Academic Session – 2020-21

CHEMISTRY PROJECT

Science Behind Cheese Making

Class : XI B

Roll No.: 11224

Submitted by: Tamanna Pandey

1

�Submitted to: Ms. Sowjanya Yepuri

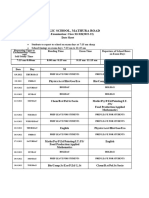

CONTENTS

[Link]. TOPIC PAGE NO.

1. Certificate 03

2. Acknowledgment 04

3. Introduction 05-07

4. Aim 08

Apparatus and Chemicals

5. 09

Required

6. Theory 10-13

7. Procedure 14-17

8. Observations 18-20

9. Conclusion 21

10. Photographs 21 -23

11. Precautions 24

12. Bibliography 25

2

� CERTIFICATE

This is to certify that, I Tamanna Pandey, a student of class

XII- Science Stream at Akshara international School, hereby

declares that the project work “Science Behind Cheese Making "

submitted to the chemistry teacher Mrs. Sowjanya Yepuri is a

record of an original work done by me to serve as the project in

chemistry for the AISSCE-2021 conducted by the Central Board

of Secondary Education (CBSE).

_____________ ____________

_____________

Signature of the Signature of the Signature of the External

Teacher of the Principal Examiner

3

� ACKNOWLEDGEMENT

Opening my fist full of gratitude, I would like to thank all those

who helped me throughout the project. A special thanks to my

Chemistry teacher Mrs. Sowjanya Yepuri for her continuous help and

guidance throughout the project. Her expertise in the subject which

she forwarded to me was a major factor that led to the

accomplishment of the task.

I would also like to thank our respected Principal Mrs Sonali

Balwatkar for his much needed help in the project.

4

� INTRODUCTION

Say Cheese! But when you say cheese, what type of cheese

do you think of? Everyone knows that cheese is a milk-

based food product with a wide range of flavors, textures

and forms. Cheeses are made around the world as a

portable, easy to store food source. Different cheeses are

made from the milk of cows, goats, camels, yak, and even

water buffalo. The exact origins of cheese making are not

known, but it is widely speculated that the first cheeses

were made when merchants stored milk in goat stomachs

for travel in desert regions of the world. The milk in the

stomach came in contact with rennet that was part of the

stomach lining and the combination of enzyme action and

heat lead to the formation of curds and whey. The

foundation for cheese making was established.

Cheesemaking is the controlled process of removing water

from milk. This process concentrates the milk’s protein, fat

and other nutrients and increases its shelf life.

Cheesemaking is one of the earliest examples of

biotechnology. Cheesemaking involves coagulating the

casein protein in milk and then separating the milk into

solid curds and liquid whey. The liquid whey is drained

away, and the curds are salted, shaped and left to ripen in

a controlled environment.

5

�The primary components of milk that are essential for

cheese making are proteins and fat. The predominant

proteins involved in curd formation are the casein

proteins. When making cheese, curd formation can be

accomplished through acidification, increasing

temperature, or adding rennet. It is not uncommon for all

three methods to be used simultaneously at different level.

Rennet is a family or series of enzyme produces in the

stomach of animals called ruminant mammals. The

enzyme helps the young digest mother’s milk. In cheese

making, we use rennet to separate milk into solid curds.

Microorganisms are used in each step of this process and

determine the flavor and texture of the final cheese.

A variety of lipases are available for cheese making. Two

common lipases are calf lipase which is considered to

make a milder cheese and lamb lipase which makes a

sharper cheese.

6

� AIM

To prepare cheese using different types of milk (whole

milk, 2% milk, and skim milk) and with the addition of

different lipases, and compare the different cheeses on the

basis of their moisture, texture, and flavor.

7

� APPARATUS AND CHEMICALS

REQUIRED

1. A sauce pan or pot

2. Cooking thermometer

3. Stove

4. Different types of milk (whole milk, 2% milk, and

skim milk)

5. Liquid vegetable rennet

6. Calf and lamb lipase

7. Bottled water

8. Salt

9. Spatula

10. Cheesecloth

11. Strainer

8

�THEORY

9

� PROCEDURE

[Link] Basic Cheesemaking Process

1. Prepare Rennet

Crush 1/4 tablet of rennet and dissolve in 1/4 cup of cool non-chlorinated

water, or add 1/4 tsp single strength liquid rennet to the water. Set your

rennet mixture aside to use later.

2. Mix Citric Acid & Milk

Add 1 1/2 tsp. of citric acid to 1 cup cool water, pour this into your

[Link], pour cold milk into your pot quickly, to mix well with the citric

acid. This will bring the milk to the proper acidity to stretch well later.

3. Heat Milk

Heat the milk slowly to 90°F. As you approach 90°F, you may notice your

milk beginning to curdle slightly due to acidity and temp.

Note: If you're having problems with milk forming a proper curd, you may

need to increase this temp to 95°F or even 100F.

4. Add Rennet

At 90°F, remove the pot from the burner and slowly add your rennet

(which you prepared in step one) to the milk. Stir in a top to bottom motion

for approx. 30 seconds, then stop. Cover the pot and leave undisturbed for

5 minutes. Check the curd after 5 minutes, it should look like custard, with

a clear separation between the curds and whey. If the curd is too soft or the

whey is milky, let it set longer, up to 30 more minutes.

Note: If you are doing experiments comparing lipase activity, this is the

step where lipase will be added.

5. Cut & Cook Curd

Cut the curds into a 1" checkerboard pattern. Place the pot back on the

stove and heat to 105°F while slowly stirring the curds with your ladle (if

you will be stretching the curds in a hot water bath, rather than using a

microwave, heat to 110°F in this step). Take the pot off the burner and

continue stirring slowly for 2-5 minutes. (More time will make a firmer

cheese)

10

� 6. Transfer & Drain Curd

With a slotted spoon, scoop curds into a colander or microwave safe bowl

(if the curd is too soft at this point, let it sit for another minute or so). Once

transferred, press the curd gently with your hand, pouring off as much

whey as possible.

7. Heat Curd & Remove Whey

If in a colander, transfer the curds into a heat safe bowl. Next, microwave

the curd for 1 minute. If desired, add 1 tsp of salt to the curds for added

flavor. You will notice more whey separation from the curd. Drain off all

whey as you did before. Quickly work the cheese with a spoon or your

hands until it is cool enough to touch (rubber gloves will help since the

cheese is almost too hot to touch at this point). Microwave two more times

for 35 seconds each, and repeat the kneading as in the last step to aid in

more whey drain off and ensure even heating of the curds. Drain off all of

the whey as you go.

8. Knead & Stretch Curd

Knead quickly, then remove curd from bowl and continue kneading until it

is smooth and shiny. Return it to the microwave if needed (if it begins to

cool before it's ready to stretch). Add salt near the finish. At this point, if

hot enough, the cheese should be soft and pliable enough to stretch, and

stretch, and stretch some more (like taffy). This is what makes it Mozzarella

[Link] Lipase Procedure

1. Add 1/16 to 1/8 teaspoon of lipase powder to 1⁄2 cup of cool water 30

minutes prior to use.

2. Add the Lipase solution to the milk immediately prior to the addition of

rennet is Step 4 of the Basic Cheese Making Procedure.

11

� OBSERVATIONS

Exercise 1.1The Milk Comparison

Data Table 1.1. Analysis of Cheese Made with Different Milk

Types.

Milk type/

Whole 2% Skim

Criterias

Moisture

Texture

Flavour

Overall

Exercise 1.2. The Role of Lipase

Data Table 1.2. Analysis of Cheese Made with Different Milk

Types.

Lipase type/

None Calf Lamb

Criterias

Moisture

Texture

Flavour

Overall

12

� CONCLUSION

We’ll write the diff characteristics of the cheese individually and

the reason behind it

13

�PHOTOGRAPHS

14

�15

�16

�17

� PRECAUTIONS

1. Choosing the Right Milk : Make sure the milk you use is not

ultra pasteurized. You can use homogenized or non-

homogenized milk. Farm fresh milk is a great option if you can

find it locally. Low fat milk will work, but the cheese will be drier

and less flavorful.

2. Prepare Work Area : Do not prepare any other food while you

are making cheese. Put all food products away. Move all sponges,

cloths and dirty towels away from your work surface, wipe your

sink and stove with soap and water. Finally use your

antibacterial cleaner to wipe down all surfaces.

3. Using a cooking thermometer is helpful so that you do not

overheat the milk.

4. While letting the curds set, clear whey should separate from the

curd. If the whey is not clear or the curds are not set, you will not

get a clean break of the curd from the pan. Allow the milk set for

a few more minutes if this is happening.

5. For more difference in texture and flavor, different cheese

starters can be added according to your preference.

18

�BIBLIOGRAPHY

19