Professional Documents

Culture Documents

National Dairy Authority: Areas For Checking YES NO Remarks 1. Milk Acceptance Test

Uploaded by

Mheruem Ah0 ratings0% found this document useful (0 votes)

31 views4 pagesThe document is a milk processing quality and safety checklist from the National Dairy Authority of the Philippines. It contains two sections: 1) milk acceptance tests to check acidity and sensory attributes, and 2) a product process flow that outlines 8 key steps including washing and sanitizing equipment, heating milk to 72°C for 15 seconds to pasteurize, cooling quickly, packaging and sealing, and freezing products. The checklist is used to ensure proper milk processing and safety standards are followed.

Original Description:

Original Title

Milk Pasteurization Checklist

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a milk processing quality and safety checklist from the National Dairy Authority of the Philippines. It contains two sections: 1) milk acceptance tests to check acidity and sensory attributes, and 2) a product process flow that outlines 8 key steps including washing and sanitizing equipment, heating milk to 72°C for 15 seconds to pasteurize, cooling quickly, packaging and sealing, and freezing products. The checklist is used to ensure proper milk processing and safety standards are followed.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views4 pagesNational Dairy Authority: Areas For Checking YES NO Remarks 1. Milk Acceptance Test

Uploaded by

Mheruem AhThe document is a milk processing quality and safety checklist from the National Dairy Authority of the Philippines. It contains two sections: 1) milk acceptance tests to check acidity and sensory attributes, and 2) a product process flow that outlines 8 key steps including washing and sanitizing equipment, heating milk to 72°C for 15 seconds to pasteurize, cooling quickly, packaging and sealing, and freezing products. The checklist is used to ensure proper milk processing and safety standards are followed.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

Republic of the Philippines

Department of Agriculture

NATIONAL DAIRY AUTHORITY

BAI Compound, Visayas Avenue, Quezon City 1101 Philippines

Tel No.: (632) 926 – 0733 – 35 Fax: (632) 926 – 8847

Email:dairynda@pldtdsl.net Website: http//nda.da.gov.ph

Milk Processing Quality and Safety Checklist

AREAS FOR CHECKING YES NO REMARKS

1. Milk Acceptance Test

1.1 Conduct Test for Acidity (COB)

1.2 Conduct Sensory Evaluation (color, no visible dirt, odor)

2. Product Process Flow

2.1 All utensils should be washed, sanitized (dipped in 200 ppm

chlorine solution for 1-2 minutes, prepared by mixing 20 mL

chlorine in 5 L water) and air dried before using.

2.2 Bottles should be rinsed first with water then dipping them

in 200 ppm chlorine solution for 1-2 minutes, then air dry.

2.3 Pour and strain raw milk in a pasteurizer or casserole

(double boiler).

2.4 Heat the milk at 50°C and gradually add in premix (sugar,

cocoa powder and stabilizers).

2.5 Continue heating process until 72°C for 15 seconds

2.6 Cool immediately to 50°C by immersing the casserole in a

basin of cold or iced water with constant stirring. Replace

warmed-up water with cold or iced water to speed up cooling of

the milk.

2.7 Pack and seal the pasteurized milk in sachets or bottles

2.8 Check any form of leak and sanitized properly seal products

by dipping into 50ppm chlorine solution

2.9 Freeze immediately

SUBTOTAL

TOTAL

REMARKS:

1. To correct above deficiencies

CHECKED BY: CONFORME:

Signature Over Printed Name Signature Over Printed Name

You might also like

- Experiment 4 - The Anaerobic Fermentation ProcessDocument5 pagesExperiment 4 - The Anaerobic Fermentation ProcessFatimatuzzahra' Binti Hardiyono FISNo ratings yet

- 6201 Eden Way Instant Full Cream Milk Powder 1kg AustraliaDocument3 pages6201 Eden Way Instant Full Cream Milk Powder 1kg AustraliamarilouNo ratings yet

- 6200 Eden Way Skim Milk Powder 1kg AustraliaDocument3 pages6200 Eden Way Skim Milk Powder 1kg AustraliamarilouNo ratings yet

- Government of Canada Gouvernement Du CanadaDocument5 pagesGovernment of Canada Gouvernement Du CanadaSaman BetkariNo ratings yet

- LAY by 1Document2 pagesLAY by 1paulwilberNo ratings yet

- Methods For Detection of Common Adulterants in FoodDocument6 pagesMethods For Detection of Common Adulterants in FoodVIVA-TECH IJRINo ratings yet

- Exp 5 SantanDocument6 pagesExp 5 SantanArdeliniNo ratings yet

- New - Coladet BSBDocument2 pagesNew - Coladet BSBmndmattNo ratings yet

- Objective 1 of Yogurt MakingDocument2 pagesObjective 1 of Yogurt MakingJohn Fritz FestejoNo ratings yet

- CHEMDocument21 pagesCHEMSidhant PandaNo ratings yet

- Aneke Cynthia Maryagnes - Soya Milk PlantDocument103 pagesAneke Cynthia Maryagnes - Soya Milk PlantAi AdegbayeNo ratings yet

- Class 12 Chemistry ProjectDocument20 pagesClass 12 Chemistry ProjectSupriyaa HejibNo ratings yet

- Product Spec Sheet Biowish Aqua FOG: Product Name Recommended Use Ingredients Physical and Chemical PropertiesDocument1 pageProduct Spec Sheet Biowish Aqua FOG: Product Name Recommended Use Ingredients Physical and Chemical PropertiesTalha NasirNo ratings yet

- Ube ProcessingDocument12 pagesUbe ProcessingBerns ReyesNo ratings yet

- Technical Data Sheet Liquid Dish SoapDocument1 pageTechnical Data Sheet Liquid Dish SoapWork ShareNo ratings yet

- Chemistry Invetigatory ProjectDocument14 pagesChemistry Invetigatory Projectsahilkumar90125No ratings yet

- Dr. Ravikumar, Department of Community Medicine, SSIMS&RC, DavangereDocument41 pagesDr. Ravikumar, Department of Community Medicine, SSIMS&RC, DavangereRaviKurleNo ratings yet

- Dr. Ravikumar, Department of Community Medicine, SSIMS&RC, DavangereDocument41 pagesDr. Ravikumar, Department of Community Medicine, SSIMS&RC, DavangereRaviKurleNo ratings yet

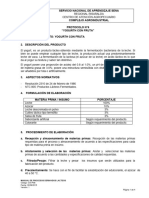

- Yogurth Con FrutaDocument4 pagesYogurth Con FrutadkosmagNo ratings yet

- Industrial Training: Submitted To: Dr. YS Dhaliwal Submitted By: Arpna H-2014-05-007Document48 pagesIndustrial Training: Submitted To: Dr. YS Dhaliwal Submitted By: Arpna H-2014-05-007Ishu MahajanNo ratings yet

- Preparation of SoymilkDocument12 pagesPreparation of SoymilkChitesh MarmatNo ratings yet

- Manufacturing of Flavoured Milk: Submitted byDocument15 pagesManufacturing of Flavoured Milk: Submitted byDipu AhirNo ratings yet

- Industrial Training: at Aavin Pachapalayam CoimbatoreDocument16 pagesIndustrial Training: at Aavin Pachapalayam CoimbatoreSakthi VelNo ratings yet

- Coladet BSBDocument2 pagesColadet BSBmndmattNo ratings yet

- EXPERIMENTDocument7 pagesEXPERIMENTCordelia benardNo ratings yet

- PBL FermentasiDocument13 pagesPBL FermentasisyafiahNo ratings yet

- Biomilk Follow On Formula 800g AustraliaDocument4 pagesBiomilk Follow On Formula 800g AustraliamarilouNo ratings yet

- Heritage IPT ReportDocument82 pagesHeritage IPT ReportTeja YadavNo ratings yet

- Basic DairyDocument144 pagesBasic Dairypriyanka minjNo ratings yet

- Science Fair Scrap BookDocument23 pagesScience Fair Scrap BookChitra KavivannanNo ratings yet

- Experiment No. 3 - Cheese MakingDocument5 pagesExperiment No. 3 - Cheese MakingBenedick Jayson MartiNo ratings yet

- Condensed MilkDocument6 pagesCondensed MilkNarayan BanerjeeNo ratings yet

- Sample Chemistry ProjectDocument16 pagesSample Chemistry ProjectAbhisek DasNo ratings yet

- Methods of Manufacture and Factors Affecting Quality of ProductsDocument16 pagesMethods of Manufacture and Factors Affecting Quality of ProductsRonak RawatNo ratings yet

- Chem Front Page - MergedDocument15 pagesChem Front Page - MergedSwapna SamalNo ratings yet

- Laboratory Activity 5 - Gluten MakingDocument2 pagesLaboratory Activity 5 - Gluten MakingReizel Grace PaladaNo ratings yet

- Rolled Sugar Cone-IndustrialDocument2 pagesRolled Sugar Cone-IndustrialMircea FilipescuNo ratings yet

- JournalDocument11 pagesJournalDesya Medinasari FathullahNo ratings yet

- FermentationDocument16 pagesFermentationSiddharth Sharan100% (1)

- Technological Services DivisionDocument12 pagesTechnological Services DivisionFoutanke Torodo100% (1)

- Laboratory ReportDocument12 pagesLaboratory ReportKevin Anora VillaramaNo ratings yet

- Soymilk ChemDocument14 pagesSoymilk ChemDishita GoelNo ratings yet

- Blue Lake Dairy Group Pty LTD: Finished Product SpecificationDocument3 pagesBlue Lake Dairy Group Pty LTD: Finished Product SpecificationmarilouNo ratings yet

- Adulterants in Milk and Milk ProductsDocument6 pagesAdulterants in Milk and Milk ProductsDhimitri PapamihalNo ratings yet

- Flavored Ice Cubes: Vi - HRC - Batch 5Document5 pagesFlavored Ice Cubes: Vi - HRC - Batch 5Sahar Batool QaziNo ratings yet

- Chemistry Project Class 12 Preparation of Soyabean Milk and It's Comparison With Natural MilkDocument11 pagesChemistry Project Class 12 Preparation of Soyabean Milk and It's Comparison With Natural MilkBhakti More50% (6)

- Technological Services Division: For More Information, Write or CallDocument20 pagesTechnological Services Division: For More Information, Write or CallFoutanke TorodoNo ratings yet

- Chemistry Invetigatory Project WorkDocument16 pagesChemistry Invetigatory Project WorkSk mNo ratings yet

- Food ProcessingDocument59 pagesFood ProcessingKurt Gullem PusoNo ratings yet

- Investigatory Project Chemistry TemplateDocument19 pagesInvestigatory Project Chemistry TemplateTamanna PandeyNo ratings yet

- Edited Kicap ReportDocument11 pagesEdited Kicap ReportmuawizzatNo ratings yet

- Sources of Bacterial ContaminationDocument18 pagesSources of Bacterial ContaminationQCL LABNo ratings yet

- Foreign Language Module 2-3Document4 pagesForeign Language Module 2-3dayana.rosesandoval01No ratings yet

- Chemistry Invetigatory Project WorkDocument16 pagesChemistry Invetigatory Project WorkSk mNo ratings yet

- Coconut burfi-CFTRI PaperDocument21 pagesCoconut burfi-CFTRI PaperSri. SiriNo ratings yet

- Wa0002.Document17 pagesWa0002.Rudra Patel100% (1)

- Richa Chemistry Project 2023-24Document14 pagesRicha Chemistry Project 2023-24Rishi NairNo ratings yet

- Sourdough Mastery: A Comprehensive Guide to Perfecting the Art of Bread MakingFrom EverandSourdough Mastery: A Comprehensive Guide to Perfecting the Art of Bread MakingNo ratings yet

- Taste of Home Slow Cooker 3E: 425 Homemade Classics Ready When You Are!From EverandTaste of Home Slow Cooker 3E: 425 Homemade Classics Ready When You Are!Rating: 5 out of 5 stars5/5 (2)