: Ship to Plant:

Assembly of motor to vehicle Assembly of motor to vehicle door requires

door additional insertion force with potential

End User: damage

Window raises and lowers End User:

Comfort closing time too long.

2.3 Process Flow

The 2019 AIAG/ VDA FMEA handbook not clearly addressed or provide guideline in detailing the type of process.

The argument from the team on “should the PFMEA include all the process such as inspection, each of movement,

each of storage and work in progress?” From previous study, the team agree that the PFMEA shall include all the

value-added process that change the physical of the product. The team also agreed that the inspection process should

be excluded from the PFMEA due to: 1) The PFMEA is the tools to determine the inspection/ control needed; 2) The

potential failure of inspection process (such as wrong decision) is control through calibration and Gage Repeatability

and Reproducibility (GRR) study; 3) The risk of producing another defect during inspection should be highlighted in

inspection standard or procedure. As for the move (Transfer between station) and wait process (Raw material storage,

Work in progress and Finish good storage), the team decided whether to include in the analysis based on probability

of defect occurred during the process. If there are minimum defect can occurred, the process can be omitted from the

PFMEA.

However, the example from the 2019 AIAG/ VDA FMEA handbook, the process step determines from step 2 can be

further analyse to step 3 and step 4 in more detail as shown in table 2. This methodology helps the team to determine

the failure mode effectively and avoid confusion in determining the failure effect.

Table 2: Sequence in analysis of parts/ components

. STRUCTURE ANALYSIS . FUNCTION ANALYSIS . FAILURE ANALYSIS

(STEP 2) (STEP 3) (STEP 4)

.2. Function of the Process Step

2. Failure Mode (FM) of the

2. Process Step and Product Characteristic

Focus Element

(Quantitative value is optional)

(OP30) Sintered Bearing Press in Press in sintered bearing to Axial position of sintered bearing

Process achieve axial position in pole is not reached

housing to max gap per print

© IEOM Society International

2959

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

2.4 Effects to determine severity score

The previous AIAG FMEA reference manual 9AIAG, 2008) have provide clear guideline to determine the severity

score for the defects based on the effect to customer or next process. The effects can be categorized to Safety and

Regulation related, Functionality including fitment related, and Appearance related. So far, the team does not face any

issues in determine the effect of defect in terms of what the customer might notice or experience, remembering that

the customer may be an internal customer as well as the ultimate end user. In addition, the 2019 AIAG/ VDA FMEA

handbook provide three level of effect which are 1) Your Plant; 2) Ship to Plant; 3) End User as shown in table 1.

2.5 Top three causes

2019 AIAG/ VDA FMEA handbook provided the need to determine the cause, start from step 2 by determining the

process work element of 4M (Man, Material, Machine, Method).

From the previous study, the potential cause of failure is defined as how the failure could occur, described in terms of

something that can be corrected or can be controlled. The team list every cause assignable to each of potential defect

(potential failure mode). The FMEA development team attempted to determine the potential cause through cause and

effect (defect) diagram (fishbone diagram) and five why analysis. However, the teams were unable to document all

the causes due to limited space (column and row) in the AIAG PFMEA sheet. The same issues occurred with 2019

AIAG/ VDA FMEA recommended form. Hence the recommendation to document only top three causes in the sheet

through team consensus and the copy of each cause and effect (defect) diagram is recommended to be documented

for future reference.

2.6 Determining occurrence score

From previous study, the team have difficulties in deciding whether the occurrence should be reflected on the “defect”

or the occurrence of “cause”. For the first organization, the team selected to use the “defect” as indicator for occurrence

score. While the second organization, develop the occurrence score rating which are “defect score rating” and cause

occurrence score rating”. 2019 AIAG/ VDA FMEA handbook have cleared the team from the previous difficulties

The handbook outline in the 5th step of FMEA as risk analysis that the occurrence score should be determine by the

type of prevention control. Hence the occurrence score determines from the prevention control of either the failure

mode (defect) or failure cause. Occurrence is the likelihood that a specific failure will occur. The likelihood of

occurrence ranking number has a relative meaning rather than an absolute value. Preventing or controlling the

causes/mechanisms of failure through a design or process change is the only way a reduction in the occurrence ranking

can be affected as shown in table 3.

3.6 Determine control

Na2019 AIAG/ VDA FMEA handbook Current Process Controls are descriptions of the controls that either prevent

to the extent possible the failure mode or cause/mechanism of failure from occurring, or detect the failure mode or

cause/mechanism of failure should it occur. Two types of Process Controls to consider: 1) Prevention: Eliminate

(prevent) the cause of the failure or the failure mode from occurring, or reduce their rate of occurrence, 2) Detection:

Identify (detect) the cause of failure or the failure mode, leading to the development of associated corrective action

(s) or counter measures. The preferred approach is to first use prevention controls, if possible. The initial occurrence

rankings will be affected by the prevention controls provided they are integrated as part of the process. The initial

rankings for detection will be based on process controls that either detect the cause/mechanism of failure, or detect

the failure mode.

© IEOM Society International

2960

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

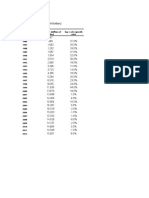

Table 3: The occurrence ranking (Extracted from 2019 AIAG/ VDA FMEA handbook)

Occurrence Potential (O) for the process

Potential Failure Causes rated according to the criteria below. Consider prevention Controls when determining the best

Occurrence estimate. Occurrence is a predictive qualitative rating made at the time of evaluation and may not reflect

Blank until filled in by

the actual occurrence. The occurrence rating number is a relative rating within the scope of the FMEA (process being

user

evaluated). For prevention Controls with multiple Occurrence Ratings, use the rating that best reflects the robustness of

the control.

Corporate or

Prediction of Failure

O Type of Control Prevention Controls Product Line

Cause Occurring

Examples

10 Extremely High None No prevention controls.

9

Prevention controls will have little effect in

Very High Behavioral

preventing failure cause.

8

7

Prevention controls somewhat effective in

High

preventing failure cause.

6

Behavioral or

Technical

5

Prevention controls are effective in preventing

Moderate

failure cause.

4

3 Low Best Practice:

Prevention controls are highly effective in

Behavioral or

preventing failure cause.

2 Very Low Technical

Prevention controls are extremely effective in

preventing failure cause from occurring due to

design (e.g. part geometry) or process (e.g. fixture

1 Extremely Low Technical

or tooling design). Intent of prevention controls –

Failure Mode cannot be physically produced due to

the failure cause.

The team decision from previous study have been determine effectively in 2019 AIAG/ VDA FMEA handbook as

depicted in figure 1 such as the prevention control only such as error proofing to the cause of defects and include set-

up verification. The detection controls cover the inspection process either during incoming, in-process or outgoing

inspection. However the 2019 AIAG/ VDA FMEA handbook does not indicate any of this control should be transfer

to control plan to detail up the inspection process.

© IEOM Society International

2961

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

Figure 1: The prevention control vs detection control (Extracted from 2019 AIAG/ VDA FMEA handbook Figure

3.5-1 and 3.5-2)

3.7 Continual Improvement Prioritization

2019 AIAG/ VDA FMEA handbook replace the improvement prioritization through risk priority number (RPN)

threshold to “action priority” risk matrix that determine the level of risk based on combination of severity, occurrence

and detection ranking. This provide solution to ambiguous recommendation from previous AIAG method that required

to prioritized based on highest severity first, the occurrence second and the detection third. This method has make no

sense in determining the action for example the severity score is 10, while occurrence is 2 and detection is 2. It is

because the occurrence and detection are already considered as low as practicable. Example of action priority risk

priority table as shown in figure 2.

Prediction of ACTION

Failure Effect S Failure Cause O Ability to Detect D PRIORITY Comments

Occurring (AP)

Low – Very low 7-10 H

Moderate 5-6 H

Moderate 4-5

High 2-4 H

Very high 1 M

9-10 Low – Very low 7-10 H

Moderate 5-6 M

Low 2-3

High 2-4 L

Very high 1 L

Very low 1 Very high – Very low 1-10 L

Figure 2: The example of action priority table

© IEOM Society International

2962

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

3. Discussion

Apart of benefit, strength and limitation in comparing with previous study result, additional strength and limitation of

AIAG-VDA FMEA handbook were found. The additional strength and limitation are discussed below.

1. FMEA Success Factors

In addition, the handbook outline the success factors in section 1.3 of the handbook. Section 1.3 outline the success

factors in integration of FMEA in the company that include, 1) several potential considerations of the FMEA i.e. real,

true, realistic, complete; 2) Senior Management Commitment, 3) Know-How protection and 3) development of

foundation and family FMEAs. However, the example is limited and further study on the FMEA development and

implementation critical success factor is highly recommended.

2. Implementation/ Adoption Strategy

There is no specific transition period to adopt the 2019 AIAG/ VDA FMEA framework especially for IATF certified

organization. Several car makers specified to their supplier should adopt the new FMEA framework when there is a

new project. From the case study conducted, both organization are not bind by their customer to adopt the new format.

Hence, for the start, the team agreed to use the new framework for the purposed of solving customer complaints on

their quality issued.

3. Linkage to other quality tools and techniques

2019 AIAG/ VDA FMEA handbook provide no clear linkage several important quality and techniques such as linkage

to control plan, cause and effect diagram, and process approaches turtle diagram. However the handbook outline the

linkages to AIAG Advance Product Quality Planning (APQP) and VDA Maturity Level Agreement (MLA). The

handbook also outline in step 1 of planning and preparation to determine the tools as part of five “T” in project plan

which are intent, Timing, Team, Task and Tools.

4. Level of detail in PFMEA

Due to number of steps to develop the PFMEA increase in the 2019 AIAG/ VDA FMEA framework, more space

required especially if the organization used the worksheet software such as excel. The information cannot be presented

on single page. Hence it is difficult to present the information in the PFMEA. Same goes to the level of detail to work

elements. Even though there is no solution provide by the team, the used of guided software application is highly

recommended by the team to provide clear guide to determine the information required by PFMEA and recommended

the space to store the information for future use.

4. Conclusion

2019 AIAG/ VDA FMEA handbook provide the systematic framework to conduct technical product and process risk

assessment to prevent defect. Potential Failure Modes and Effects Analysis in Manufacturing and Assembly Processes

(PFMEA) is an important preventive method for quality assurance, and through it informed action priority

methodology provide decisions based on the severity levels and probabilities of occurrences and detection of the

failure modes. The framework also can be effectively applied for problem solving techniques. Both version of PFMEA

have been develop according to AIAG (2009) and AIAG VDA (2019) version have been developed, review and tested

in case organizations. However, there are several issues that potentially face by the organizations that implement

several management systems such as there is limited specific tools and techniques provided, limited space to fill in

the format provided, and limited example of intent and adoption strategy.

© IEOM Society International

2963

Proceedings of the International Conference on Industrial Engineering and Operations Management

Dubai, March 6-8, 2020

The future research should focus on linking the PFMEA framework with other quality tools and study the effectiveness

through the result and the performance improvement after adopting the FMEA. More case study is required on

different context of organization, different industry and sector, difference business process and difference size of

organization.

References

Ramly, E. F., Atan, H.. (2018). Case Study on Development of Process Failure Mode Effect Analysis (PFMEA) –

Issues and Recommendation. Proceedings of the International Conference on Industrial Engineering and Operations

Management, Bandung. Indonesia, March 6-8, 2018

AIAG and VDA. (2019). Failure Mode and Effects Analysis - Fmea Handbook: design Fmea, process Fmea,

supplemental Fmea for monitoring et system response. Southfild, MI.

AIAG - Chrysler LLC, Ford Motor Co., General Motors Corp. (2008). Potential failure mode and effects analysis

(Fmea): reference manual. Southfield, MI.

Biography

Edly F. Ramly is Certification Director for EFR Certification and Fellow for IEOM. He is renowned coach, auditor,

consultant and trainer. With his excellent technical expert and interpersonal skills, he has conducted various high

impact trainings and workshop in the area of operation management, industrial engineering, management system

including quality, environment and occupational health and safety, workplace improvement, variation and waste

reduction, and practical problem solving techniques including statistical tools. Apart from being trained as Lead

Auditor in various management system, he is also qualified auditor for Automotive Industry IATF 16949. During his

service with Pera Neville Clarke, he is also tutor for QMS lead auditor course. His industrial experience was in the

automotive industry. During his stayed with the TRW Automotive, he was tasked with the responsibility of promoting

and implementing Lean and Six-Sigma within the Organization. Due to his extensive exposure in Lean and Six-Sigma

Management System, he was invited by Malaysia Productivity Corporation (MPC) and Asia Productivity Organization

(APO) to conduct public training in the area of Six-Sigma implementation and Lean Implementation. In 2014, he been

awarded as one of Malaysia Productivity Specialist by Malaysia Ministry of International Trade and Industry.

Hood Atan is a full time project consultant and qualified auditor in the fields of Quality, Health & Safety and

Environmental Management system. Mr. Hood Atan holds a Bachelor of Engineering in Mechanical (Industrial)

degree and a Master in Engineering (Industrial Engineering) degree from Universiti Teknologi Malaysia. Having

worked as a Quality Engineer, Quality Manager, Quality and Environmental Management Representative for

numerous years from bottom, middle and to top management. His industrial experience was in the manufacturing

industry. During his stayed with the TRW Automotive, he was tasked with the responsibility of promoting and

implementing VDA 6.3, QS-9000, ISO/TS 16949, ISO14001, ISO 13485, ISO50001, OSHAS 18001 management

system and Lean Six Sigma initiatives within the organization. Besides, he also responsible for supplier audit either

local or oversea such as Thailand, Singapore, Vietnam, Indonesia, China and India.

© IEOM Society International

2964

View publication stats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Chapter 2Document38 pagesChapter 2Mariana SotoNo ratings yet

- Manual Módulo Gunt CE640e - V0.4Document78 pagesManual Módulo Gunt CE640e - V0.4Mariana SotoNo ratings yet

- Sunday Morning Must-HaveDocument4 pagesSunday Morning Must-HaveMariana SotoNo ratings yet

- Exhibit 1: Gap's Annual Sales (In Millions of Dollars)Document6 pagesExhibit 1: Gap's Annual Sales (In Millions of Dollars)Mariana SotoNo ratings yet

- Statics, Fourteenth Edition: R.C. Hibbeler All Rights ReservedDocument13 pagesStatics, Fourteenth Edition: R.C. Hibbeler All Rights ReservedMariana SotoNo ratings yet

- Irregular Verbs CuadroDocument4 pagesIrregular Verbs CuadroMariana SotoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design of Electric Auto RickshawDocument20 pagesDesign of Electric Auto RickshawRithik GowdaNo ratings yet

- Tutorial 7B: Tutorial Tahap Clo-PloDocument12 pagesTutorial 7B: Tutorial Tahap Clo-PloJojnojie DannyzNo ratings yet

- December '95: 707-164 S4 CARRARO AXLE REF. 125650 For "CASE" Spare Parts ListDocument8 pagesDecember '95: 707-164 S4 CARRARO AXLE REF. 125650 For "CASE" Spare Parts ListOskars Rozefelds100% (1)

- CPM Parts Catalog 6-20-13Document60 pagesCPM Parts Catalog 6-20-13Adrian MotocNo ratings yet

- Attachment ReportDocument1 pageAttachment Reportfire benderNo ratings yet

- Track Adjusters, Springs, Track Frames & Wear PartsDocument24 pagesTrack Adjusters, Springs, Track Frames & Wear PartsMICHAEL MONGUINo ratings yet

- 2009 3560ton Lowboys Web PDFDocument55 pages2009 3560ton Lowboys Web PDFFelipe Pan Iturra Ramirez100% (2)

- 3 Highway MedianDocument64 pages3 Highway MedianLovely Mae Cruza GawinganNo ratings yet

- Hydraulic ExcavatorDocument24 pagesHydraulic Excavatorиван ТрояновNo ratings yet

- JLG 1500SJ Service Maintenance ManualDocument706 pagesJLG 1500SJ Service Maintenance Manualmilandilov100% (1)

- From Pandemic Disruption To Global Supply Chain RecoveryDocument50 pagesFrom Pandemic Disruption To Global Supply Chain RecoveryZaima LizaNo ratings yet

- BF6M 1013 FCG3 PDFDocument6 pagesBF6M 1013 FCG3 PDFEdwin Alfonso Hernandez MontesNo ratings yet

- 3 Monthly Routine Fire PumpsDocument2 pages3 Monthly Routine Fire PumpsMarciokronembergerNo ratings yet

- Ventilation Systems Operating ExperienceDocument44 pagesVentilation Systems Operating ExperienceNandan RajeNo ratings yet

- Ebike Error Codes and Their Solutions - Bosch 503, Shimano W103 and More E-MOUNTAINBIKE MagazineDocument1 pageEbike Error Codes and Their Solutions - Bosch 503, Shimano W103 and More E-MOUNTAINBIKE MagazineRaúl GutiérrezNo ratings yet

- Operating Instr. Reachstackers 3578011601 - EN - 07.2011 (NEW) PDFDocument258 pagesOperating Instr. Reachstackers 3578011601 - EN - 07.2011 (NEW) PDFmario100% (1)

- Life Sustaining BusinessDocument5 pagesLife Sustaining BusinessPennLive100% (10)

- Inventions ExamvedaDocument56 pagesInventions ExamvedaTalhaNo ratings yet

- Soochna 2012 FinalDocument140 pagesSoochna 2012 FinalHanuma Reddy100% (1)

- MahindraArmoredProductsBrochureCompressed PDFDocument60 pagesMahindraArmoredProductsBrochureCompressed PDFJoseph GhorayebNo ratings yet

- 2014 - Present Bodyshop Manual: General Information Construction Panel ReplacementDocument155 pages2014 - Present Bodyshop Manual: General Information Construction Panel ReplacementJaripoterNo ratings yet

- Handbook Part 4Document6 pagesHandbook Part 4Michał JabłońskiNo ratings yet

- To Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineDocument3 pagesTo Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineBanwari Lal Prajapat100% (1)

- Most Expensive Cars in The WorldDocument5 pagesMost Expensive Cars in The WorldUmesh GuptaNo ratings yet

- Frigid A Ire Ftf530f Washer ManualDocument9 pagesFrigid A Ire Ftf530f Washer ManualJames GoodingNo ratings yet

- Y. B. Patil Polytechnic Akurdi, Pune: - Introduction To AutomobilesDocument15 pagesY. B. Patil Polytechnic Akurdi, Pune: - Introduction To AutomobilesNilesh PatilNo ratings yet

- Doosan 500 General MaintenanceDocument27 pagesDoosan 500 General MaintenanceGohan JayNo ratings yet

- Market Strategies of Hero Motocorp LTDDocument103 pagesMarket Strategies of Hero Motocorp LTDdeepak GuptaNo ratings yet

- ZF CAT CV-Transmission-Mercedes G85 A 4 RGB 2021-02 ENDocument12 pagesZF CAT CV-Transmission-Mercedes G85 A 4 RGB 2021-02 ENSaul BogotaNo ratings yet

- Repair Kit: BE05 - BE30 BrakesDocument12 pagesRepair Kit: BE05 - BE30 BrakesUku TatoNo ratings yet