Professional Documents

Culture Documents

Stability Inspection Methodfor Existing Retaining Walls

Uploaded by

Mani RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stability Inspection Methodfor Existing Retaining Walls

Uploaded by

Mani RajCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/274665908

Stability Inspection Method for Existing Retaining Walls

Article in Quarterly Report of RTRI · August 2013

DOI: 10.2219/rtriqr.54.159

CITATIONS READS

3 697

5 authors, including:

Masahiro Shinoda Keita Abe

National Defense Academy of Japan Railway Technical Research Institute

108 PUBLICATIONS 388 CITATIONS 53 PUBLICATIONS 376 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Seepage failure View project

Retaining wall View project

All content following this page was uploaded by Masahiro Shinoda on 14 February 2017.

The user has requested enhancement of the downloaded file.

PAPER

Stability Inspection Method for Existing Retaining Walls

Masahiro SHINODA, Dr. Eng. Susumu NAKAJIMA, Dr. Eng. Keita ABE, Dr. Eng.

Senior Researcher, Assistant Researcher, Assistant Researcher,

Foundation and Geotechnical Engineering Laboratory, Structures Technology Division

Toshiaki EHARA Yuki KUBOTA

Researcher, Researcher,

Foundation and Geotechnical Engineering Laboratory, Structures Technology Division

Visual inspection methods are currently used on existing retaining structures. Conse-

quently it is difficult to evaluate a structural health of the retaining walls quantitatively. In

this study, a series of model tests on retaining walls were carried out to develop an inspection

method for quantitatively evaluating existing railway retaining walls. It has been found from

the series of model tests that vibration tests are an effective means to determine the vibration

characteristics of retaining walls, which reflect their structural health. Test results indicated

that small scale vibration tests could be applied to evaluation the structural health of existing

retaining structures.

Keywords: inspection, retaining wall, vibration test

1. Introduction 2. Current state of railway retaining structures

The high number of old railway structures in Japan 2.1 Maintenance standards in Japan

emphasizes the importance of having proper maintenance

methodologies. Proper management of railway structures There are approximately 30 thousand kilometers of

requires early detection of deformation in structures. Once railway lines in Japan, operated by several railway organi-

deformations are detected, continuous observation and zations (seven Japan Railway companies, over 100 private

retrofitting work are also important. Methods for quanti- railway companies and several local governments). Japa-

tatively assessing the structural health of railway bridge nese railway organizations maintain their structures in

substructures in Japan have already been developed.

START

In the case of retaining walls however, visual inspec-

tion is still used to evaluate the structural health of ex- (Interval ; within 2 years)

isting retaining walls because a quantitative inspection Condition rating “B,C,S”

General Inspection

method has not yet been developed. And yet, a quantitative

evaluation method is urgently needed, given the subjective Condition rating “A”

Condition rating “B,C”

nature of purely visual inspections. Individual Inspection

Given this background, the present study aims to de-

velop a quantitative inspection method for establishing the Condition rating “B” Condition rating “A”

structural health of existing retaining walls. This paper Countermeasures/Retrofitting works

begins with a brief introduction of the current state of ex- /Monitoring

isting retaining structures. Secondly it gives a brief outline

of the small scale exciter, which has been newly developed

Records

to evaluate the structural health of retaining walls. Lastly,

results are discussed of model tests conducted to determine Fig. 1 Maintenance procedure according to the Stan-

the applicability of the small scale exciter. dards for Maintenance in Japan

Table 1 Relationships between soundness and structural condition)

Condition rating Structure state

State that threatens operational safety, safety of passengers, public

A safety, guarantee of regular train operation, or deterioration that

might cause this situation.

B Deterioration that might result in A rate condition in the future.

C Slight deterioration.

S Good condition.

QR of RTRI, Vol. 54, No. 3, Aug. 2013 159

safe condition by referring to the Japanese Maintenance U-shaped wall

Code of Maintenance Standards in Japan [1]. General pro- Cantilever type wall 1.8%

5.2% Counterfort wall

cedures for structural maintenance in the Maintenance 0.1% Type of wall Site No.

Gravity type wall

standards and relationships between the condition rating 7.9% Masonry/Ashlar block 6,106

and the structure state are shown in Fig.1 and Table 1. Leaning type 688

Leaning type wall

As indicated in Fig. 1,“General Inspections”are con- 8.6% Gravity type 629

ducted on all railway structures at maximum two-year in- Cantilever type 413

tervals, and are mainly visual.“Individual Inspections”are Masonry wall U-shaped 145

Ashlar block wall

made however on specific structures in which more severe 76.4% Counterfort wall 8

deterioration has been detected during the General Inspec- Total 7,989

tion by means of detailed visual surveys or using measure-

ment equipment. As mentioned above in the Introduction, Fig. 3 Number of retaining walls by type

this study aims to develop a methodology which can be

U-shaped wall

used to quantitatively evaluate the structural health of re- 5.3% Counterfort wall

taining walls as an alternative to detailed visual surveys. Gravity type wall

0.2%

6.2% Type of wall Number Length(km)

Leaning type 409 41.1

2.2 Survey of current state of Japanese railway re- Cantilever type Masonry/Ashlar block 802 40.6

taining walls wall

12.1% Leaning type Cantilevet type wall 249 13.0

wall

38.3% Gravity type wall 85 6.7

A preliminary survey on current state of Japanese Masonry

U-shaped wall 105 5.7

Ashlar block wall

railway retaining structures was conducted using the 37.8% Counterfort wall 7 0.2

“Structural Management Supporting system (SMS)”[2]. Total 1,657 107.3

The SMS is the database system which contains compre-

hensive information about all types of railway structure, Fig. 4 Construction length of retaining wall by type

such as RC structures, steel structures, foundations, abut-

ments, retaining walls, tunnels and slopes etc. The SMS inputting data about their own structures.

was developed in association with 14 Japanese railway or- In the preliminary survey, information about typical

ganizations and the Railway Technical Research Institute. types of retaining wall in Japan (see Fig. 2) was extracted

Currently, 27 railway organizations utilize the SMS by from the SMS database. In total, data for 7,989 sites was

extracted.

Masonry (or Ashlar) type retainig wall Leaning type retaining wall

Figure 3 shows results of the survey which arranges

the data by type of retaining wall. The numbers of masonry

and ashlar block retaining walls exceeded 6,000 and ac-

counted for 76.4 % of the total data. The number of leaning

type retaining wall was the second largest, and accounted

for 8.6 % of the total number of sites. Valid data contain-

ing the construction length was extracted from among the

total 7,989 sites, since construction length is also an impor-

tant parameter in addition to the number of sites. Figure

4 shows retaining walls and the construction lengths of

Cantilever type retaining wall Gravity type retaining wall

retaining wall by type, which were obtained by averaging

valid data from 1,657 sites.

The construction length of leaning type retaining walls

stands first among all types of retaining walls and ac-

counted for 38.3 % of the valid data. The percentage of the

masonry and ashlar block retaining wall reached 37.8 %. It

was found from the above survey that the leaning type and

masonry or ashlar block retaining wall occupied 76.1 % of

the total construction length underscoring the importance

of managing this type of structures. It was also found from

the survey that the 85 % of leaning type retaining walls

U-saped retaining wall Counterfort wall

were lower than 4 m in height.

2.3 Typical deformation of railway retaining walls

Deformation of railway retaining structures can be di-

vided into two groups: deformation due to destabilization,

and deformation due to deterioration. Typical deformation

of railway retaining structures is schematically illustrated

in Fig. 5.

Settlement, inclination, swelling, difference in level

Fig. 2 Types of retaining wall and difference at construction joints due to external thrust

160 QR of RTRI, Vol. 54, No. 3, Aug. 2013

can be categorized as deformation due to the destabiliza- +

tion. Exfoliation of concrete and clogging of the drainage

facilities are categorized as deformation due to deteriora- Girder

tion.

Cyclic load due to the train passing, increase of earth

pressure due to the additional construction of the em- Iron ball

bankment, increase of dynamic earth pressure due to the Velocity

earthquake, increase of water pressure due to the change sensor

of the water level in backfill soil are deemed to be sources

of external thrust, which may lead to deformation due to

destabilization. Deterioration of the structure is attributed Bridge pier

to cyclic change in thermal or humid conditions during the

structure’s serviceable life.

Deformation due to the destabilization may lead to

secondary deformation such as backfill loosening or bear-

ing capacity failure. Therefore, early detection and retro-

fitting work to prevent deformation due to destabilization

are particularly important, while no non-destructive tests

to detect such problems have yet been developed. Follow-

ing on, this study attempts to propose a method for non-

destructive evaluation of existing retaining walls.

Difference at

Exfoliation of concrete Ground

Dislocation at

construction joint construction joint

Fig. 6 Outline of percussion test

4

Inclination a)

Velocity (kine)

2

Cracking

Drainage pipe 0

Construction joint

-2

Clogging of drainage facilities

-4

Settlement 0 1 2 3 4

Time (s)

Fig. 5 Typical deformation of retaining wall 0.03

Amplitude (kine * s)

b) Resonance (7.69 Hz)

3. Development of small scale exciter

0.02

3.1 Percussion tests

0.01

Non-destructive testing has been carried out in Japan

on bridge substructures, in the form of percussion tests. In

the past, of the health of railway bridge substructures was 0.00

evaluated by dynamic settlement, frequency and amplifica- 0 5 10 15 20 25

tion of vibration during the passing of trains in addition to Frequency (Hz)

the static measurement of inclination or settlement of the 360

bridge piers. However, this method is insufficient to evalu- c) Resonance (7.69 Hz)

Phase (degree)

ate the performance of bridge substructures quantitatively 270

because measurements made during the passing of trains

mentioned above, depend heavily on the weight and pass- 180

ing speed of the trains.

In order to reduce the above-mentioned problem, a dif- 90

ferent type of percussion test was proposed by Nishimura

et al (1988) [3]. In the latter, the natural frequency of the

0

bridge pier is measured with high accuracy and is used for 0 5 10 15 20 25

evaluating the structural health of the pier. This method is Frequency (Hz)

based on the knowledge that the natural frequency of the

bridge substructure decreases with damage and increases Fig. 7 Typical result of percussion test

QR of RTRI, Vol. 54, No. 3, Aug. 2013 161

with reinforcement.

The natural frequency of bridge piers is found by carry- 200

Acceleration (gal)

ing out a spectrum analysis using measured free vibration, a)

which is recorded by velocity sensors. Free vibration is in- 100

duced by striking the top of the piers using an iron ball, as

schematically illustrated in Fig. 6.

0

A time history of the velocity obtained from the per- -100

cussion test is shown in Fig. 7a). The natural frequency of

the structures can be evaluated based on the Fourier and -200

phase spectrum as shown in Fig. 7b) and 7c), respectively. 0 20 40 60 80 100

The maximum amplitude for the frequency 7.69 Hz is thus Time (s)

obtained as the resonance in accordance with the result of 200

Acceleration (gal)

the phase spectrum in which the resonance occurred in the b)

phase of 180 degrees. In practice, the actual performance of 100

a bridge pier can be evaluated by comparing the measured

natural frequency with that obtained immediately after

0

construction or with the criterion for potential natural fre- -100

quency. Potential natural frequency is the experimentally-

based value proposed by the Railway Technical Research -200

Institute which can be applied to structures in a particular 0 2 4 6

site where the natural frequency was not recorded immedi- Time (s)

ately after the construction. 0.010

Amplitude (gal.s)

c)

3.2 Development of the small scale exciter

As mentioned above, percussion tests have been con-

0.005

ducted on bridge substructures. Applying the same meth-

ods to determine the structural health of retaining walls

poses the following problems: 0.000

1. An input load with a high frequency component can- 0 20 40 60 80 100

not be applied because the input is applied by strik- Frequency (Hz)

ing the top of the pier.

2. The weight of the iron ball (30 kg in general) makes Fig. 9 Example of input from small scale exciter

it difficult to handle.

3. Amplitude of the input load is difficult to measure Table 2 Performance of small scale exciter

quantitatively. Rated sine force (N) 98

4. Amplitude of the input load cannot be kept constant

because the load is applied by different inspector Max. Displacement (mm) 80

each time.

Max. Velocity (cm/s) 74.8

The small scale exciter developed for this study is Max. acceleration (m/s2) 14

schematically illustrated in Fig. 8. A permanent magnet is

adopted for the magnetic circuit mainly because of the por- Frequency range (Hz) 3-200 (at Max. Acc.)

tability despite the resulting difficulty to apply large am-

System power AC100V

plitude and high frequency component as the input. In the

prototype exciter, the vibration force is induced by sending Weight (N) 147

electronic current to the driving coil in the magnetic field.

Dimensions

Neodymium permanent magnet

Driving coil Length mm 358

Width mm 336

Height mm 194

Direction of force Magnetic Flux density

As schematically illustrated in Fig. 8, an input force vector

is determined by the direction of electric current and mag-

B : Magnetic flux density [T] netic flux density based on the Fleming’s left hand rule.

The amplitude of force can be evaluated in eq. (1).

F = BLI (1)

F : Force [N] I : Magnetic current [A]

Magnetic circuit where B is the value of magnetic flux density, L is the

Fleming’s left hand rule

length of the cable in the magnetic flux, and I is the mag-

Fig. 8 Outline of prototype small scale exciter netic current. In this study, the following parameters were

162 QR of RTRI, Vol. 54, No. 3, Aug. 2013

used: B = 0.49 T, L = 26.7 m and I = 7.5 A. Performance of Displacement transducer 90 Two component loadcell

the developed small scale exciter is summarized in Table 2. 50 +

Examples of the acceleration time history and its Fou- 100

200

rier spectrum induced by the prototype small scale exciter +

are shown in Fig. 9 a), b) and c). Sinusoidal sweep excita- +

tion is usually adopted as the input acceleration to apply

300

the same amplitude of force to the target structure over all +

the frequency components as shown in Fig. 9 b). Applicabil- +

300

ity of the prototype small scale exciter is discussed later in + Accelerometer

the paper with the introduction of the static loading tests +

1000

.35

conducted using a model retaining wall. 300

.3

1:0

1:0

4. Application of the small scale exciter to evaluate 100

+

500

the structural health of a retaining wall

4.1 Outline of the model test 200

As discussed in the introduction to the percussion test,

vibration characteristics of the structure can be used as +

140

Two component loadcell

an index to evaluate the structural health of the retaining

wall. Therefore, a set of the loading tests on the retaining Fig. 11 Cross section of leaning type retaining wall mod-

wall were conducted to investigate the correlation between el (units in mm)

vibration characteristics and displacement of the model re- 100

taining wall.

The test apparatus used in the model test is schemati- 80

80

Horizontal displacement

cally illustrated in Fig. 10. The test apparatus consisted of

of soil chamber (mm)

Displacement

変位

a steel strut, shear soil chamber, hydraulic loading jacks.

The soil chamber was 3 m high with a width and length of 60

2 m.

Models of leaning and masonry type retaining walls 40 40

were placed on a horizontal subsoil consisting of dense air-

dried silica sand. The total height of the model retaining 20 20

wall was 1 m while the embedded depth was 0.2 m. A back- 10

5

fill layer was also constituted with air-dried silica sand. 0 0

The relative densities of the subsoil and backfill layer were

90 and 80 %, respectively. 0 2 4 6 8 10

A cross section of the model leaning type retaining

Loading step

wall is shown in Fig. 11. Two component load cells were in-

stalled on the wall facing and at the bottom of the footing. Fig. 12 Loading process

The outer size of the masonry type retaining wall model

was the same as that of the leaning type retaining wall Horizontal displacement was applied to the shear soil

model, while the wall facing was made by ashlars. chamber using three horizontal hydraulic loading jacks

as shown in Fig. 12. The displacement amplitudes of the

middle and top loading jacks were controlled so that the

soil chamber showed the simple shear mode of deforma-

Soil chamber Upper jack tion as schematically illustrated in the Fig. 12. Vibration

tests using the developed small scale exciter were carried

out during each of the loading and unloading stages. High-

Middle jack

sensitivity accelerometers were attached to the wall to

35

measure changes in vibration characteristics as displace-

2400

1:0.

3

1000

ment of the wall facing increased.

1:0.

Bottom jack

Silica sand 4.2 Test results

Dr=80%

200

Changes in the transfer function of the amplitude of

Silica sand Loading the leaning and masonry type retaining wall models are

635

Dr=90% platen shown in Fig. 13 and 14. The transfer functions corre-

sponding to the initial state and those at a displacement

amplitude of 80 mm were compared in these figures. In the

initial state, a clear peak can be observed around 40 Hz

Fig. 10 Layout of test apparatus both in leaning and masonry type retaining walls.

QR of RTRI, Vol. 54, No. 3, Aug. 2013 163

0.20

Transfer function (amplitude)

Horizontal disp.(mm)

120

120mm 36.6 Hz 41.2 Hz

90 80mm

Initial Large spectrum area Threshold value

0.15 60

40mm

state

Amplitude

30

10mm

→Deformed retaing wall

0

0mm Small spectrum area

0 2 4 6 8 10 12 14

0.10 Loading step

→Without any deterioration

80 mm loaded

0.05

0.00

10 20 30 40 50 Frequency (Hz)

Frequency (Hz)

Fig. 15 Schematic diagram showing differences in the

Fig. 13 Change in vibration characteristics of leaning Fourier spectrum of amplitude

type retaining wall model

Fourier spectrum, hereafter referred to as the spectrum

0.60 area, is used as an index to evaluate the structural health

of the retaining structure. In the case deterioration, the

Transfer function (amplitude)

Horizontal disp.(mm)

120mm

120

90 80mm

Just after opening value of spectrum area is larger than when the retaining

60 40mm

of masonry joint wall is structurally healthy. Before applying the proposed

30

0.40 0

10mm

Initial state method in practice, a threshold value, indicating the safety

0mm

of the retaining wall would have to be determined. The va-

40.0 Hz

0 2 4 6 8 10 12 14

Loading step

lidity of the proposed method for inspecting existing struc-

tures has been confirmed by Nakajima et al (2012) [4].

0.20 18.8 Hz A greater number of site tests remain to be performed,

in order to meet the shortfall in spectrum area data which

Loaded state is needed to set a threshold value. Consequently, until

enough data is collected, assessing the structural health of

a retaining wall must be achieved by comparing the spec-

0.00 trum areas of a healthy retaining wall with that of a dete-

10 20 30 40 50

Frequency (Hz) riorated retaining wall.

Fig. 14 Change in vibration characteristics of masonry

type retaining wall model 5. Summary

In the case of the leaning type retaining wall, the value The discussion in this paper can be summarized as fol-

of the peak amplitude frequency decreased as displacement lows:

grew and the peak amplitude value for a displacement 1. The management of leaning type and masonry type

of 80 mm was larger than that in the initial state. In the retaining walls was identified as being of primary

masonry type retaining wall model however, the opening importance since they are the most common of these

of the masonry joint triggered the change in the amplitude types of railway structure.

transfer function. Figure 14 shows that the loaded state 2. Small scale exciter, capable of applying a constant

amplitude surpassed that of the initial state, especially at input force amplitude in whole frequency compo-

low frequency. This indicates that the masonry type retain- nents, was developed as a method to evaluate the

ing wall tends to vibrate easily. structural health of retaining walls.

The model tests demonstrated that the vibration char- 3. Based on the results from the series of model tests

acteristics of the retaining wall were affected by its struc- it has been found out that the vibration characteris-

tural health. In the case of the masonry type retaining tics of a retaining wall are affected by its structural

wall, the importance of the facing rigidity was also high- health.

lighted. 4. The behavior of the retaining wall discussed above

indicates that the spectrum area can be used as

4.3 A proposed procedure to evaluate the structural an index to quantitatively evaluate the structural

health of a retaining wall health of a retaining wall.

The basic concept underlying the proposed method is

schematically illustrated in Fig. 15. As discussed above, 6. Future study

vibration characteristics of the retaining wall were affected

by the structural health of the retaining wall. In the pro- The insufficient of the field data means that there is

posed method, therefore, the area of the amplitude in the no current alternative to comparing spectrum areas of in-

164 QR of RTRI, Vol. 54, No. 3, Aug. 2013

spected retaining walls with those of sound retaining walls References

constructed nearby. Site test data shall be collected in the

course of further study in order to be able to determine a [1] Railway Technical Research Institute, Maintenance

proper threshold value, which may then be applied to dis- Standards for Railway structures, 2007.

tinguish between deteriorated and sound retaining walls. [2] Oyado, M., Miyashita, M., Ueda, S. and Sakairi, A., An

attempt of rationalization for maintenance of railway

structure using supporting system, Proc. of 5th Inter-

6. Future study national conference for bridge maintenance, Safety and

Management, pp.3459-3466, 2010.

The insufficient of the field data means that there is [3] Nishimura A., Okumura, F. and Tanamura S., Integ-

no current alternative to comparing spectrum areas of in- rity Judgment of Railway Bridges by Percussion Tests

spected retaining walls with those of sound retaining walls for Structure Response, Quarterly Report of RTRI, Vol.

constructed nearby. Site test data shall be collected in the 29, No.4, pp.184-189, 1988.

course of further study in order to be able to determine a [4] Nakajima, S., Shinoda, M., Abe, K., Mai, T. and Ehara

proper threshold value, which may then be applied to dis- T, Application of vibration testing for structural

tinguish between deteriorated and sound retaining walls. health evaluation of existing railway retaining walls,

International Workshop on ICT in Geo-Engineering

(ICTGE2012), 2012.

QR of RTRI, Vol. 54, No. 3, Aug. 2013 165

View publication stats

You might also like

- Structural Audit GuideDocument4 pagesStructural Audit GuideDean Arig100% (1)

- BAED PHYC2121 General Physics 1 2ndDocument34 pagesBAED PHYC2121 General Physics 1 2ndDou ItashiNo ratings yet

- Pushover Analysis of 4 Storey Reinforced Concrete BuildingDocument5 pagesPushover Analysis of 4 Storey Reinforced Concrete BuildingIon SococolNo ratings yet

- Axial Shortening Effect On Vertical ElementDocument7 pagesAxial Shortening Effect On Vertical Elementnovakno1No ratings yet

- BEST STEPS - PhysicsDocument12 pagesBEST STEPS - PhysicsAlex GoldsmithNo ratings yet

- Rigid Pavement Design: 29.1.1 Modulus of Sub-Grade ReactionDocument9 pagesRigid Pavement Design: 29.1.1 Modulus of Sub-Grade Reactionnageshkumarcs100% (1)

- C StrucAnalysis Wong Jan17 1Document4 pagesC StrucAnalysis Wong Jan17 1Hattori HanzoNo ratings yet

- Damage Asessment PaperDocument18 pagesDamage Asessment PaperRashid ShamsNo ratings yet

- Analysis of Damage To The Existing Structure Under DistressDocument5 pagesAnalysis of Damage To The Existing Structure Under DistressInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- General Chemistry 2: Quarter 4 - Module 1, Week 5Document48 pagesGeneral Chemistry 2: Quarter 4 - Module 1, Week 5Kashmir RiveraNo ratings yet

- Maintenance of TG Foundation Affected by AARDocument18 pagesMaintenance of TG Foundation Affected by AARjamjam75No ratings yet

- International Journal of Engineering Research And Management (IJERM) Performance Evolution and Audit of Structure by NDT MethodsDocument6 pagesInternational Journal of Engineering Research And Management (IJERM) Performance Evolution and Audit of Structure by NDT MethodsAbuturab SharikmaslatNo ratings yet

- Ijert Ijert: Feasibility Study of RC Structure For Additional Floor Using NDT Approach-A Case StudyDocument5 pagesIjert Ijert: Feasibility Study of RC Structure For Additional Floor Using NDT Approach-A Case StudyburhanNo ratings yet

- structural-audit-of-a-residential-building-IJERTV11IS040151Document3 pagesstructural-audit-of-a-residential-building-IJERTV11IS040151TANISHKA VASNo ratings yet

- Design and Safety Measures Analysis in Construction of Bhopal Metro ProjectDocument3 pagesDesign and Safety Measures Analysis in Construction of Bhopal Metro ProjectInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review On Condition Assessment and NDT of BuildingDocument2 pagesReview On Condition Assessment and NDT of BuildingManish BhatkarNo ratings yet

- Sample Draft Final Report (Iloilo)Document15 pagesSample Draft Final Report (Iloilo)A.B. CbmNo ratings yet

- Steel Bridge Maintenance in JapanDocument16 pagesSteel Bridge Maintenance in JapanArkarNo ratings yet

- Effect of External Post-Tensioning in Retrofitting of RC BeamsDocument8 pagesEffect of External Post-Tensioning in Retrofitting of RC BeamsŽarko LazićNo ratings yet

- Pull-Out Behavior of Headed Anchors Used in A Totally Prefabricated Counterfort Retaining Wall SystemDocument18 pagesPull-Out Behavior of Headed Anchors Used in A Totally Prefabricated Counterfort Retaining Wall SystemEnri05No ratings yet

- Advanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiDocument8 pagesAdvanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiVishvajit PatilNo ratings yet

- Push Over Analysis For Concrete Structures at Seismic Zone-3 Using ETABS Software PDFDocument8 pagesPush Over Analysis For Concrete Structures at Seismic Zone-3 Using ETABS Software PDFmahmood hunarNo ratings yet

- Seismic Fragility Assessment of RC Frame-Shear Wall Structures Designed According To The Current Chinese Seismic Design CodeDocument9 pagesSeismic Fragility Assessment of RC Frame-Shear Wall Structures Designed According To The Current Chinese Seismic Design Codejackfrazer2No ratings yet

- Damage Assessment Criteria for Progressive Collapse Analysis of RC FramesDocument14 pagesDamage Assessment Criteria for Progressive Collapse Analysis of RC Framesمحمد حارثNo ratings yet

- Seismic analysis of steel structures with different bracing patternsDocument35 pagesSeismic analysis of steel structures with different bracing patternsJay BavarvaNo ratings yet

- Pushover Analysis of R.C. Frame Building With Shear Wall: Nitin Choudhary Prof. Mahendra WadiaDocument5 pagesPushover Analysis of R.C. Frame Building With Shear Wall: Nitin Choudhary Prof. Mahendra Wadiabadr amNo ratings yet

- A Review of Different Assessment Methods of Corrosion of Steel Reinforcementin ConcreteDocument18 pagesA Review of Different Assessment Methods of Corrosion of Steel Reinforcementin ConcreteNi ZhimingNo ratings yet

- Quotation For Amantran CHS Miraroad PDFDocument5 pagesQuotation For Amantran CHS Miraroad PDFShakuntala GuptaNo ratings yet

- Evaluating The Condition of Existing Building For RepairingDocument7 pagesEvaluating The Condition of Existing Building For RepairingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Irjet V4i7516 PDFDocument7 pagesIrjet V4i7516 PDFRajat MohanNo ratings yet

- Nondestructive Testing for Bridge EvaluationDocument11 pagesNondestructive Testing for Bridge EvaluationMichael MatshonaNo ratings yet

- Non-Destructive-Testing Methods For Concrete Structures: LettersDocument8 pagesNon-Destructive-Testing Methods For Concrete Structures: LettersSupriyo PodderNo ratings yet

- Fbuil 10 1346571Document23 pagesFbuil 10 1346571Steeven CampoverdeNo ratings yet

- Seismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part II: Theoretical Comparisons and Analytical StudiesDocument10 pagesSeismic Behavior of Nonseismically Detailed Interior Beam-Wide Column Joints-Part II: Theoretical Comparisons and Analytical StudiesPaul KohanNo ratings yet

- Pushover Analysis of Multi-Storey Concrete StructuresDocument10 pagesPushover Analysis of Multi-Storey Concrete Structureskarishma uthanapadanNo ratings yet

- ESR9 Poster Lloyd'sDocument1 pageESR9 Poster Lloyd'sArturo GonzalezNo ratings yet

- A JournalDocument6 pagesA JournalAfdhal LazuardiansyahNo ratings yet

- 9 III March 2021Document13 pages9 III March 2021IJRASETPublicationsNo ratings yet

- Time-Varying Reliability Analysis of Long-Span Continuous Rigid Frame Bridge Under Cantilever Construction Stage Based On The Mon-Itored Strain DataDocument12 pagesTime-Varying Reliability Analysis of Long-Span Continuous Rigid Frame Bridge Under Cantilever Construction Stage Based On The Mon-Itored Strain Datafahmi aballiNo ratings yet

- Abdulazeez Et Al - Assessing Strucctural Intergrity of Existing Building StructuresDocument10 pagesAbdulazeez Et Al - Assessing Strucctural Intergrity of Existing Building StructureskojakondaNo ratings yet

- DLD 2021122Document10 pagesDLD 2021122Nagha RamasamyNo ratings yet

- 923 2949 1 PB Evaluasi StrukturDocument10 pages923 2949 1 PB Evaluasi StrukturResa MuliadiNo ratings yet

- Ijciet 09 07 017Document12 pagesIjciet 09 07 017Shashank SinghNo ratings yet

- JSCE Specifications For Steel and Composite Structures: K. Nogami T. YodaDocument11 pagesJSCE Specifications For Steel and Composite Structures: K. Nogami T. YodaHuan VoNo ratings yet

- Ojce20120100002 30541081Document6 pagesOjce20120100002 30541081sonny nebbiNo ratings yet

- Condition Assessment of RCC ESR Using NDT MethodsDocument4 pagesCondition Assessment of RCC ESR Using NDT Methodsjayant pathakNo ratings yet

- Research On Application of Buckling Restrained BraDocument22 pagesResearch On Application of Buckling Restrained BraRahul KumarNo ratings yet

- Processes: Static Behaviors and Applications of Buckling Monitoring Members With Rigid EndsDocument22 pagesProcesses: Static Behaviors and Applications of Buckling Monitoring Members With Rigid EndsNanak BatraNo ratings yet

- Bolts Post Installed l1Document9 pagesBolts Post Installed l1José Antonio Alarcón LeónNo ratings yet

- ANJUDocument19 pagesANJUMdNo ratings yet

- Structural Audit: A Need of An Hour: Rushabh Karnavat Vivek SinghDocument3 pagesStructural Audit: A Need of An Hour: Rushabh Karnavat Vivek SinghVishvajit PatilNo ratings yet

- Performance Based Analysis of RC Buildings with Shear Walls and InfillsDocument21 pagesPerformance Based Analysis of RC Buildings with Shear Walls and InfillsBasil Baby-PisharathuNo ratings yet

- Proposed Specification of Durability Design For Concrete StructuresDocument33 pagesProposed Specification of Durability Design For Concrete StructuresOSE0597No ratings yet

- Design Sensitivity Analysis of Three-Storey Reinforced Concrete Moment Resisting Frame Structures Using Peerformance Based Seismic EngineeringDocument5 pagesDesign Sensitivity Analysis of Three-Storey Reinforced Concrete Moment Resisting Frame Structures Using Peerformance Based Seismic Engineeringjpmsawali100% (1)

- Modelling Rockfall Protection Fences (Cantarelli Et Al.)Document6 pagesModelling Rockfall Protection Fences (Cantarelli Et Al.)massimo.bochioloNo ratings yet

- Nonlinear Performance Evaluation of High Rise Building StructureDocument8 pagesNonlinear Performance Evaluation of High Rise Building StructureRifqi Fauzan GamesNo ratings yet

- Structural Health Monitoring of Exterior Beam-Column Subassemblies (Feb 2022)Document17 pagesStructural Health Monitoring of Exterior Beam-Column Subassemblies (Feb 2022)Hamid GoodarziNo ratings yet

- Comparative Study On Design Results of A Multi-Storied Building Using Staad Pro and Etabs For Regular and Irregular Plan ConfigurationDocument12 pagesComparative Study On Design Results of A Multi-Storied Building Using Staad Pro and Etabs For Regular and Irregular Plan ConfigurationRishabhZoneNo ratings yet

- Monitoring and Enhanced Fatigue Evaluation of A Steel Railway BridgeDocument10 pagesMonitoring and Enhanced Fatigue Evaluation of A Steel Railway BridgeSaba AliyariNo ratings yet

- Seismic Evaluation of RC Framed Building With and Without Shear Walls (Performance Based DesignDocument9 pagesSeismic Evaluation of RC Framed Building With and Without Shear Walls (Performance Based Designdesigner STRNo ratings yet

- Shmidt Hammer TestDocument10 pagesShmidt Hammer Testmoloko masemolaNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationParimalkumar TalpadaNo ratings yet

- Disclosure To Promote The Right To Information: IS 2508 (1984) : Low Density Polyethylene Films (PCD 12: Plastics)Document36 pagesDisclosure To Promote The Right To Information: IS 2508 (1984) : Low Density Polyethylene Films (PCD 12: Plastics)SRR QAQCNo ratings yet

- Disclosure To Promote The Right To Information: IS 2508 (1984) : Low Density Polyethylene Films (PCD 12: Plastics)Document36 pagesDisclosure To Promote The Right To Information: IS 2508 (1984) : Low Density Polyethylene Films (PCD 12: Plastics)SRR QAQCNo ratings yet

- Disclosure To Promote The Right To Information: IS 2508 (1984) : Low Density Polyethylene Films (PCD 12: Plastics)Document36 pagesDisclosure To Promote The Right To Information: IS 2508 (1984) : Low Density Polyethylene Films (PCD 12: Plastics)SRR QAQCNo ratings yet

- Power Converters ProblemsDocument2 pagesPower Converters Problemsramya sreeNo ratings yet

- Determination of Specific Heat Ratio and Error Analysis For EngineDocument8 pagesDetermination of Specific Heat Ratio and Error Analysis For EngineunnotedNo ratings yet

- Prac Que MP Dual NatureDocument5 pagesPrac Que MP Dual Naturetasneemkirana900No ratings yet

- Micro Motion F-Series Compact, Drainable Coriolis Flow and Density MetersDocument7 pagesMicro Motion F-Series Compact, Drainable Coriolis Flow and Density MeterskEWQ 865kNo ratings yet

- Geography 02 - Solar System Latitude and Longitude - DPP 02Document2 pagesGeography 02 - Solar System Latitude and Longitude - DPP 02shantanukumthekar007No ratings yet

- Coulomb's Law Experiment ReportDocument11 pagesCoulomb's Law Experiment ReportQhairunnissaNo ratings yet

- 9TH - Icse - Physics - Worksheet - Upthrust in Fluids, Archimedes' Principle and Floatation 2Document7 pages9TH - Icse - Physics - Worksheet - Upthrust in Fluids, Archimedes' Principle and Floatation 2manojboaNo ratings yet

- Sample Report - Aggregate 20mmDocument2 pagesSample Report - Aggregate 20mmPinnacle InfraNo ratings yet

- 11 LevelingDocument57 pages11 LevelingEvereth SartoNo ratings yet

- AC Generator Fundamentals and WaveformsDocument41 pagesAC Generator Fundamentals and WaveformsKARTHIK LNo ratings yet

- Lahore Grammar School Mid-Year Examinations - December 2020 Grade A1 Physics PaperDocument14 pagesLahore Grammar School Mid-Year Examinations - December 2020 Grade A1 Physics PaperAbdul Muqeet AzizNo ratings yet

- Elmeasure Transducer CatalogDocument1 pageElmeasure Transducer CatalogSEO BDMNo ratings yet

- 2014 JC1 BT H2 PHY P1 Question SolutionDocument15 pages2014 JC1 BT H2 PHY P1 Question Solutionshakthee sivakumarNo ratings yet

- Oan551 Sensors and Transducers 1840897986 Oan551 SsatDocument11 pagesOan551 Sensors and Transducers 1840897986 Oan551 SsatSenthil kumar NatarajanNo ratings yet

- Comparison A Simulation Model of Heat Exchanger With Real Equipment PDFDocument6 pagesComparison A Simulation Model of Heat Exchanger With Real Equipment PDFstevenNo ratings yet

- PTR4Document4 pagesPTR4Darrel LampitocNo ratings yet

- Weekly Home Learning Plan For Grade 12 STEM in Gen Physics 1, Quarter 2, Online Distance LearningDocument4 pagesWeekly Home Learning Plan For Grade 12 STEM in Gen Physics 1, Quarter 2, Online Distance LearningM. Darius LagascaNo ratings yet

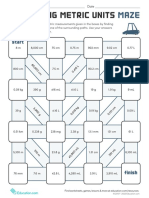

- Converting Metric Units MazeDocument1 pageConverting Metric Units Mazekamil siddiquiNo ratings yet

- TLE7 AFA AGRICROP - Q1 - M3 - v2Document37 pagesTLE7 AFA AGRICROP - Q1 - M3 - v2Alan Banluta100% (1)

- 01-Waves and OscillationDocument67 pages01-Waves and OscillationShubham SharmaNo ratings yet

- Phy400 Experiment 1Document4 pagesPhy400 Experiment 1Aida SyasyaNo ratings yet

- Calibration and Use of Syringe PumpsDocument5 pagesCalibration and Use of Syringe PumpsJason SantosoNo ratings yet

- Thermodynamics 1 Initial Draft 1Document230 pagesThermodynamics 1 Initial Draft 1john pakinganNo ratings yet

- Performance Evaluation For Indirect Evaporative Cooling On Cellular SitesDocument52 pagesPerformance Evaluation For Indirect Evaporative Cooling On Cellular SitesAndres Felipe SánchezNo ratings yet

- Brix Coefficient and CoffeeDocument29 pagesBrix Coefficient and CoffeeEden MolinaNo ratings yet

- CHE312A: Assignment 3: Solutions: AssumptionsDocument13 pagesCHE312A: Assignment 3: Solutions: AssumptionsRazvan Botezatu100% (1)

- Assignment #2 SolvedDocument50 pagesAssignment #2 SolvedHéctor Manuel Rodríguez FelicianoNo ratings yet