Professional Documents

Culture Documents

Steam Pipe Expansion Joint Specification

Uploaded by

AbhijeetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steam Pipe Expansion Joint Specification

Uploaded by

AbhijeetCopyright:

Available Formats

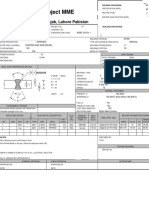

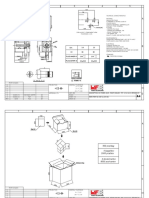

PIPE SIZE : 400 NB 0

SCH : SCH 20 0

MATL : ASTM A 106 Gr B 0

DESIGN PRESSURE (kg/cm2g) / (barg) : 2.5 0

TEST PRESSURE (kg/cm2g) / (barg) : 3.75 0

DESIGN TEMP (0C) : 153 0

FLOWING MEDIUM : STEAM 0

DENSITY (kg/m3) : 10 0

FLOW DIRECTION : VERTICAL 0

VELOCITY (m/sec) : - 0

BELLOW DESIGN REQUIREMENT :

TYPE : UNTIED SINGLE EXPANSION JOINT 0

BELLOW MATERIAL : SS 304 0

MATERIAL END & CENTRE PIECE: - 0

BELLOW DESIGN PRESSURE (kg/cm2g) / (barg) : 7.5 / F.V. 0

BELLOWS DUTY : (mm) 0

AXIAL : 16 0

LATERAL1 : (±) 5 0

LATERAL 2 ( TO 1) : (±) 5 0

NO OF CYCLES : 7000 0

MAX. SPRING RATE :

AXIAL : (N/cm) 634 * 0

LATERAL : (N/cm) 3698 * 0

END CONNECTION :

FLANGED : WELDING END : FLANGED ENDS 0

RATING : 150 # 0

FLG MATERIAL : - 0

THERMAL INSULATION THK (mm) : 65 0

INTERNAL SLEEVES : YES 0

MAXIMUM INSTALLATION LENGTH (mm) : 600 * 0

PLY MULTI PLY 0

REQUIRED QTY OF BELLOW 2 NOS

* VENDOR TO CONFIRM

SPECIAL NOTES :- 1) BELLOW TO BE DESIGNED AS PER EJMA & ASME SEC. VIII. FOR FULL VACUUM SERVICE & 4 TO 5 (kg/cm2) MORE THAN INTERNAL DESIGN PRESSURE OF PIPE.

2) ORDER TO BE PLACED ONLY AGAINST APPROVAL OF VENDOR TECHNICAL QUOTATION WITH G.A.

3) VENDOR TO MARK FLOW ARROW ON BELLOW.

4) VENDOR HAVE TO PROVIDE VACUUM TEST PROCEDURE.

5) THIS SPECIFICATION IS PREPARED BASED ON ISOMETRIC RELEASED. IF ANY CHANGE IN LINE ROUTING WILL CAUSE CHANGE IN BELLOW SPECIFICATION.

REVISION NO. 0

ISSUED FOR ENQUIRY

PREPD. BY / DATE

CHKD. BY / DATE

APPD. BY / DATE

You might also like

- Untied BellowDocument1 pageUntied BellowAbhijeetNo ratings yet

- Specification For Bellows / Expansion Joints Contractors Pvt. Ltd. Arya EngineersDocument1 pageSpecification For Bellows / Expansion Joints Contractors Pvt. Ltd. Arya EngineersAbhijeetNo ratings yet

- SPECIFICATION FOR BELLOWS EXPANSION JOINTDocument1 pageSPECIFICATION FOR BELLOWS EXPANSION JOINTAbhijeetNo ratings yet

- Rotor Track and Balance ReportDocument2 pagesRotor Track and Balance ReportFemi AgbanaNo ratings yet

- Nitrogen Clean-Outs: Total Well Hole Volume Total CT AnnularDocument10 pagesNitrogen Clean-Outs: Total Well Hole Volume Total CT Annularapi-19738429No ratings yet

- New Catalog-P03-Bourdon PGDocument2 pagesNew Catalog-P03-Bourdon PGyogitatanavadeNo ratings yet

- SampleDocument3 pagesSampleMạnh Dũng TrầnNo ratings yet

- Pv1 - Mto Sheet: Hemi Hemi SE SEDocument4 pagesPv1 - Mto Sheet: Hemi Hemi SE SEPatrick TinimbangNo ratings yet

- Spi2000 0109Document1 pageSpi2000 0109Puneet SharmaNo ratings yet

- QUIK-LOQ MALE CABLE MOUNT CONNECTORDocument1 pageQUIK-LOQ MALE CABLE MOUNT CONNECTORdfdsfdNo ratings yet

- Norcomp N C: 821K Yyy - 1 7 3 L Yy 1Document1 pageNorcomp N C: 821K Yyy - 1 7 3 L Yy 1dfdsfdNo ratings yet

- Description: Serie 2141 - 3.5Mm Horizontal Entry Modular With Rising Cage Clamp - WR-TBL WERI PART NO: 691 214 110 0xxDocument2 pagesDescription: Serie 2141 - 3.5Mm Horizontal Entry Modular With Rising Cage Clamp - WR-TBL WERI PART NO: 691 214 110 0xxlogNo ratings yet

- Granulometria Por Peneiramento de Agregados NBR NM 27:2001 NBR NM 248:2003 NBR 6502:1995Document2 pagesGranulometria Por Peneiramento de Agregados NBR NM 27:2001 NBR NM 248:2003 NBR 6502:1995jhonnes silvaNo ratings yet

- GIC Pressure GaugeDocument2 pagesGIC Pressure GaugeSUSOVAN BISWASNo ratings yet

- GIC Bourdon SensingDocument2 pagesGIC Bourdon SensingNCNo ratings yet

- Bourdon Sensing Pressure GaugeDocument2 pagesBourdon Sensing Pressure GaugeJitendra BhosaleNo ratings yet

- 7 - 200 315 630 kVA X-Mer - Spec No 32Document1 page7 - 200 315 630 kVA X-Mer - Spec No 32Raghav GhateNo ratings yet

- Pressure Gauge GuideDocument3 pagesPressure Gauge GuideMangesh MohiteNo ratings yet

- Costing Calculations:: ENQUIRY - 602 Shed-2-R1Document17 pagesCosting Calculations:: ENQUIRY - 602 Shed-2-R1Rakesh SharmaNo ratings yet

- Crawler CraneDocument11 pagesCrawler CraneidonotspammeNo ratings yet

- Final Year Project MME: CEET University of The Punjab, Lahore PakistanDocument9 pagesFinal Year Project MME: CEET University of The Punjab, Lahore PakistanAhmad HasanNo ratings yet

- Dwg. of Elastromeric BearingDocument2 pagesDwg. of Elastromeric BearingSAJEED MOHAMMADNo ratings yet

- Pipe Configuration: Nodes TotalsDocument3 pagesPipe Configuration: Nodes TotalsJohn ANo ratings yet

- Process Data: Shell Side Tube SideDocument1 pageProcess Data: Shell Side Tube SideATUL SONAWANENo ratings yet

- iSV2 60TR 48V400ADocument1 pageiSV2 60TR 48V400AdimitriNo ratings yet

- Corbel Design With Angle LimitDocument2 pagesCorbel Design With Angle LimitFrederick TanNo ratings yet

- FPS Rig Loadings Spreadsheet Disclaimer ExplainedDocument9 pagesFPS Rig Loadings Spreadsheet Disclaimer ExplainedfNo ratings yet

- CSPG Compact Capsule Sensing Pr. Gauges 1Document2 pagesCSPG Compact Capsule Sensing Pr. Gauges 1NCNo ratings yet

- Shell Side Tube Side Process DataDocument1 pageShell Side Tube Side Process DataATUL SONAWANENo ratings yet

- PTFE Plate BearingDocument1 pagePTFE Plate BearingChoi Lai LonNo ratings yet

- Vms Approval: QC Check Sheet No. Dimension Tolerance Result 1 Result 2 Sign 1 2Document2 pagesVms Approval: QC Check Sheet No. Dimension Tolerance Result 1 Result 2 Sign 1 2Luong LeNo ratings yet

- Solder Sleeves For Coax - B-044-22-NDocument2 pagesSolder Sleeves For Coax - B-044-22-NGeeNo ratings yet

- Connecting pipes headloss calculationDocument4 pagesConnecting pipes headloss calculationMarius Mihai BuzdugaNo ratings yet

- Ga Drawing of 125a PDB Panel 06-10-18-ModelDocument1 pageGa Drawing of 125a PDB Panel 06-10-18-ModelNareshkumar SarojNo ratings yet

- Costing TemplateDocument1 pageCosting Templatesaras precisionNo ratings yet

- Heat Load OTDocument14 pagesHeat Load OTarjun akNo ratings yet

- RCC13 PunchingDocument10 pagesRCC13 PunchingMosab Abdelhalim Abdelkarim MakkiNo ratings yet

- Code 1-Ground 2-1st - FloorDocument11 pagesCode 1-Ground 2-1st - FloorelsayedNo ratings yet

- Main Burner End Pipe DrawingDocument1 pageMain Burner End Pipe DrawingApril Gilmae LayasanNo ratings yet

- Spring SpecificationDocument1 pageSpring SpecificationAbhijeetNo ratings yet

- 2130572-01 GENERAL ARRANGEMENT - IdwDocument1 page2130572-01 GENERAL ARRANGEMENT - IdwTakul ThongyooNo ratings yet

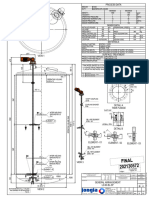

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- VERTICAL CYLINDRICAL VESSEL WITH FLANGED FLAT TOP AND BOTTOMDocument1 pageVERTICAL CYLINDRICAL VESSEL WITH FLANGED FLAT TOP AND BOTTOMsandesh sadvilkarNo ratings yet

- 7m OCT W Solar LightDocument4 pages7m OCT W Solar LightBelal ElsayedNo ratings yet

- Solid Front - Pr. Gauges Bourdon Sensing: FeaturesDocument4 pagesSolid Front - Pr. Gauges Bourdon Sensing: FeaturessayantikaNo ratings yet

- RCC13 Punching Shear-01Document11 pagesRCC13 Punching Shear-01Rodain NajjarNo ratings yet

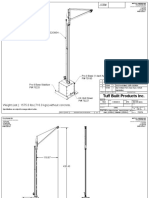

- Tuff Built Products Inc.: Pro-9 Mast, 120R-132/385H PT# 70349Document2 pagesTuff Built Products Inc.: Pro-9 Mast, 120R-132/385H PT# 70349efrain bulaNo ratings yet

- Payslip Video2u Muhammad Azlan Dec2015Document1 pagePayslip Video2u Muhammad Azlan Dec2015boy ibizaNo ratings yet

- Cementation Calculations SpreadsheetDocument8 pagesCementation Calculations SpreadsheetAnupam SinghNo ratings yet

- XXXXX XXXXX: Super Speciality Ot Heat Load EstimateDocument2 pagesXXXXX XXXXX: Super Speciality Ot Heat Load Estimatearjun akNo ratings yet

- Pressure Gauge - Cataloge - GICDocument2 pagesPressure Gauge - Cataloge - GICmuralikrishnan.govindarajNo ratings yet

- Commercial Bollard Data SheetDocument2 pagesCommercial Bollard Data SheetEugenioNo ratings yet

- Staad To Mat3dDocument13 pagesStaad To Mat3dphanikrishnabNo ratings yet

- Entrepiso 2Document15 pagesEntrepiso 2yonatandiazNo ratings yet

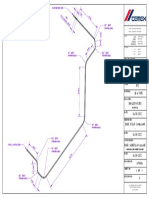

- Total Length: 2120 MM (1: 5) Thickness: 5mm: A3 MybmrchucDocument1 pageTotal Length: 2120 MM (1: 5) Thickness: 5mm: A3 MybmrchuctênchỉđểgọiNo ratings yet

- RCC13 Punching ShearDocument11 pagesRCC13 Punching ShearRodain NajjarNo ratings yet

- Manual de Instrucciones LIEBHERRDocument324 pagesManual de Instrucciones LIEBHERRsandra morales100% (1)

- Technical Characteristics and Packaging of DC Power JackDocument3 pagesTechnical Characteristics and Packaging of DC Power JackMário João VicenteNo ratings yet

- TiedDocument1 pageTiedAbhijeetNo ratings yet

- Project comment resolution sheetDocument1 pageProject comment resolution sheetAbhijeetNo ratings yet

- Steam Pipe Expansion Joint SpecificationDocument1 pageSteam Pipe Expansion Joint SpecificationAbhijeetNo ratings yet

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- Spring Specification-R2Document1 pageSpring Specification-R2AbhijeetNo ratings yet

- Ssaa Stiffness Travel S Sa Sasa Sas VarDocument1 pageSsaa Stiffness Travel S Sa Sasa Sas VarAbhijeetNo ratings yet

- Routing Change, Addition of Expansion Loop Stress Isometric Drawing From My End & Expansion Joint Data Sheet (If Used in Analysis)Document1 pageRouting Change, Addition of Expansion Loop Stress Isometric Drawing From My End & Expansion Joint Data Sheet (If Used in Analysis)AbhijeetNo ratings yet

- TiedDocument1 pageTiedAbhijeetNo ratings yet

- Ssaa Stiffness Travel S Sa Sasa Sas VarDocument1 pageSsaa Stiffness Travel S Sa Sasa Sas VarAbhijeetNo ratings yet

- Comment Resolution Sr. No. Page No From Commented Stress Design Basis Final ResolutionDocument1 pageComment Resolution Sr. No. Page No From Commented Stress Design Basis Final ResolutionAbhijeetNo ratings yet

- Spring Specification-R2Document1 pageSpring Specification-R2AbhijeetNo ratings yet

- General Data Stiffness Travel Loading Dimensions Assembly Details Other Details VarDocument1 pageGeneral Data Stiffness Travel Loading Dimensions Assembly Details Other Details VarAbhijeetNo ratings yet

- Routing Change, Addition of Expansion Loop Stress Isometric Drawing From My End & Expansion Joint Data Sheet (If Used in Analysis)Document1 pageRouting Change, Addition of Expansion Loop Stress Isometric Drawing From My End & Expansion Joint Data Sheet (If Used in Analysis)AbhijeetNo ratings yet

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- Spring SpecificationDocument1 pageSpring SpecificationAbhijeetNo ratings yet

- Spring SpecificationDocument1 pageSpring SpecificationAbhijeetNo ratings yet

- Comment Resolution Sr. No. Page No From Commented Stress Design Basis Final ResolutionDocument1 pageComment Resolution Sr. No. Page No From Commented Stress Design Basis Final ResolutionAbhijeetNo ratings yet

- Comment Resolution Sr. No. Page No From Commented Stress Design Basis Final ResolutionDocument1 pageComment Resolution Sr. No. Page No From Commented Stress Design Basis Final ResolutionAbhijeetNo ratings yet

- General Data Stiffness Travel Loading Dimensions Assembly Details Other Details VarDocument1 pageGeneral Data Stiffness Travel Loading Dimensions Assembly Details Other Details VarAbhijeetNo ratings yet

- 7 LibraryDocument1 page7 LibraryAbhijeetNo ratings yet

- Stress Report StatusDocument1 pageStress Report StatusAbhijeetNo ratings yet

- RMDIPER's mission of lifelong learning and holistic developmentDocument1 pageRMDIPER's mission of lifelong learning and holistic developmentAbhijeetNo ratings yet

- Fundamentals Satellite Communication Part 1Document51 pagesFundamentals Satellite Communication Part 1Safwan MohamedNo ratings yet

- OpenStage Provisioning Interface Developer's GuideDocument182 pagesOpenStage Provisioning Interface Developer's GuideEstêvão Samuel Procópio AmaralNo ratings yet

- Prefabrication IntroductionDocument3 pagesPrefabrication IntroductionGiri ThirthaNo ratings yet

- Merivaara - Maintenance Instructions - Patient and Emergency Trolley EmergoDocument32 pagesMerivaara - Maintenance Instructions - Patient and Emergency Trolley EmergoMantenimiento Area IINo ratings yet

- Transformers ExplainedDocument23 pagesTransformers ExplainedshaluNo ratings yet

- Tupi BV: Index of Revisions Rev. Description And/Or Revised SheetsDocument7 pagesTupi BV: Index of Revisions Rev. Description And/Or Revised SheetsRobles DreschNo ratings yet

- DS Ass IDocument2 pagesDS Ass Inalluri_08No ratings yet

- Ficha Tecnica Ciac Hi Wall 60 HZ R-22Document1 pageFicha Tecnica Ciac Hi Wall 60 HZ R-22Eduardo GarcíaNo ratings yet

- Pre Rex TutorialDocument8 pagesPre Rex TutorialNishant PandaNo ratings yet

- Revision For First Term 9GCE 2010 11Document30 pagesRevision For First Term 9GCE 2010 11Anonymous 8VJhV1eI2yNo ratings yet

- Bluetooth SpeakersDocument18 pagesBluetooth SpeakersPhil Nayebi100% (3)

- Design Example For Beams With Web Openings: Ue ToDocument9 pagesDesign Example For Beams With Web Openings: Ue ToalbertoxinaNo ratings yet

- Design of Slotted Waveguide Antenna for Radar at X-BandDocument3 pagesDesign of Slotted Waveguide Antenna for Radar at X-BandSyed Nazim shahNo ratings yet

- Modeling Biologics, Antibodies & ProteinsDocument2 pagesModeling Biologics, Antibodies & Proteinsthamizh555No ratings yet

- Municipal Solid Waste (MSW) As A Renewable Source of Energy: Current and Future Practices in ChinaDocument9 pagesMunicipal Solid Waste (MSW) As A Renewable Source of Energy: Current and Future Practices in ChinaWeiller Rafael Galli Silva100% (1)

- Oracle Apps Technical ConsultantDocument5 pagesOracle Apps Technical ConsultantRamesh Babu KadiyamNo ratings yet

- 132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Document134 pages132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Sunil S I ShippingNo ratings yet

- Bungalow House Plans Photos PhilippinesDocument16 pagesBungalow House Plans Photos PhilippinesDaryl Badajos100% (1)

- Thika Water and Sewerage Company Limited Tender Notice PDFDocument1 pageThika Water and Sewerage Company Limited Tender Notice PDFUsman ArifNo ratings yet

- Unlock The Rest of Learning Java, 4th Videos: Edition and 30,000 Other Books andDocument8 pagesUnlock The Rest of Learning Java, 4th Videos: Edition and 30,000 Other Books andRennyDortaNo ratings yet

- Artificial Intelligence CSCI/PHIL-4550/6550Document26 pagesArtificial Intelligence CSCI/PHIL-4550/6550Alan StandingNo ratings yet

- GEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Document120 pagesGEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Nattapong Natt100% (1)

- OilsistemDocument212 pagesOilsistemapi-2635664650% (2)

- Dr. Leach's Filter Potpourri: Transfer FunctionsDocument33 pagesDr. Leach's Filter Potpourri: Transfer FunctionsAhmad FauziNo ratings yet

- Datos de PresionesDocument3 pagesDatos de PresionesWilson Jaime Saucedo LeonNo ratings yet

- Student Information Maintenance System ProjectDocument4 pagesStudent Information Maintenance System ProjectHarshpreet Singh0% (1)

- 8th ChapterDocument39 pages8th ChapterMasthan BabuNo ratings yet

- Edm Electrodes: Function of The ElectrodeDocument8 pagesEdm Electrodes: Function of The ElectrodeTaimur KhalidNo ratings yet

- Series QuestionsDocument5 pagesSeries QuestionsAnushka BijarniaNo ratings yet

- Aircraft Electrical Wiring Interconnect System (EWIS) Best PracticesDocument176 pagesAircraft Electrical Wiring Interconnect System (EWIS) Best Practicesnayapepe100% (5)