Professional Documents

Culture Documents

D155a5 Brochure

Uploaded by

rachidaccOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D155a5 Brochure

Uploaded by

rachidaccCopyright:

Available Formats

FLYWHEEL HORSEPOWER

225 kW 302 HP @ 1900 rpm

OPERATING WEIGHT

38700 kg 85,320 lb

D155A-5

D

155A

CRAWLER DOZER

www.Komatsu.com Printed in Japan 200803 IP. AD (05)

Photo may include optional equipment

CEN00003-02 Materials and specifications are subject to change without notice

is a trademark of Komatsu Ltd. Japan

Downloaded from www.Manualslib.com manuals search engine

D155A-5

CRAWLER DOZER

FLYWHEEL HORSEPOWER

D155A-5 Crawler Dozer 225 kW 302 HP @ 1900 rpm

W ALK-A

WALK -AROUND

ROUND Reduced maintenance with

OPERATING WEIGHT

38700 kg 85,320 lb

hydraulic reservoir sight gauge BLADE CAPACITY

and spin-off filters housed in Semi-U: 8.8 m3 11.5 yd3

Full-U: 11.8 m3 15.4 yd3

Easy to learn and easy to operate left hand joystick compartment. Gull wing engine side

controls all tractor motion, while right hand joystick doors for easy and safer engine servicing. (See

controls all blade functions for accurate grading and high other reduced maintenance features on page 8.)

productivity. See pages 4 and 5.

The entirely new Komatsu D155A-5

carries on the tradition

of excellence established by the highly

regarded D155A-3. Komatsu torque converter

reduces shocks for

smooth operation. See page 9.

Blade tilt lines

completely protected.

Modular power train for increased Wet type multiple-disc

serviceability and durability. Forward A Komatsu-designed resilient equalized steering clutches/brakes

Komatsu Torqflow transmission offers undercarriage (REU). Unique X-type bogies eliminate both clutch and brake

mounted pivot shafts isolate final drives

from blade loads. See page 8.

single lever control of speed (3 forward provide tremendous traction on uneven ground. adjustment for facilitating maintenance.

and 3 reverse) and directional changes. See page 4. Improves traction component durability and See page 5.

operator comfort. See page 6.

Photos may include optional equipment

2 3

Downloaded from www.Manualslib.com manuals search engine

D155A-5

CRAWLER DOZER

O

OPERATOR

PERATOR’’S

S Electronic Monitor Panel

An electronic monitoring system prevents minor problems from developing into major ones.

C

All meters and gauges are controlled by a microcomputer, which provides a wide indication

COMPARTMENT

OMPARTMENT range for easier, more precise reading.

●

●

Electrical Charge Lamp

Engine Air Intake Pre-heat Lamp

●

Operator’s Compartment ●

●

Engine Coolant Temperature Caution Lamp

Engine Coolant Temperature Gauge

Engine Oil Pressure Caution Lamp

All steering, direction, and speed changes can be made with a single joystick control. ● Fuel Gauge

When the operator wants to move the machine forward and to the left, he simply moves the ● Service Meter

● Monitor Caution Cancel Switch

joystick forward and to the left. When he desires a gear change, he merely twists his wrist. ● Monitor Caution Lamp

The machine responds to the movement of the lever, providing the operator with feeling of ● Transmission Oil Temperature Gauge

natural control with Komatsu joystick.

Low-Noise Design

The engine, power train components, and

Easy-to-Operate Work Equipment

Control Lever

Wet type multiple-disc steering

control valves are rubber-mounted to the ● A PPC valve is used with the right joystick clutches/brakes

frame. A low-noise engine used and a blade control. This improves operator com-

radiator mask which diverts the engine noise. fort because of reduced operating effort Wet type multiple-disc type steering clutches are controlled by left hand single-lever joystick.

Engine side covers provide more than style and stroke. Steering clutches are spring loaded and hydraulically released, eliminating clutch adjustment

by damping engine noise. for maintenance-free operation. Wet multiple-disc steering brakes are spring loaded and

● With the Closed-Center Load Sensing

hydraulically released, and interconnected with steering clutches for steep turn. Steering

(CLSS) hydraulic system, blade lever

brakes also function as service brakes with pedal operation.

stroke is directly proportional with blade

speed, regardless of the load and travel

speed. This results in superb, fine controll-

ability.

Hexagonal Pressurized Cab

(Optional)

Air filters and a higher internal air pressure

combine to prevent external dust from enter-

ing the cab. The cab’s hexagonal design pro-

vides excellent front, side, and rear visibility.

The REU and the oil damper mount cab

soften shock for operator comfort and extend

components life.

Photo may include optional equipment

Steering Functions Blade Functions Ripper Functions

Forward and Lifting and Forward

reverse lowering and rearward

Right and left Tilting Raise and

steering lower

First, to second,

Left Hand to third shifting Right Hand

Photo may include optional equipment

Photo may include optional equipment

4 5

Downloaded from www.Manualslib.com manuals search engine

D155A-5

CRAWLER DOZER

U

UNDERCARRIAGE

NDERCARRIAGE

Flexibility Powerful Drawbar Pull for All Kinds of Terrain

AND F

AND FRAME

RAME Flexibly grasps ground surface due to Komatsu’s unique track-

roller design for more and better ground contact.

The X-bogie and rubber pad provide different suspension

characteristics depending on the ground surface. On flat

ground, REU functions as a conventional rigid undercarriage.

● Independent X-bogies and rubber pads (cushions) are

incorporated into the track rollers. On uneven terrain, the REU maximizes the suspension effect

Undercarriage the shoes always follow the contour of the ground, ensuring

a greater actual ground contact for greatly-improved

drawbar pull.

Advanced Resilient Equalized carriage. When the machine travels on

Undercarriage (REU) uneven ground, the REU maximizes the

suspension effect. The Komatsu REU

On flat ground Track frame

The Komatsu X-type bogie resilient

equalized undercarriage (REU) performs system improves traction, component

independent see-saw movements. Tremen- durability, and operator comfort.

dous traction can be achieved even on

Conventional Undercarriage Functions as a conventional rigid Ensures almost the same traction force as

uneven ground, because the shoe always

There is minimal shoe slippage with the undercarriage. a conventional rigid undercarriage.

follows the contour of the ground.

conventional low drive type undercarriage.

A rubber shock absorber is mounted on the The shoe slip limit has been substantially

X-type bogie and decreases vibration and raised due to long tracks and large ground On uneven ground

shock. This X-bogie and rubber cushion contact area. The large traction force thus

provide different absorption characteristics, obtained, in combination with high engine

depending on the ground surface. When the power, results in superb drawbar pull. With

machine travels on flat ground, the REU the low center of gravity, dynamic stability

Seesaw movement is performed Compared with a rigid type, the actual ground contact

functions as a conventional rigid under- is excellent. corresponding to ground surface. area increases and powerful drawbar pull is ensured

because the track shoes follow the contour of the

ground. Large deformation of the rubber pads

contributes to greater suspension effect.

Comfortable Ride on Uneven Ground Minimum Shock in Riding Over Obstacles

Outer

bogie Rubber Conventional

rigid type

pad 4

Fall height A

Suspension effect

Inner

bogie

1 B

A REU

Flat ground travel Rough terrain travel Obstacle height B

Center

On uneven ground, the rubber pad provides four times the When riding over obstacles, the height of the machine fall is low.

suspension effect.

Shaft:

Fixed to track

frame

Track

roller

Frame

Flat Bottom Frame

The pivot shafts and monocoque frames prevent mud build-

up. The design facilitates good maneuverability in muddy

conditions and reduces the chance of hanging up on stumps

or boulders.

6 7

Downloaded from www.Manualslib.com manuals search engine

D155A-5

CRAWLER DOZER

E

ENGINE

NGINE AND

AND S

SPECIFICATIONS

PECIFICATIONS

T

TORQUE

ORQUE C

CONVERTER

ONVERTER ENGINE

Komatsu SA6D140E-2, water-cooled, 4-cycle, turbocharged and

STEERING

Joystick controls for all directional movements. Simply tilt the joystick

aftercooled, diesel engine, 6 cylinders with 140 mm 5.51" bore x to the left to make a left turn. Tilt it to the right for a right turn.

Engine 165 mm 6.50" stroke and 15.24 ltr 930 in3 piston displacement. Pushing the lever forward results in the machine forwarding, while

pulling it toward the operator reverses the machine. Gear shifting

Flywheel horsepower*:

also possible with the single-steering lever.

SAE J1349. . . . . . . . . . . . . . . . . . . . 225 kW 302 HP at 1900 rpm

Fuel Efficient Engine Modular Power Train Components

DIN 6270 . . . . . . . . . . . . . . . . . . . . . 225 kW 305 PS at 1900 rpm Wet, multiple-disc steering are spring-loaded hydraulically released.

The field-proven, rugged reliable Komatsu Modular design has facilitated removal/ Maximum torque . . . . . . . . . . . . . . 160 kg•m 1,157 lb/ft @ 1250 rpm Wet, multiple-disc, pedal-controlled service brakes are spring-

* Net flywheel horsepower output for standard engine (SAE J1349) actuated and hydraulically released. Gearshift lock lever also applies

225 kW 302 HP SA6D140E-2 provides high installation of power train components,

including air cleaner, alternator (not charging), water pump, lubricating service brakes.

torque for efficient dozing power and high shortening machine downtime. oil pump, fuel pump, muffler, and fan.

Minimum turning radius . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7 m 12'2"

reliability and low fuel consumption. Direct-injection fuel system. All-speed mechanical governor. (As measured by track marks on ground.)

Wet, Multiple-Disc Brakes Forced lubrication driven by gear pump. Full-flow filter for lube

Automatic Preheating Mechanism oil purification. Dual element, dry-type air filters with automatic

Eliminate brake adjustments for dust ejector and dust indicator. 24 V/11 kW electrical starting UNDERCARRIAGE

The best preheating times is set maintenance-free operation. motor. 24 V/35A alternator. 2 x 12 V/170 Ah batteries.

Suspension. . . . . . . . . . . . . . . . . . Oscillation-type with equalizer bar

automatically by sensing ambient temp- and forward mounted pivot shafts

erature. This simplifies the preheating Various Features for Track roller frame . . . . . . . . . . . . . . . . . . . . Monocoque, high-tensile-

TORQFLOW TRANSMISSION

operation. Easy Maintenance strength steel construction

Komatsu’s TORQFLOW transmission consists of a water-cooled,

● Radiator reserve tank 3-element, 1-stage, 1-phase torque converter and a planetary gear, Lubricated track rollers are resiliently mounted to roller frame

through a series of exclusive X-type bogies whose oscillating

multiple-disc clutch transmission which is hydraulically actuated

● Gull-wing engine side doors motion is cushioned by rubber pads.

and force-lubricated for optimum heat dissipation. Joystick control

● Centralized oil pressure test ports of gears (3 forward and 3 reverse) and directional steering changes. Number of track rollers (each side) . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gearshift lock lever and neutral safety switch prevent machine from Number of carrier rollers (each side) . . . . . . . . . . . . . . . . . . . . . . . . 2

● Centralized filter arrangement accidental starts.

Lubricated tracks. Unique dust seals for preventing entry of foreign

abrasives into pin-to-bushing clearance for extended service. Track

Travel speed Forward Reverse tension easily adjusted with grease gun.

1st 0–3.7 km/h 0–2.3 mph 0–5.0 km/h 0–3.1 mph

Number of shoes (each side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2nd 0–6.7 km/h 0–4.2 mph 0–8.2 km/h 0–5.1 mph Grouser height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 mm 3.1"

3rd 0–11.0 km/h 0–6.8 mph 0–13.9 km/h 0–8.6 mph Shoe width (standard/maximum) . . . . . . . . 560 mm 22"/710 mm 28"

Ground contact area . . . . . . . . . . . . . . . . . . . . . 35950 cm2 5,572 in2

Ground pressure (tractor only) . . . . . . 76.5 kPa 0.78 kg/cm2 11.1psi

1000 kgf

D155A-5

1000 lb

Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2100 mm 6'11"

Power Shift kN

DRAWBAR PULL VS. SPEED.

160

70

COOLANT AND LUBRICANT

MAXIMUM USABLE PULL

DEPENDS ON TRACTION AND CAPACITY (REFILLING)

140 WEIGHT OF TRACTOR INCLUDING

600

60 MOUNTED EQUIPMENT. Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 ltr 26.2 U.S. gal

120 Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 ltr 132.1 U.S. gal

DRAWBAR PULL

50

500 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ltr 9.8 U.S. gal

100

Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 ltr 0.4 U.S. gal

40 400 Transmission, bevel gear

80

and steering system . . . . . . . . . . . . . . . . . . . 60 ltr 15.9 U.S. gal

Final drive (each side). . . . . . . . . . . . . . . . . . . . 58 ltr 15.3 U.S. gal

30 300

60 F1

20 200 OPERATING WEIGHT (APPROXIMATE)

40 F2

Tractor weight:

10 100

20 F3 Including rated capacity of lubricant, coolant, full fuel tank, operator

and standard equipment . . . . . . . . . . . . . . . . . . . 27900 kg 61,510 lb

0 0

0 2 4 6 8 10 12 14 km/h

Above equipment plus optional side covers, air conditioner and 560 mm

22" extreme service shoes . . . . . . . . . . . . . . . . . 28600 kg 63,050 lb

0 2 4 6 8 MPH

TRAVEL SPEED Operating weight: Including Semi-U tiltdozer, multi-shank ripper,

steel cab, ROPS, operator, standard equipment, rated lubricant,

coolant full fuel tank, optional engine side covers, air conditioner and

FINAL DRIVE 560 mm 22” extreme service shoes . . . . . . . . . . 38700 kg 85,320 lb

Ground pressure . . . . . . . . . . . . . . . 105.9 kPa 1.08 kg/cm2 15.4 psi

Double-reduction, spur and planetary final drives increase tractive

effort. Segmented sprockets are bolt-on for easy in-the-field

replacement.

8 Photo may include optional equipment 9

Downloaded from www.Manualslib.com manuals search engine

D155A-5

CRAWLER DOZER

DIMENSIONS (SEMI-U TILT DOZER) STANDARD EQUIPMENT

● Air cleaner, double element with ● Fenders ● ROPS mounting brackets

A 3955 mm 13'0"

dust indicator ● Horn, warning ● Suspension seat

B 2080 mm 6'10" ● Alternator, 35 ampere ● Hydraulics for dozer ● Starting motor, 11 kW/24V

C 2260 mm 7'5" ● Batteries, 2 x 12V/170 Ah ● Lighting system, (includes 2 front, 1 rear) ● Track roller guard, end sections

D 2695 mm 8'10" ● Blower cooling fan ● Mono-lever steering control ● Track shoe assembly

E 3500 mm 11'6" ● Bogie roller guards ● Muffler with rain cap —Sealed and lubricated track

● Decelerator pedal ● Radiator reserve tank ● 560 mm 22" single grouser shoe

F 925 mm 3'0"

● Electronic instrument monitor panel ● Rear cover ● Underguards, oil pan and transmission

G 870 mm 2'10"

H 2510 mm 8'3"

I 3210 mm 10'6"

J 8155 mm 26'9"

K 4975 mm 16'4"

OPTIONAL EQUIPMENT

ROPS CANOPY SHOES

● Additional weight 505 kg 1,110 lb

● Meets ISO 3471, SAE J1040 APR88, and ISO 3449 Shoes (optional) Additional weight Ground contact area

FOPS standards. 560 mm 22" single

● Roof dimensions: grouser shoes 0 kg 0 lb 35950 cm2 5,572 in2

—Length: 1275 mm 4'2" 610 mm 24" single

—Width: 1500 mm 4'11" grouser shoes +210 kg +460 lb 39160 cm2 6,070 in2

—Height from operator compartment floor: 1757 mm 5'9"

660 mm 26" single

STEEL CAB grouser shoes +400 kg +880 lb 42370 cm2 6,567 in2

● Additional weight: 285 kg 630 lb

Ground Clearance: 485 mm 1'7" 710 mm 28" single

● All-weather, enclosed pressurized cab.

grouser shoes +620 kg +1,370 lb 45580 cm2 7,056 in2

● Roof dimensions:

—Length: 1765 mm 5'9" 560 mm 22" extreme

—Width: 1720 mm 5'8" service shoes +460 kg +1,010 lb 35950 cm2 5,572 in2

—Height from floor to ceiling: 1515 mm 5' 610 mm 24" extreme

HYDRAULIC SYSTEM service shoes +700 kg +1,540 lb 39160 cm2 6,070 in2

VARIABLE MULTI-SHANK RIPPER

Closed-center load sensing system (CLSS) designed for precise and Hydraulic cylinders . . . . . . . . . . . . . . . . . . . . Double-acting, piston ● Additional weight (including hydraulic control unit): 660 mm 26" extreme

responsive control, and for efficient simultaneous operation. 3710 kg 8,180 lb service shoes +940 kg +2,070 lb 42370 cm2 6,567 in2

Number of cylinders Bore ● Beam length: 2260 mm 7'5"

Hydraulic control unit: ● Hydraulically-controlled parallelogram-type ripper with OTHER

Blade Lift 2 120 mm 4.72" three shanks. Digging angle steplessly adjustable

All spool control valves externally mounted beside the hydraulic tank. ● Air conditioner

Gear-type hydraulic pump with capacity (discharge flow) of 255 ltr Blade Tilt 1 180 mm 7.09" ● Maximum digging depth: 870 mm 2'10" ● Backup alarm

67.4 U.S. gal/min at rated engine rpm. Ripper Lift 2 160 mm 6.30" ● Maximum lift above ground: 925 mm 3' ● Cab heater and defroster

● Standard digging angle*: 49°

Ripper Tilt 2 160 mm 6.30" ● Engine side cover

Relief valve setting. . . . . . . . . . . . . . 20.6 MPa 210 kg/cm2 2,990 psi VARIABLE GIANT RIPPER ● Locks, filler caps and covers

Control valves: Hydraulic oil capacity (refilling): ● Additional weight (including hydraulic control unit): ● Hinged, strengthened radiator mask

Spool control valve for Semi-U tilt dozer and Full-U tilt dozer. Semi-U tilt dozer . . . . . . . . . . . . . . . . . . . . . . . . 97 ltr 25.6 U.S. gal 2760 kg 6,080 lb ● Reversible fan

Positions: U-tilt dozer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 ltr 25.6 U.S. gal ● Beam length: 1535 mm 5' ● Rigid drawbar

● Hydraulically-controlled parallelogram-type ripper with one shank. ● Seat belt

Blade lift. . . . . . . . . . . . . . . . . . . . . . . Raise, hold, lower, and float Multi-shank ripper (additional volume) . . . . . . . . 35 ltr 9.2 U.S. gal

Digging angle steplessly adjustable ● Tool kit and ordinary spare parts

Blade tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Right, hold, and left Giant ripper (additional volume) . . . . . . . . . . . . 35 ltr 9.2 U.S. gal

● Maximum digging depth: 1220 mm 4'

Additional control valve required for variable digging angle ● Maximum lift above ground: 925 mm 3'

multi-shank ripper and giant ripper. ● Standard digging angle*: 49°

Positions:

* Measured with ripper point on ground and shank is vertical

Ripper lift . . . . . . . . . . . . . . . . . . . . . . . . . . Raise, hold, and lower

Ripper tilt . . . . . . . . . . . . . . . . . . . . . Increase, hold, and decrease

DOZER EQUIPMENT

Use of high-tensile-strength steel in moldboard for strengthened blade construction. Blade tilt hose piping is mounted inside the dozer

push arm to protect from damage.

Overall length Blade Blade Maximum lift Maximum drop Maximum tilt Additional

with dozer capacity* length x height above ground below ground adjustment weight

Semi-U 6300 mm 8.8 m3 3955 mm x 1720 mm 1250 mm 590 mm 1000 mm 4900 kg

Tilt Dozer 20'8" 11.5 yd3 13' x 5'8" 4'1" 1'11" 3'3" 10,800 lb

Full-U 6695 mm 11.8 m3 4265 mm x 1760 mm 1250 mm 590 mm 1080 mm 5600 kg

Tilt Dozer 22' 15.4 yd3 14' x 5'9" 4'1" 1'11" 3'7" 12,350 lb

Angle 6502 mm 4.9 m3 4850 mm x 1205 mm 1295 mm 745 mm 520 mm 5140 kg

Tilt Dozer 21'4" 6.4 yd3 15'11" x 3'11" 4'3" 2'5" 1'8" 11,330 lb

*Blade capacity is based on the SAE recommended practice J1265

10 11

Downloaded from www.Manualslib.com manuals search engine

You might also like

- 101 Creative Problem Solving Techniques by James M. HigginsDocument241 pages101 Creative Problem Solving Techniques by James M. HigginsJacostorius96% (56)

- 101 Creative Problem Solving Techniques by James M. HigginsDocument241 pages101 Creative Problem Solving Techniques by James M. HigginsJacostorius96% (56)

- ZF ASTronic Error CodesDocument16 pagesZF ASTronic Error Codesahmedkhl87% (109)

- Ficha Tecnica Motor DP6H-UFAA88Document9 pagesFicha Tecnica Motor DP6H-UFAA88SYA33% (3)

- CfMoto CF150T-5I Echarm EFI Main ManualDocument243 pagesCfMoto CF150T-5I Echarm EFI Main ManualAnna Ryan0% (1)

- Komatsu D155ax 3 Super Dozer Bulldozer Service Repair Manual SN 60001 and Up 1590145474Document38 pagesKomatsu D155ax 3 Super Dozer Bulldozer Service Repair Manual SN 60001 and Up 1590145474rachidaccNo ratings yet

- 1979 Chevrolet Corvette SpecificationsDocument122 pages1979 Chevrolet Corvette SpecificationsB100% (1)

- Mercedes 722.6Document2 pagesMercedes 722.6Kelvin Tan Boon Lork100% (5)

- MF 5460Document586 pagesMF 5460Maximiliano Hitschfeld100% (2)

- Portafolio ServiciosDocument21 pagesPortafolio ServiciosFranklin LewisNo ratings yet

- Gd675 5 BrochureDocument8 pagesGd675 5 BrochureJose Miguel Oyola CoronadoNo ratings yet

- Clarke JU6H Specification SheetDocument2 pagesClarke JU6H Specification Sheetabhayundale100% (1)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- MAK4462 Machine - Tools Lecture - Notes 2Document68 pagesMAK4462 Machine - Tools Lecture - Notes 2muhammet çalımNo ratings yet

- COOLING TOWERS - SOURCE PREDICTION, MODELLING AND NOISE CONTROLDocument15 pagesCOOLING TOWERS - SOURCE PREDICTION, MODELLING AND NOISE CONTROLbinho58No ratings yet

- D155a5 BrochureDocument6 pagesD155a5 BrochurerachidaccNo ratings yet

- D155a BrochureDocument6 pagesD155a BrochureWang ZhenpingNo ratings yet

- Komatsu D275A-5R Crawler Dozer: Powerful 337 kW Engine and Large Blade CapacitiesDocument8 pagesKomatsu D275A-5R Crawler Dozer: Powerful 337 kW Engine and Large Blade CapacitiesBalraj Bawa100% (1)

- Horsepower Gross: 474 KW 636 HP at 1800 RPM Net: 455 KW 610 HP at 1800 RPM Operating Weight 71640 KG 157,940 LBDocument8 pagesHorsepower Gross: 474 KW 636 HP at 1800 RPM Net: 455 KW 610 HP at 1800 RPM Operating Weight 71640 KG 157,940 LBeduardox11No ratings yet

- D375a 6 - Cen00372 02Document14 pagesD375a 6 - Cen00372 02Daniel FerreiraNo ratings yet

- Komatsu GD755-5R Motor Grader SpecsDocument8 pagesKomatsu GD755-5R Motor Grader SpecskazemiNo ratings yet

- Net Horsepower 391 KW 525 HP Operating Weight 66985 KG 147,680 LBDocument7 pagesNet Horsepower 391 KW 525 HP Operating Weight 66985 KG 147,680 LBChristian MorenoNo ratings yet

- Rawler Ozer: With Steering Clutch/Brake SystemDocument10 pagesRawler Ozer: With Steering Clutch/Brake SystemDinh Phu LeNo ratings yet

- Skid-Steer Loader: Left Side Standard Instrument PanelDocument2 pagesSkid-Steer Loader: Left Side Standard Instrument PanelMario AguirreNo ratings yet

- P2002 JRDocument4 pagesP2002 JRturandotNo ratings yet

- SD 110 Step 1 TrainingDocument254 pagesSD 110 Step 1 TrainingAgung Ardhana100% (1)

- Ydraulic Xcavator: Flywheel HorsepowerDocument9 pagesYdraulic Xcavator: Flywheel HorsepowerJimmy CordovaNo ratings yet

- D65ex-15eo Sales BrochuresDocument12 pagesD65ex-15eo Sales BrochuresMiguel Angel Mendo CordovaNo ratings yet

- A. Pengenalan Alat 2 JamDocument55 pagesA. Pengenalan Alat 2 Jampradhana200450% (2)

- Wa320 5Document12 pagesWa320 5Ahmet100% (3)

- Mov-On Elevating Fifth WheelDocument3 pagesMov-On Elevating Fifth WheelGustavo A CastroNo ratings yet

- Work Boats Waflaf 2346 - 7760Document8 pagesWork Boats Waflaf 2346 - 7760Adhietama SumarsonoNo ratings yet

- Pipelayers CPH v1.1 03.13.14 PDFDocument13 pagesPipelayers CPH v1.1 03.13.14 PDFbugseNo ratings yet

- N° Affectation EquipementDocument4 pagesN° Affectation EquipementDOOH MBARGANo ratings yet

- CGE Quester Spec Sheet E29Document2 pagesCGE Quester Spec Sheet E29Ruveen Jeetun100% (1)

- Small Diesel Scooptram LHDS: Vehicle SpecificationDocument3 pagesSmall Diesel Scooptram LHDS: Vehicle SpecificationKenny CasillaNo ratings yet

- Komatsu D575ADocument4 pagesKomatsu D575ARasoolKhadibiNo ratings yet

- Okada Hydraulic Breaker: Demolition AttachmentsDocument4 pagesOkada Hydraulic Breaker: Demolition AttachmentsFabian BonillaNo ratings yet

- Wa200 5 PDFDocument7 pagesWa200 5 PDFHilarius Eric PratamaNo ratings yet

- Product Presentation DD15 Technical 2009-07-27Document29 pagesProduct Presentation DD15 Technical 2009-07-27Alex RmzNo ratings yet

- TRACTOR PRICE LISTDocument2 pagesTRACTOR PRICE LISTsexmanijakNo ratings yet

- Duflo Pomp PDFDocument2 pagesDuflo Pomp PDFAnonymous G1iPoNOKNo ratings yet

- Wa250 5Document7 pagesWa250 5TRY GRUPNo ratings yet

- UJ Application CatalogueDocument13 pagesUJ Application Catalogueravinder.singh91968No ratings yet

- Aqua Series Water-Cooled Chillers 04-811-50038Document2 pagesAqua Series Water-Cooled Chillers 04-811-50038sil_muahdibNo ratings yet

- MLT 523 T with 2300 kg Lifting Capacity and 4.92 m HeightDocument2 pagesMLT 523 T with 2300 kg Lifting Capacity and 4.92 m HeightNegro Cardenas U CNo ratings yet

- Catalog Komatsu D65ex12 d65px 12 Crawler Dozer BulldozerDocument12 pagesCatalog Komatsu D65ex12 d65px 12 Crawler Dozer Bulldozerapray aprayNo ratings yet

- sh330 5 sh330lc 5 sh350hd 5 sh350lhd 5Document14 pagessh330 5 sh330lc 5 sh350hd 5 sh350lhd 5Lily Lu50% (4)

- R 5-10t Service ManualDocument92 pagesR 5-10t Service ManualВиктор МушкинNo ratings yet

- Embreagem e Bba Dagua CASE - DAVIDBROWNDocument21 pagesEmbreagem e Bba Dagua CASE - DAVIDBROWNPedro Alberto BenitesNo ratings yet

- D475a 5 PDFDocument14 pagesD475a 5 PDFzlNo ratings yet

- Demag Crane Catalog PDF FreeDocument58 pagesDemag Crane Catalog PDF FreeRabin SedighPourNo ratings yet

- WPL Lamella Separator Data SheetDocument2 pagesWPL Lamella Separator Data SheetSuhas JadhavNo ratings yet

- For Applications in Mines 102 - 204 KW - 137 - 274 HP at 1500 - 2300 Min - RPM Us-MshaDocument2 pagesFor Applications in Mines 102 - 204 KW - 137 - 274 HP at 1500 - 2300 Min - RPM Us-MshaигорNo ratings yet

- TDDCAT035Document408 pagesTDDCAT035Jack ElhaqNo ratings yet

- D475a 5Document14 pagesD475a 5RasoolKhadibi100% (1)

- D65ex-12 D65ex-12 LT D65PX-12Document12 pagesD65ex-12 D65ex-12 LT D65PX-12ho gataNo ratings yet

- 12-10G GH-3VCMDocument1 page12-10G GH-3VCMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- ZG5, ZG6-Series Gas Pumps en-USDocument3 pagesZG5, ZG6-Series Gas Pumps en-USBrussNo ratings yet

- D51ex D51PX-22 Cebm019109-39-44Document6 pagesD51ex D51PX-22 Cebm019109-39-44Suharto ZuhriNo ratings yet

- D51ex D51PX-22 Cebm019109-39-44Document6 pagesD51ex D51PX-22 Cebm019109-39-44Suharto ZuhriNo ratings yet

- Bulldozer KOMATSU D65Document14 pagesBulldozer KOMATSU D65Irwan Ix9No ratings yet

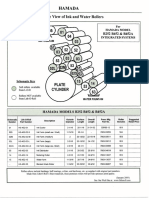

- Hamada:, Rtnhjt-O-A R.R. View WaterDocument10 pagesHamada:, Rtnhjt-O-A R.R. View WaterXaqani AxmedovNo ratings yet

- Mitsubishi 6d24 Spec SheetDocument2 pagesMitsubishi 6d24 Spec Sheetjaved samaaNo ratings yet

- 345C 365C 385C NPI Large Hydraulic Information IIDocument63 pages345C 365C 385C NPI Large Hydraulic Information IIAnjelo Jeanhpool Hidalgo AlvaradoNo ratings yet

- Bulldozer d65pDocument10 pagesBulldozer d65pRisky UpNo ratings yet

- 31050862Document11 pages31050862farukNo ratings yet

- Fl4025 Cople DodgeDocument4 pagesFl4025 Cople DodgeGelasio VegaNo ratings yet

- TDC Cat033.e0.ed1 - 20180425Document26 pagesTDC Cat033.e0.ed1 - 20180425Giang NguyễnNo ratings yet

- Ficha T. Motor JU6H-UFD0Document9 pagesFicha T. Motor JU6H-UFD0Nelson IglesiasNo ratings yet

- Ax 7Document16 pagesAx 7امین پارساNo ratings yet

- Dokumen - Tips Komatsu D155a 1 Dozer Bulldozer Service Repair Manual SN 15001 and Up 1607027661Document30 pagesDokumen - Tips Komatsu D155a 1 Dozer Bulldozer Service Repair Manual SN 15001 and Up 1607027661rachidaccNo ratings yet

- Public Bus Energy Consumption Investigation For Transition To Electric Power and Semi-Dynamic ChargingDocument6 pagesPublic Bus Energy Consumption Investigation For Transition To Electric Power and Semi-Dynamic ChargingGurdeep singhNo ratings yet

- LHM 550 PDFDocument0 pagesLHM 550 PDFMelina LaborNo ratings yet

- 04-Gearbox 311 - OkDocument61 pages04-Gearbox 311 - OkNaveedullah Awan100% (1)

- Maintenance Guide of ShangLi Diesel ForkliftDocument1 pageMaintenance Guide of ShangLi Diesel ForkliftBladimir SolizNo ratings yet

- BMW Torque ChartDocument5 pagesBMW Torque ChartmarcelcardNo ratings yet

- Abb VFD DrivesDocument4 pagesAbb VFD DrivesKalidass BackNo ratings yet

- 2013 450 SXF FactoryEdition EngineDocument28 pages2013 450 SXF FactoryEdition EnginecharlesNo ratings yet

- Q400 Power PlantDocument70 pagesQ400 Power PlantMoshiurRahman100% (2)

- How universal joints transmit power at varied anglesDocument20 pagesHow universal joints transmit power at varied anglesBrihaspati Singh0% (2)

- Atlas Copco Wagner Inc.: Technical Specifications and Performance DataDocument4 pagesAtlas Copco Wagner Inc.: Technical Specifications and Performance DatatakiNo ratings yet

- Ndsa Ud290wdDocument4 pagesNdsa Ud290wdsknambiarsNo ratings yet

- Single-Screw Extruders and Barrier ScrewsDocument17 pagesSingle-Screw Extruders and Barrier ScrewsAkhilesh KumarNo ratings yet

- Tractor FORD 4000 4Document8 pagesTractor FORD 4000 4Alex CastilloNo ratings yet

- 70 Drilling Rig Operation ManualDocument74 pages70 Drilling Rig Operation ManualDean Rein100% (1)

- GP N Brochure ProdriveDocument7 pagesGP N Brochure ProdriveTc Mrt Çap TmlNo ratings yet

- Electrical Drives and Traction Lecture NotesDocument64 pagesElectrical Drives and Traction Lecture NotesJayaprakash DasNo ratings yet

- Marcegaglia Cold-Drawn-Bars en Gen11Document13 pagesMarcegaglia Cold-Drawn-Bars en Gen11lucidbaseNo ratings yet

- RB001 PPT Basic RobotDocument32 pagesRB001 PPT Basic RobotmsreerajvarmaNo ratings yet

- Onion PillerDocument6 pagesOnion Pillergaurav punethaNo ratings yet

- Design of Guyed Electrical Transmission Structures: ASCE Manuals and Reports On Engineering Practice No. 91Document2 pagesDesign of Guyed Electrical Transmission Structures: ASCE Manuals and Reports On Engineering Practice No. 91moisesNo ratings yet

- Avenger 200 SPC BAJAJDocument45 pagesAvenger 200 SPC BAJAJJuan Manuel OrtegaNo ratings yet

- U140E U241E VacTestDocument5 pagesU140E U241E VacTestbyungchul kimNo ratings yet

- Workshop Manual Section on Propeller Shaft Removal and InstallationDocument180 pagesWorkshop Manual Section on Propeller Shaft Removal and Installationjrrodrigueza2No ratings yet