Professional Documents

Culture Documents

Design and Development of Automatic Seed Sowing Machine: P. Premalatha and Sharath Singh

Uploaded by

Teshome GetachewOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Development of Automatic Seed Sowing Machine: P. Premalatha and Sharath Singh

Uploaded by

Teshome GetachewCopyright:

Available Formats

Asian Journal of Electrical Sciences

ISSN: 2249-6297, Vol. 8, No. S1, 2019, pp. 51-54

© The Research Publication, www.trp.org.in

Design and Development of Automatic Seed Sowing Machine

P. Premalatha1 and Sharath Singh2

1&2

Assistant Professor, Department of Electrical and Electronics Engineering,

MVJ College of Engineering, Bangalore, Karnataka, India

E-Mail: hod_electrical@mvjce.edu.in

Abstract - Indian economy is dependent on agriculture to a drum and seed sowing process takes place without any

great extent. Increase in production, tends to improve social wastage of seeds. It also has an ultrasonic sensor fixed in

welfare, particularly in rural areas. This project aims to the front for proper navigation of the robot over the field.

increse the productivity and to reduce the time for seed sowing After completion of each row the robot must turn, and it has

process and wastage of seeds. Automatic seed sowing machine

designed and developed, which uses Solar powered DC motors

to start the seed sowing in the second row. This is done with

driven by L298N driver circuit with Aurdino UNO R3 control the help of the sensor which detects the end of the row. In

kit. An ultrasonic sensor is also installed to detect the obstacle the conventional method the sowing takes place in only one

in the path and end of each row. row then it must be shifted manually to second row.

Keywords: Automation, Agriculture Productivity, Arduino Addition of sensor in this proposed model reduces the

UNO3, L298N Driver, Solar Powered DC Motor human intervention. Control action is provided by

ARDUINO UNO R3 which is interfaced to sensor through

I. INTRODUCTION USB channel. DC motors are driven by L298N driver

circuit. As the technique of sowing seed with robot is good

Agriculture plays an important role in the Indian economy. and efficient the time consumption will be less and

The introduction of technology to agriculture will result in gradually reducing the amount of manpower. Seeding depth

reduction of manpower and corresponding increase in will be accurate this tends to no later or earlier growth of

productivity. The main aim of this project is to design and plants and the yield will be of same growth. Seeds will be

develop an automatic seed sowing robot with minimal cost sowed accurately in rows and this tends accurate plantation

affordable by the small-scale formers. This seed sowing and causes very well growth of food and economy. The

robot reduces the labour cost involved in agriculture and it Complete system becomes ecofriendly, since DC motors

saves the time. The model proposed makes use of an used here are powered by solar panel.

ultrasonic sensor and Arduino controller unit which helps

the robot to move freely over the field without human

intervention. And, it sends a message to the owner once the

seed drum becomes empty.

The process of seed sowing was costly and time

consumption was high with the help of farmers where these

existing problem was overcome by the usage of electronic

controller. [1] The uasage of “MSP430 MICRO

CONTROLLER” was introduced where the time

consumption was reduced. But the human intervention was

required. To overcome these the BLUETOOTH Control

was introduced [2] where the control was easy with time

consumption reduced with increase in production. Still the

human control was required where he should posses the

technical knowledge for control action. There was still the

problem of power so, it was overcomed by the SOLAR

PANEL [3]. Where the problem of power was completelly

Fig.1 Block diagram of the Automatic seed sowing machine

solved. But the automatic control was not developed which

is succesfully achived by our Automatic Seed Sowing

III. PROPOSED SYSTEM

Machine.

A. Arduino UNO R3: The Arduino UNO is a widely used

II. METHODOLOGY

open-source microcontroller board based on the AT mega

328 microcontroller and developed by Arduino. The board

The proposed model uses solar powered DC motors placed

is equipped with sets of digital and analog input/output (I/O)

in the wheels of the robot. The fall of seeds from the seed

pins that may be interfaced to various expansion boards

51 AJES Vol.8 No.S1 June 2019

P. Premalatha and Sharath Singh

(shields) and other circuits [4]. The board features 14 C. DC Motor: A dc motor is a device that converts direct

Digital pins and 6 Analog pins. It is programmable with current (electrical energy) into mechanical energy [6]. Two

the Arduino IDE (Integrated Development Environment) dc motors are used for driving the wheels connected to the

via a type B USB cable. It can be powered by a USB cable robot. L298N is a dc motor driver used for driving dc

or by an external 9-volt battery, though it accepts voltages motors. 60RPM Centre Shaft Economy Series DC Motor is

between 7 and 20 volts. It is also similar to the Arduino high-quality low-cost DC geared motor. It has steel gears

Nano and Leonardo. Layout and production files for some and pinions to ensure longer life and better wear and tear

versions of the hardware are also available. "Uno" means properties. The gears are fixed on hardened steel spindles

one in Italian and was chosen to mark the release of polished to a mirror finish. The output shaft rotates in a

Arduino Software (IDE) 1.0. The Uno board and version 1.0 plastic bushing. The whole assembly is covered with a

of Arduino Software (IDE) were the reference versions of plastic ring. Gearbox is sealed and lubricated with lithium

Arduino, now evolved to newer releases. The Uno board is grease and require no maintenance. The motor is screwed to

the first in a series of USB Arduino boards, and the the gear box from inside. Although motor gives 60 RPM at

reference model for the Arduino platform. The ATmega328 12V, but motor runs smoothly from 6 V to 12V and gives

on the Arduino Uno comes preprogrammed with a boot wide range of RPM, and torque.

loader that allows to upload new code to it without the use

of an external hardware programmer. It communicates using

the original STK500 protocol. The Uno also differs from all

preceding boards in that it does not use the FTDI USB-to-

serial driver chip. Instead, it features the Atmega16U2

(Atmega8U2 up to version R2) programmed as a USB-to-

serial converter.

Fig. 4 Dc Motor & Wheel

D. Keypad: 4*4 Keypad is been used for setting the vertical

input and horizontal input as shown in the table for different

seeds. The keypad input given based on the table provided

for sowing in the robot.

Fig. 2 Arduino Control Kit

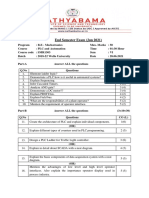

TABLE I SEED SOWING D ISTANCE

B. Ultrasonic Sensor: The Ultrasonic Sensor sends out a S. Name of Vertical distance

Horizontal

high-frequency sound pulse and then times how long it distance (row to

No. Seed’s (plant to plant) cm

row) cm

takes for the echo of the sound to reflect back. The sensor

1. Cotton 33.02 101.6

has 2 openings on its front. One opening transmits

ultrasonic waves, (like a tiny speaker), the other receives 2. Jowar 12 60.96

them, (like a tiny microphone). The speed of sound is 3. Ground nut 10 30

approximately 341 meters (1100 feet) per second in air [5].

4. Soya bean 18 30

The ultrasonic sensor uses this information along with the

time difference between sending and receiving the sound 5. Millet 30 Continues (5)

pulse to determine the distance to an object.it uses the 6. Thoor dal 33.02 101.6

following mathematical equation. Distance = Time * speed 7. Sunflower 30 60.96

of sound divided by 2. Time = the time between when an

ultrasonic wave is transmitted and when it is received. 8. Sweet corn 15 60.96

9. Maize 15 60.96

10. Bengal gram 15-20 30

E. GSM Module: Sim808 module contains a set of TTL

Serial interface 5V-18V Power supply [7]. Supports sending

and receiving text messages telephone, GPS and supports

http protocol. It also has special features such as recording

function, Bluetooth. Easy to debug. Equipped with micro-

Fig. 3 Ultrasonic sensor sim card position, convenient to users

AJES Vol.8 No.S1 June 2019 52

Design and Development of Automatic Seed Sowing Machine

Fig. 5 GSM Module

Fig. 7 Automatic seed sowing machine prototype

F. L298N Driver: L293D is a typical Motor driver or Motor

Driver IC which allows DC motor to drive on either

direction. L293D is a 16-pin IC which can control a set of Once the obstacle is found it will be detected by ultrasonic

two [6] DC motors simultaneously in any direction. It sensor and it sends signal to the controller. As a result, the

means that you can control two DC motor with a single robot turns and moves certain distance which is given by the

farmer (Horizontal input), it again turns back and continues

L293D IC. Dual H Bridge Motor Driver integrated circuit

to sow the seed. Here the robot turning is alternatively as it

(IC). L293D is a dual H bridge motor driver integrated

results in proper movement of robot through the field.

circuit (IC). Motor drivers act as current amplifiers since

they take a low-current control signal and provide a higher- Hence the system is designed fully automatic. The special

feature of these robots is that it sends the message whenever

current signal. This higher current signal is used to drive the

the seed gets empty in seed drum which is detected by LDR.

motors.

It sends “Seed Drum Is Empty” message to the registered

mobile number of the farmer. Here we have used GSM

Module to get message whenever the seed gets empty in

seed drum. Message is sent to the registered number.

Fig. 6 L298N Driver

IV. WORKING

Automatic seed sowing robot works with the power supply

from solar panel and battery. It requires the manual input

which are of two types namely Vertical and Horizontal

input. Vertical input refers to the distance between the two

plants and horizontal input refers to the distance between

the rows. The input is provided through once the input is

given then the power switch is Switched ON. And power

supply is provided to DC wheels.

Based on the distance provided by farmer the robot moves

to a fixed distance and stops. At the same time seed gear

system rotates and seed falls through the pipe. Once when

the robot stops the servo motor operates and makes the seed

falling chamber open and after some delay it closes itself.

Process continues and robot continues to move until the

obstacle is found.

Fig. 8 Flow Chart

53 AJES Vol.8 No.S1 June 2019

P. Premalatha and Sharath Singh

V. ADVANTAGES

Using advanced ASSR technology and wireless routing,

vehicles can be quickly reprogrammed to change path or

operation, eliminating the need for expensive retrofitting.

New directions, tasks, and work cells can be created almost

instantaneously without the need for physical equipment

installation. Through the advancement of control systems

ASSRs offer a safe and predictable method of delivery,

while avoiding interference with human and building

factors. ASSRs can operate almost around the clock,

without the need for breaks and vacation time. In addition,

ASSRs operate in conditions that may not be suitable for

human operators, such as extreme temperatures and

hazardous environments.

Fig. 9 Message sent from the ASSM to the registered mobile

Automated Seed Sowing, combined with RF technology,

interface with the Warehouse Control System or Warehouse

Management System to improve accuracy and efficiency.

ASSRs have little downtime and operate at a fixed rate to

meet a predictable metric for operational activity. No

conventional material-handling infrastructures required.

Increase of ASSRs in line with the growth in volume of

operations. Updating is possible without shutting down the

system. Poly house Seeds are broadcasted on the soil which

results in the loss and damage of the seeds. As the cost of

seeds is more and cannot be affordable for the farmers so

there is the need for the proper placement of seeds in the

soil.

VI. DISADVANTAGES

1. Electronic Component cannot sustain any variation in

high temperature. Fig. 10 Message sent from the ASSM to the registered mobile

2. Accuracy will be reduced due to cloud and mud.

REFERENCES

VII. RESULT AND FUTURE SCOPE

[1] K. Amit Kumar and Vishal Parit, “Design and development of

We have designed and developed the Automatic seed template row planter”, Transnational Journal of Science and

Technology, Vol. 3, No. 7, 2016.

sowing machine which successfully sows the seeds based [2] Swati D. Sambare and S.S. Belasare, “Use of robotics technology for

on the input provided by the user. It moves certain distance seed sowing in Agriculture”, International Journal of Electrical and

based on input given and stops for some duration to drop the Data Communication, Vol. 2, No.1, 2016.

seed. And this process continues until obstacle is found. [3] Rashmi A Pandhare and Tejas Padathare, “Design and development

of automatic operated seed sowing machine”, International Journal

Then it turns and moves certain distance horizontally and it of Recent and Innovation Trend in Computing and Communication,

turns back to sow the seed in next row. Hence our Robot Vol. 5, No. 2, 2017.

can be used by small scale farmers successfully without any [4] B. Yogesh Ramdas, “Green growth management by using arm

technical knowledge. Our seed sowing machine also gives controller”, International Journal of Engineering Research and

Applications, Vol. 4, No. 3, pp. 360-363, March 2014.

the message to the farmer when the seed Drum is empty and [5] B. S. Shivprasad, M. N. Ravishankara and B. N. Shoba” Design and

also after the seeding process is complete. Operation is implementation of seeding and fertilizing agriculture robot”,

possible without any human intervention. International Journal of Application or Innovation in Engineering

&Management, Vol. 3, No. 6, June 2014.

[6] Abdulrahman, Mangesh Koli, Umesh Kori and Ahamedakbar, “Seed

We have designed our robot for small scale farmers where sowing robot”, International Journal of computer science trends and

in future it can be designed for large scale. The system can Technology, Vol. 5, No. 2, March 2017.

be upgraded by introducing ploughing of fields and closing [7] R. Sagar Chavan, Prof. Rahul Shelke and Prof. Shrinivas R. Zanwar.

of seeds automatically. It can be made still more user “Enhanced agriculture robotic system”, International Journal of

Engineering Sciences & Research Technology, pp. 368-371, Feb.

friendly with improvements like efficiency and accuracy. 2015.

AJES Vol.8 No.S1 June 2019 54

You might also like

- Engineering Materials 2 - Chapter 18Document4 pagesEngineering Materials 2 - Chapter 18Andres PerezNo ratings yet

- Exploring Arduino: Tools and Techniques for Engineering WizardryFrom EverandExploring Arduino: Tools and Techniques for Engineering WizardryRating: 4.5 out of 5 stars4.5/5 (5)

- CNC Drilling Machine For Printed Circuit BoardDocument4 pagesCNC Drilling Machine For Printed Circuit BoardEditor IJTSRDNo ratings yet

- Automatic Plant Irrigation System Using ArduinoDocument4 pagesAutomatic Plant Irrigation System Using ArduinoMUSIC IS LIFENo ratings yet

- Sample Interview QuestionsDocument5 pagesSample Interview QuestionsZezo MarchettiNo ratings yet

- Smart Dustbin Using Arduino Report 1Document24 pagesSmart Dustbin Using Arduino Report 1Ñîžäm Ñž100% (1)

- Water Trash CollectorDocument3 pagesWater Trash CollectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Automated Agriculture Monitoring and Controlling System Using ArduinoDocument5 pagesSmart Automated Agriculture Monitoring and Controlling System Using ArduinoChristloveNo ratings yet

- Review On Different Microcontroller Boards Used in IoTDocument11 pagesReview On Different Microcontroller Boards Used in IoTIJRASETPublicationsNo ratings yet

- Full Paper of Arduino Based Obstacle Avoidance RobotDocument3 pagesFull Paper of Arduino Based Obstacle Avoidance RobotsabahatNo ratings yet

- Solar Agricultural Sprayer RobotDocument7 pagesSolar Agricultural Sprayer RobotIJRASETPublicationsNo ratings yet

- Seed Sowing Robot-IJRASETDocument8 pagesSeed Sowing Robot-IJRASETIJRASETPublicationsNo ratings yet

- Remote Area Monitoring RobotDocument5 pagesRemote Area Monitoring RobotIJSTENo ratings yet

- Digital Electronics - Arduino Robot ProjectDocument17 pagesDigital Electronics - Arduino Robot ProjectWri AnNo ratings yet

- REPORTDocument22 pagesREPORThohi4808No ratings yet

- Project MweDocument18 pagesProject Mweanilvs2004No ratings yet

- CNC Machine Based On Laser Engraver Using Arduino UNODocument4 pagesCNC Machine Based On Laser Engraver Using Arduino UNOIJSTE100% (1)

- CNC Drilling Machine For Printed Circuit Board: Need To Cite This Paper? Want More Papers Like This?Document5 pagesCNC Drilling Machine For Printed Circuit Board: Need To Cite This Paper? Want More Papers Like This?Fauzan Ammar PutraNo ratings yet

- Obstacle Avoidance Robot Using ArduinoDocument5 pagesObstacle Avoidance Robot Using ArduinoRichard Kaven SerquinaNo ratings yet

- Automatic Seed Sowing Machine Using Solar PanelDocument4 pagesAutomatic Seed Sowing Machine Using Solar PanelIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Iarjset 2021 8714Document4 pagesIarjset 2021 8714Amit KumarNo ratings yet

- Automatic Seed Sowing Robot: International Research Journal of Engineering and Technology (IRJET)Document3 pagesAutomatic Seed Sowing Robot: International Research Journal of Engineering and Technology (IRJET)Teshome GetachewNo ratings yet

- Smart Waste Management System Using ARDUINO: November 2019Document7 pagesSmart Waste Management System Using ARDUINO: November 2019Rajesh KannanNo ratings yet

- Obstacle avoidance robot using ArduinoDocument7 pagesObstacle avoidance robot using ArduinoPramod TNo ratings yet

- Solar Powered Intelligent Grass Cutter RobotDocument5 pagesSolar Powered Intelligent Grass Cutter RobotAjayNo ratings yet

- CHNDDocument22 pagesCHNDchandhuNo ratings yet

- IoT Controlled Grass Cutter With Solar PDocument7 pagesIoT Controlled Grass Cutter With Solar PNikko Dumaliang13No ratings yet

- 13 Phys DR Hla Htay Win - LectDocument11 pages13 Phys DR Hla Htay Win - LectPanuphong NNo ratings yet

- 9 May2019Document4 pages9 May2019Jay Prakash Narayan VermaNo ratings yet

- Electric Press Machine by Using Stepper MotorDocument11 pagesElectric Press Machine by Using Stepper MotorIJRASETPublicationsNo ratings yet

- Automatic Solar Grass CutterDocument4 pagesAutomatic Solar Grass CutterLoveable Ajith0% (1)

- AkhilDocument25 pagesAkhilNiharikaNo ratings yet

- SUMOBOT Docu PDFDocument4 pagesSUMOBOT Docu PDFFreddie MendezNo ratings yet

- Women Safety Night Patrolling RobotDocument8 pagesWomen Safety Night Patrolling RobotIJRASETPublicationsNo ratings yet

- Nietjet 1002S 2022 003Document6 pagesNietjet 1002S 2022 003NIET Journal of Engineering & Technology(NIETJET)No ratings yet

- DT Project Sem 4Document9 pagesDT Project Sem 4Utkarsh YadavNo ratings yet

- Solar Based Wireless Grass CutterDocument5 pagesSolar Based Wireless Grass CutterIJSTE100% (2)

- ... For Dummy: "Controlling Your Arduino Mobile Robot Using Android Bluetooth App"Document52 pages... For Dummy: "Controlling Your Arduino Mobile Robot Using Android Bluetooth App"amirNo ratings yet

- Arduino Based Voice Controlled System: Devyani Randive, Parag Mane, Priti Khapre, Aniket Dange Mr.S.D. KakdeDocument4 pagesArduino Based Voice Controlled System: Devyani Randive, Parag Mane, Priti Khapre, Aniket Dange Mr.S.D. KakdeJoel Malsi JuniorNo ratings yet

- Diminishing Road Accidents On Sharp Curves Using ArduinoDocument4 pagesDiminishing Road Accidents On Sharp Curves Using ArduinoIJARP PublicationsNo ratings yet

- Design of Smart Mechanical Grass CutterDocument4 pagesDesign of Smart Mechanical Grass CutterQhai AnimatorNo ratings yet

- Design of Smart Mechanical Grass CutterDocument4 pagesDesign of Smart Mechanical Grass CutterLarweh DanielNo ratings yet

- Arduino Based Bluetooth Controlled RobotDocument4 pagesArduino Based Bluetooth Controlled RobotTonyNo ratings yet

- CHNDDocument22 pagesCHNDchandhuNo ratings yet

- Touchless Faucet Using Arduino Final TPDocument29 pagesTouchless Faucet Using Arduino Final TPGEORGE FRIDERIC HANDELNo ratings yet

- Automated Irrigation SystemDocument20 pagesAutomated Irrigation SystemVishakh SuneNo ratings yet

- Smart Gun War Field Spy Robot Using Arduino and ZigbeeDocument10 pagesSmart Gun War Field Spy Robot Using Arduino and ZigbeeIJRASETPublicationsNo ratings yet

- Solar Agricultural Sprayer RobotDocument8 pagesSolar Agricultural Sprayer RobotIJRASETPublicationsNo ratings yet

- Smart Waste Management SystemDocument25 pagesSmart Waste Management SystemTauheed MullaNo ratings yet

- Arduino Based Obstacle Avoiding Robot: Electrical Engineering Department 6 Semester, Batch 2017, Section (A)Document11 pagesArduino Based Obstacle Avoiding Robot: Electrical Engineering Department 6 Semester, Batch 2017, Section (A)Spring SuperbNo ratings yet

- IOT Based Automatic Water Container Filler Using ArduinoDocument6 pagesIOT Based Automatic Water Container Filler Using ArduinoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gesture Controlled Robot Using ArduinoDocument9 pagesGesture Controlled Robot Using ArduinoAli Najim Al-AskariNo ratings yet

- Android Phone Controlled Bluetooth Robot: April 2016Document12 pagesAndroid Phone Controlled Bluetooth Robot: April 2016Fakhr Al-TimimiNo ratings yet

- Research Proposal (Plaza)Document10 pagesResearch Proposal (Plaza)Edmarjan ConcepcionNo ratings yet

- Fire Fighting RobotDocument60 pagesFire Fighting RobotkalaivaniNo ratings yet

- JJEM050202-IOT Poultry FarmingDocument6 pagesJJEM050202-IOT Poultry Farmingtry againNo ratings yet

- Irjet V7i61194Document4 pagesIrjet V7i61194Aryan ShrivaNo ratings yet

- Bluetooth: ArduinoDocument52 pagesBluetooth: ArduinoHavoc BarathNo ratings yet

- Final ProposalDocument13 pagesFinal ProposalAzizNo ratings yet

- An Algorithm Based Low Cost Automated System For Irrigation With Soil Moisture SensorDocument5 pagesAn Algorithm Based Low Cost Automated System For Irrigation With Soil Moisture SensorMugdha DokeNo ratings yet

- Solar Based Agriculture TractorDocument23 pagesSolar Based Agriculture TractoryashNo ratings yet

- What Is Productivity?: To ItDocument8 pagesWhat Is Productivity?: To ItTeshome GetachewNo ratings yet

- SAU1302 - (Wollo University)Document2 pagesSAU1302 - (Wollo University)Teshome GetachewNo ratings yet

- SAU1302 - (Wollo University)Document2 pagesSAU1302 - (Wollo University)Teshome GetachewNo ratings yet

- Management Control System in Manufacturing Companies: A Case of BGI EthiopiaDocument16 pagesManagement Control System in Manufacturing Companies: A Case of BGI EthiopiaTeshome GetachewNo ratings yet

- Wollo University-End Sem Exam-PLC and AutomationDocument1 pageWollo University-End Sem Exam-PLC and AutomationTeshome GetachewNo ratings yet

- Project Charter: Holistic Vehicle Tracking SystemDocument21 pagesProject Charter: Holistic Vehicle Tracking SystemTeshome GetachewNo ratings yet

- Design and Implementation of Multi Seed Sowing Machine: Research PaperDocument8 pagesDesign and Implementation of Multi Seed Sowing Machine: Research Paper113314No ratings yet

- Automatic Seeds Plantation Robot Using Lab View: Abstract - in India, About 70% of Population IsDocument3 pagesAutomatic Seeds Plantation Robot Using Lab View: Abstract - in India, About 70% of Population IsTeshome GetachewNo ratings yet

- Code - Seed Sowing RobotDocument7 pagesCode - Seed Sowing RobotTeshome GetachewNo ratings yet

- Code - Seed Sowing RobotDocument7 pagesCode - Seed Sowing RobotTeshome GetachewNo ratings yet

- Indg90 PDFDocument10 pagesIndg90 PDFajaymechengineerNo ratings yet

- Automated Solar Powered Seed Sowing Machine: Project Reference No.:39S - Be - 0598Document3 pagesAutomated Solar Powered Seed Sowing Machine: Project Reference No.:39S - Be - 0598zain abideenNo ratings yet

- V3i2 1407Document7 pagesV3i2 1407kusuma RanjithNo ratings yet

- Automated Solar Powered Seed Sowing Machine: Project Reference No.:39S - Be - 0598Document3 pagesAutomated Solar Powered Seed Sowing Machine: Project Reference No.:39S - Be - 0598zain abideenNo ratings yet

- Automated Solar Powered Seed Sowing Machine: Project Reference No.:39S - Be - 0598Document3 pagesAutomated Solar Powered Seed Sowing Machine: Project Reference No.:39S - Be - 0598zain abideenNo ratings yet

- Automatic Seeds Plantation Robot Using Lab View: Abstract - in India, About 70% of Population IsDocument3 pagesAutomatic Seeds Plantation Robot Using Lab View: Abstract - in India, About 70% of Population IsTeshome GetachewNo ratings yet

- Automatic Seed Sowing Robot: International Research Journal of Engineering and Technology (IRJET)Document3 pagesAutomatic Seed Sowing Robot: International Research Journal of Engineering and Technology (IRJET)Teshome GetachewNo ratings yet

- Smart Robot For Seed Defect Monitoring and Seed SowingDocument5 pagesSmart Robot For Seed Defect Monitoring and Seed SowingTeshome GetachewNo ratings yet

- Effects of Harmonics On Power SystemsDocument8 pagesEffects of Harmonics On Power SystemsHassan AliNo ratings yet

- EasyRET Tri-Band Antenna with 3 Integrated RCUsDocument2 pagesEasyRET Tri-Band Antenna with 3 Integrated RCUsDragićević IvanNo ratings yet

- Parts Catalog: L B P 7 6 8 0 C X / 7 6 6 0 C D N / 7600C/LBP7210CdnDocument54 pagesParts Catalog: L B P 7 6 8 0 C X / 7 6 6 0 C D N / 7600C/LBP7210CdnAndi PrengaNo ratings yet

- 2011 Toyota Sienna Engine Immobilizer System Diagnostic Code B2799Document2 pages2011 Toyota Sienna Engine Immobilizer System Diagnostic Code B2799Lucas RamirezNo ratings yet

- Process Flow Chart - Smart MeterDocument4 pagesProcess Flow Chart - Smart MeterQAD LotusNo ratings yet

- 2-1 EDC Lab Manual Jntuk R20 - 201021Document96 pages2-1 EDC Lab Manual Jntuk R20 - 201021Durgasaiteja923 SunnyNo ratings yet

- Riverray Datasheet LRDocument2 pagesRiverray Datasheet LRingaboNo ratings yet

- EA534Document1 pageEA534api-3833673No ratings yet

- Advant Controller 450 - ABB SolutionsBankDocument107 pagesAdvant Controller 450 - ABB SolutionsBankTNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2011/0156494 A1Document16 pagesPatent Application Publication (10) Pub. No.: US 2011/0156494 A1Tony GaryNo ratings yet

- Circuits II Lab SyllabusDocument8 pagesCircuits II Lab SyllabusJuan Glicerio C. ManlapazNo ratings yet

- Hontzsch Flowtherm NT Data SheetDocument3 pagesHontzsch Flowtherm NT Data SheetAlejandro DorantesNo ratings yet

- Experiment 7 Capacitors: PurposeDocument7 pagesExperiment 7 Capacitors: Purposeعباس حمودNo ratings yet

- Optional Medical Accessories for Blood Pressure MonitorDocument2 pagesOptional Medical Accessories for Blood Pressure MonitorMaulana Raka PratamaNo ratings yet

- Q1 Module 4 - V2Document21 pagesQ1 Module 4 - V2edsonNo ratings yet

- Mcqs Electrochemistry: Chemistry by Saad AnwarDocument5 pagesMcqs Electrochemistry: Chemistry by Saad AnwarPhoton Online Science Academy0% (1)

- Sunlu s2 ManualDocument9 pagesSunlu s2 ManualDan HendersonNo ratings yet

- LogDocument8 pagesLogKimberly ChalesNo ratings yet

- 805TS Weighing Indicator ManualDocument47 pages805TS Weighing Indicator ManualEl DOnNo ratings yet

- SFT1192S.5: Solid State Devices, IncDocument2 pagesSFT1192S.5: Solid State Devices, IncIPUNK PURNOMONo ratings yet

- Comparison and Evaluation of Anti-Windup PI ControDocument7 pagesComparison and Evaluation of Anti-Windup PI Contro17K41A0 440No ratings yet

- OSN 3500 Hardware Installaion Report - MTN HQ PN SiteDocument3 pagesOSN 3500 Hardware Installaion Report - MTN HQ PN Sitepatrickkis294923No ratings yet

- Smart Baby SitterDocument6 pagesSmart Baby SittermohitNo ratings yet

- Index: Matching Networks and QWTDocument20 pagesIndex: Matching Networks and QWTKavita KamerikarNo ratings yet

- JNTUH Analog IC Design Short Term CourseDocument3 pagesJNTUH Analog IC Design Short Term Courseshaik moinuddin imranNo ratings yet

- Evlink Com Power Ve Ca3 en (Web Catalog)Document72 pagesEvlink Com Power Ve Ca3 en (Web Catalog)netvistaNo ratings yet

- OEM Electricity Revisi#1Document6 pagesOEM Electricity Revisi#1EndraNo ratings yet

- Home Appliance: Household Cooking Cleaning Food PreservationDocument5 pagesHome Appliance: Household Cooking Cleaning Food PreservationSachin NandeNo ratings yet

- Service Manual: Mixing ConsoleDocument89 pagesService Manual: Mixing ConsoleleeNo ratings yet