Professional Documents

Culture Documents

Asco Sintering ISO 9001:2000: Confidential

Uploaded by

sachOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asco Sintering ISO 9001:2000: Confidential

Uploaded by

sachCopyright:

Available Formats

www.ascosintering.

com Asco Sintering ISO 9001:2000

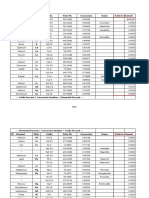

TRANSVE ULTIMAT IMPACT APPARENT

RSE YIELD E TENSILE STRENGT HARDNESS YOUNG'S EQUIVALENT

DENSITY RUPTURE STRENGTH STRENGT ELONGATI H FT-lbs ROCKWELL MODULUS MPIF

MATERIAL g/cm3 psi (A) psi(A) H psi(A) ON % (A,B) (A,E) (F) 10^6 psi (A) SPECIFICATION ASCO DESIGNATION APPLICATIONS

IRON 7.0 72000 22000 32000 5 15 HRB 70 21.0 F-0000-17 Soft magnetic applications.

CARBON STEEL 6.9 76000 28000 38000 1.5 5 HRB 55 19.5 F-0005-25 Moderate strength and machinability

7.0 140000 80000 80000 <0.5 4 HRC 25 20.5 F-0005-70 HT High strength

7.0 100000 40000 57000 1 5 HRB 70 20.5 F-0008-35 Good strength

7.1 145000 90000 95000 < 0.5 5 HRC 35 21.5 F-0008-85 HT Highest strength and wear

COPPER STEEL 6.7 95000 45000 50000 < 1.0 5 HRB 60 17.5 FC-0205--40 Medium strength structural parts

6.8 120000 86000 90000 < 0.5 4.5 HRC 31 18.5 FC-0205-80HT Heat treatment for wear and strength

6.7 125000 55000 60000 < 1.0 5 HRB 73 17.5 FC-0208-50

6.8 130000 91000 90000 < 0.5 4.5 HRC 35 18.5 FC-0208-80HT

NICKEL STEEL 6.9 100000 30000 50000 2.5 12 HRB 59 19.5 FN-0205-25 Heat treatable nickel steel

6.9 160000 110000 120000 < 0.5 4.5 HRC 29 19.5 FN-0205-105HT provides high strengh,

6.9 105000 40000 55000 1.5 8 HRB 71 19.5 FN-0208-35 wear and impact.

6.9 150000 124000 120000 < 0.5 4.5 HR 31 19.5 FN-0208-105HT

7.0 120000 40000 60000 3 14.5 HRB 71 20.5 FN-0405-35

7.0 200000 103000 135000 < 0.5 6.5 HRC 31 20.5 FN-0405-130HT

HYBRID LOW 7.1 230000 140000 150000 < 1.0 9 HRC 36 21 FLN-4205-140HT Heat treated low alloy steel

ALLOY STEEL 7.1 260000 145000 170000 <0.5 10 HRC 38 21 FLN2-4405-160HT provides high strength and wear

7.2 280000 160000 190000 <0.5 10 HRC 40 22.5 FLN2-4405 ASCO-180HT-UTS

7.0 175000 110000 120000 1.5 11 HRB 90 N/A FLN4C-4005 ASCO-110 Yield strength As-sintered low alloy steel

7.2 182000 125000 135000 1.6 16 HRB 96 N/A FLN4C-4005 ASCO-125 Yield strength provides high impact strength

SINTER HARDENING 6.9 280000 100000 140000 <0.5 10 HRC 33 N/A FLNC-4408 (MOD) Cost effective low alloy steel

7.0 190000 N/A 100000 < 1.0 9 HRC 31 20.5 FLC-4608-90 HT provides high strength and wear

7.0 260000 135000 140000 <0.5 10 HRC 30 N/A FL-5305 ASCO-130HT-UTS

7.2 280000 150000 160000 <0.5 11 HRC 33 N/A FL-5305 ASCO-160HT-UTS

Sheet1 Confidential Page 1

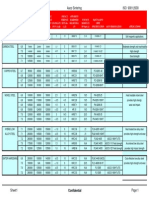

www.ascosintering.com Asco Sintering ISO 9001:2000

TRANSVE ULTIMAT IMPACT APPARENT

RSE YIELD E TENSILE STRENGT HARDNESS YOUNG'S EQUIVALENT

DENSITY RUPTURE STRENGTH STRENGT ELONGATI H FT-lbs ROCKWELL MODULUS MPIF

MATERIAL g/cm3 psi (A) psi(A) H psi(A) ON % (A,B) (A,E) (F) 10^6 psi (A) SPECIFICATION ASCO DESIGNATION APPLICATIONS

INFILTRATED STEEL 7.3 166000 60000 87000 3 10 HRB 89 23.5 FX-1008-50 Copper infiltration provides

7.3 189000 115000 120000 < 0.5 6.5 HRC 43 23.5 FX-1008-110HT machinability and toughness

7.3 156000 70000 80000 1 7 HRB 90 21 FX-2008-60 As heat treated it provides

7.3 159000 74000 100000 < 0.5 5 HRC 36 21 FX-2008-90HT wear resistance and toughness

HI-PERFORMANCE 7.0 300000 110000 150000 1.75 20 HRC 33 N/A ASCO Hi-Strength 1 High strength & good ductility

ALLOYS 6.9 300000 110000 152000 1.5 15 HRC38 N/A ASCO Hi-Strength 2 High strength, impact, & hardness

7.5 N/A 113000 155000 1.5 16 HRC38 N/A ASCO Hi-Impac 1 High strength, impact, & hardness

7.5 N/A 95000 130000 3.5 34 HRC20 N/A ASCO Hi-Impac 2 Very high impact. High Strength

7.5 N/A 65000 90000 7.5 110 HRB85 N/A ASCO Hi-Impac 3 Best impact resistant PM Material

Sheet1 Confidential Page 2

www.ascosintering.com Asco Sintering ISO 9001:2000

TRANSVE ULTIMAT IMPACT APPARENT

RSE YIELD E TENSILE STRENGT HARDNESS YOUNG'S EQUIVALENT

DENSITY RUPTURE STRENGTH STRENGT ELONGATI H FT-lbs ROCKWELL MODULUS MPIF

MATERIAL g/cm3 psi (A) psi(A) H psi(A) ON % (A,B) (A,E) (F) 10^6 psi (A) SPECIFICATION ASCO DESIGNATION APPLICATIONS

STAINLESS STEEL 6.4 108000 34000 41000 0.5 5 HRB 59 15.5 SS-316N1-25 Good strength and corrosion propertie

300 SERIES 6.4 86000 32000 39000 0.5 3.5 HRB 62 15.5 SS-303N1-25

6.9 N/A 46000 68000 10 35 HRB 70 20 SS-303N1-38 Best machinability for stainless

6.9 N/A 24000 48000 20 55 HRB 35 20 SS-303L-15 good corrosion resistance

6.9 N/A 45000 70000 13 48 HRB 65 20 SS-316N2-38 High corrosion resistance and

6.9 N/A 30000 57000 21 65 HRB 45 20 SS 316L-22 good mechanical properties

STAINLESS STEEL 6.5 113000 93000 105000 < 0.5 2.5 HRC 23 18 SS-410-90HT Hardenable and magnetic

400 SERIES 7 N/A 30000 50000 15 65 HRB 50 24 SS-434L-24 Less corrosion resistance

MONEL 8.7 N/A 34000 79000 48 N/A HRB 60 26 ASTM B164 Extremely ductle/Highly corrosion resista

COPPER 8.3 N/A 10000 28000 25 45 HRH 30 13.5 C-0000-7 Contacts and heat sinks

BRASS 7.6 57000 15000 27000 14 12 HRH 80 12 CZP-3002-13 Structural and appearance

7.6 52000 13500 23000 9 27 HRH 73 12.5 CZP-2002-11

8.0 71000 16500 31500 16 25 HRH 88 13.5 CZP-3002-14

8.0 70000 17000 35000 18 45 HRH 82 14.5 CZP-2002-12

NICKEL SILVER 7.9 50000 18000 26000 10 22 HRH 86 13.5 CNXP-1816 Cosmetic and structural

SOFT-MAGNETIC 7.0 72000 22000 32000 5 15 HRB 70 21.0 F-0000-17 Magnetically responsive

7.0 N/A 32000 45000 10 N/A HRB 45 20.5 FY-4500 used for armatures, pole

7.5 N/A 25000 40000 15 68 HRB 40 16 FN-5000 pieces and rotors

FULL DENSITY 7.6 N/A N/A N/A N/A N/A HRC 35-60 N/A SS-440 C ASCO-HD-440 C High density for food processing

STAINLESS and medical applications

440 C

Sheet1 Confidential Page 3

You might also like

- Lightning Link Printable Template V1.0Document4 pagesLightning Link Printable Template V1.0Gilberto Hill82% (22)

- Potential Failure Mode and Effects Analysis (Design FMEA)Document12 pagesPotential Failure Mode and Effects Analysis (Design FMEA)sachNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- Welding Duplex Stainless SteelDocument44 pagesWelding Duplex Stainless SteelInoCastilloNo ratings yet

- Pecp3001 PDFDocument716 pagesPecp3001 PDFРинат Сагидов100% (2)

- Bliss Manufacturing Lab ScopeDocument2 pagesBliss Manufacturing Lab ScopesachNo ratings yet

- EN10025 - Steel Grades SpecificationsDocument6 pagesEN10025 - Steel Grades SpecificationsFYNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Heat Resistant Alloy HK40 Data SheetDocument2 pagesHeat Resistant Alloy HK40 Data SheethawyegNo ratings yet

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Document4 pagesMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89No ratings yet

- Piston Ring PDFDocument3 pagesPiston Ring PDFArun SNo ratings yet

- Wire RoadDocument16 pagesWire Road02081987No ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4Alin ChehadeNo ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- ECG-Calculation Sheets: Design of Concrete StructuresDocument5 pagesECG-Calculation Sheets: Design of Concrete StructuresBahaa Gaber100% (1)

- 810-701 CRSeals Handbook FULL Apr-2018 rv1 PDFDocument225 pages810-701 CRSeals Handbook FULL Apr-2018 rv1 PDFLuis ReyesNo ratings yet

- 810-701 CRSeals Handbook FULL Apr-2018 rv1 PDFDocument225 pages810-701 CRSeals Handbook FULL Apr-2018 rv1 PDFLuis ReyesNo ratings yet

- Ferrous and Nonferrous Alloys Technical UpdateDocument8 pagesFerrous and Nonferrous Alloys Technical Updateatfrost4638No ratings yet

- Parts ListDocument52 pagesParts Listsalomonferrer3502No ratings yet

- 24UTP Railway GBDocument8 pages24UTP Railway GBwpsssamsungNo ratings yet

- Astm A-297 HPDocument2 pagesAstm A-297 HPeduardo_exsys100% (1)

- Convert XRF Data Element %Document8 pagesConvert XRF Data Element %manas773No ratings yet

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Document5 pagesDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- Materials Data SheetDocument3 pagesMaterials Data Sheetobertoc100% (1)

- 630 (17-4) Precipitation Hardening Stainless Steel BarDocument4 pages630 (17-4) Precipitation Hardening Stainless Steel Barehudingram6535No ratings yet

- Heat Resistant Alloy HN Data SheetDocument2 pagesHeat Resistant Alloy HN Data SheetAzize RazamNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- Steel Grade: Material Data SheetDocument4 pagesSteel Grade: Material Data SheetAlin ChehadeNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- DatasheetDocument1 pageDatasheetStuxnetNo ratings yet

- Aluminum 1100 InformationDocument1 pageAluminum 1100 InformationaxatpgmeNo ratings yet

- Ultra HT As PlatesDocument13 pagesUltra HT As PlatesavikNo ratings yet

- Metal Coated HSLA Steels, EN10346:2015Document3 pagesMetal Coated HSLA Steels, EN10346:2015ronakguptaNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- RuukiDocument20 pagesRuukiproje01No ratings yet

- Datasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1Document5 pagesDatasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1aceinsteinNo ratings yet

- Mat. 17MnV6 CaracteristiciDocument2 pagesMat. 17MnV6 CaracteristiciDani VaduvaNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- Rotel RB 1080 Service ManualDocument6 pagesRotel RB 1080 Service Manualsandy nNo ratings yet

- MAT 1100 MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100Document3 pagesMAT 1100 MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100Diógenes da Silva PereiraNo ratings yet

- C7025 (英文) ver1 6Document11 pagesC7025 (英文) ver1 6顏健軒No ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNo ratings yet

- PlanerDocument2 pagesPlanerdhruvNo ratings yet

- Design & Development of Copaction Trail With PMDocument13 pagesDesign & Development of Copaction Trail With PMArunKumarNo ratings yet

- Data Sheet: Steam Condenser Protection Type HOV-SCDocument2 pagesData Sheet: Steam Condenser Protection Type HOV-SCRonak PatelNo ratings yet

- ALUMINIUM ALLOYS FOR EXTRUDED PROFILESDocument19 pagesALUMINIUM ALLOYS FOR EXTRUDED PROFILESDon JonesNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- Ampco 45: Technical Data SheetDocument2 pagesAmpco 45: Technical Data SheetcristianoluzNo ratings yet

- Sunflex Sae 100R7 Thermoplastic Hose BS4983: 1973 DIN 24951 PT 2 ISO3945Document1 pageSunflex Sae 100R7 Thermoplastic Hose BS4983: 1973 DIN 24951 PT 2 ISO3945Nova VanoNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- Free Cutting Cold Drawn 11SMnPb30 Calibrated AUSADocument2 pagesFree Cutting Cold Drawn 11SMnPb30 Calibrated AUSAsobheysaidNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, Killedamit kumar sarkarNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Copper Bussman FusesDocument9 pagesCopper Bussman FusesKhaled BellegdyNo ratings yet

- 5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeDocument2 pages5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeMemona FayyazNo ratings yet

- B Chiew SP - RSA - SymposiumDocument35 pagesB Chiew SP - RSA - SymposiumAung SoneNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Acswire en XinhuaDocument5 pagesAcswire en XinhuaZai Nul AriefNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- Sandvik 12R11 Strip Steel DatasheetDocument5 pagesSandvik 12R11 Strip Steel DatasheetKashish0% (1)

- Brakes Clutches PDFDocument6 pagesBrakes Clutches PDFMarvinNo ratings yet

- Ak Dimax Hf-10 PDB 042312Document12 pagesAk Dimax Hf-10 PDB 042312human bodyNo ratings yet

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Gaming Code Class 2Document3 pagesGaming Code Class 2sachNo ratings yet

- Scan 28june ClassDocument3 pagesScan 28june ClasssachNo ratings yet

- Project QuestionairreDocument4 pagesProject QuestionairreaubreyNo ratings yet

- Cdiue: Alaoy Lette Ame Lack E WNDDocument3 pagesCdiue: Alaoy Lette Ame Lack E WNDsachNo ratings yet

- Plinko Game Score SimulatorDocument3 pagesPlinko Game Score SimulatorsachNo ratings yet

- Ways To Wow Media PDFDocument72 pagesWays To Wow Media PDFEmm GheorghiuNo ratings yet

- Arad HyaDocument1 pageArad HyasachNo ratings yet

- Whitehat Coding 12Document1 pageWhitehat Coding 12sachNo ratings yet

- Fixedrect Movingrect: Var FunctionDocument2 pagesFixedrect Movingrect: Var FunctionsachNo ratings yet

- Choose the Envelope with the Highest Expected ValueDocument2 pagesChoose the Envelope with the Highest Expected Valuebraetto_1x1No ratings yet

- Monkeygohappy CodeDocument6 pagesMonkeygohappy CodesachNo ratings yet

- Plinko Game Score SimulatorDocument3 pagesPlinko Game Score SimulatorsachNo ratings yet

- Internal Combustion Engine FundamentalsDocument30 pagesInternal Combustion Engine FundamentalssachNo ratings yet

- EULADocument6 pagesEULAsachNo ratings yet

- Haldex Valve Catalog: Quality Parts For Vehicles at Any Life StageDocument108 pagesHaldex Valve Catalog: Quality Parts For Vehicles at Any Life Stagehoussem houssemNo ratings yet

- PPAP Requirements TableDocument2 pagesPPAP Requirements TablesachNo ratings yet

- Monkeygohappy CodeDocument6 pagesMonkeygohappy CodesachNo ratings yet

- Haldex Valve Catalog: Quality Parts For Vehicles at Any Life StageDocument108 pagesHaldex Valve Catalog: Quality Parts For Vehicles at Any Life Stagehoussem houssemNo ratings yet

- Asco Sintering ISO 9001:2000: ConfidentialDocument3 pagesAsco Sintering ISO 9001:2000: ConfidentialsachNo ratings yet

- Stainless Steel (Autosaved)Document47 pagesStainless Steel (Autosaved)LOGINNo ratings yet

- Zambia's Mining IndustryDocument3 pagesZambia's Mining IndustryBonaventure Kalaba100% (3)

- (Advances in Trace Substances Research) Hansen, George - MacCarthy, Laurel A. - Brooks, Clyde S. - Brooks, Philip L - Metal Recovery From Industrial Waste-Lewis Publishers - CRC Press (1991) PDFDocument286 pages(Advances in Trace Substances Research) Hansen, George - MacCarthy, Laurel A. - Brooks, Clyde S. - Brooks, Philip L - Metal Recovery From Industrial Waste-Lewis Publishers - CRC Press (1991) PDFAkram LamaNo ratings yet

- ISO 1456-2009Document32 pagesISO 1456-2009sharma.sumeet2290No ratings yet

- Production of Vaculok ® SteelsDocument3 pagesProduction of Vaculok ® Steelskaveh-bahiraeeNo ratings yet

- CorimpexDocument38 pagesCorimpexmahotkatNo ratings yet

- UNIT-I Building Conctruction (BCE & BT-204)Document66 pagesUNIT-I Building Conctruction (BCE & BT-204)Vikash SinghNo ratings yet

- 01 Tay Nam Noi ThatDocument102 pages01 Tay Nam Noi ThatngotiensiNo ratings yet

- MSS SP-42-1999Document16 pagesMSS SP-42-1999Surat ButtarasriNo ratings yet

- Cope Cable Tray Catalog PDFDocument272 pagesCope Cable Tray Catalog PDFAlfredoLimaNo ratings yet

- APW 35 1B 2 6 3 DatasheetDocument2 pagesAPW 35 1B 2 6 3 DatasheetirinaNo ratings yet

- Premiumline Cleaning Machines and AccessoriesDocument34 pagesPremiumline Cleaning Machines and AccessoriesOvidiu GherendNo ratings yet

- Precision Steel Warehouse, IncDocument1 pagePrecision Steel Warehouse, Incapi-28059540No ratings yet

- LESSON 3.1 (Iron Ore and Pig Iron) (Autosaved)Document27 pagesLESSON 3.1 (Iron Ore and Pig Iron) (Autosaved)Lovely Jaze SalgadoNo ratings yet

- 45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchDocument2 pages45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchImtiyaz KhanNo ratings yet

- Equivalent Material 1Document2 pagesEquivalent Material 1Dodi SuhendraNo ratings yet

- ASTM A519-96 Seamless Carbon & Alloy Steel Mech TubingDocument12 pagesASTM A519-96 Seamless Carbon & Alloy Steel Mech TubingJoe ScopeliteNo ratings yet

- Materials Handbook For Nuclear Repair ApplicationsDocument312 pagesMaterials Handbook For Nuclear Repair ApplicationsModNo ratings yet

- Hatim PDFDocument2 pagesHatim PDFআফজাল -উল ইসলাম নূর100% (1)

- Chemical Anchoring Hollow Brick BlockDocument2 pagesChemical Anchoring Hollow Brick Blockcrazy_rotinNo ratings yet

- Document (2) - MergedDocument13 pagesDocument (2) - Merged208048022No ratings yet

- A Review On Design and Fabrication of Fuel Fired Crucible FurnaceDocument12 pagesA Review On Design and Fabrication of Fuel Fired Crucible FurnaceJamilu TankoNo ratings yet

- Unit 1 - Basic Mechanical Engineering - WWW - Rgpvnotes.inDocument9 pagesUnit 1 - Basic Mechanical Engineering - WWW - Rgpvnotes.inKanwarlal KharolNo ratings yet

- Q Panel SpecDocument2 pagesQ Panel SpecJohn TigerNo ratings yet