Professional Documents

Culture Documents

L3 - Suspension Bridge - Cable Forces Jan 11 - Final

Uploaded by

Almagesto QuenayaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L3 - Suspension Bridge - Cable Forces Jan 11 - Final

Uploaded by

Almagesto QuenayaCopyright:

Available Formats

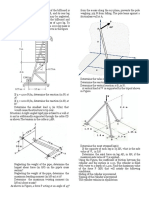

Suspension Bridge Part II: Cables

Figure 1: Cables of The George Washington Bridge, New York City (© Asaavedra32, Modifiedi)

FORM: The Cable

Figure 3 shows the form (a parabola)

Unlike cantilevers and columns, which that a cable takes on under a uniformly

are straight and stiff, cables are flexible distributed load, q, like that of a

structural elements. A flexible structural suspension bridge.

element can resist only axial tensile

forces; it cannot resist compression,

shear or bending. Because of their

flexibility, cables can change their shape

so that any applied load will only create

tensile forces in them. For example, a

cable that has a single point load, Q, Figure 3: Cable Shape Under a Uniformly

applied at midspan takes on the shape Distributed Load

shown in Figure 2.

These forms taken by cables under

certain loading conditions are called

funicular forms. A distinct funicular

form exists for each unique loading

Figure 2: Cable Shape Under a Point Load condition. The main cable of a

© Maria E. Moreyra Garlock 1

suspension bridge is an example of a The axial force can be found by using

funicular form. Due to the nature of the trigonometric relationships of horizontal

distributed load, the cables develop the and vertical force components. First, the

parabolic curvature that is characteristic angle of the cable at a particular point is

of suspension bridges. found by the following relationship:

V

tan(α ) =

H

where V is the vertical force component

and H is the horizontal force component

acting on the cable. The resulting axial

force in the cable, N (lbs or k), is

determined with the formula:

N = H cos(α ) +V sin(α )

where α is the slope of the cable.

Alternatively, one can use Pythagorean

theorem:

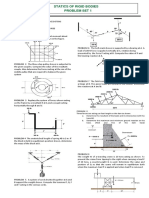

Figure 4: Various Funicular Forms N = H 2 +V 2

EXAMPLE 1: Axial Force in the

FORCES: Axial Tension Cables of the George Washington

Bridge in the midspan

The tensile force that develops in the

cable acts along the axis of the cable

(N), which can be separated into a

horizontal (H) and vertical (V)

component (Figure 5). In the previous

study, we illustrated how to find the

vertical and horizontal forces at the

tower due to main span and backspan. Figure 6: Main span free-body diagram of bridge

from tower to midspan

Thus, we can use these values at the

tower to find the axial force in the cable.

Determine: The axial force in the cable

of the George Washington Bridge at the

towers on the main span side and at

midspan.

Given:

Figure 5: Slope of The Cable, α (from previous calculations of

suspension bridges – Part I)

Vertical Reaction at the Tower,

VM = 82,300 k

© Maria E. Moreyra Garlock 2

Horizontal Reaction at the Tower,

HM = 221,400 k Tensile Stress

Since at midspan, the cable is horizontal: Recall from the Introduction Structural

Vertical Reaction at Midspan, Study that stress is computed by dividing

V= 0k the axial force by the cross-sectional

Horizontal Reaction at Midspan, area. For cables the axial loads are

H = 221,400 k tensile. The resulting stresses are also

tensile and we’ll refer to them as tensile

Solution: stresses, ft.

Step 1: Calculate the slope of the cable N

ft =

at the tower and at midspan. A

V "V % At the midspan of the bridge the cable is

tan(α ) = α = tan −1 $ '

H #H & horizontal and therefore the tensile force,

N, is in the horizontal direction. This

At the Tower: tensile force is equal (in magnitude and

direction) to the horizontal reaction, H,

" 82, 300 % at the tower as seen in the previous

α tower main span = tan −1 $ ' = 20° example. We will use this tensile force

# 221, 400 &

to calculate the tensile stress, ft in the

cable. See Figure 7:

At Midspan:

" 0 %

α midspan = tan −1 $ ' = 0°

# 221, 400 &

The cable is horizontal at midspan,

therefore it makes sense that α = 0.

Figure 7: Cable Under Tension

Step 2: Calculate the axial force of the

EXAMPLE 2: Stress in the Cables of

cable at the tower and at midspan.

the George Washington Bridge

N = H cos(α ) + V sin(α )

Determine: The stress in the cable of the

George Washington Bridge at midspan

At the Tower: and calculate its efficiency.

N tower main span = 221, 400 cos(20°) + 82, 300sin(20°)

Given:

N tower main span = 236, 200k There are four cables each with an area,

A= 800 in2

At Midspan: Recall the tensile force,

H = 221,400 k

N midspan = 221, 400 cos(0°) + 0sin(0°)

Ammann used an allowable stress,

fallow of 82 ksi for steel cable.

N midspan = 221, 400k

Solution:

© Maria E. Moreyra Garlock 3

transformation of vertical forces into

Step 1: Calculate the total cross- horizontal reactions and is dependent on

sectional area of the cables the chosen form. The load applied to the

bridge is defined by q*L while the form

A = number of cables * Aonecable of the bridge is defined by the ratio of

the main span to the sag, L/d.iii While

A = 4 * 800in2 = 3,200in2 the equation permits you to calculate the

tensile force in a cable given certain

Step 2: Calculate the tensile stress in parameters span (L), sag (d), and the

each cableii: distributed load (q), the choice of these

parameters, is ultimately made by the

N midspan H 221, 400k designer. These choices dictate how the

ft = = = forces are resisted in the structure and

A A 3, 200in 2 influence the aesthetic of the bridge.

ft = 69.2 ksi

Step 3: Calculate the efficiency of the

cablesii:

ft 69.2ksi

Efficiency = =

fallow 82ksi

Efficiency = 0.84

CONCLUSIONS

Notice from the previous example that

the axial force at midspan is equal to the

horizontal force in the towers. At

midspan, the slope is 0°. As we move

along the cable towards the tower

support, the cable slope increases. As the

cable slope increases, the horizontal

components of force remain constant,

but the vertical force components

increases, thus increasing the overall

axial force in the cable. The tensile force

is therefore greatest at the tower supports

where the slope is the greatest.

q * L2

H= is the main equation for a

8* d

suspension bridge. It represents the

© Maria E. Moreyra Garlock 4

Summary of Terms ksi he calculated a required area of 3,190

in2 (rounded to 3,200 in2).

-A: cross-sectional area [in2]

-H: horizontal reaction at tower and T

f allow = therefore,

tensile force in cable, [lbs] or [k] A

-V: vertical reaction at tower, [lbs] or [k]

-α : the slope of the cable [degrees] F 261,000k

-N: axial force in the cable [lbs] or [k] A= = ≈ 3,200in 2

f allow 82ksi

-ft: tensile stress, [psi] or [ksi]

Since the area required comes directly

Summary of Equations from the allowable stress in the cables,

ft = fallow and the efficiency is 1.

Slope of Cable:

V

tan(α ) = iii

H The Innovators; The Engineering

Pioneers who Made America Modern,

Axial Force in Cable: by David P. Billington, John Wiley &

N = H cos(α ) + V sin(α ) Sons, Inc., New York, 1996, p. 7, 9 and

12.

Tensile Stress:

N

ft =

A

Notes

i

Image obtained from Wikimedia

Commons from author Asaavedra32,

licensed under the Creative Commons

Attribution-Share Alike 3.0 Unported:

https://creativecommons.org/licenses/by-

sa/3.0. Modified by changing the color

to greyscale and rotating.

ii

Ammann calculated the maximum

tensile force, N, in the cable (which

occurs at the tower closer to the New

York side) to be 261,000 k (which is

similar to the value we would obtain if

we used the back span values for V and

N as approximated in the previous

structural study). Using this force (rather

than the force at midspan) and fallow = 82

© Maria E. Moreyra Garlock 5

You might also like

- Modern Electrical Installation for Craft StudentsFrom EverandModern Electrical Installation for Craft StudentsRating: 4.5 out of 5 stars4.5/5 (4)

- Structural Study 3 - 2008Document5 pagesStructural Study 3 - 2008kakashi1992No ratings yet

- Arches - The Salginatobel BridgeDocument9 pagesArches - The Salginatobel BridgemartrantNo ratings yet

- Theory PresentationDocument28 pagesTheory PresentationIcaNo ratings yet

- Cables and Arches: Structures Supporting LoadsDocument17 pagesCables and Arches: Structures Supporting LoadsMariya MariyaNo ratings yet

- arches problemsDocument17 pagesarches problemsprpattanaik2003No ratings yet

- Structural Analysis I CE 2152: CablesDocument8 pagesStructural Analysis I CE 2152: CablesJanith amarawickramaNo ratings yet

- Tutorial 3Document2 pagesTutorial 3piyush kumarNo ratings yet

- Cable Mind MapDocument3 pagesCable Mind MapMarsylthie TimothyNo ratings yet

- Suspension Cable BridgesDocument29 pagesSuspension Cable Bridgesrameshbabu_197967% (3)

- Structural Analysis - I, B. Tech., 4th Semester, Civil Engineering, Module-V, Part - IIDocument35 pagesStructural Analysis - I, B. Tech., 4th Semester, Civil Engineering, Module-V, Part - IIKarthiKeyan100% (1)

- Institute of Engineering Thapathali Campus: A Lab Report On Deflection of BeamsDocument17 pagesInstitute of Engineering Thapathali Campus: A Lab Report On Deflection of BeamsBarun ShresthaNo ratings yet

- Influence LineDocument5 pagesInfluence LinePeterIbikunleNo ratings yet

- STATICS OF RIGID BODIES CHAPTER 2 PROBLEMSDocument2 pagesSTATICS OF RIGID BODIES CHAPTER 2 PROBLEMSNeil Anthony Pojas BlancaNo ratings yet

- Tutorial3Document2 pagesTutorial3deetosh22No ratings yet

- Deflection Theory Analysis of Different Cable Profiles For Suspension BridgesDocument11 pagesDeflection Theory Analysis of Different Cable Profiles For Suspension BridgesRajat GuptaNo ratings yet

- Arched BridgesDocument13 pagesArched BridgesRikesh SapkotaNo ratings yet

- Cables & Arches PresentationDocument29 pagesCables & Arches PresentationDesireNo ratings yet

- MACE-SA-LN5-Cables & ArchesDocument42 pagesMACE-SA-LN5-Cables & ArchesGrow UpNo ratings yet

- Billboard structure reaction forces and tipping loadDocument3 pagesBillboard structure reaction forces and tipping loadBenjie MorenoNo ratings yet

- SRB DRBDocument44 pagesSRB DRBAcads AccountNo ratings yet

- Tutorial 1 Rigid Bodies and FBD PDFDocument7 pagesTutorial 1 Rigid Bodies and FBD PDFBharat SaiNo ratings yet

- Rangk. Ac Steady StateDocument75 pagesRangk. Ac Steady StateEndah Husein ANo ratings yet

- Lec 11Document39 pagesLec 11renNo ratings yet

- Chapter 6 Shear and moments in beams updting 2020Document19 pagesChapter 6 Shear and moments in beams updting 2020k.ghanemNo ratings yet

- Chpater OneDocument103 pagesChpater Oneanushreewankhade35No ratings yet

- Lecture 4Document25 pagesLecture 4Rana EL ArabeNo ratings yet

- Statics of Rigid Bodies Problem Set 1 Lecturer: Engr. MmrtatingDocument1 pageStatics of Rigid Bodies Problem Set 1 Lecturer: Engr. MmrtatingLeaNo ratings yet

- Tutorial 2Document6 pagesTutorial 2A SкNo ratings yet

- 7 SuspensionDocument98 pages7 SuspensionRajkumar NatarajanNo ratings yet

- 23AE60R01 Expt5 AerospaceStructuresLaboratoryDocument8 pages23AE60R01 Expt5 AerospaceStructuresLaboratorySuhasNo ratings yet

- Tutorial 1 (For Week 2 Tutorials)Document2 pagesTutorial 1 (For Week 2 Tutorials)2200851No ratings yet

- Energy TheoremsDocument15 pagesEnergy TheoremsAdams IbrahimNo ratings yet

- Unit No: 09 Cable StructuresDocument34 pagesUnit No: 09 Cable StructuresRoman BaralNo ratings yet

- Couple and Support ReactionsDocument70 pagesCouple and Support ReactionsShilpashree VNo ratings yet

- 1 - IntroductionDocument74 pages1 - IntroductionNikhil PatelNo ratings yet

- 8 Equilibrium of Force SystemsDocument13 pages8 Equilibrium of Force SystemsRachelle AlquizolaNo ratings yet

- Influence Line Diagrams in 40 CharactersDocument67 pagesInfluence Line Diagrams in 40 Characterspengnium100% (1)

- Structural AnalysisDocument95 pagesStructural AnalysisTam Alasadi100% (4)

- Deflection of BeamsDocument28 pagesDeflection of BeamsishwaryaNo ratings yet

- Group 4 Structures Lab Report 7Document6 pagesGroup 4 Structures Lab Report 7Roshan RameshNo ratings yet

- Engineering Electromagnetics: Energy and PotentialDocument44 pagesEngineering Electromagnetics: Energy and Potentialkallepalli venu ManikantaNo ratings yet

- E01 EFieldEquiPotentialDocument9 pagesE01 EFieldEquiPotentialVea CalpoturaNo ratings yet

- Biology and Physics Study Material by Top EducatorsDocument2 pagesBiology and Physics Study Material by Top EducatorsHhhhNo ratings yet

- Buckling of ColumnsDocument35 pagesBuckling of ColumnsMuhammad HaziqNo ratings yet

- Electrostatic Comb Drive Levitation and Control MethodDocument9 pagesElectrostatic Comb Drive Levitation and Control MethodtaNo ratings yet

- Cable: Fundamental Characteristic of Cable & ArchDocument15 pagesCable: Fundamental Characteristic of Cable & ArchSiddharth Singh JeenaNo ratings yet

- Potential Energy and Conservation of EnergyDocument16 pagesPotential Energy and Conservation of EnergyzakNo ratings yet

- Engr. Aprille Ellen E. QuebadaDocument22 pagesEngr. Aprille Ellen E. Quebadaronnie oraleNo ratings yet

- 3.1. ProblemsDocument20 pages3.1. Problemssaumya irugalbandaraNo ratings yet

- UNIT 16 Direct Current IDocument5 pagesUNIT 16 Direct Current IUlung Gondo Kusumo KhoeNo ratings yet

- Physics ProjDocument12 pagesPhysics ProjReaperNo ratings yet

- Design of Ohe StructureDocument10 pagesDesign of Ohe StructureAnubhav Hem Kumar JainNo ratings yet

- Objective - Students Will Be Able To: Influence LinesDocument21 pagesObjective - Students Will Be Able To: Influence LinesRafsanul HaqueNo ratings yet

- Set 5 A& B. Due On September 16: 5 A Q1. Draw Reaction Force and Moment Components Exerted by Supports On Member ABCDEFDocument3 pagesSet 5 A& B. Due On September 16: 5 A Q1. Draw Reaction Force and Moment Components Exerted by Supports On Member ABCDEFsatyamkumarmodNo ratings yet

- Feynman Lectures Simplified 2B: Magnetism & ElectrodynamicsFrom EverandFeynman Lectures Simplified 2B: Magnetism & ElectrodynamicsNo ratings yet

- Problems in Quantum Mechanics: Third EditionFrom EverandProblems in Quantum Mechanics: Third EditionRating: 3 out of 5 stars3/5 (2)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 2.L2 - Suspension Bridge - Part 1 Tower Anchors Jan 11 - Final PDFDocument5 pages2.L2 - Suspension Bridge - Part 1 Tower Anchors Jan 11 - Final PDFJuniorz ZavaletaNo ratings yet

- Instalaciones de GLP Videos MexicoDocument1 pageInstalaciones de GLP Videos MexicoAlmagesto QuenayaNo ratings yet

- ReadmeDocument2 pagesReadmeAlmagesto QuenayaNo ratings yet

- Piping LinksDocument1 pagePiping LinksAlmagesto QuenayaNo ratings yet

- Bai Tap Cad 3DDocument42 pagesBai Tap Cad 3DKieen LeeNo ratings yet

- Vessel Pressure TestingDocument3 pagesVessel Pressure Testingalokbdas100% (1)

- PELICULASDocument1 pagePELICULASAlmagesto QuenayaNo ratings yet

- 5.6 Especificación de Conversiones de ComposiciónDocument8 pages5.6 Especificación de Conversiones de ComposiciónAlmagesto QuenayaNo ratings yet

- Readme SSQDocument1 pageReadme SSQAlmagesto QuenayaNo ratings yet

- ASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012Document18 pagesASTM E 165 - 2012 (Standard Practice For Liquid Penetrant Examination For General Industry) - 2012omar quiñonesNo ratings yet

- Steel beam and grating bill of materialsDocument2 pagesSteel beam and grating bill of materialsAlmagesto QuenayaNo ratings yet

- Welding DefectsDocument1 pageWelding DefectsAlmagesto QuenayaNo ratings yet

- Chapter 1Document8 pagesChapter 1Carlos VegaNo ratings yet

- 5.6 Especificación de Conversiones de ComposiciónDocument8 pages5.6 Especificación de Conversiones de ComposiciónAlmagesto QuenayaNo ratings yet

- NACE CIP Part II - (3) Coatings Application - (Qs - As)Document9 pagesNACE CIP Part II - (3) Coatings Application - (Qs - As)Almagesto QuenayaNo ratings yet

- NACE CIP Part II - (6) Coatings For Industry - (Qs - As)Document23 pagesNACE CIP Part II - (6) Coatings For Industry - (Qs - As)Almagesto QuenayaNo ratings yet

- Leyenda Accesorio: Item Linea Elemento ADocument3 pagesLeyenda Accesorio: Item Linea Elemento AAlmagesto QuenayaNo ratings yet

- What Is Isometric Drawing Rev1Document24 pagesWhat Is Isometric Drawing Rev1Almagesto QuenayaNo ratings yet

- ReferencesDocument5 pagesReferencesMohammed AliNo ratings yet

- Reliant Oven Promo Pack LowresDocument9 pagesReliant Oven Promo Pack LowresVictor RequenaNo ratings yet

- API To Assign Item To An Organization in Inventory)Document47 pagesAPI To Assign Item To An Organization in Inventory)deepunym0% (1)

- Rotex SpecDocument30 pagesRotex SpecspringkimNo ratings yet

- Requara. H. Wickens Fundamentals of Rail Vehicle Dynamics Guidance and StabiliteDocument42 pagesRequara. H. Wickens Fundamentals of Rail Vehicle Dynamics Guidance and Stabilitetesfaye awelNo ratings yet

- Deep-Learning Based SAR Ship Detection With Generative Data AugmentationDocument9 pagesDeep-Learning Based SAR Ship Detection With Generative Data AugmentationRana UsmanNo ratings yet

- Lecture (05) Boolean Algebra and Logic Gates: By: Dr. Ahmed ElshafeeDocument12 pagesLecture (05) Boolean Algebra and Logic Gates: By: Dr. Ahmed ElshafeevenkateshNo ratings yet

- Kouign Amann RecipeDocument59 pagesKouign Amann RecipeDanny DawsonNo ratings yet

- Documentatie Imprimanta M940Document22 pagesDocumentatie Imprimanta M940Florin StanciulescuNo ratings yet

- Utilities EscalatorsDocument29 pagesUtilities EscalatorsCharles Joseph JacobNo ratings yet

- De400 CatDocument2 pagesDe400 CatLena LorenkoNo ratings yet

- Solomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16Document32 pagesSolomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16عبدالقادر مكونن سعيدNo ratings yet

- Tembungomol pump vibration measurement guideDocument1 pageTembungomol pump vibration measurement guidefazzlieNo ratings yet

- CIS Security Metrics v1.1.0Document175 pagesCIS Security Metrics v1.1.0dohungthuanNo ratings yet

- Beamtool Scan Plan: Inspection LayoutDocument3 pagesBeamtool Scan Plan: Inspection LayoutSantanu SahaNo ratings yet

- Oracle Date Functions and Aggregate FunctionsDocument18 pagesOracle Date Functions and Aggregate FunctionsChandra Bhushan SahNo ratings yet

- Supplement Nice Specialty Areas and Work Role Ksas and TasksDocument548 pagesSupplement Nice Specialty Areas and Work Role Ksas and Tasksadi8066No ratings yet

- Datasheet de Uma Memória Eeprom - 95640Document46 pagesDatasheet de Uma Memória Eeprom - 95640Anthony AndreyNo ratings yet

- Detailed ResumeDocument3 pagesDetailed Resumevscs.198293% (15)

- Service Fujitsu Inverter r410Document80 pagesService Fujitsu Inverter r410Henrique MagalhaesNo ratings yet

- Nordson EFD Ultimus I II Operating ManualDocument32 pagesNordson EFD Ultimus I II Operating ManualFernando KrauchukNo ratings yet

- A Coordination Framework For Sales and Operations PlanningDocument20 pagesA Coordination Framework For Sales and Operations PlanningprasannaNo ratings yet

- Windstar 2000 U1147Document1 pageWindstar 2000 U1147adris banquethNo ratings yet

- Biomedical Applications of Composite MaterialsDocument30 pagesBiomedical Applications of Composite MaterialsRita Singh50% (2)

- PAX Planner: Your PAX Code: 8PNLS7 Total Price:dhs 4.580.00Document6 pagesPAX Planner: Your PAX Code: 8PNLS7 Total Price:dhs 4.580.00anwarNo ratings yet

- HP Vertica 7.1.x GettingStartedDocument71 pagesHP Vertica 7.1.x GettingStartedRahul VishwakarmaNo ratings yet

- R48 3500e Rectifier UM1R483500e PDFDocument28 pagesR48 3500e Rectifier UM1R483500e PDFHythamMidani100% (1)

- SATRACK Guidance System for Missiles & SatellitesDocument15 pagesSATRACK Guidance System for Missiles & SatellitesVarun Gv100% (1)

- Training Regulation: Provincial Training Center - ZN TM-CNZDocument28 pagesTraining Regulation: Provincial Training Center - ZN TM-CNZKindly LegarteNo ratings yet